Introduction

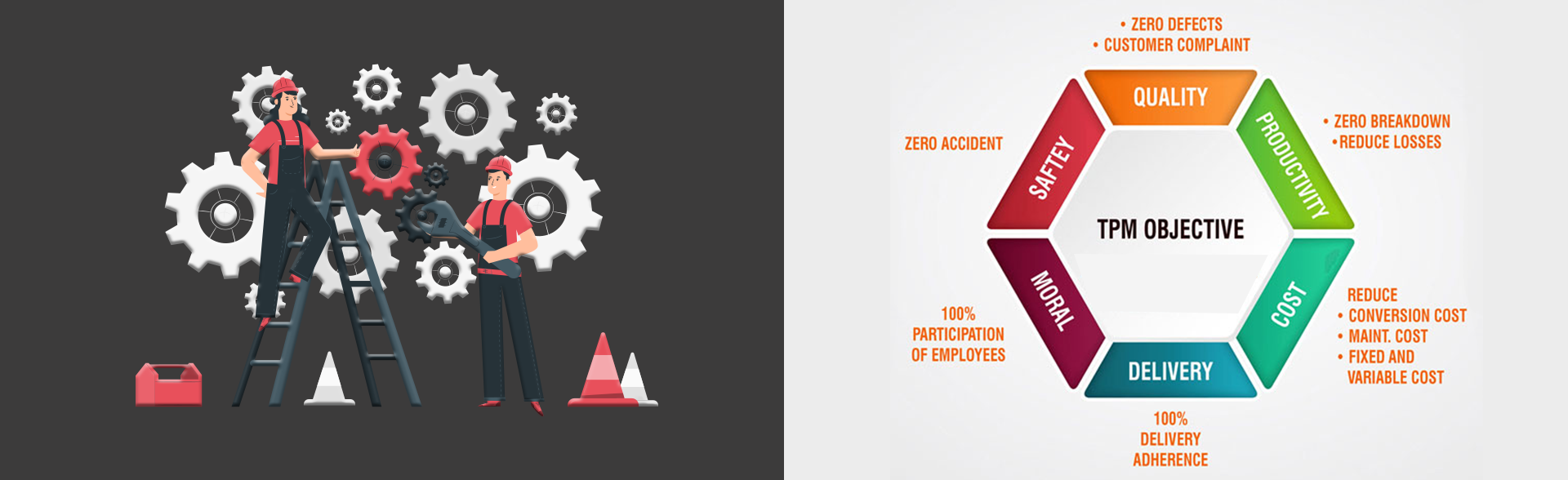

To increase the efficiency of machines and equipment’s of a business, a preventive and pro-active maintenance is vital. This process which involves the workers and floor personnel’s efforts in maintaining the work floor is called Total Productive Maintenance (TPM)It bridges the gap between production and maintenance departments. TPM ensures an increased production along with job

Skills

You’ll Gain

➤ Participants will understand the importance of “I use, I maintain” concept.

➤ An insight into concept of machine hour wastage and how to reduce machine waste hours and cost, and increase productivity

➤ effects on productivity and how it helps in zero down time of machines.

➤ How to effectively reduce machine down time

➤ How to reduce process cycle time

➤ Making the maintenance process and product defect-free.

➤ Preventive maintenance and its positive

Is this

course for you?

The following professionals can opt for TPM program:

➤ Those who seek growth in production, operations, maintenance activities in an organization

➤ Engineers, floor supervisors, maintenance staff, production managers, planners/analysts, operators, and support staff.

Pre-requisites

Prior experience of at least 2 years in Management, maintenance and production department is preferable. However, an open mind is sufficient to learn the concepts.

Course curriculum

Maintenance

- Context and definitions

- Types of maintenance

- P-F Interval

Reliability in maintenance

- Dependability (RAMS)

- Operational indicators

- Improvement of availability and maintainability

Total Productive Maintenance

- Origin and concept

- The five principles

- The eight pillars

- Understanding and effecting OEE (Overall Equipment Effectiveness)

- Understanding root cause analysis, Pareto / cause, and effect diagram, Gemba

- understanding and Implementation of AM (Autonomous maintenance) process

- Understanding the concept and importance of SMED(Single-minute Digit exchange of die ), the steps involved, implementation and maintenance of SMED.

- Change management

- Rates, indicators, and levers

Course Brochure

Request for DEMO