Supply and Operations Planning – S&OP

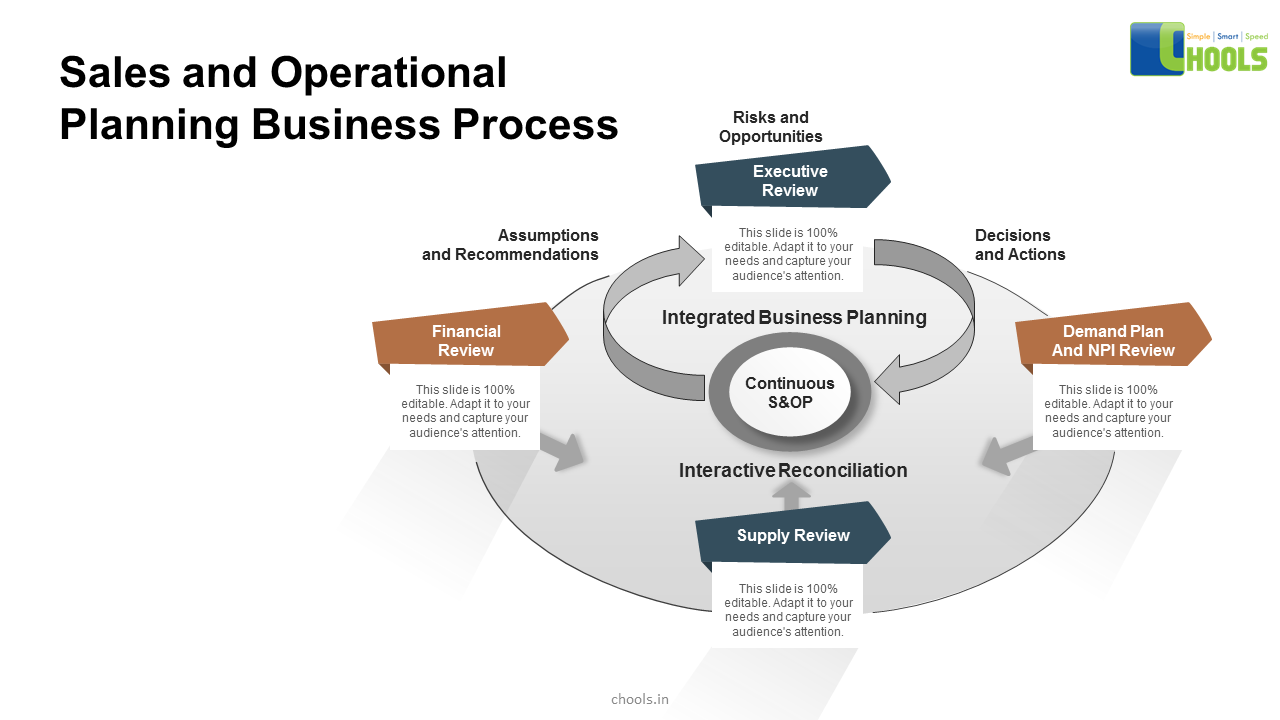

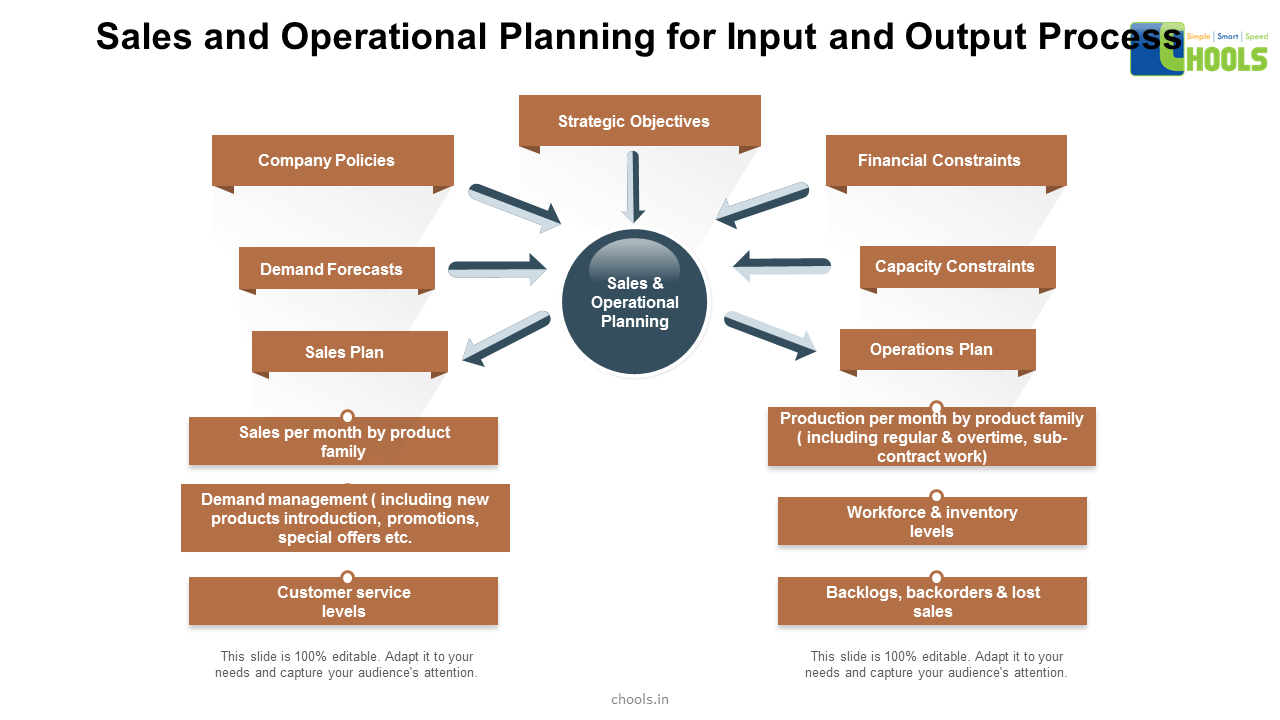

The Complexity of global supply chain is inevitable, however, developing the effective internal and external Strategies within your organization’s Value Chain – Vendor to business to Customer is the key to sustain competitive advantage, drive world-class performance and customer satisfaction, reduce supply chain costs. We at Chools will guide your organization in establishing those long and short-term strategies to embed agility and resilience within your operations, Optimize costs and build talent to create a responsive organization to deliver best in class customer satisfaction. One of those unavoidable strategies for supply chain success is Supply and Operations Planning, which links supply chain, manufacturing, finance, marketing and sales teams to bring into line demand, supply and finance plans. S&OP allows decision makers to reach consent on the best operating plan to optimize critical resources to achieve business objectives and increase market share.

Predicted Gains

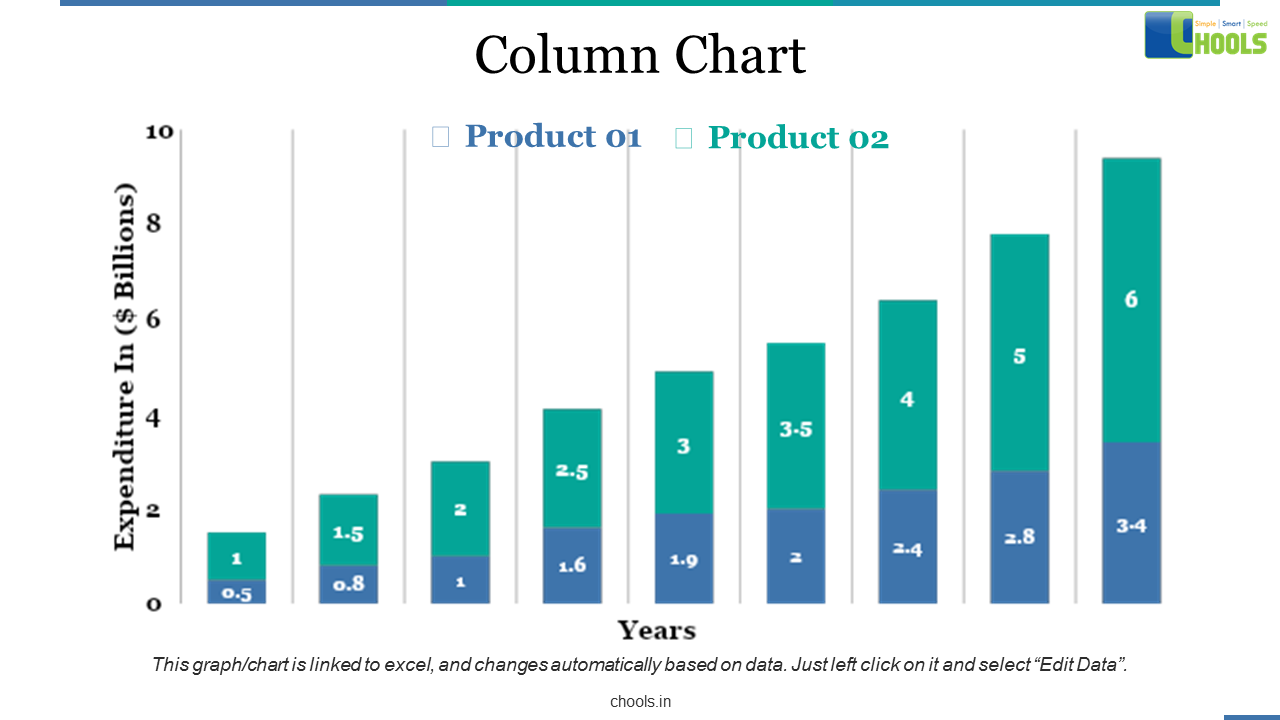

- Increased profitability driven by lower waste and higher operational efficiency and resources utilization.

- Balanced Supply and Demand and effective responsiveness through reliable Data communication and stakeholders’ collaboration.

- Exceeding Customer expectations and on time deliveries driven by inventory and backlog optimization.

- Reduce excess inventory, production schedule adjustments, and production changeovers through effective demand planning built based on accurate demand forecast.

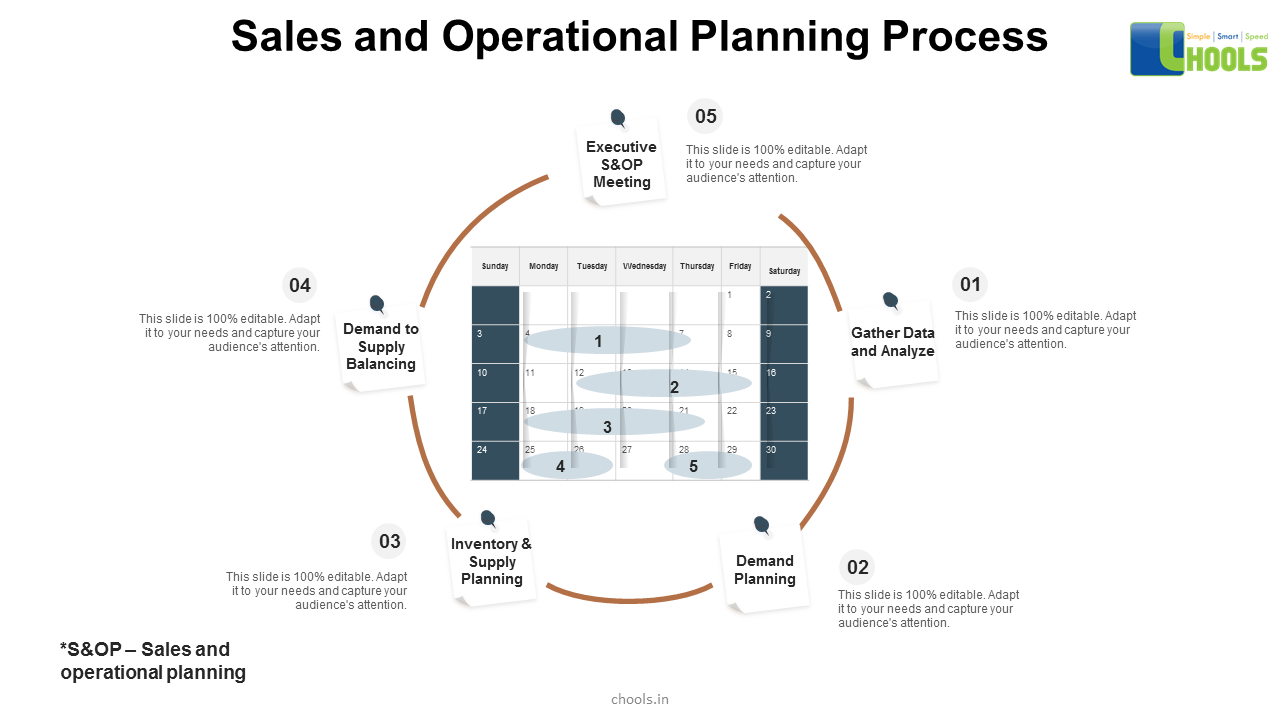

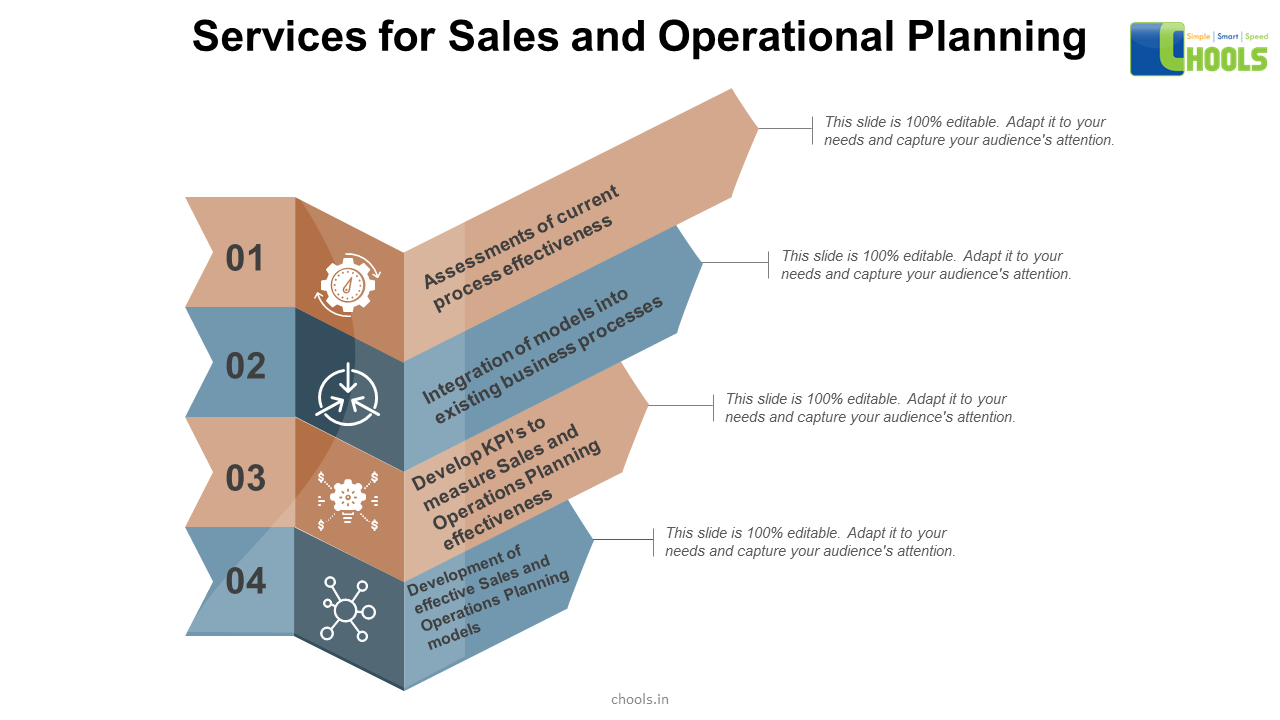

Our Methodology

Our Team of Consultants will lead you in establishing the following:

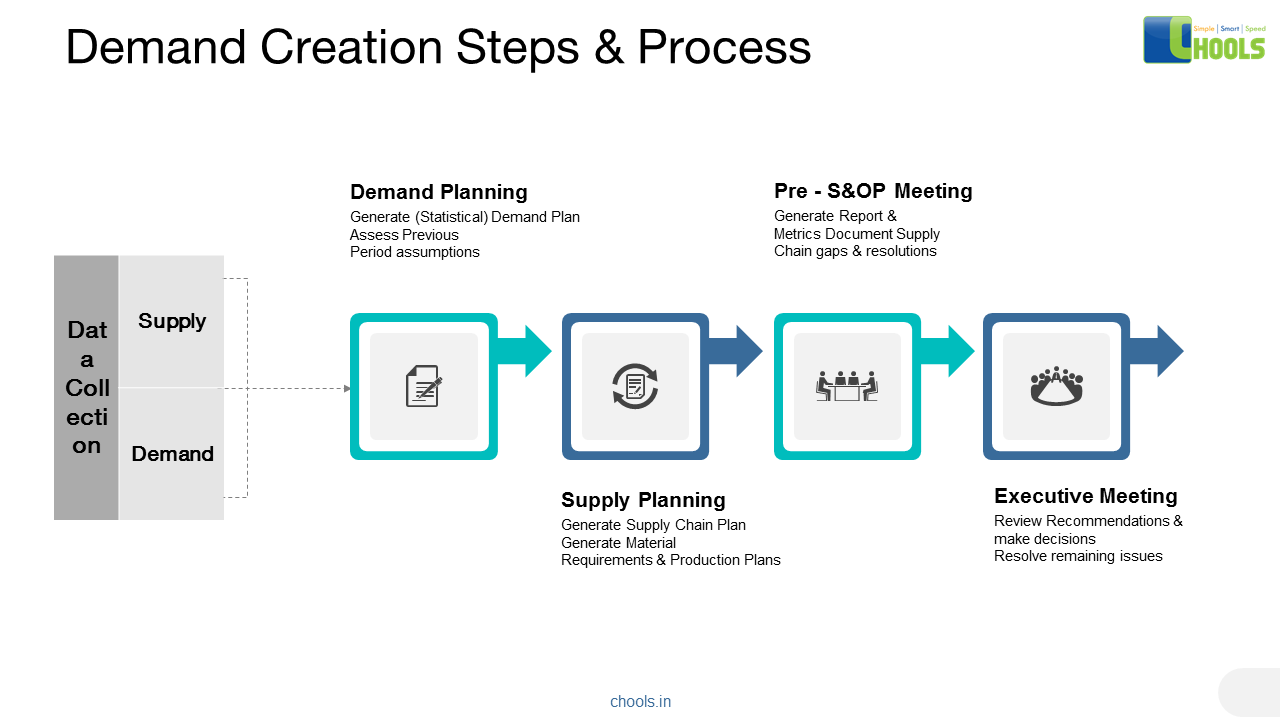

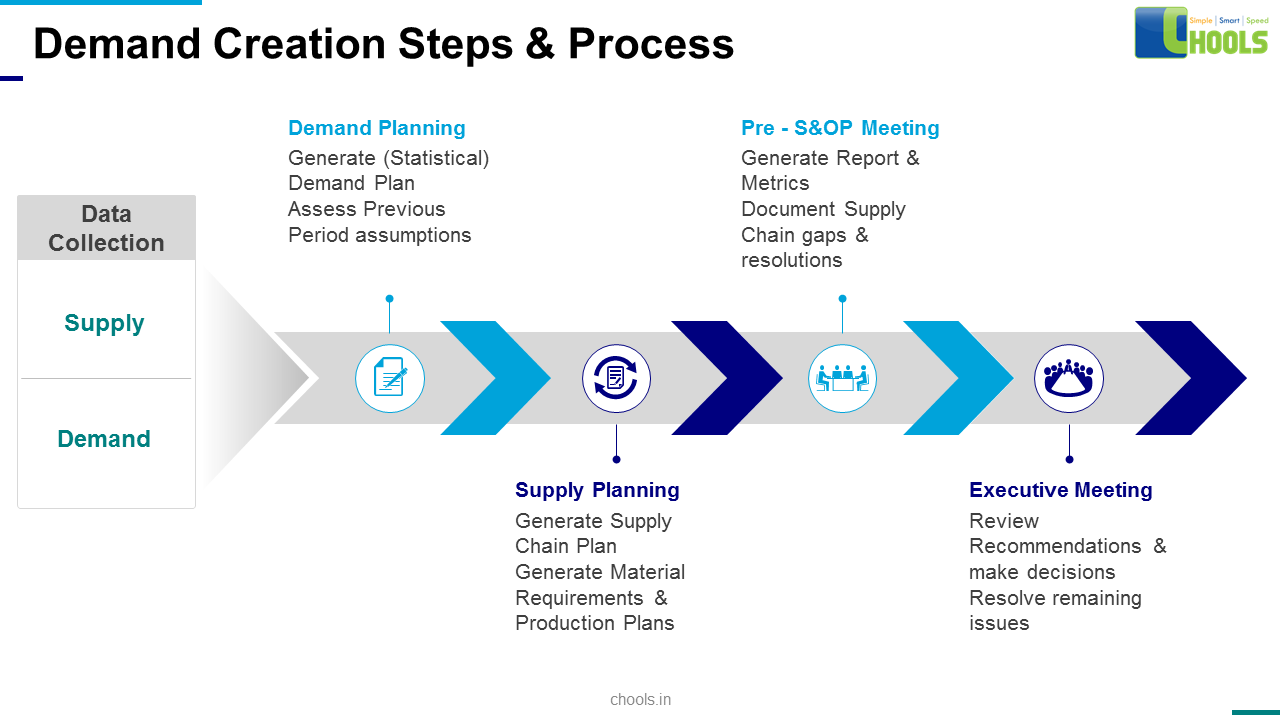

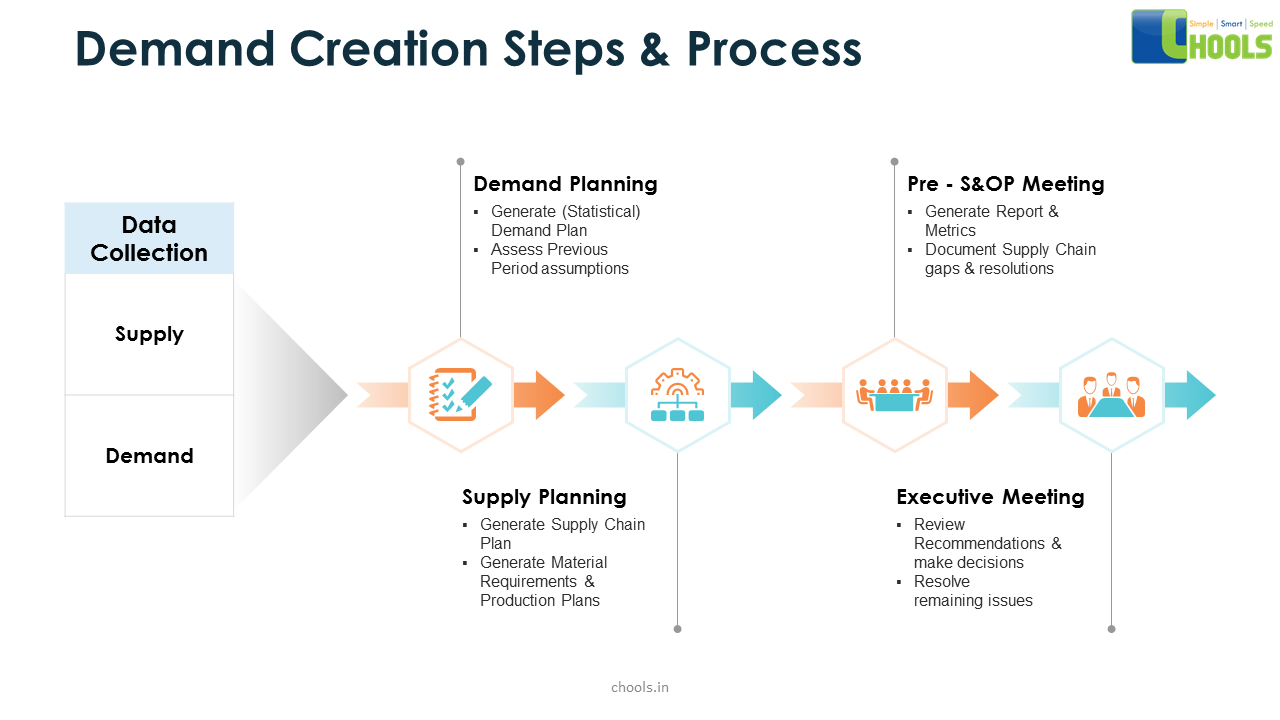

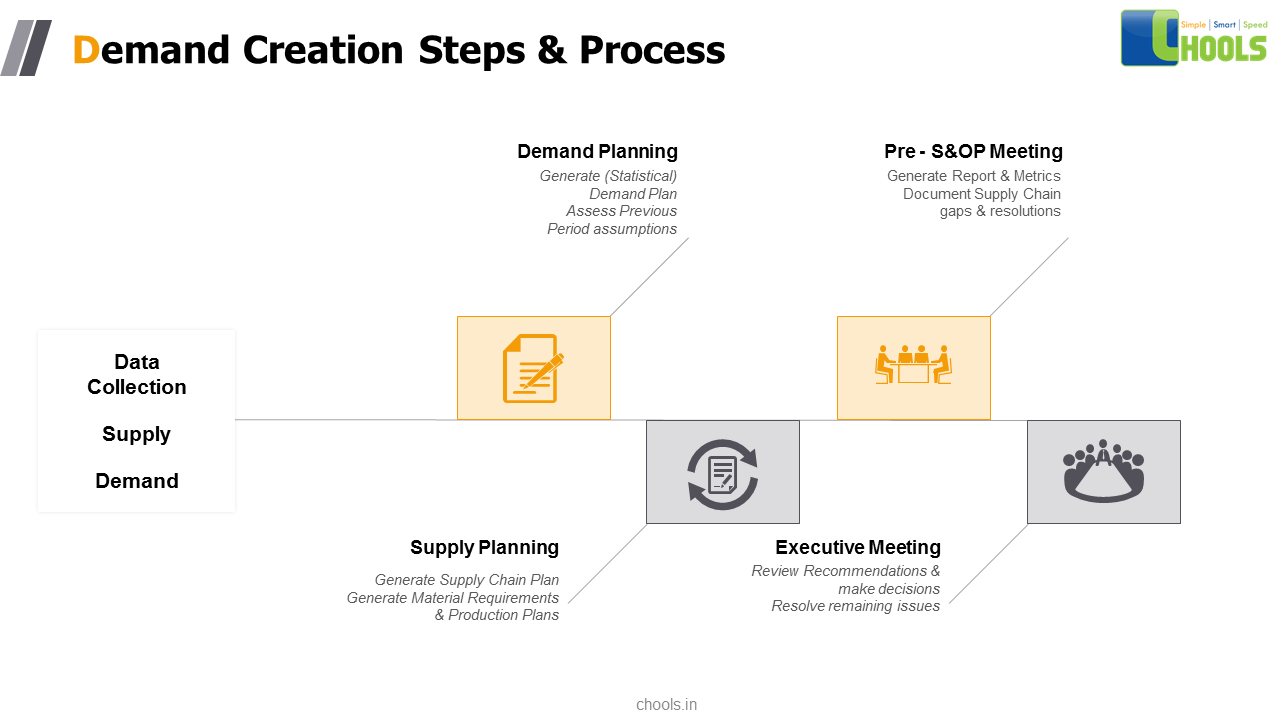

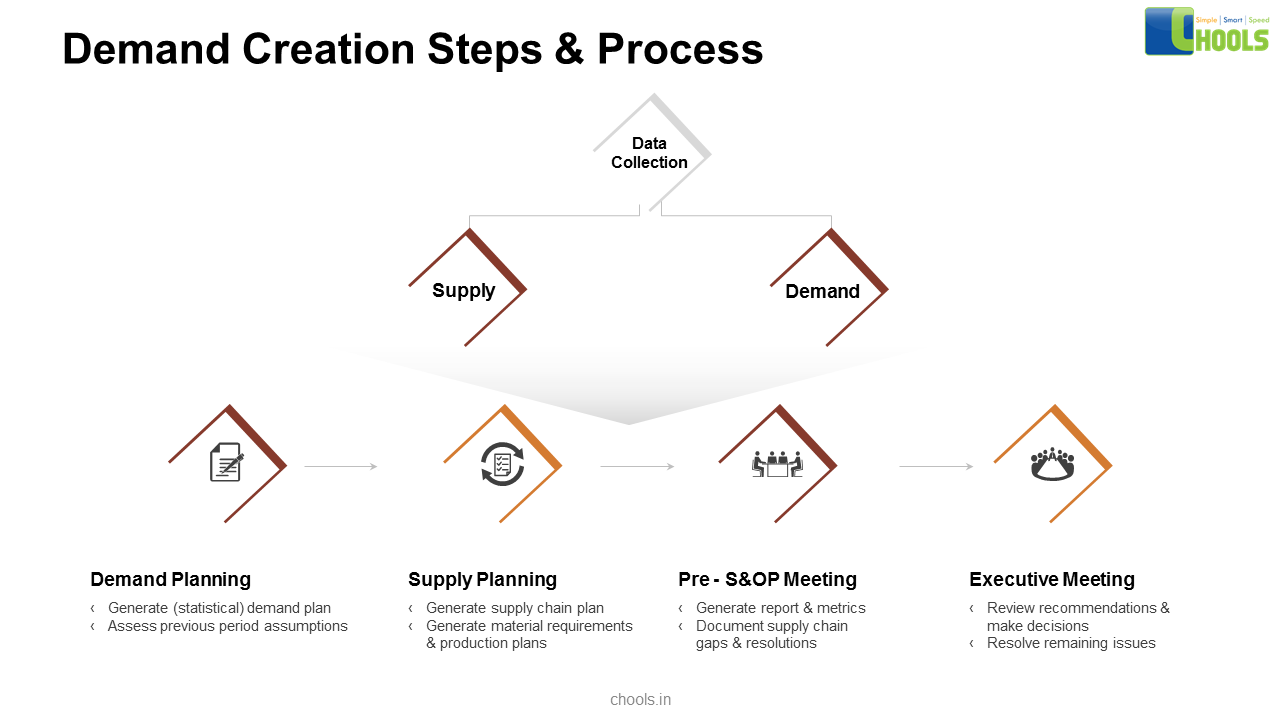

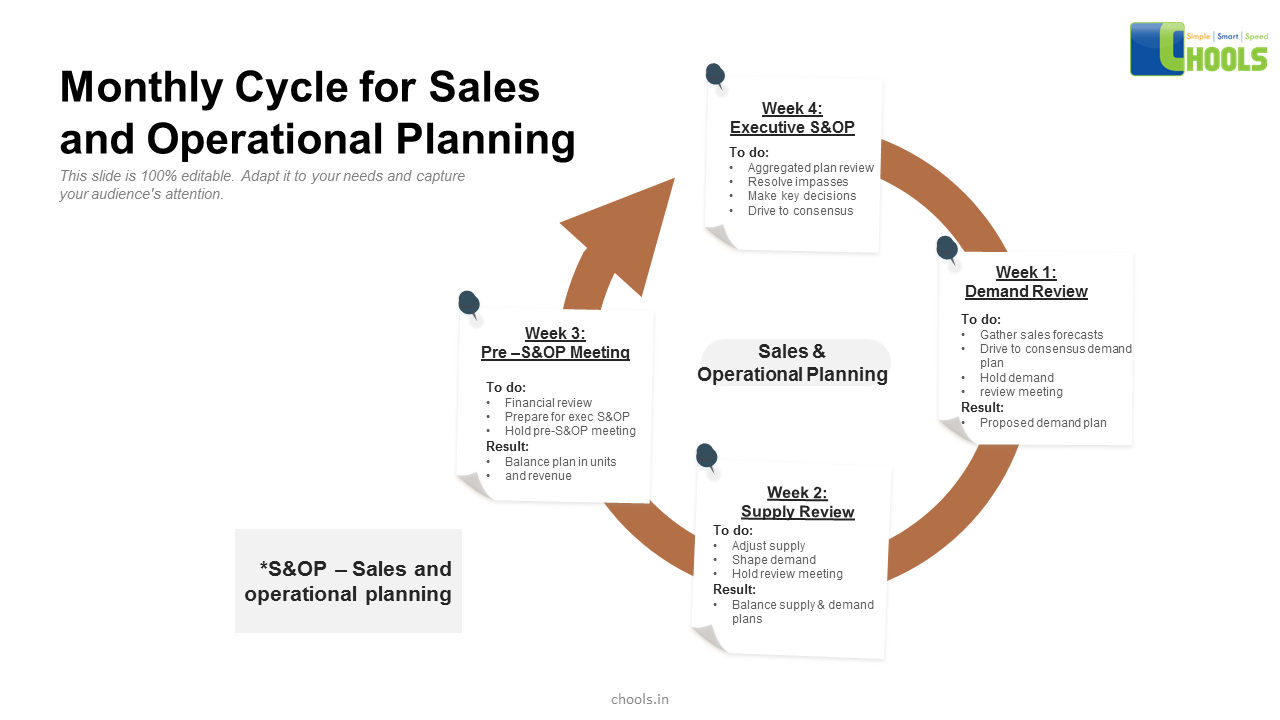

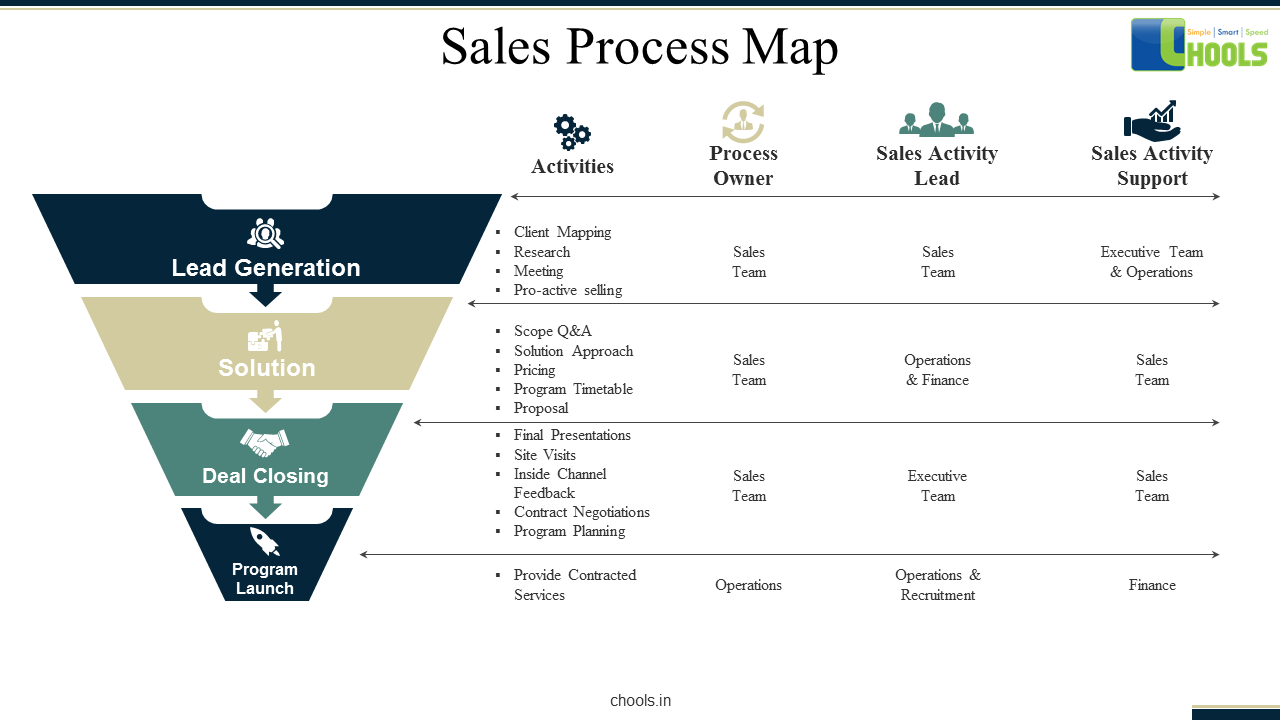

Process

➤ Data Collection

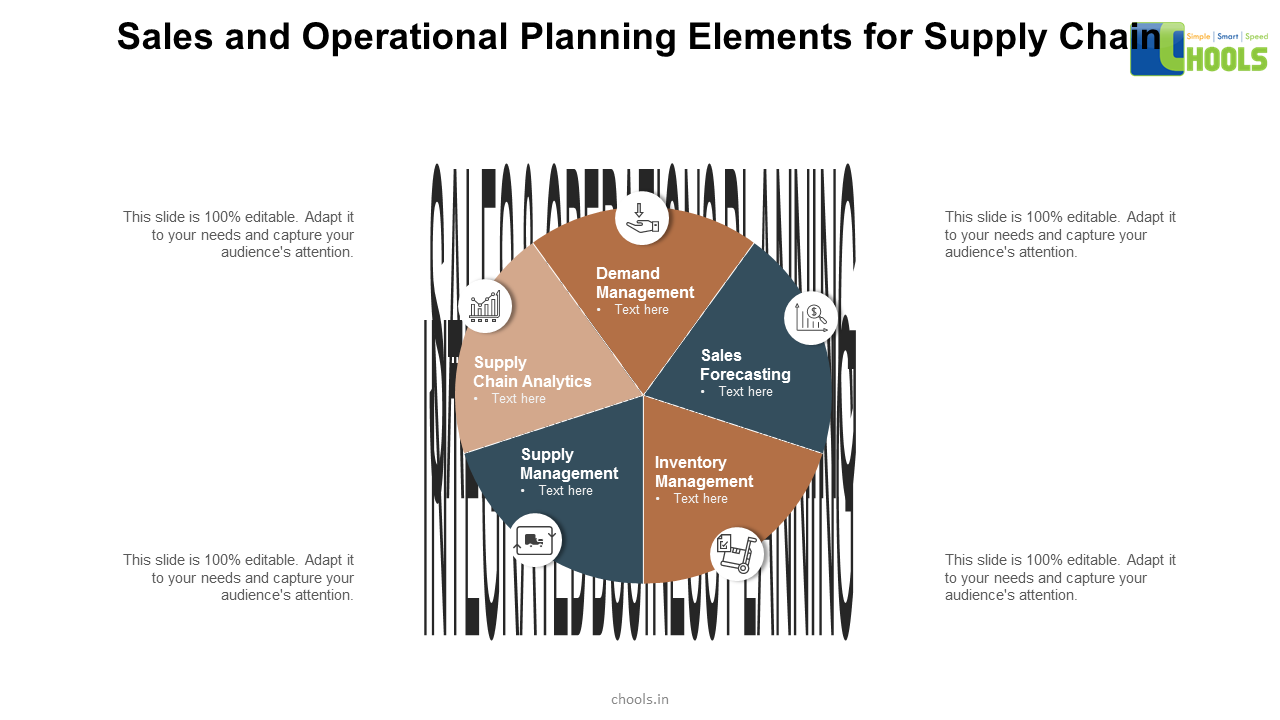

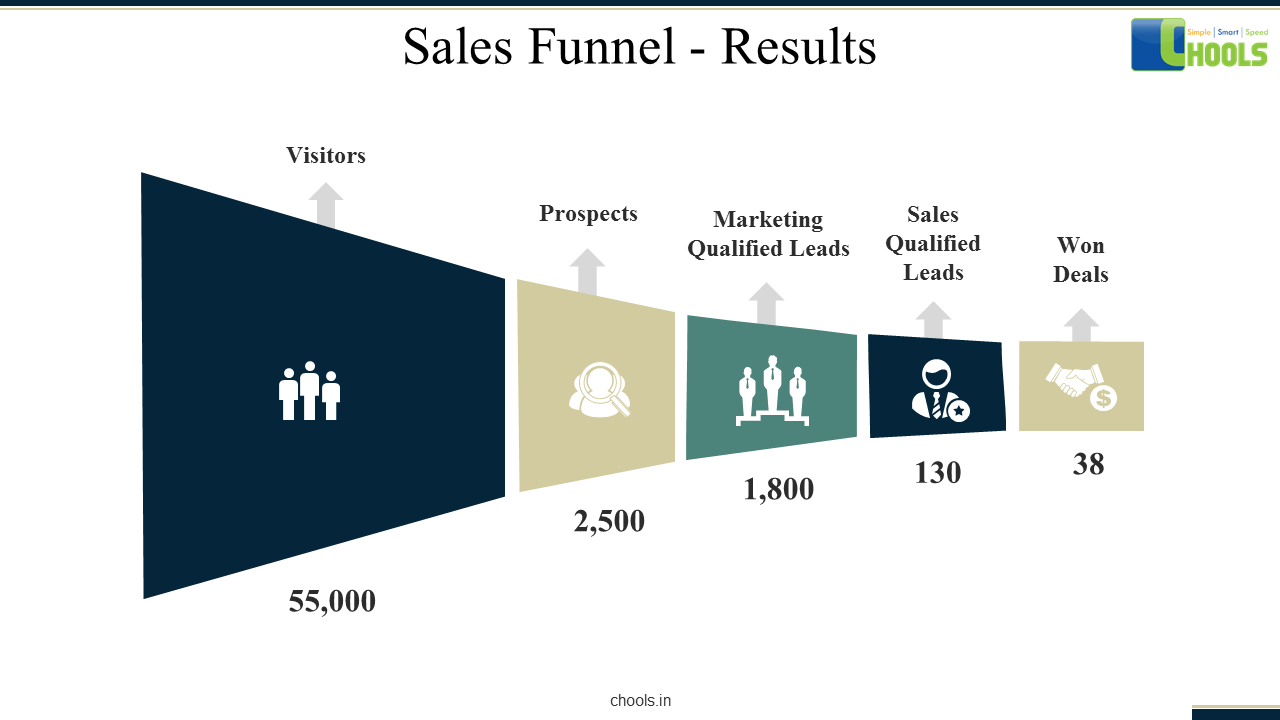

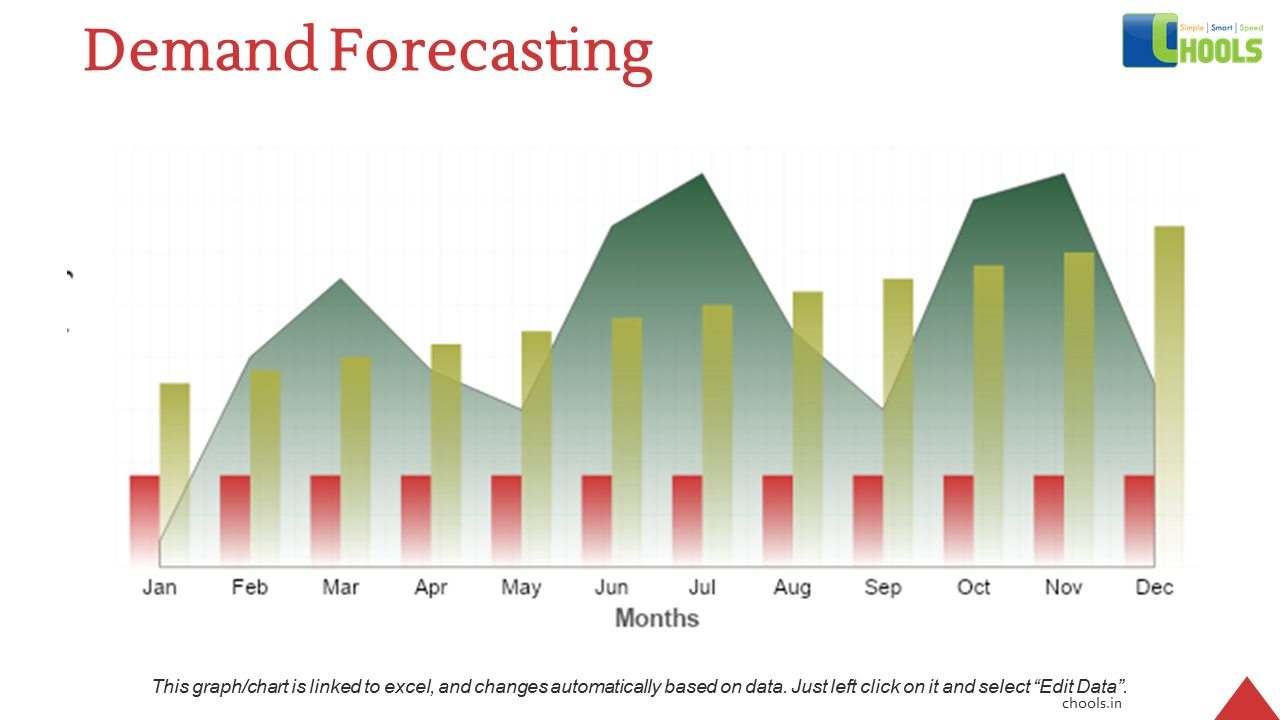

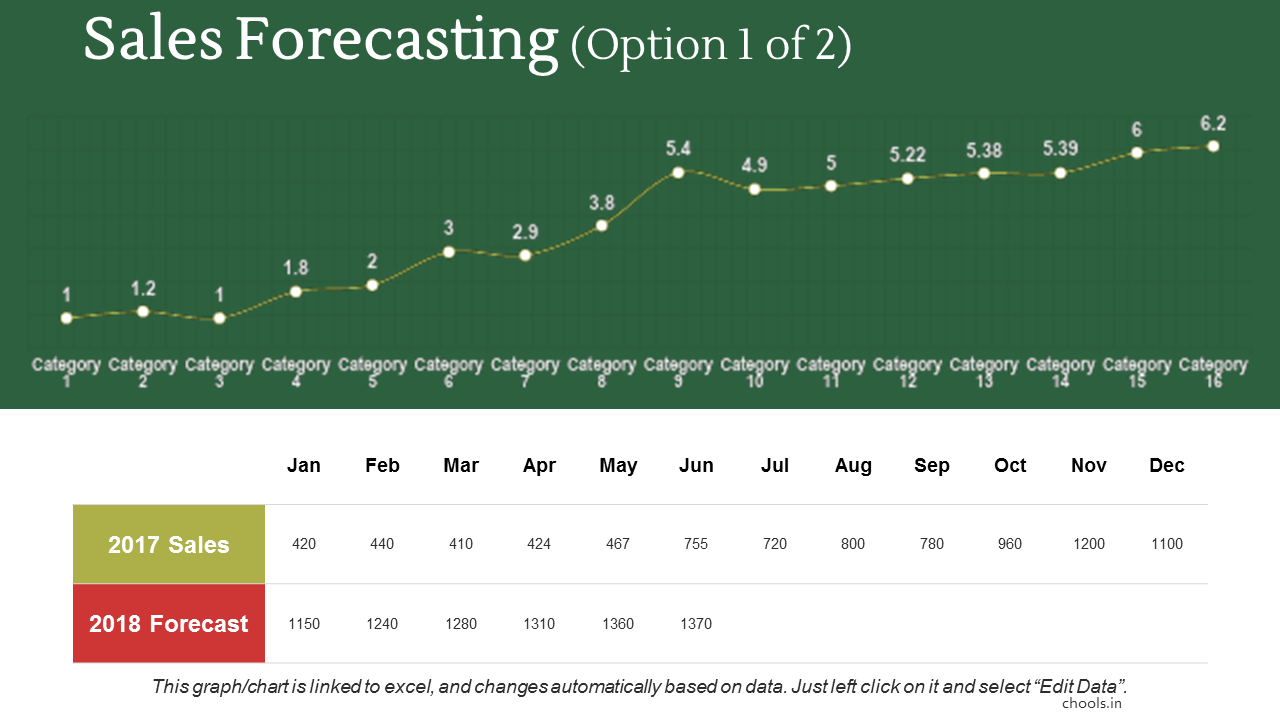

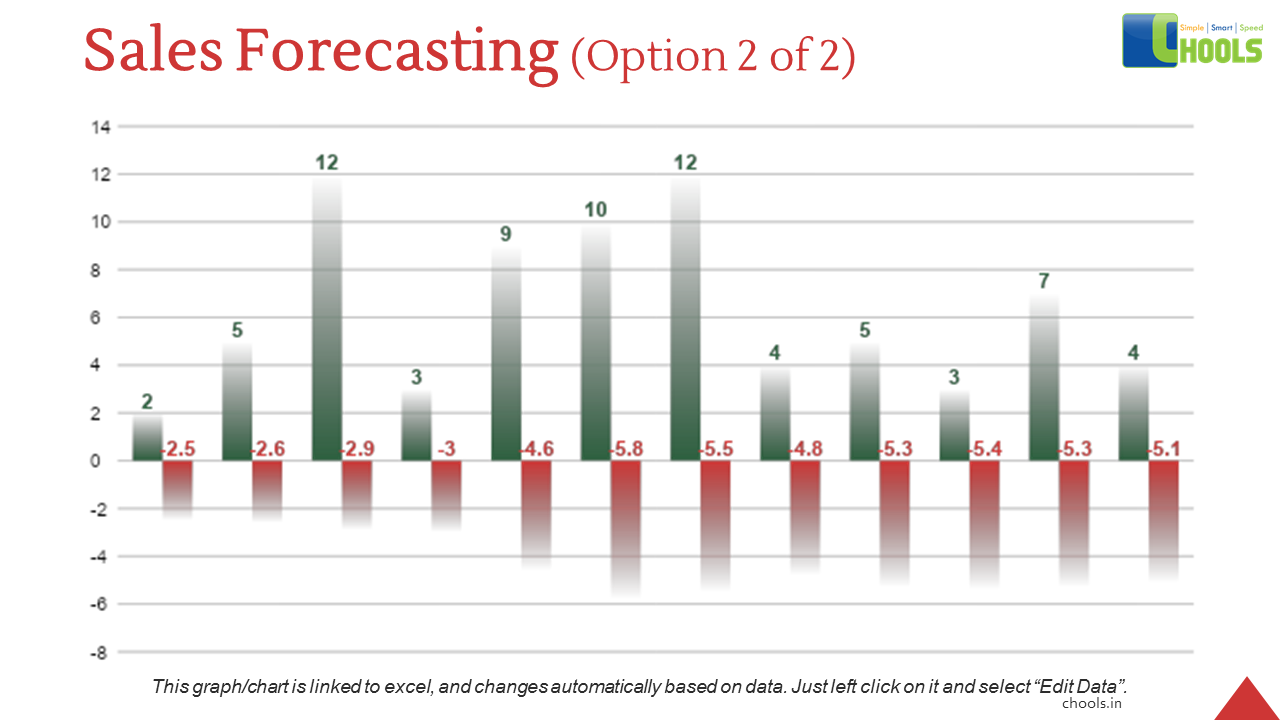

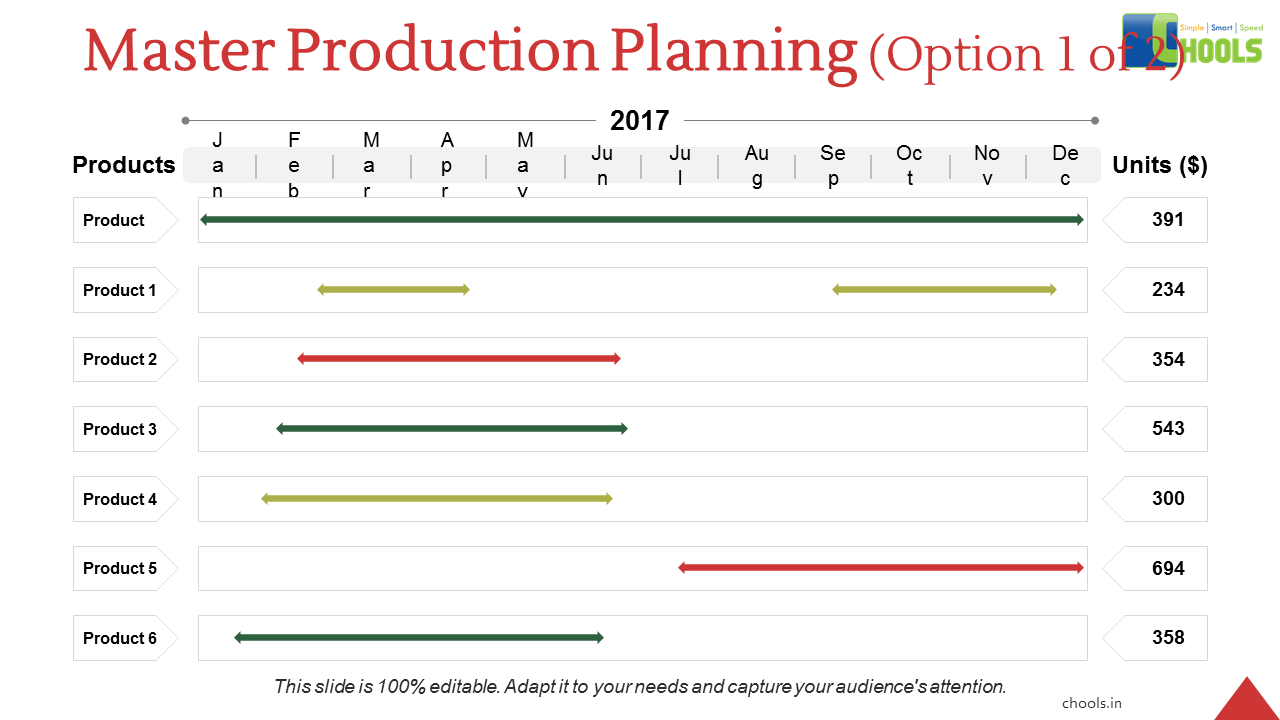

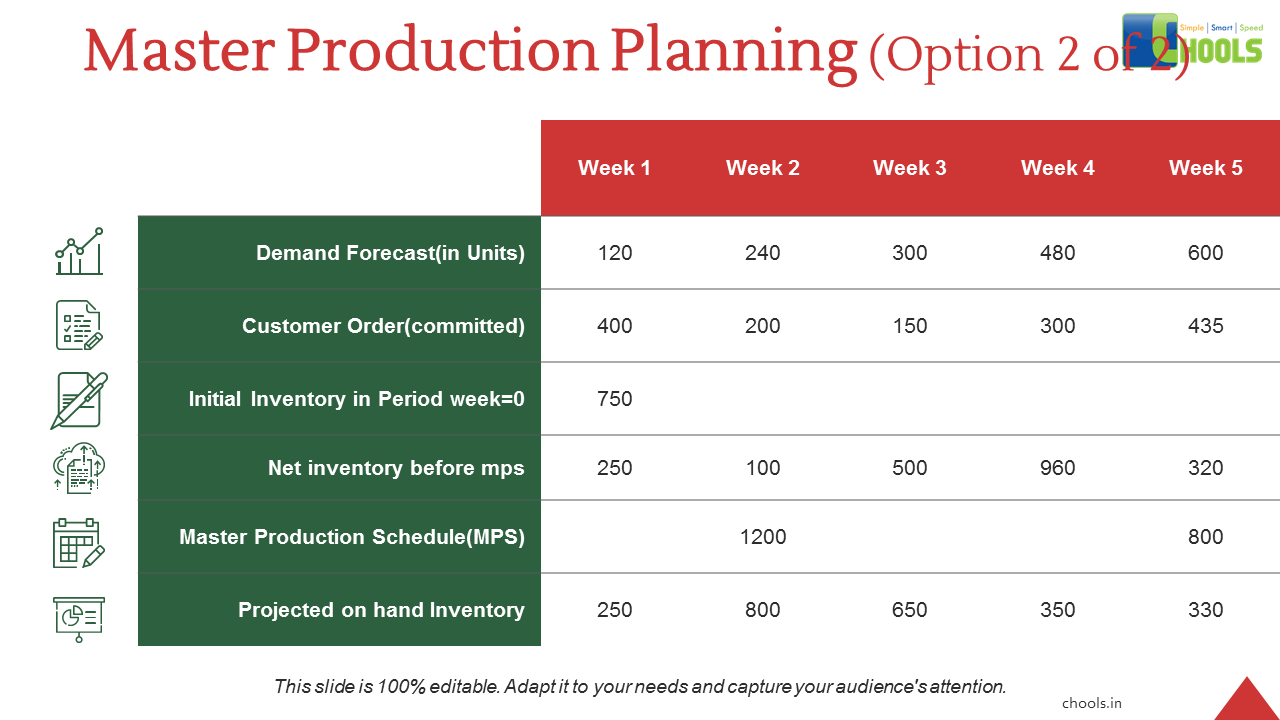

➤ Demand Planning

➤ Supply Planning

➤ Pre- S&OP Meeting

➤ Executive S&OP

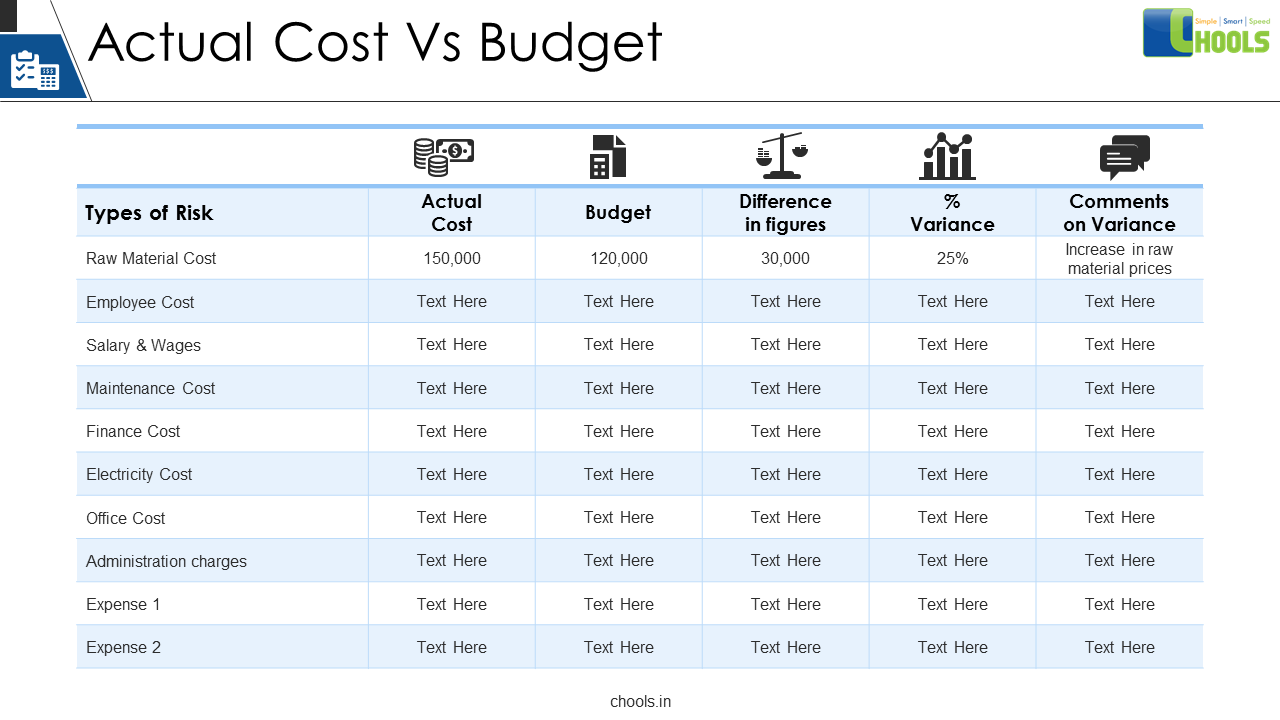

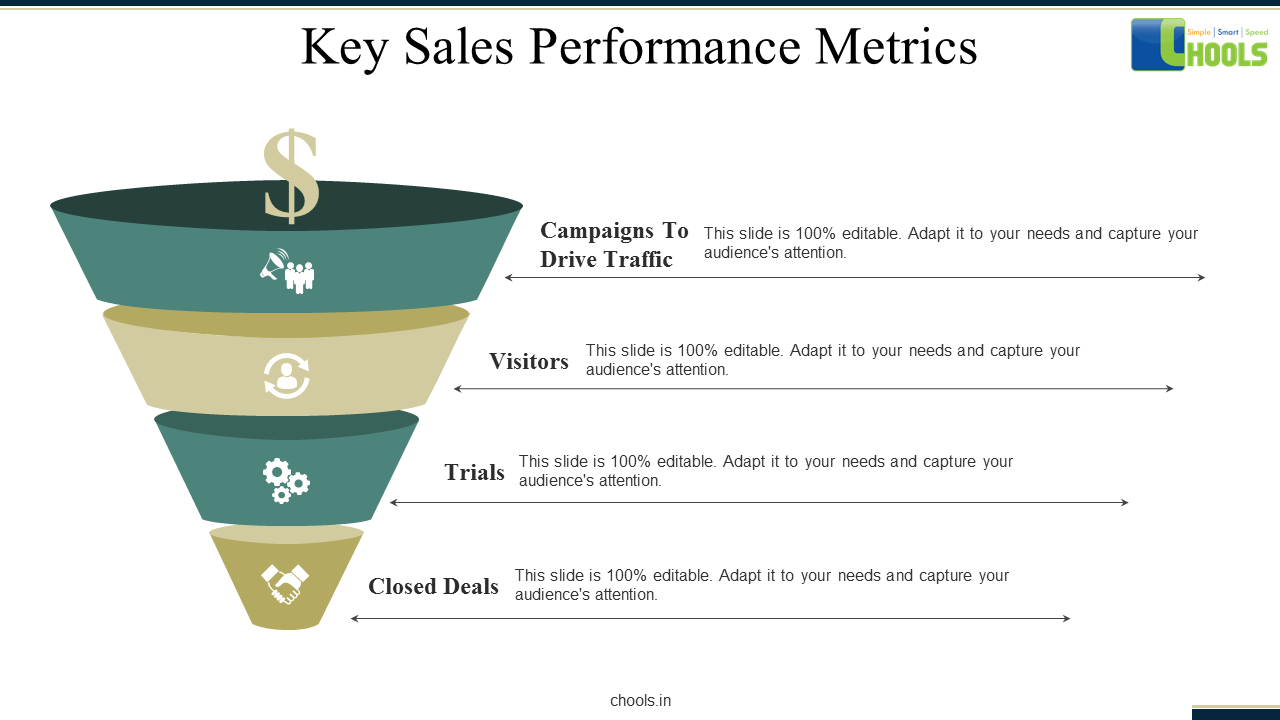

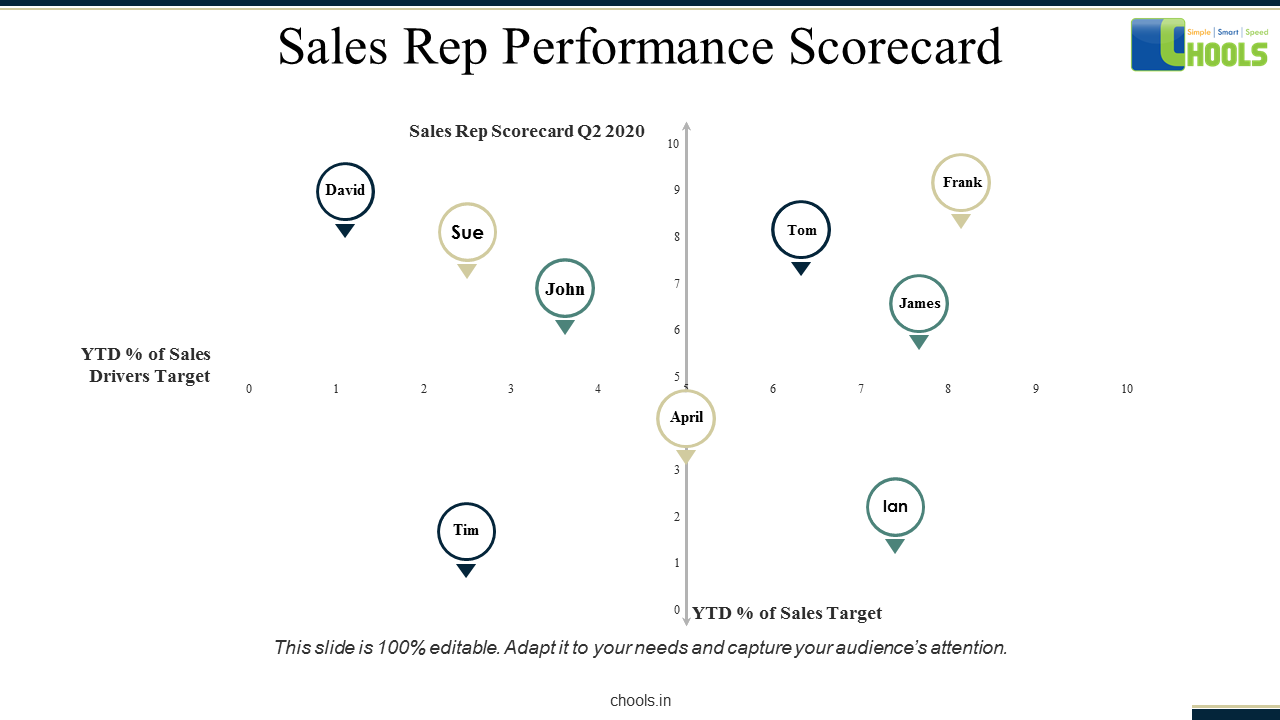

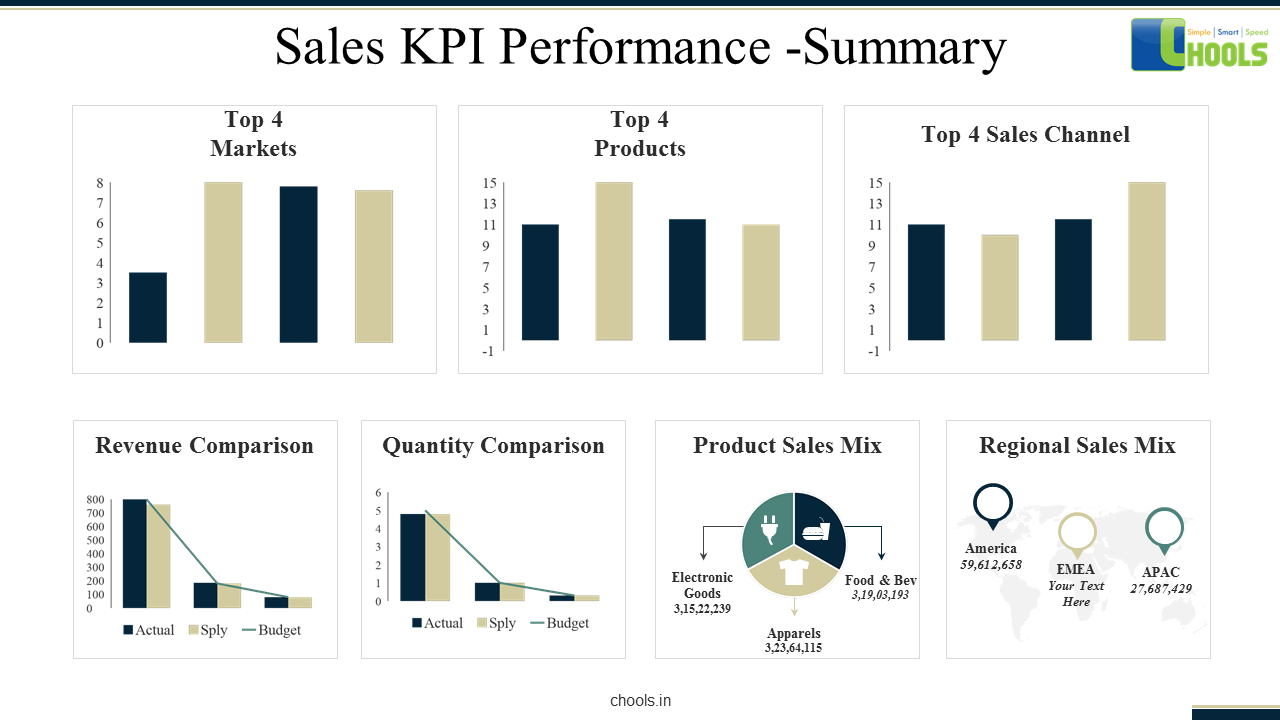

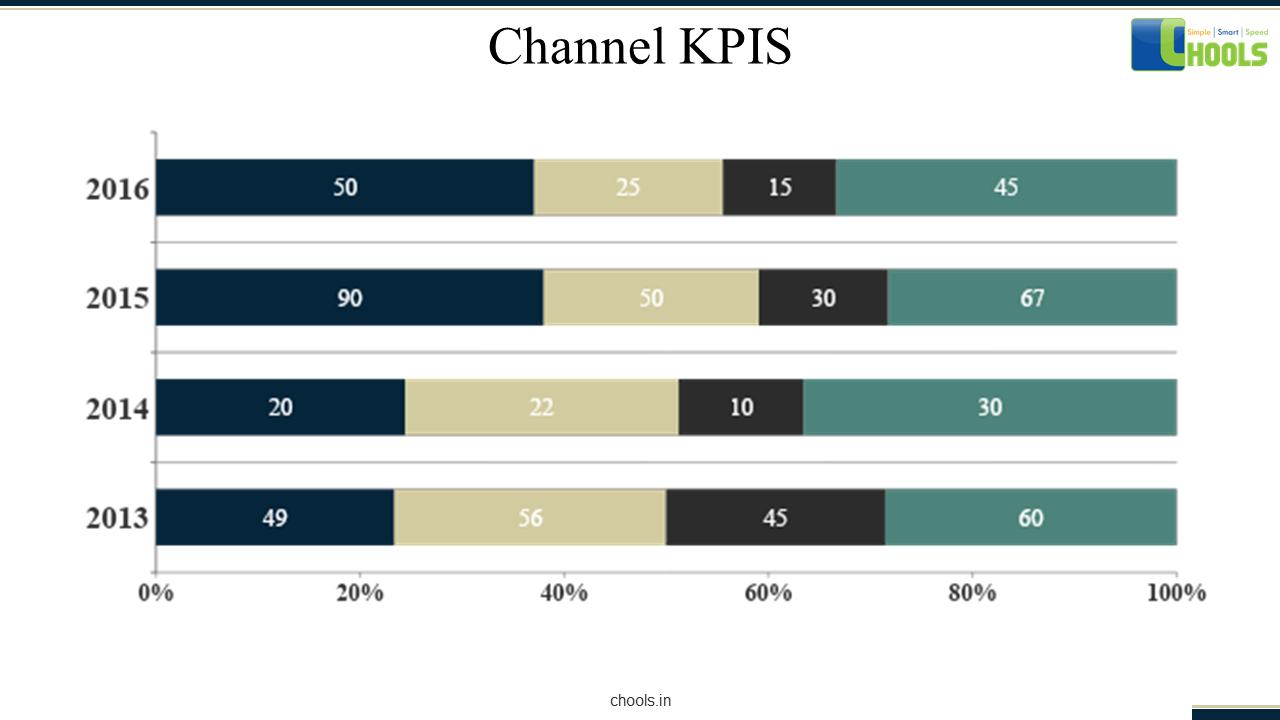

Key Performance Measures:

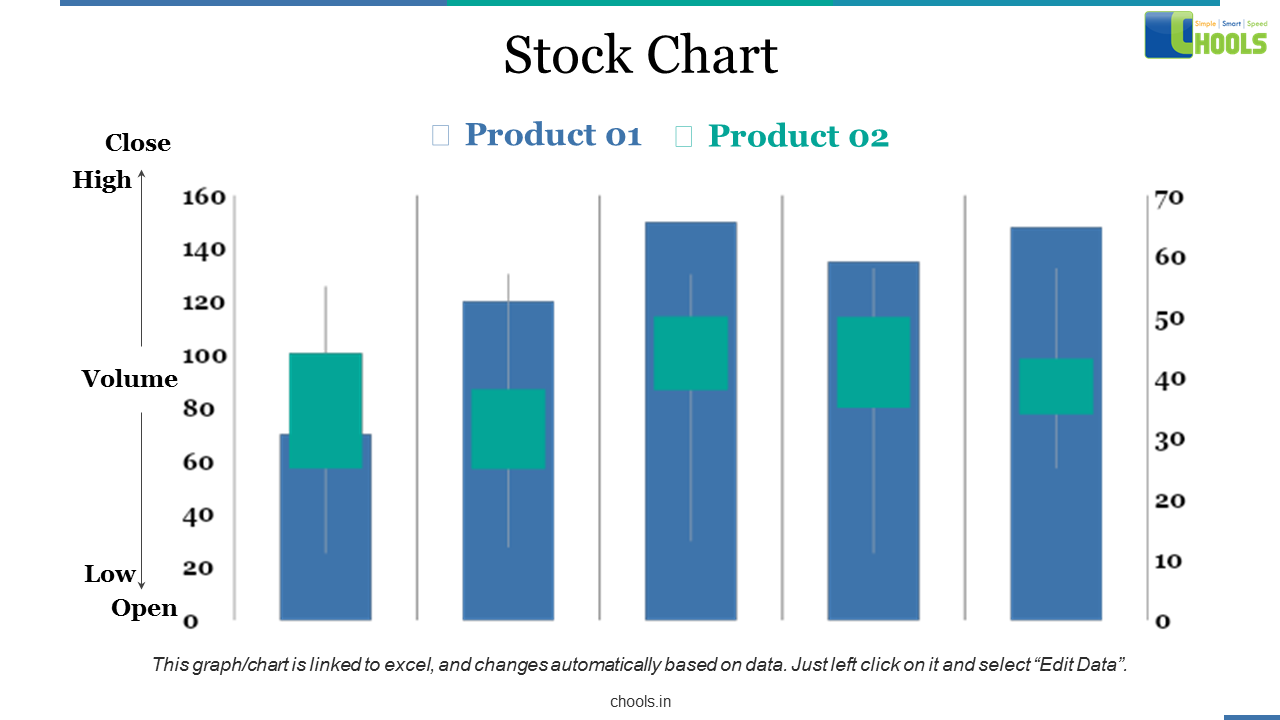

➤ Stock Fill Rates

➤ Inventory Turns and Sell through

➤ On time Delivery

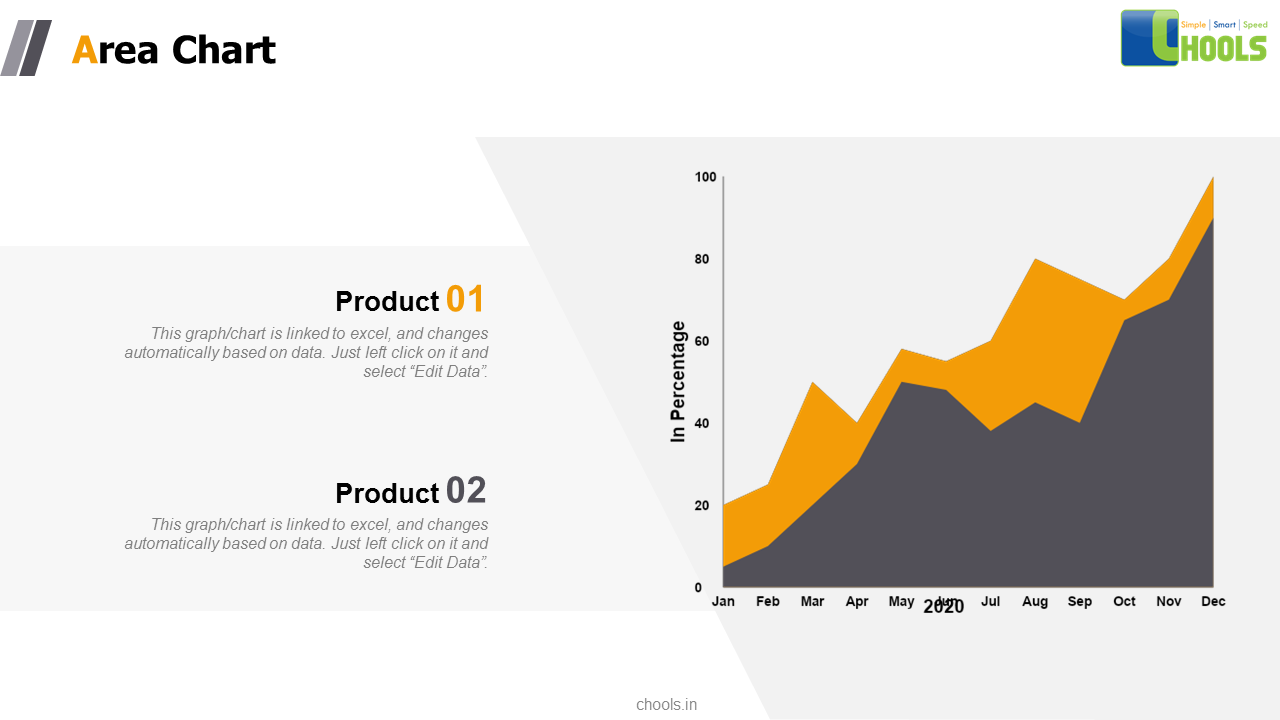

➤ Demand planning-Forecast Accuracy

➤ Demand Compliance

➤ Schedule Compliance

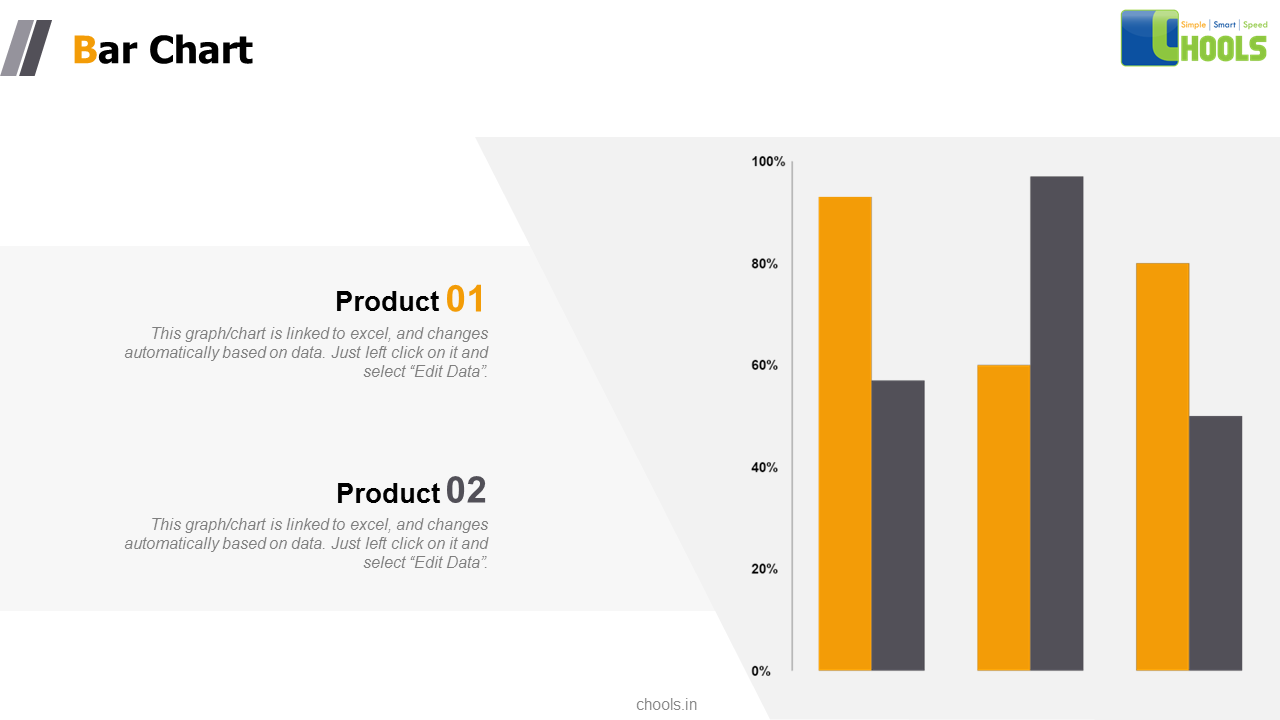

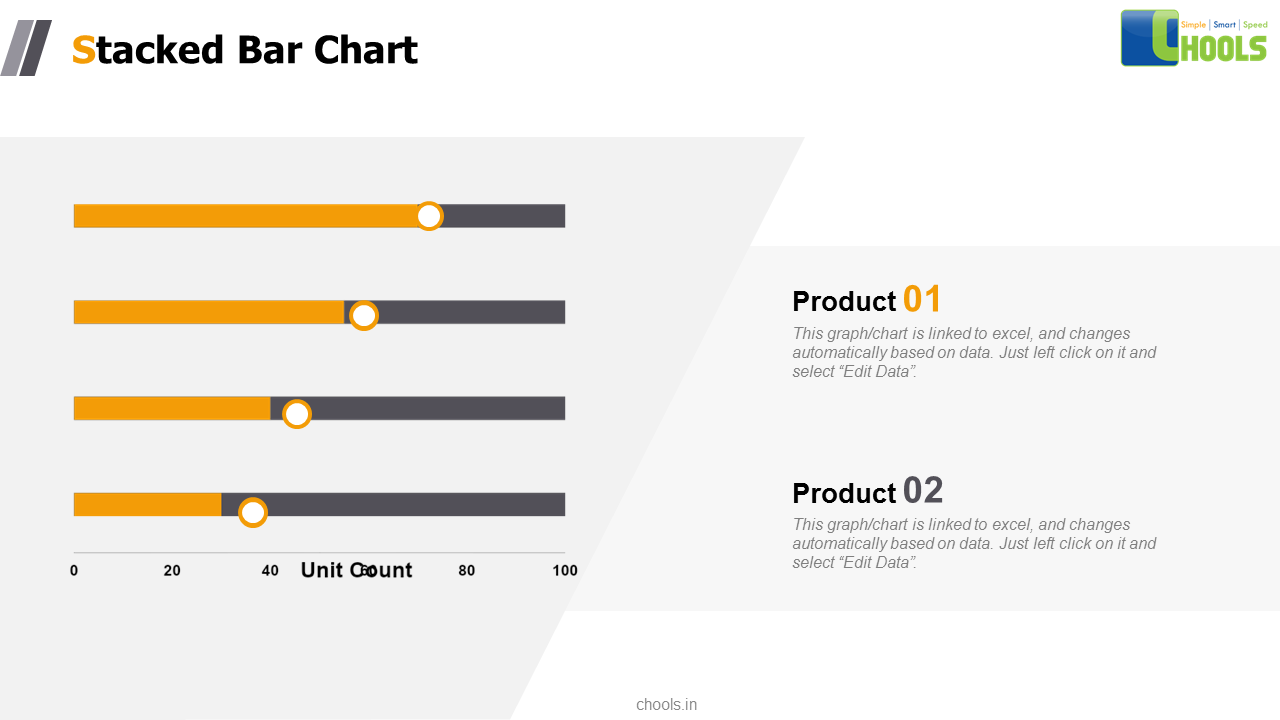

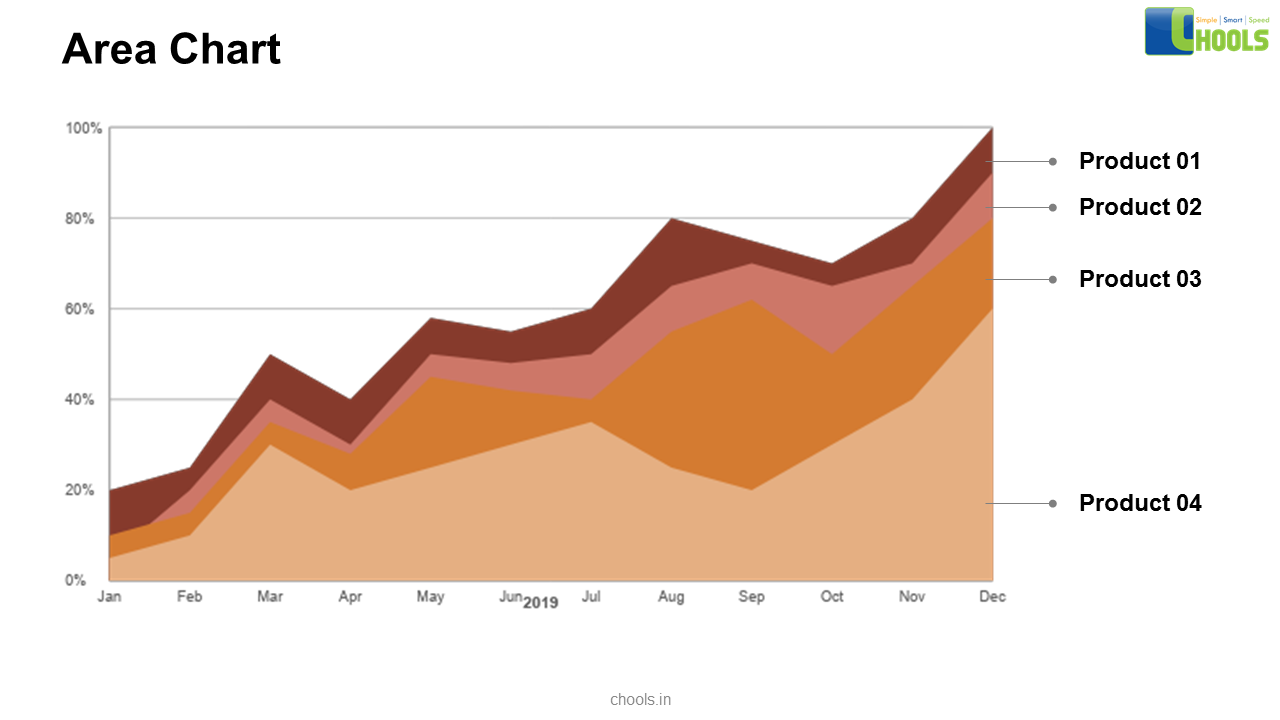

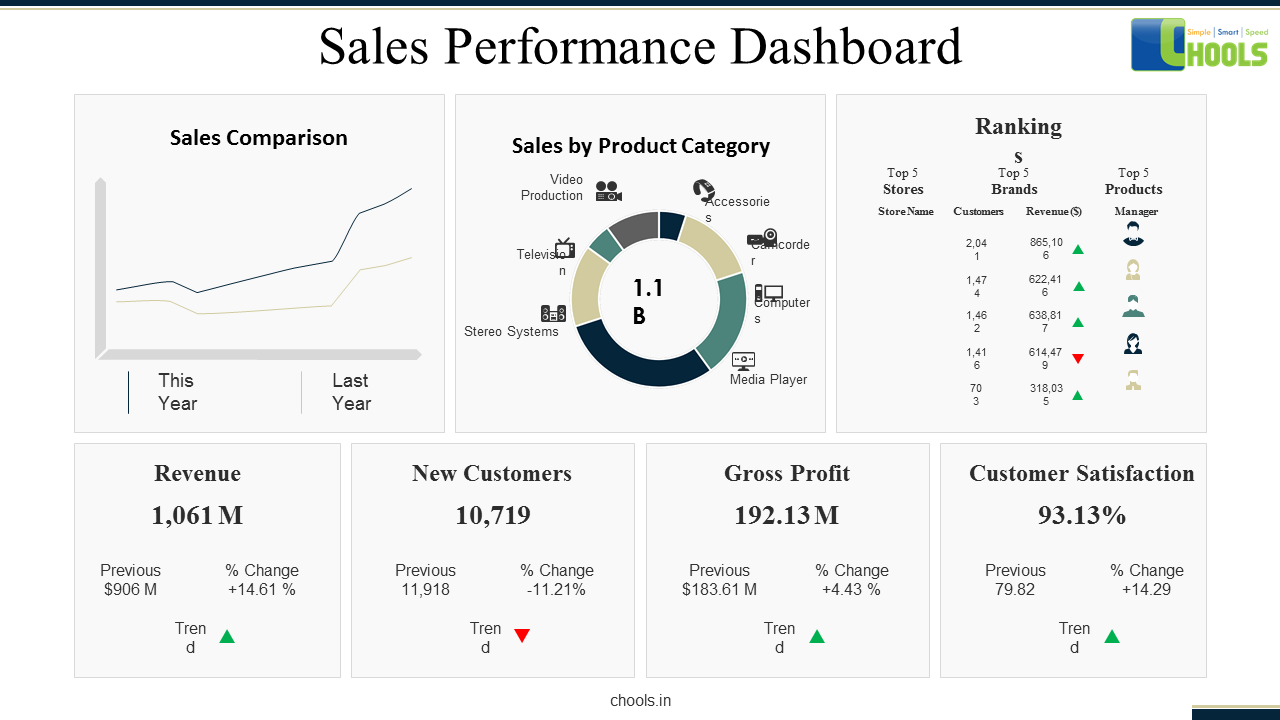

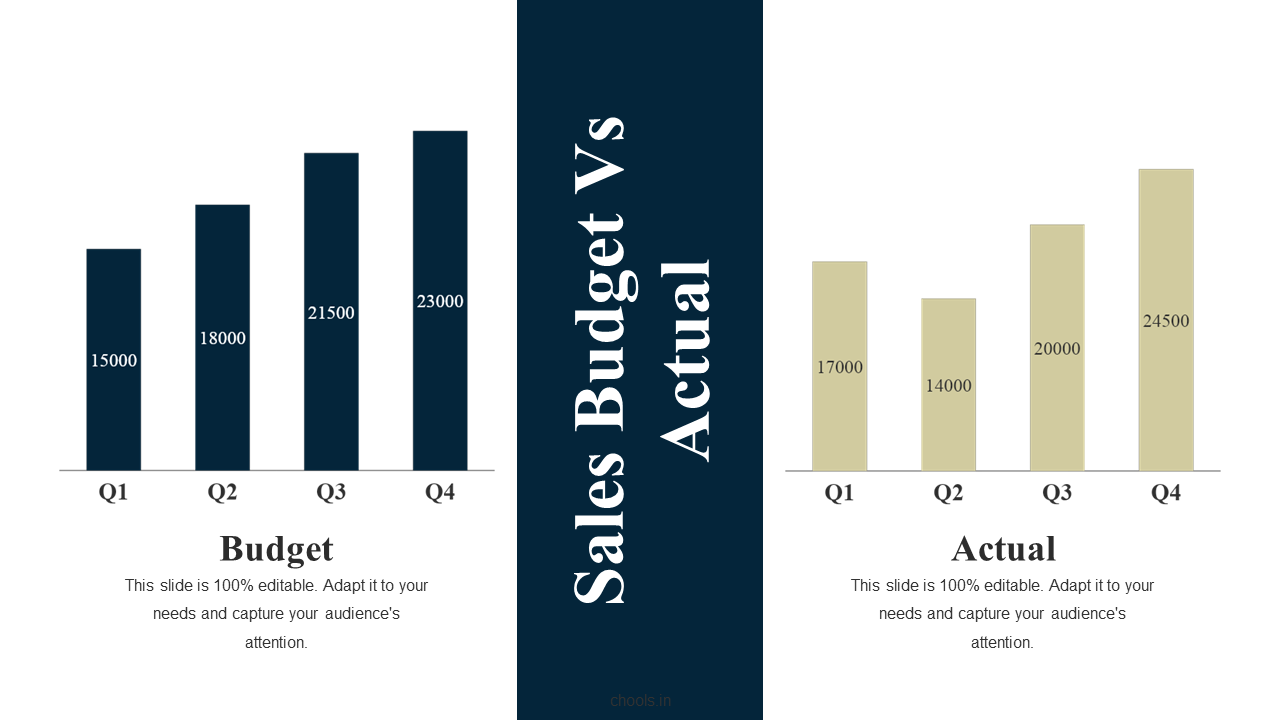

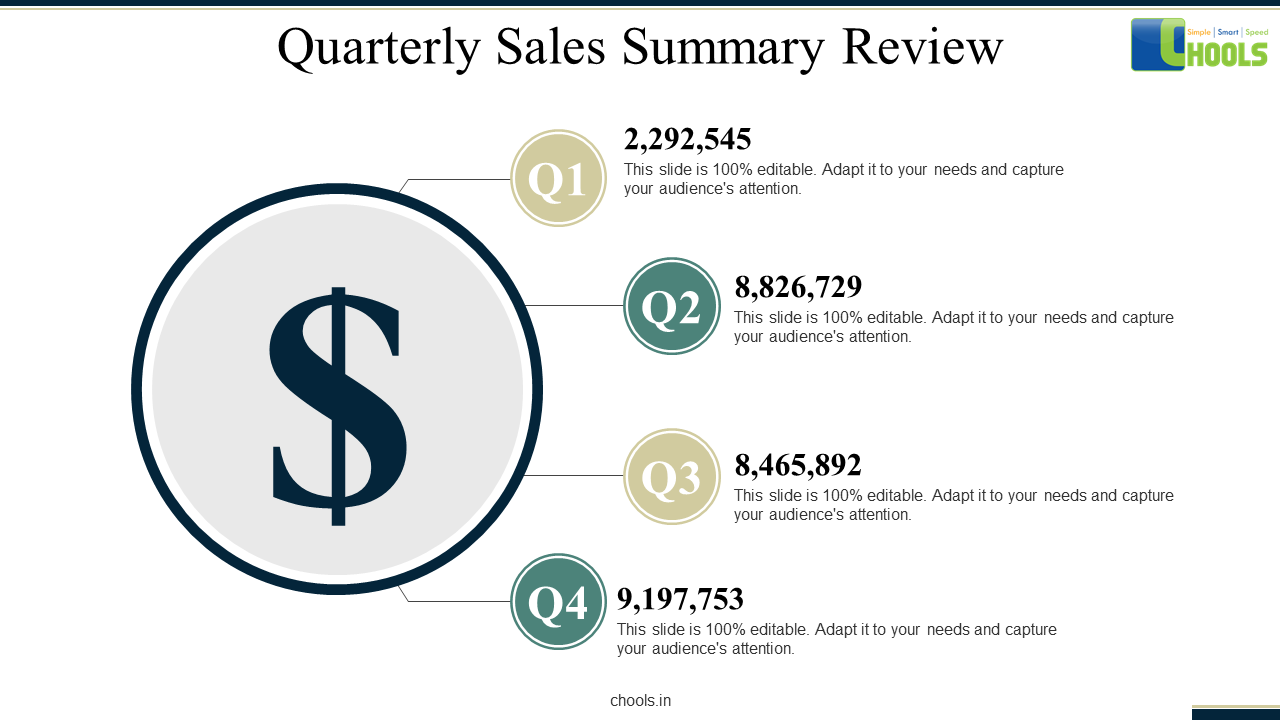

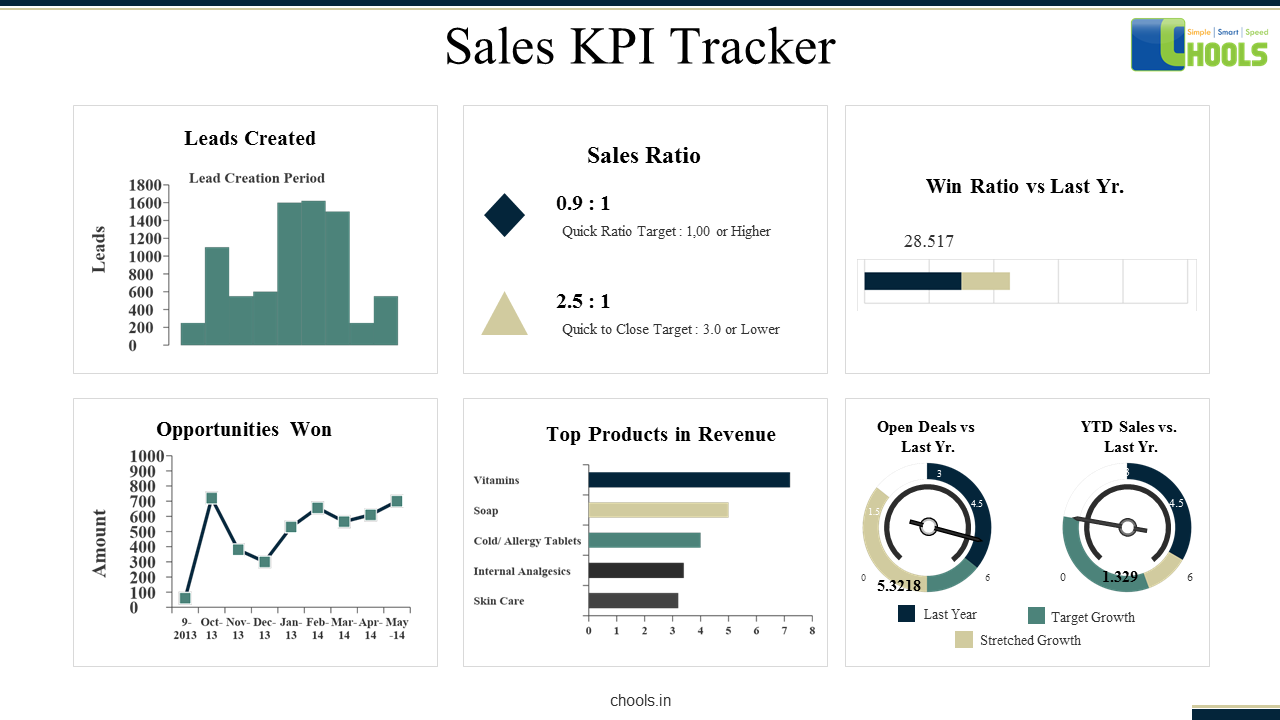

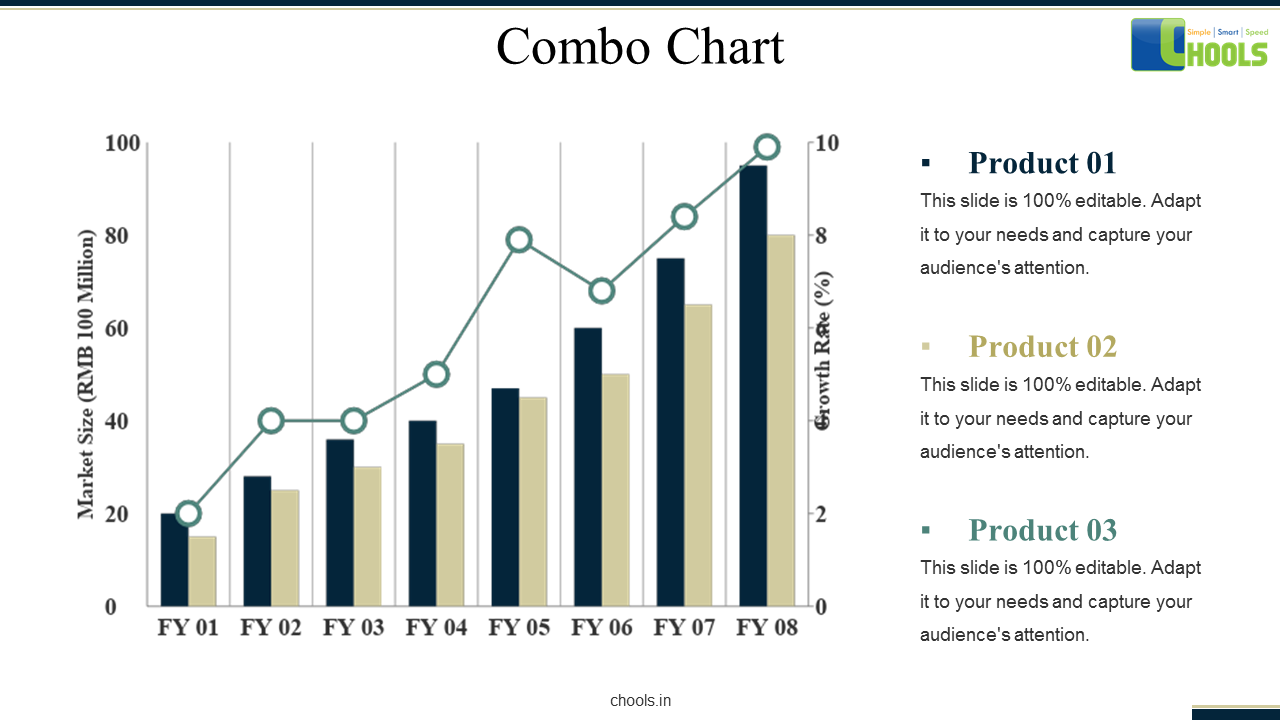

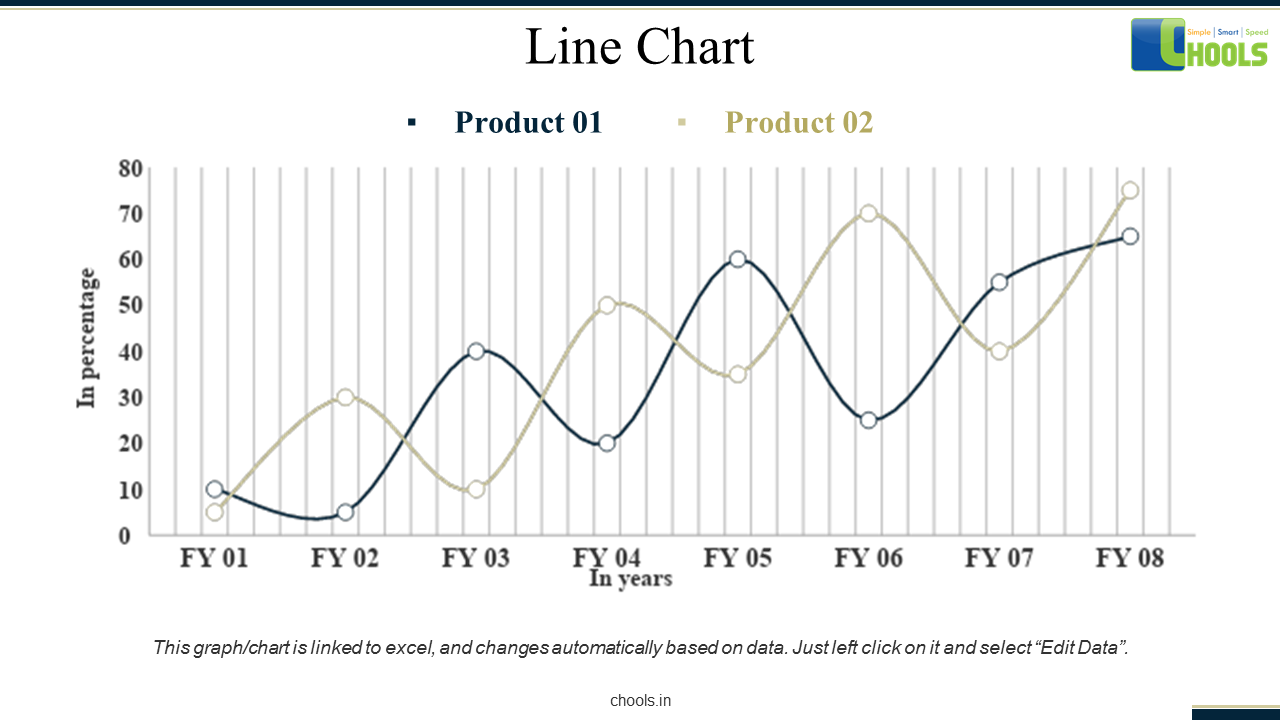

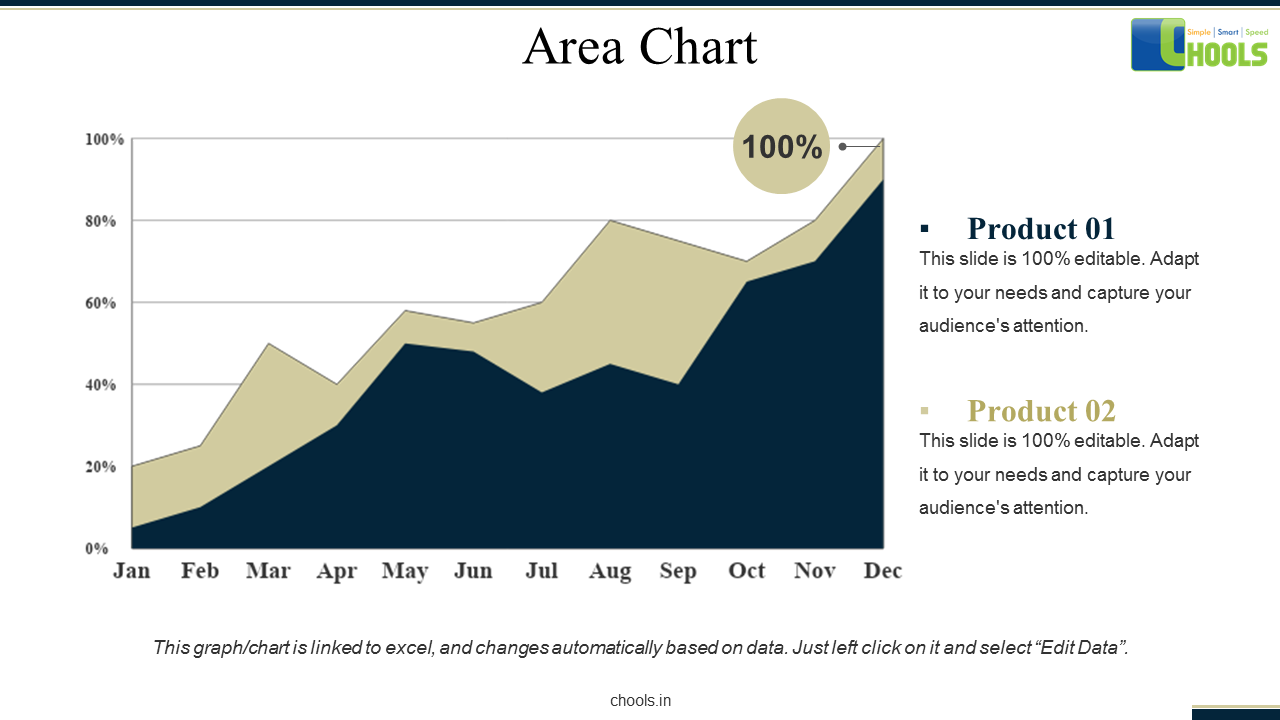

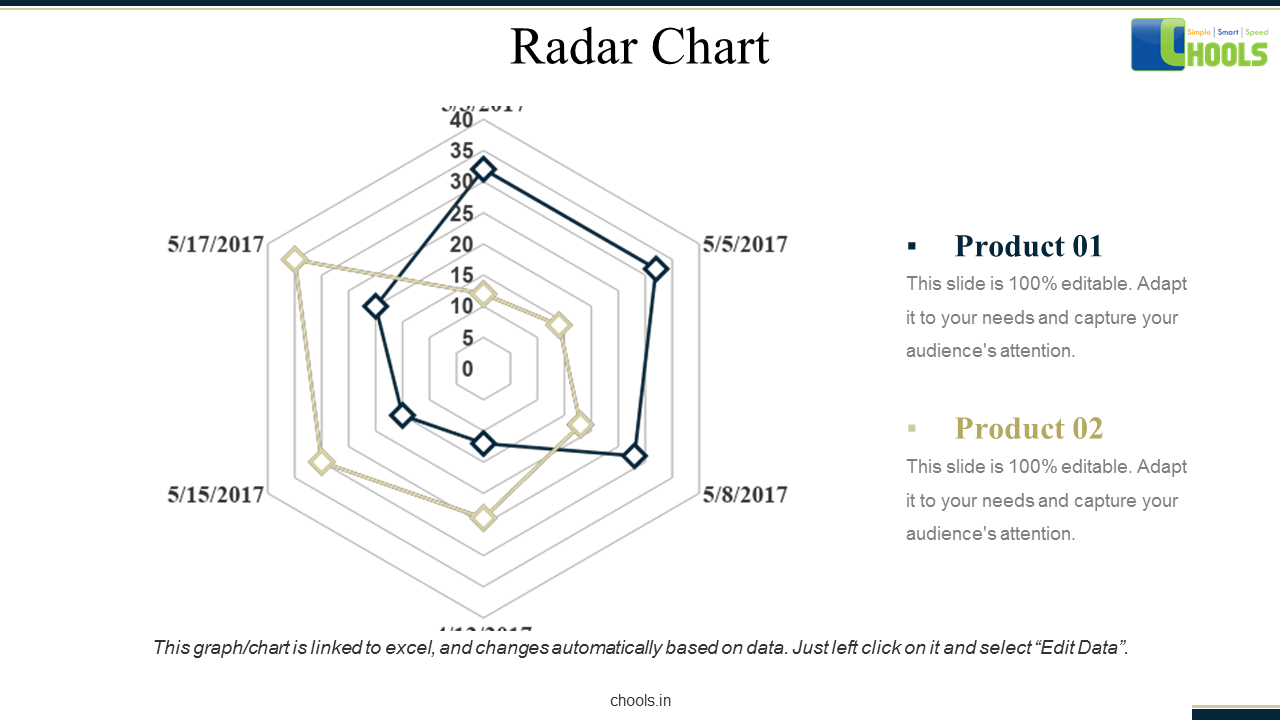

7- Dashboard

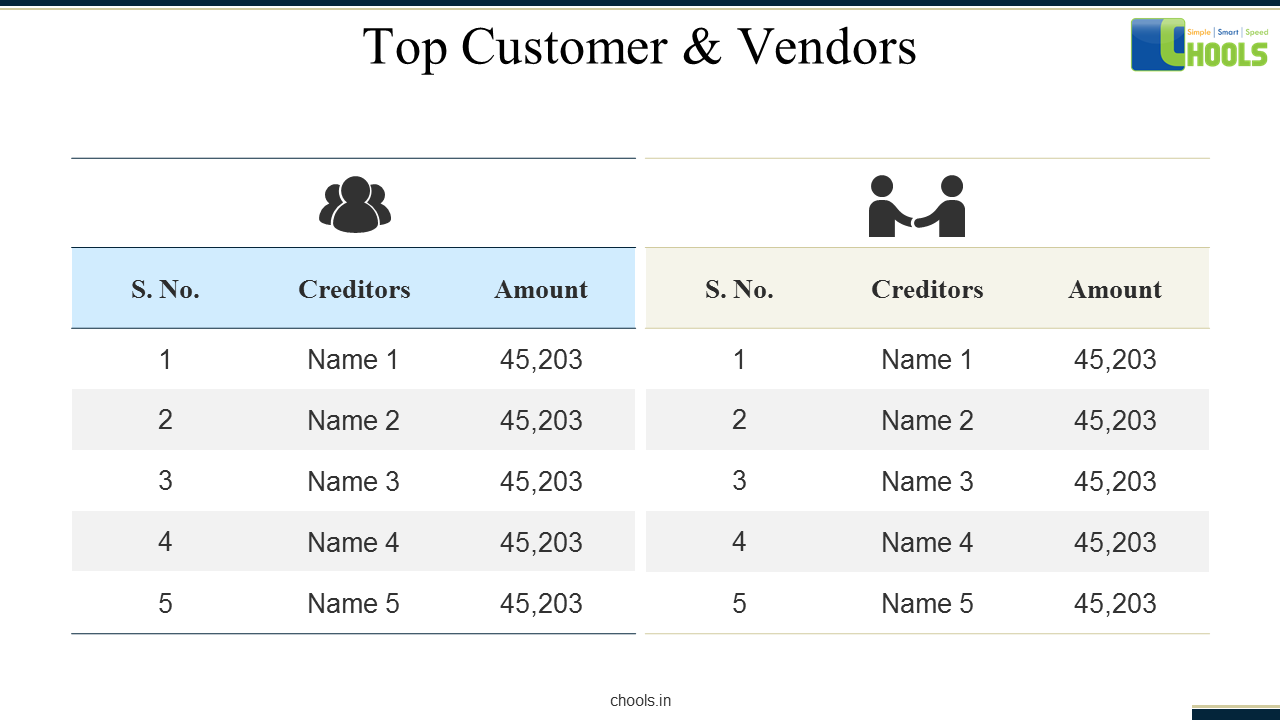

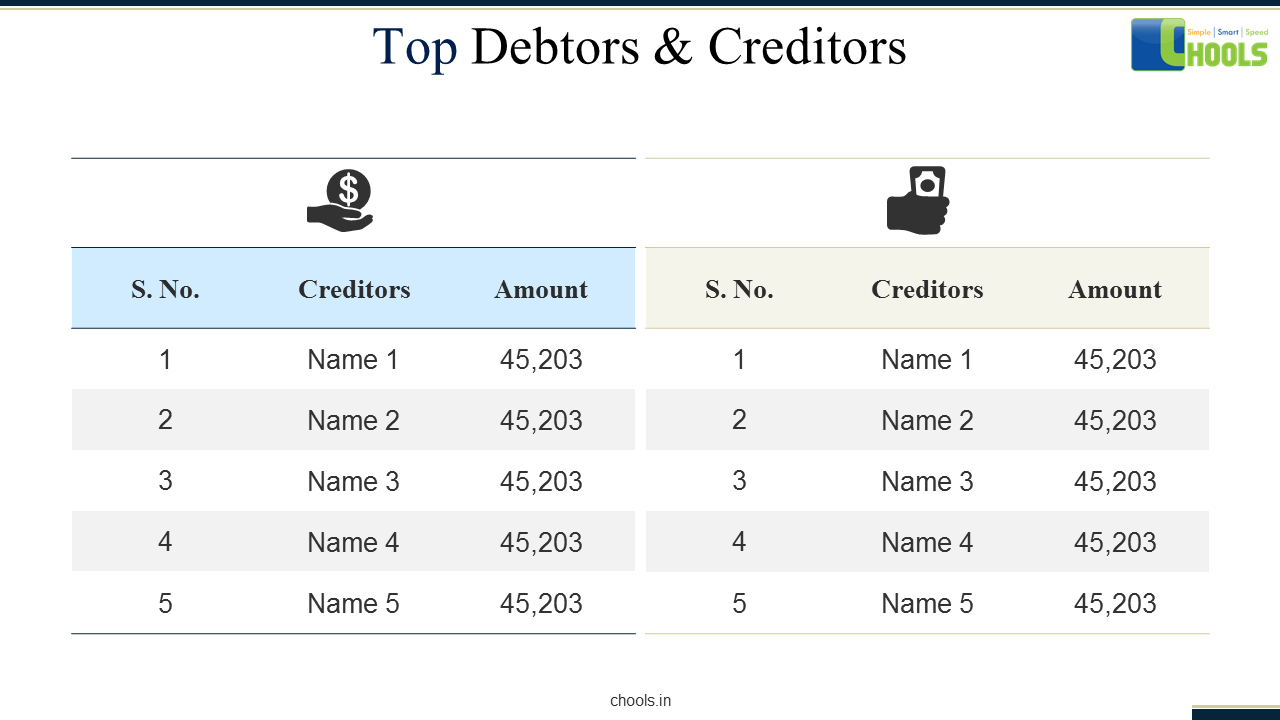

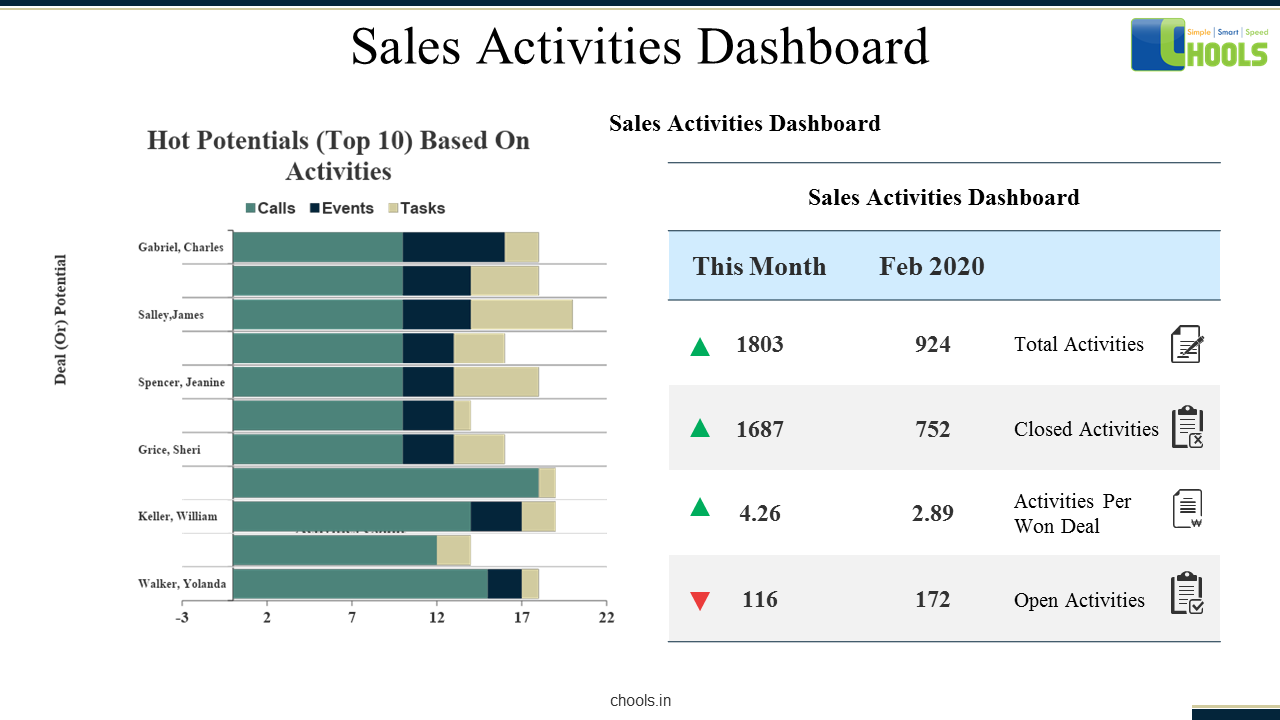

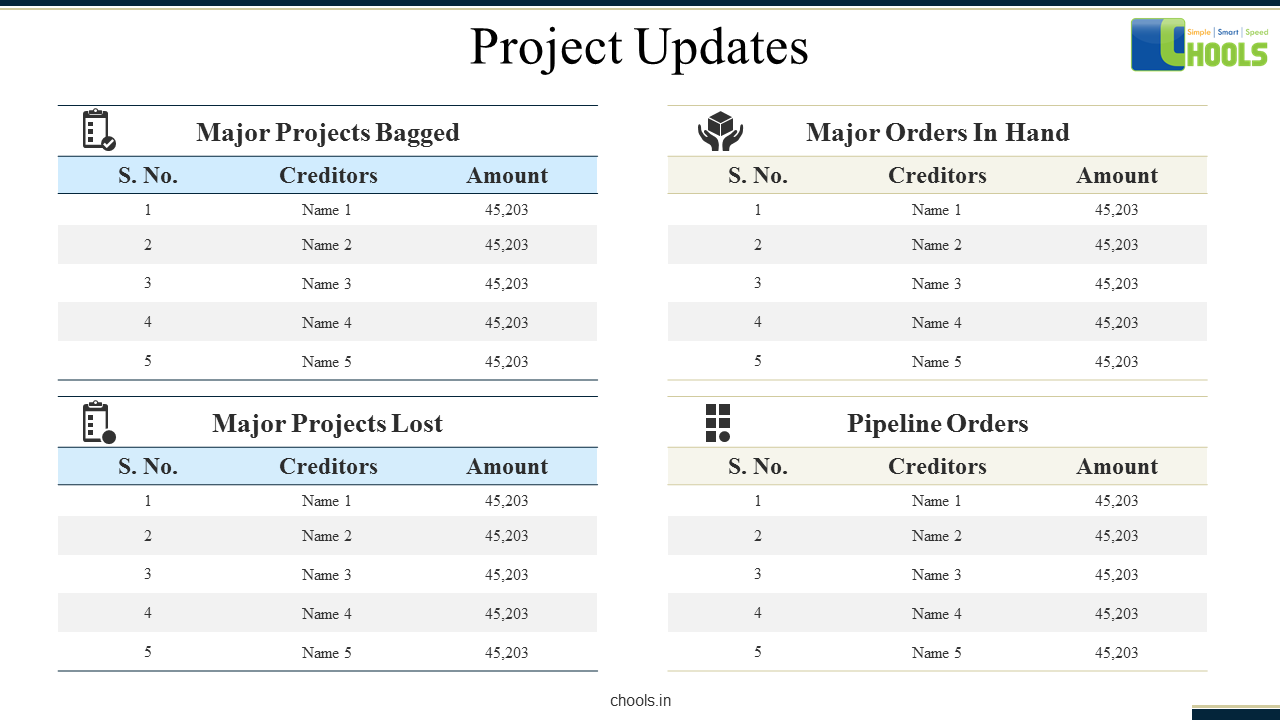

➤ Sales and operations performance Dashboard

➤ S&OP Review Dashboard

➤ Demand Analysis Dashboard

➤ Capacity Utilization Report

➤ Production Constraint Alert Map

➤ Supply vs. Demand Dashboard

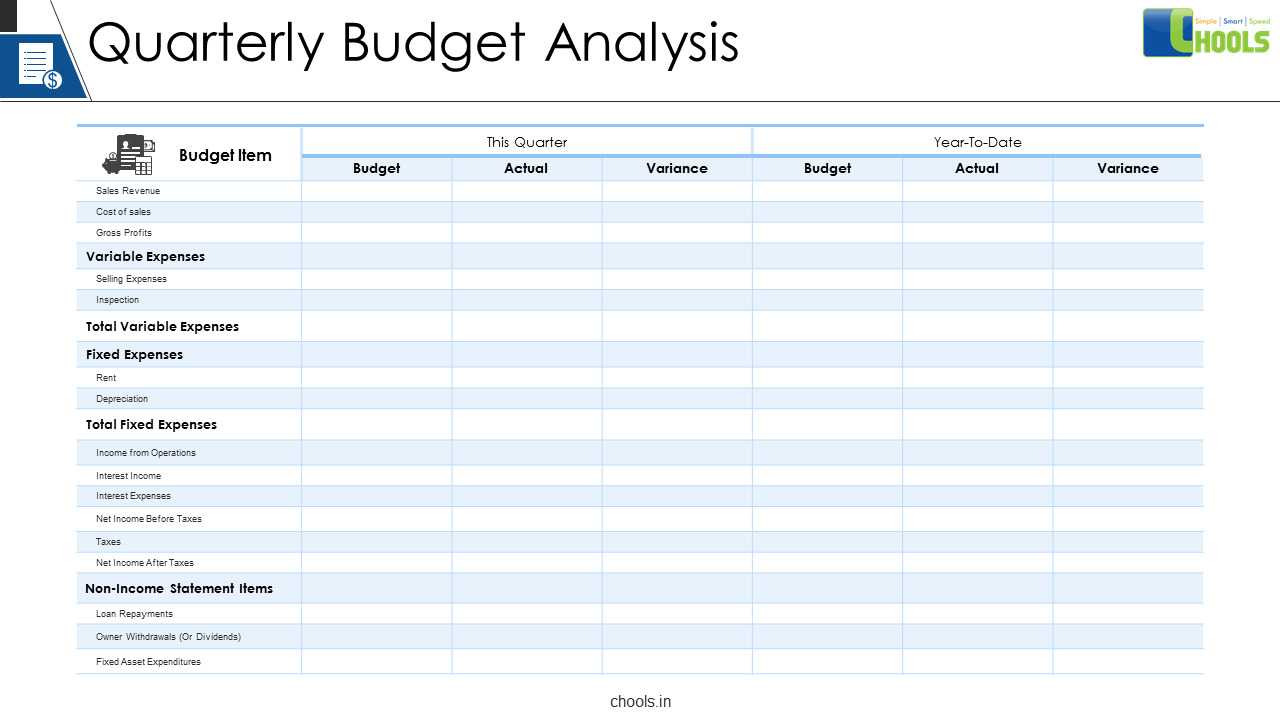

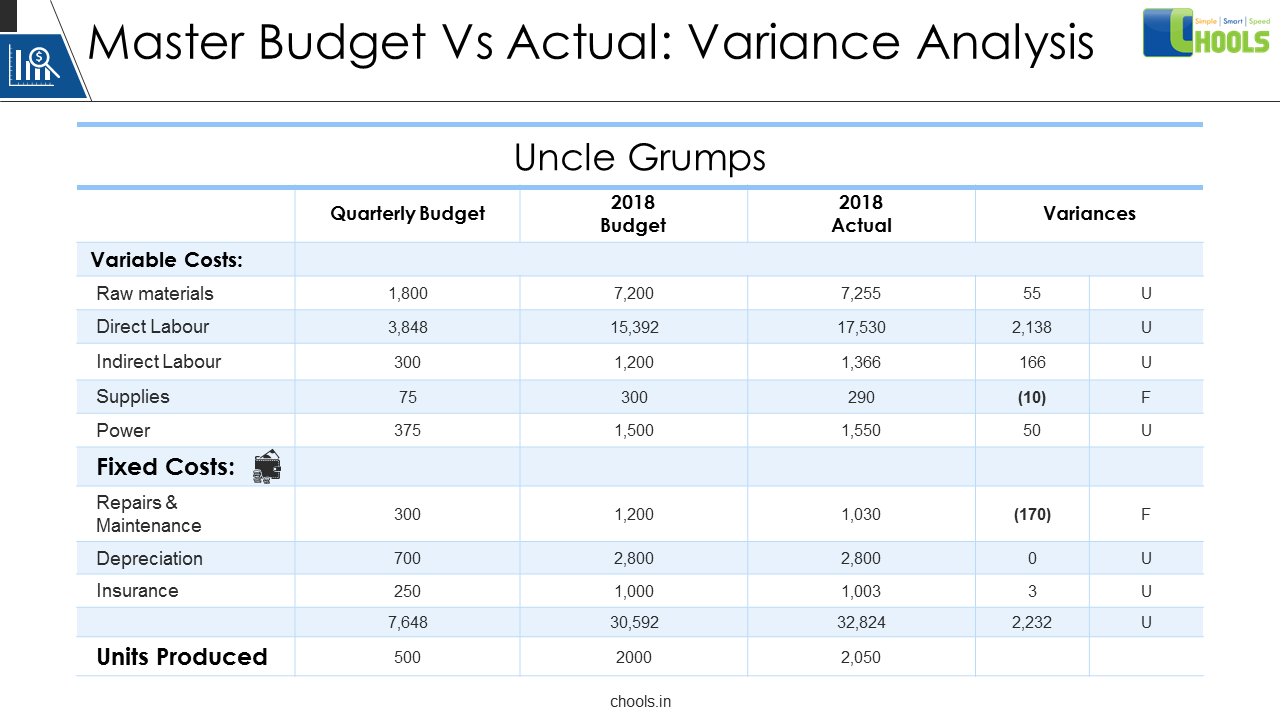

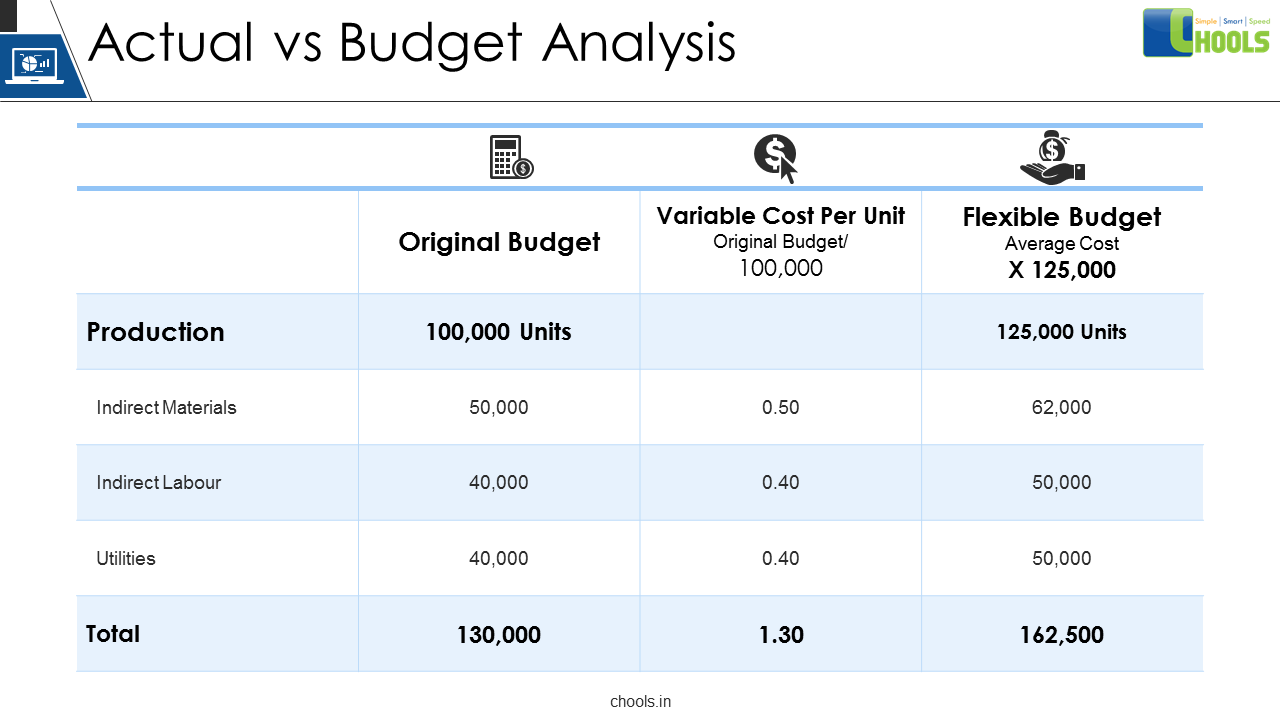

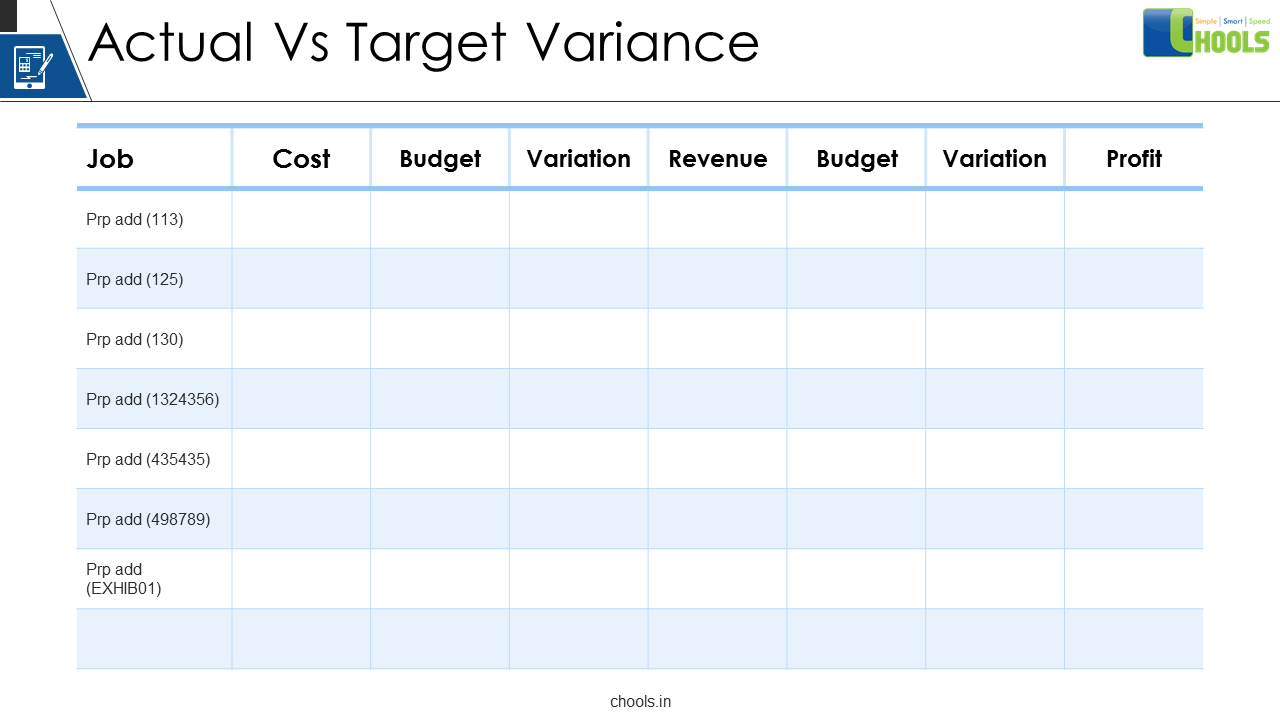

➤ Financial Reports

Related Case Study

CASE

✔ Chools was hired by 100 fortune Food and beverage company in North India to drive and develop its Productivity, Lean Six sigma, and supply chain excellence. SC S&OP was one of the strategies Chools adopted.

ACT

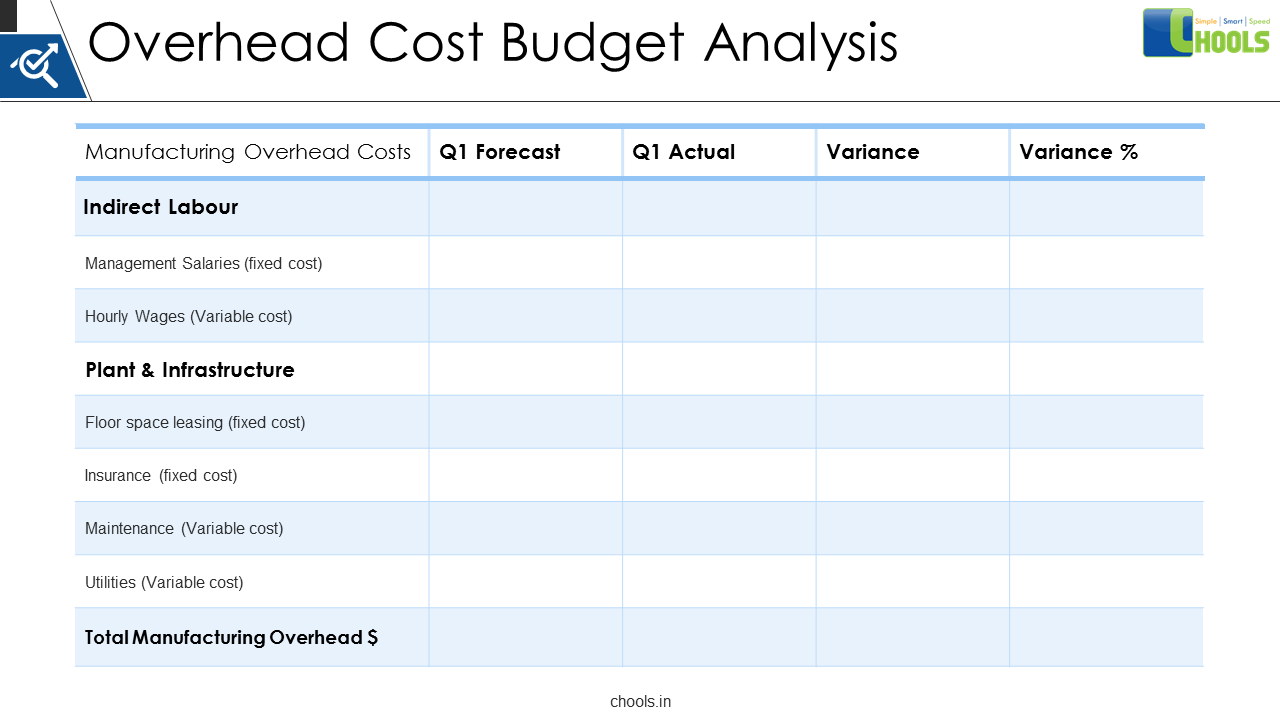

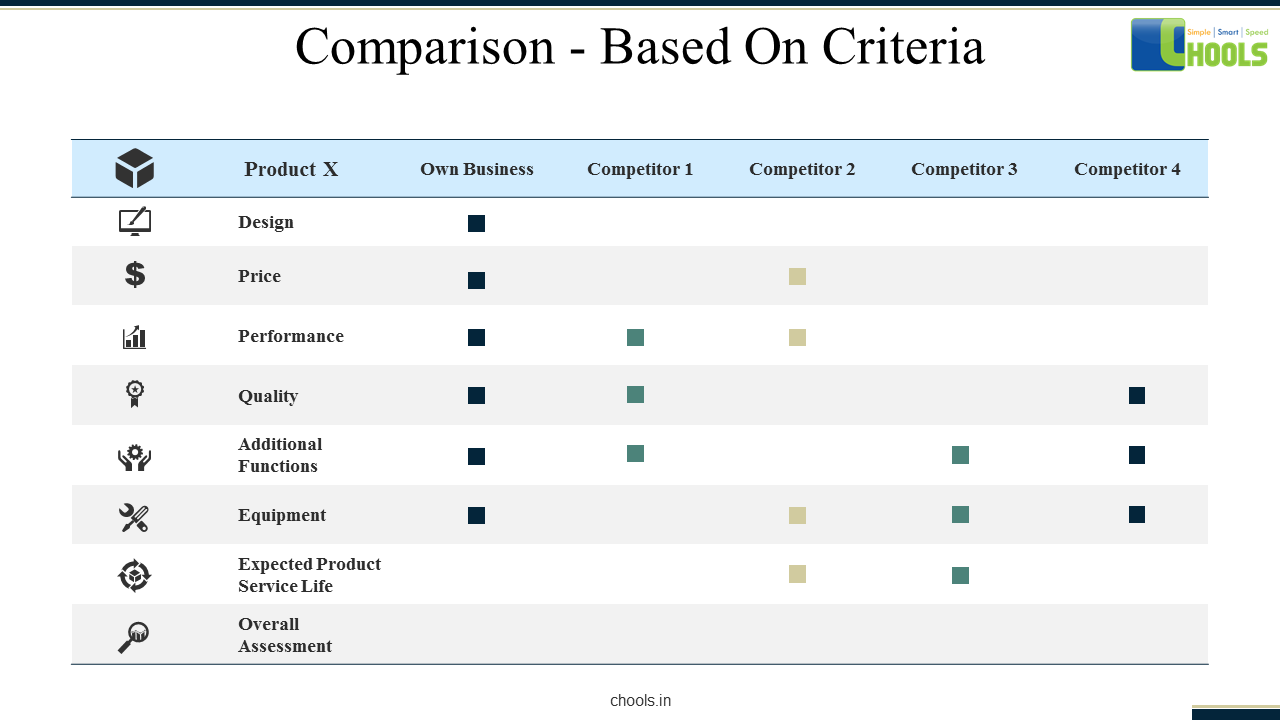

✔ Chools Consultants conducted Supply chain assessments and impact analysis; leading the team in Establishing the S&OP Process, KPI’s and Dashboard .

RESULTS

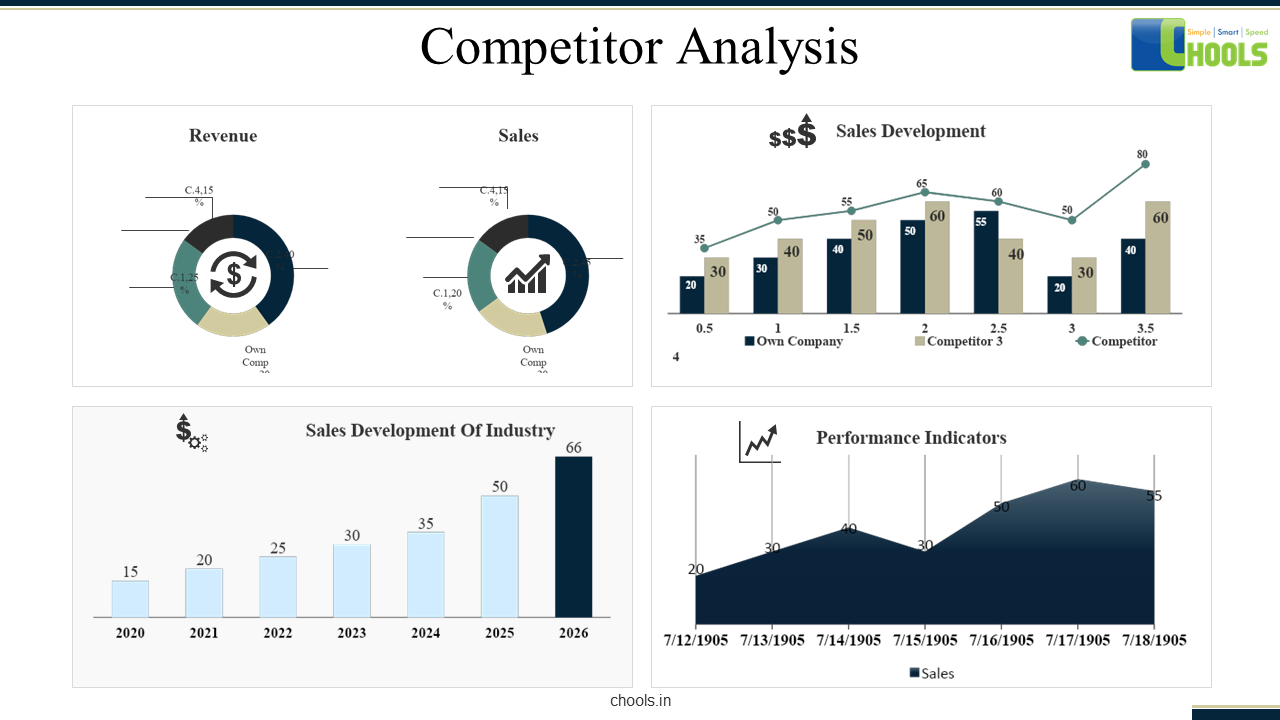

✔ $3MM annual productivity was achieved – 3% of supply chain base spend; delivered through reduction in transportation and inventory holding costs and optimizing production adjustments and operational efficiecy.

Supply and Operations Planning - Case Study

The Challenge

An obsolete inventory was consistent in running beyond the target. The cause was attributed to the gaps in the supply chain planning process. Additionally, a formal Sales & Operations Planning process was absent. Chools was consulted for developing an effective S&OP strategy and implementation procedure to bring out the optimum efficiency in the industrial process.

The Solution

Chools identified the areas that needed actionable changes. Top leaders were completely in the sync for a renewed S&OP implementation across multiple business units. The project team started with a distinct and integrated improvement project. The vision and charter designed aimed at harmonizing processes and tools at every place possible. It was intended to also address the needs of different markets and business units. The collaborating teams ensured insightful project reviews. The commonality was identified and the overall integration was eased.

➤ The project teams prominently addressed the gaps in the areas of demand, supply and the new product introduction along with the gaps in the implementation of the S&OP process. The team emphasized on upgrading the underlying IT systems, with updated tools for supporting data aggregation and for reporting at S&OP levels.

➤ Chools initiated the organizational changes that would reflect in the improvements in business and processes.

The Outcome

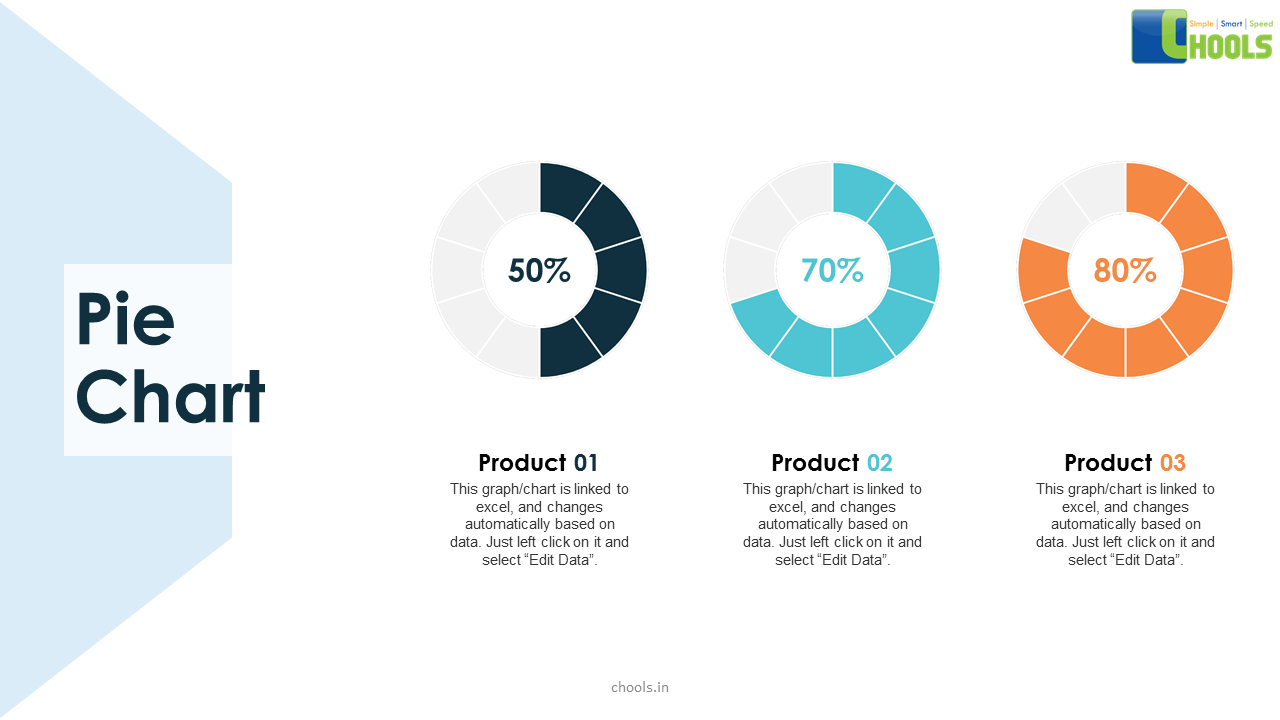

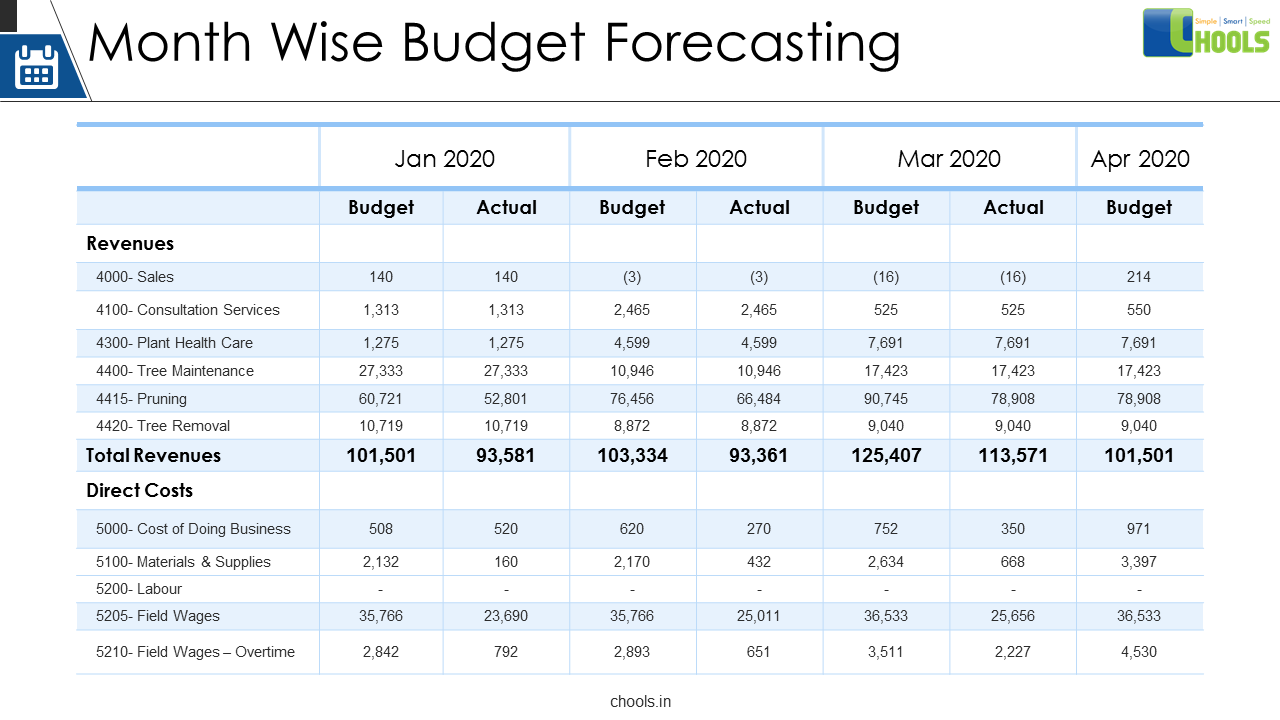

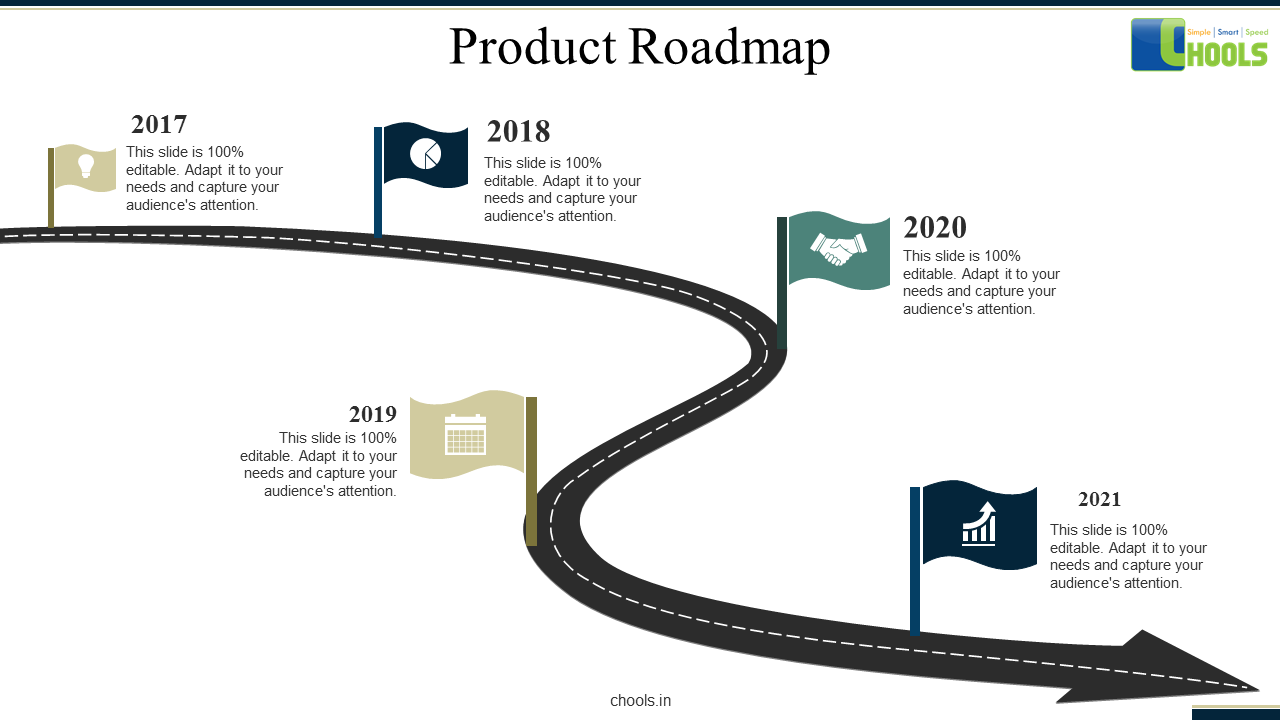

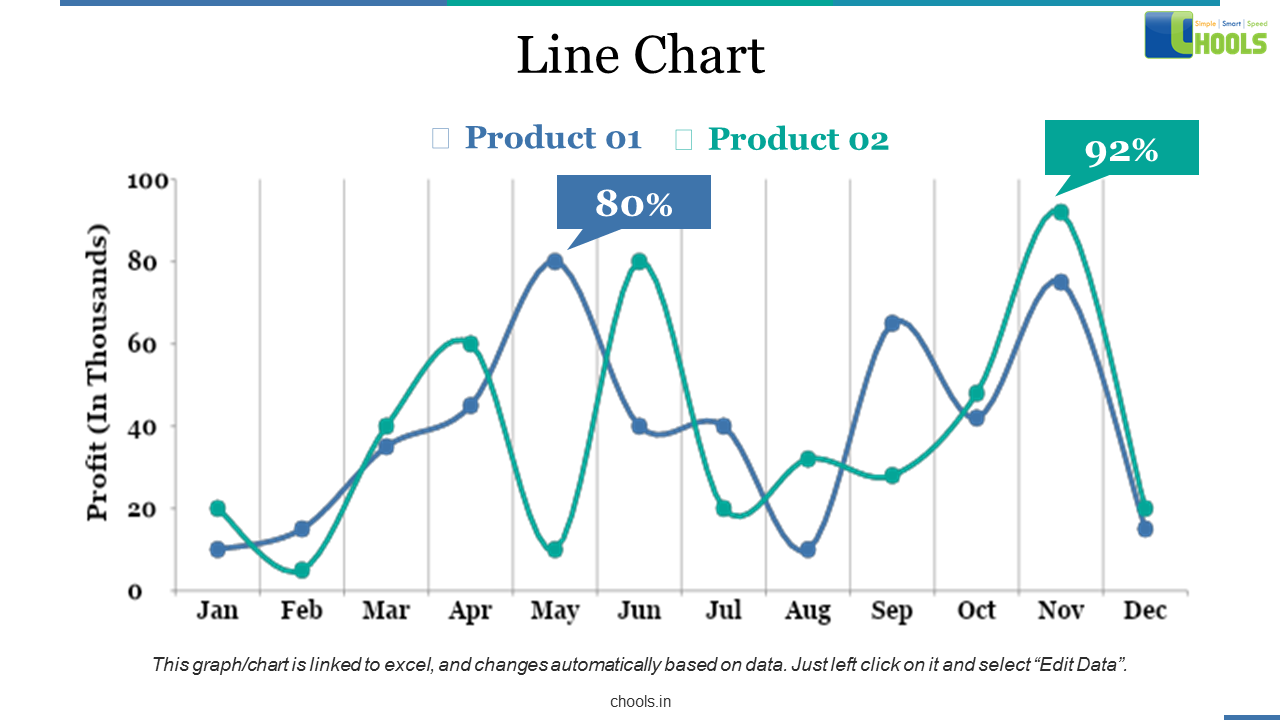

The project reached its intended conclusion after several months from the initiation. Chools had rolled S&OP across several business decisions. Business decisions were driven managing a set of KPIs across critical S&OP components. Identification of the forecast errors saw improvement. Business units were on a successful track in achieving a 50% reduction in obsolete inventory. S&OP maturity tracking system was implemented for ensuring consistent continuous improvement with a defined timeline. The automated S&OP reporting system was launched. Web-based interface was developed to the forecasting system. It greatly improved the ability to collect forecast inputs directed from the Salesforce. S&OP was integrated with financial planning. The S&OP was effectively utilized in the next quarterly financial planning cycle.

The Challenge

An international corporation with a world-wide reputation was considering an organizational restructuring. They needed to develop an integrated forecast and S&OP business planning process. The business need was focused on getting high-quality transparent forecasts that supported and enhanced corporate, brand and financial planning. The sales and marketing entities had to be aligned with the technical operations to achieve the outcome of exceptional efficiencies in the supply chain.

The Action Plan

A cross-functional team was formed which consisted of prime internal stakeholders and the external experts. With their collaboration, a comprehensive project charter was established. The charter was developed with the intention of objectively align interests that surrounded the project goals and objectives. The other aspects that contributed to the success factors were deliverables, timeline and the team.

The project was split into 2 phases:

➤ Analysis and Design: Includes the processes regarding baseline, optimization identification and process design.

➤Implementation and Assessment: Includes Operational Excellence and Organizational Integration.

The structured analyses were leveraged utilizing external views and internal scans. The baseline analyses were utilized for Organization Assessment, Process and System and Defining Metrics.

Cross-functional mapping sessions were extensively carried out with internal and external resources.

The Business Results

The implementations were carried out functionally and cross-functionally. The benefits followed the same trajectory. The resultant change created a base for institutional knowledge, for information documentation.

➤The S&OP process established was regulated with strict operating principles. It was robust, well-attended and committed. S&OP process was implemented with a forecasting system, it provided the tools needed in the management of the process. Later the incorporation and implementation of the same were carried out in financial and production systems.

➤The well-structured S&OP forum could drive the organization aligning financial and production forecasting. The result brought significant improvement to the gross to net process. Forecast accuracy saw an improvement of 10% and the reduced inventory amounted to several million dollars.

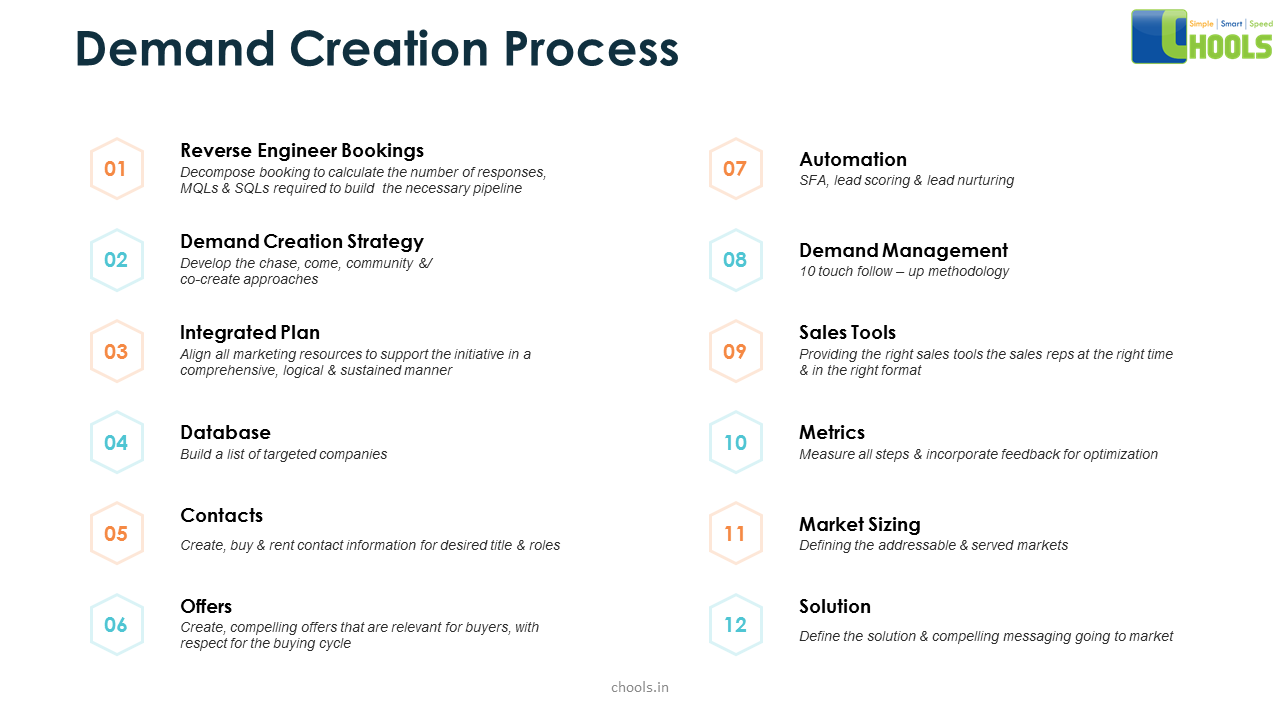

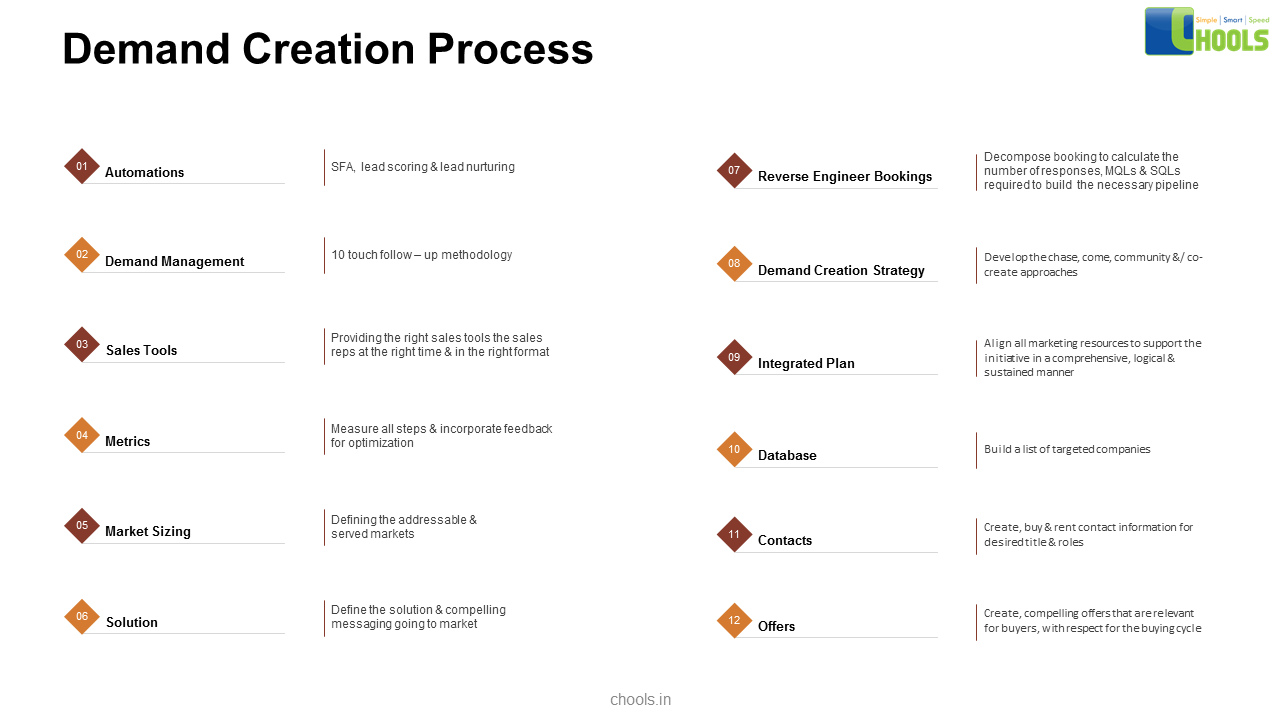

1. 4 GROWTH DRIVER

2. DEMAND CHAIN MANAGEMENT

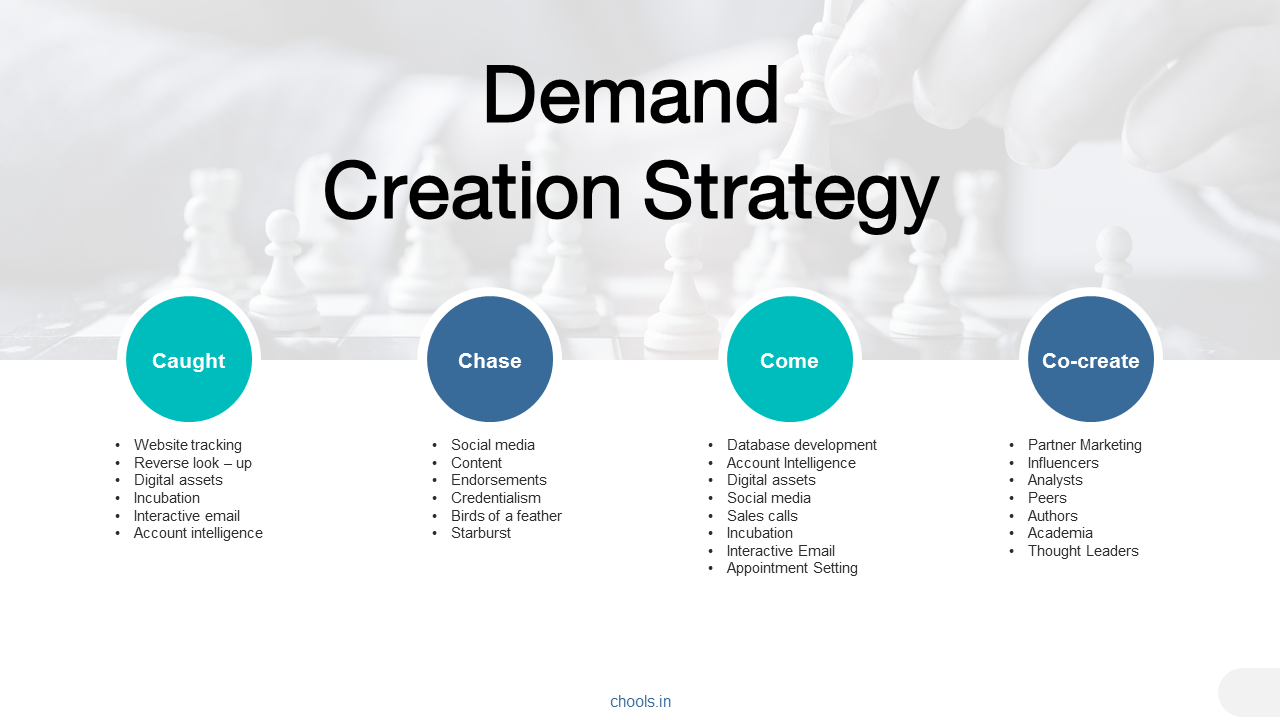

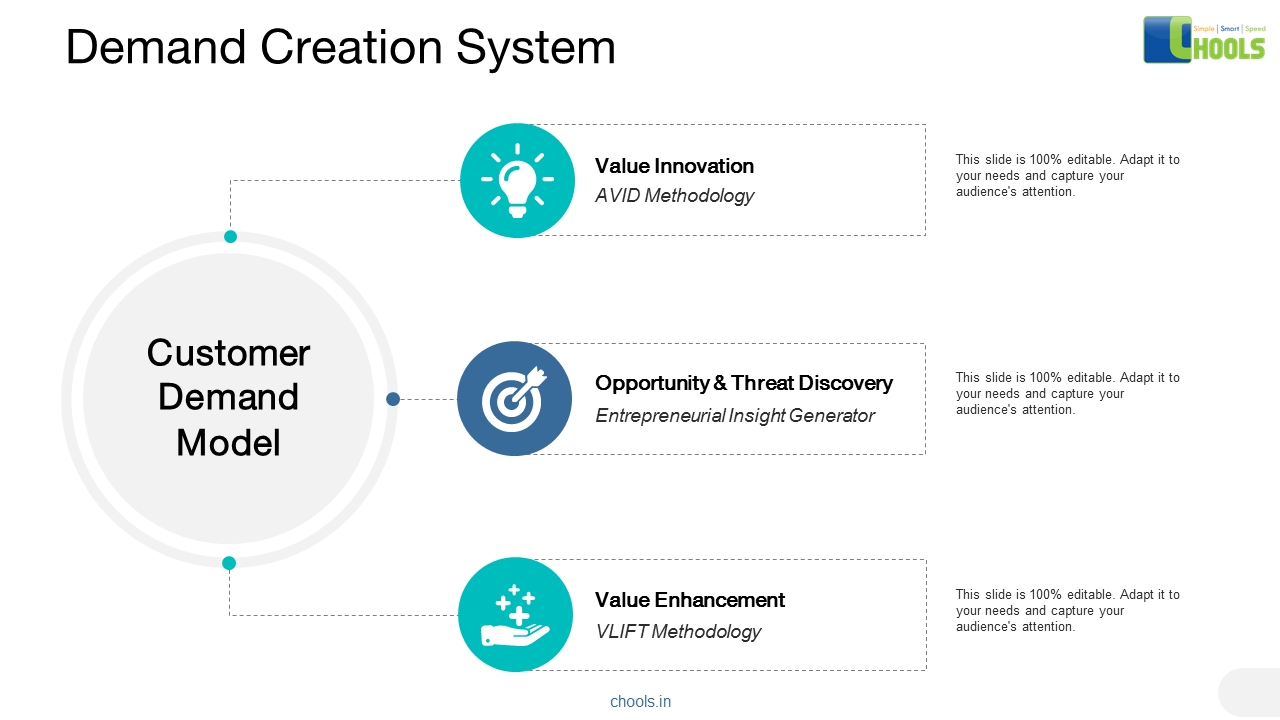

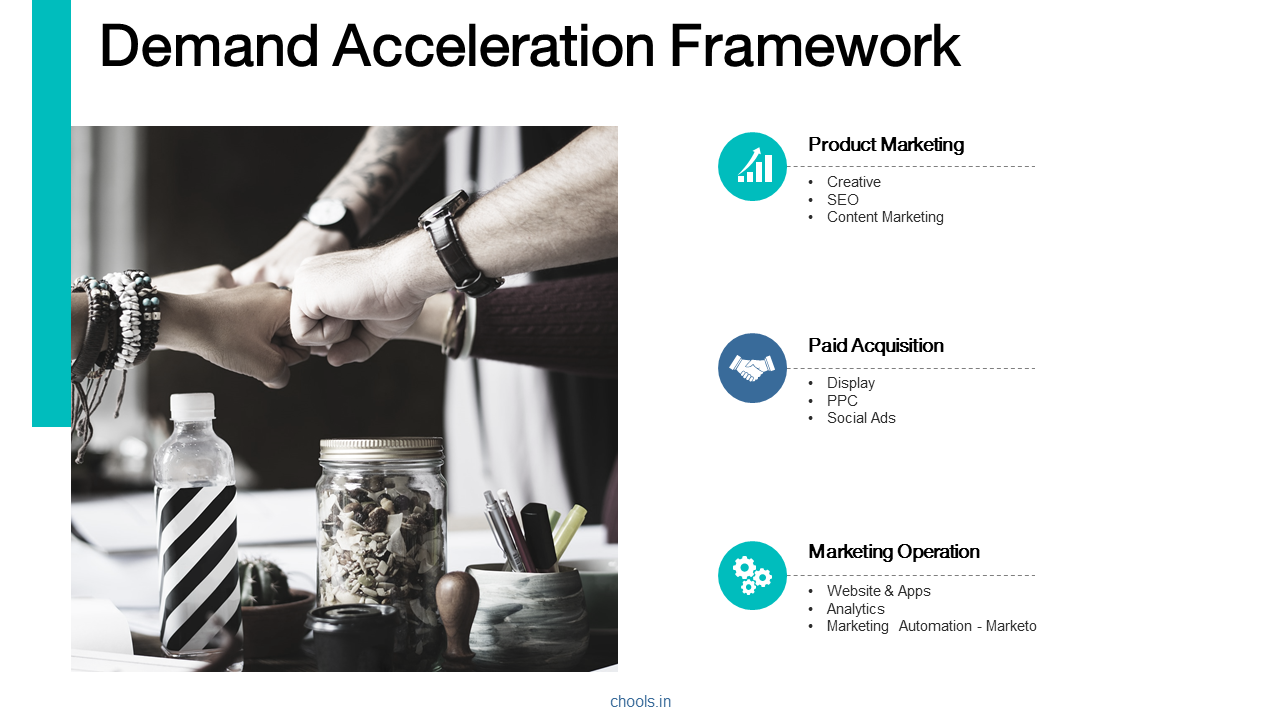

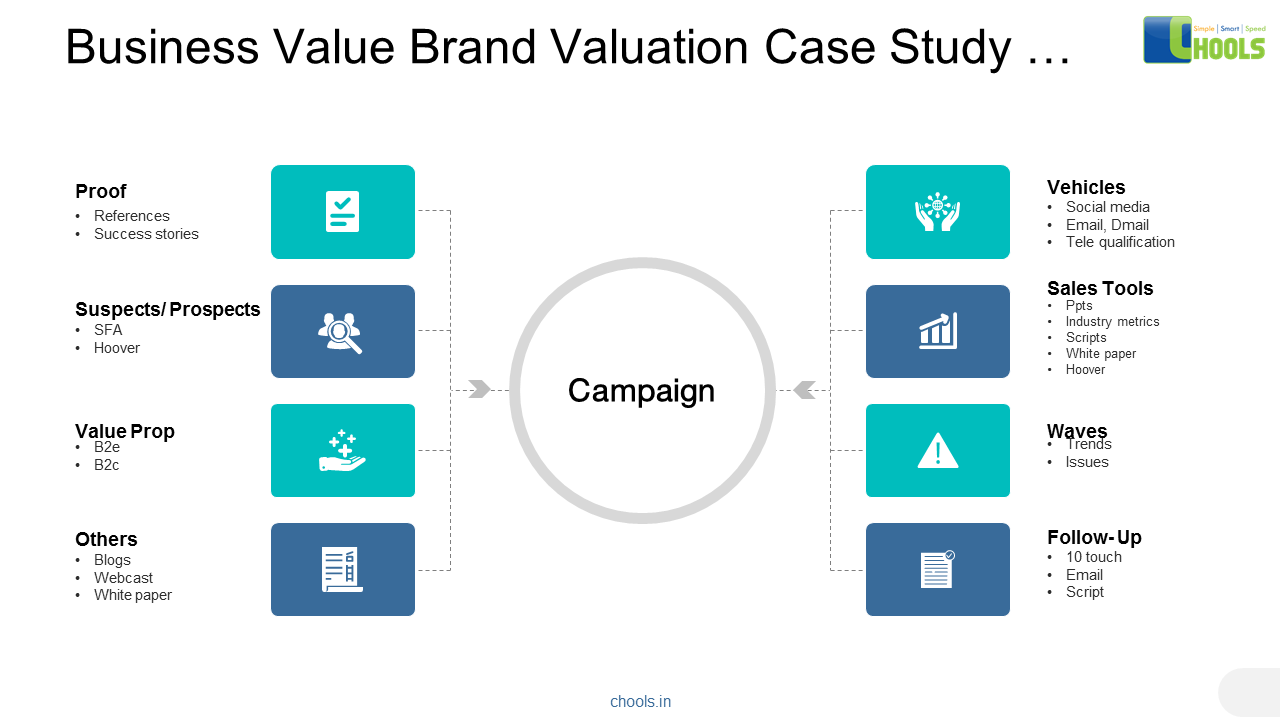

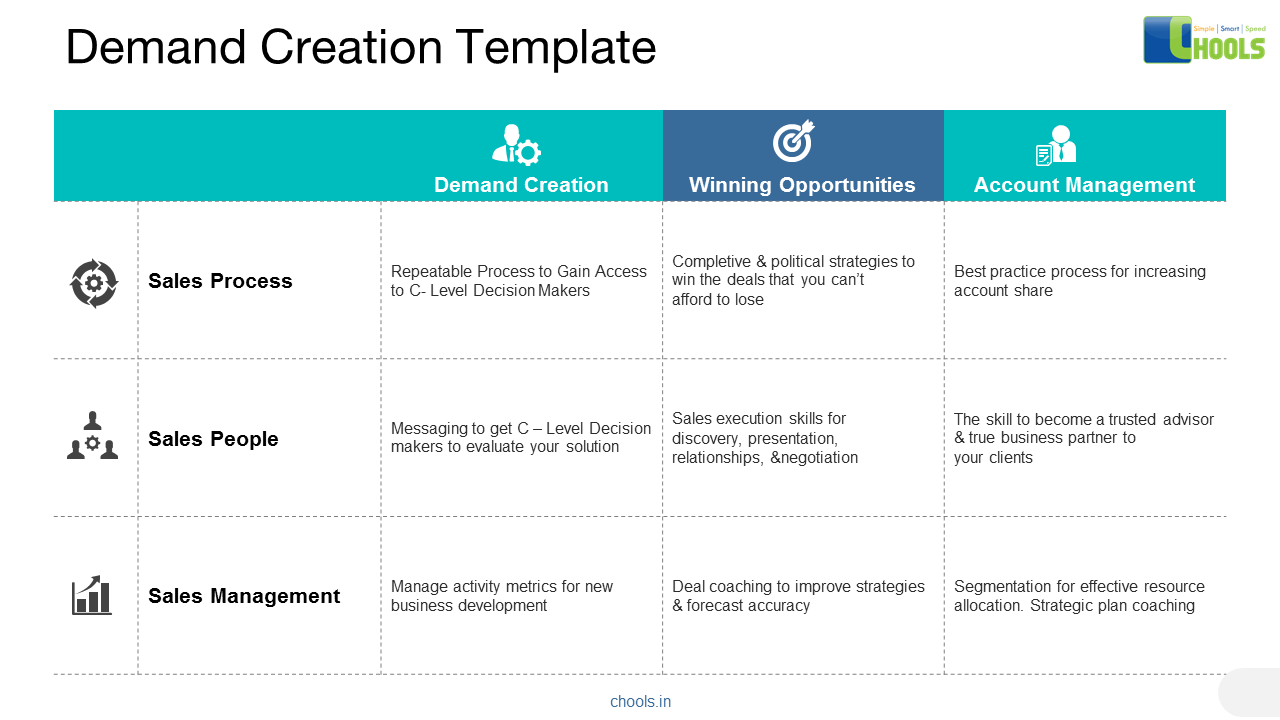

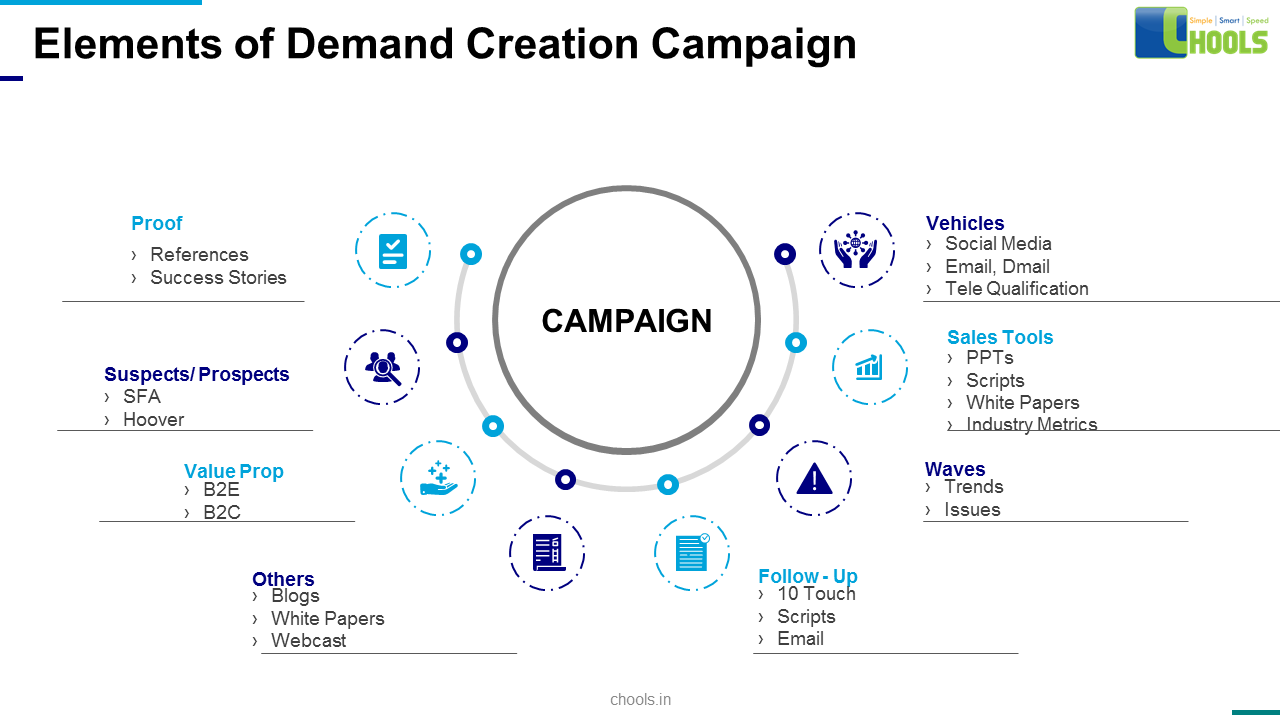

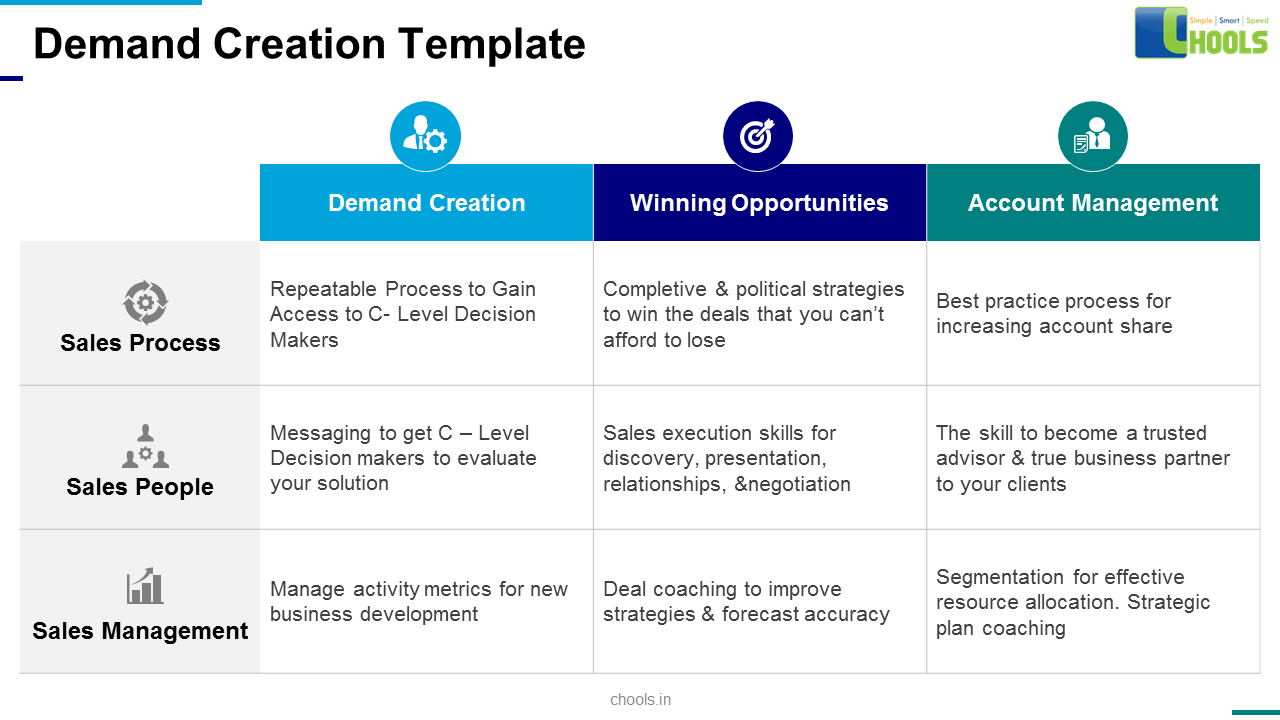

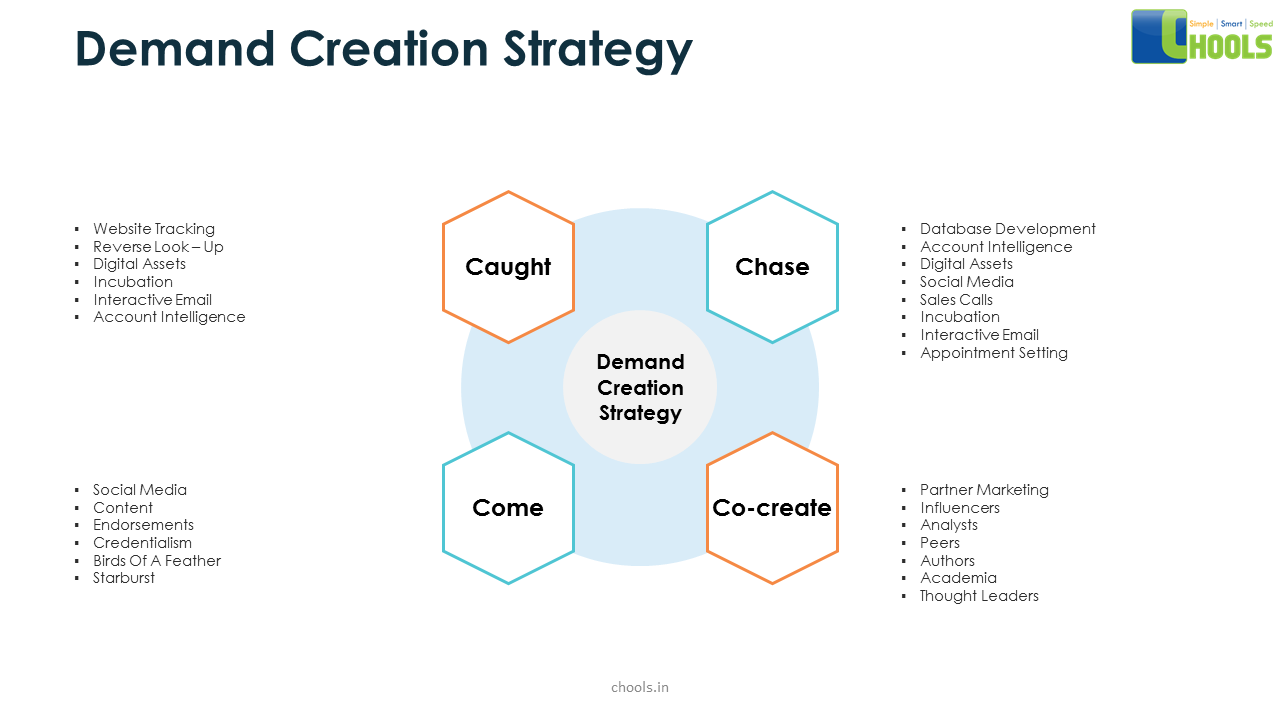

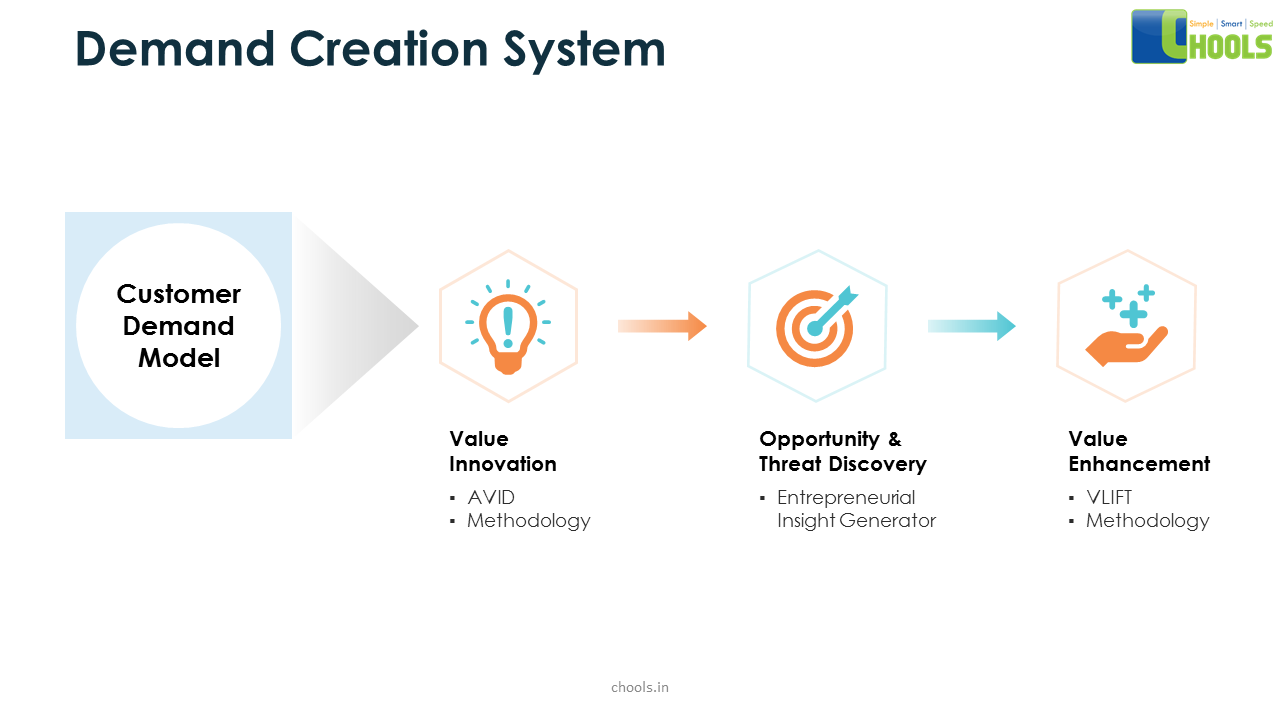

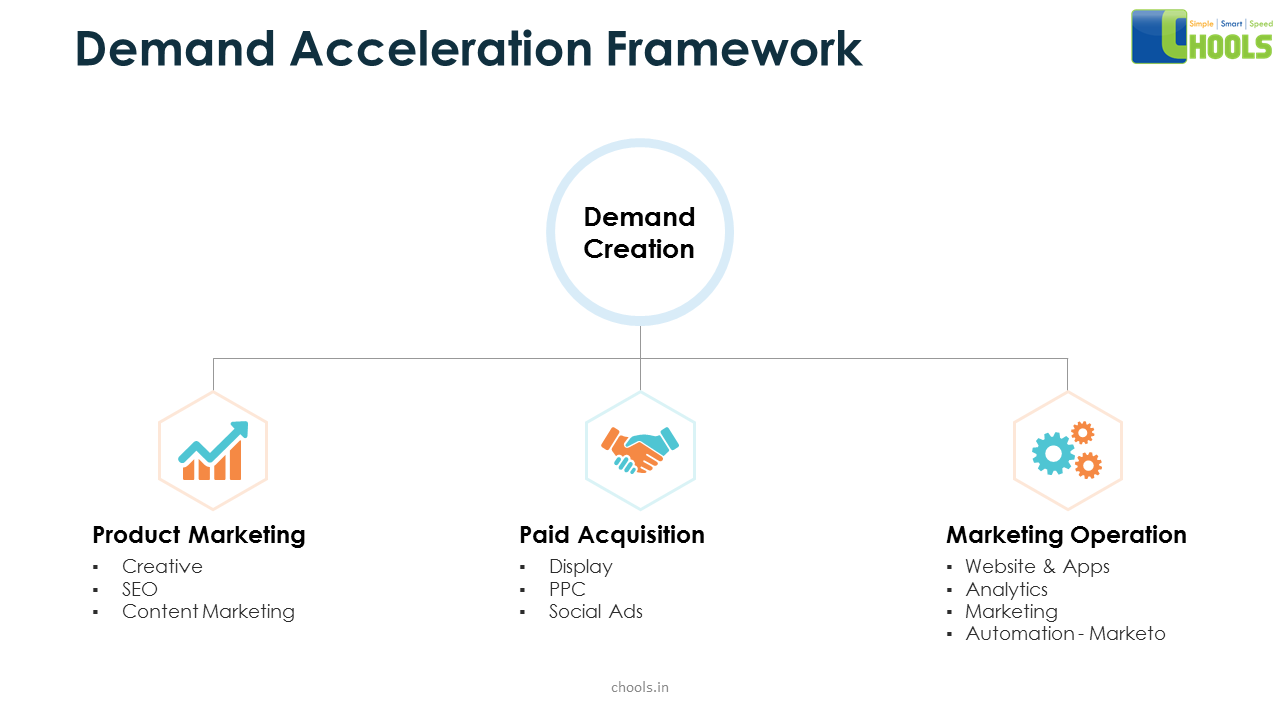

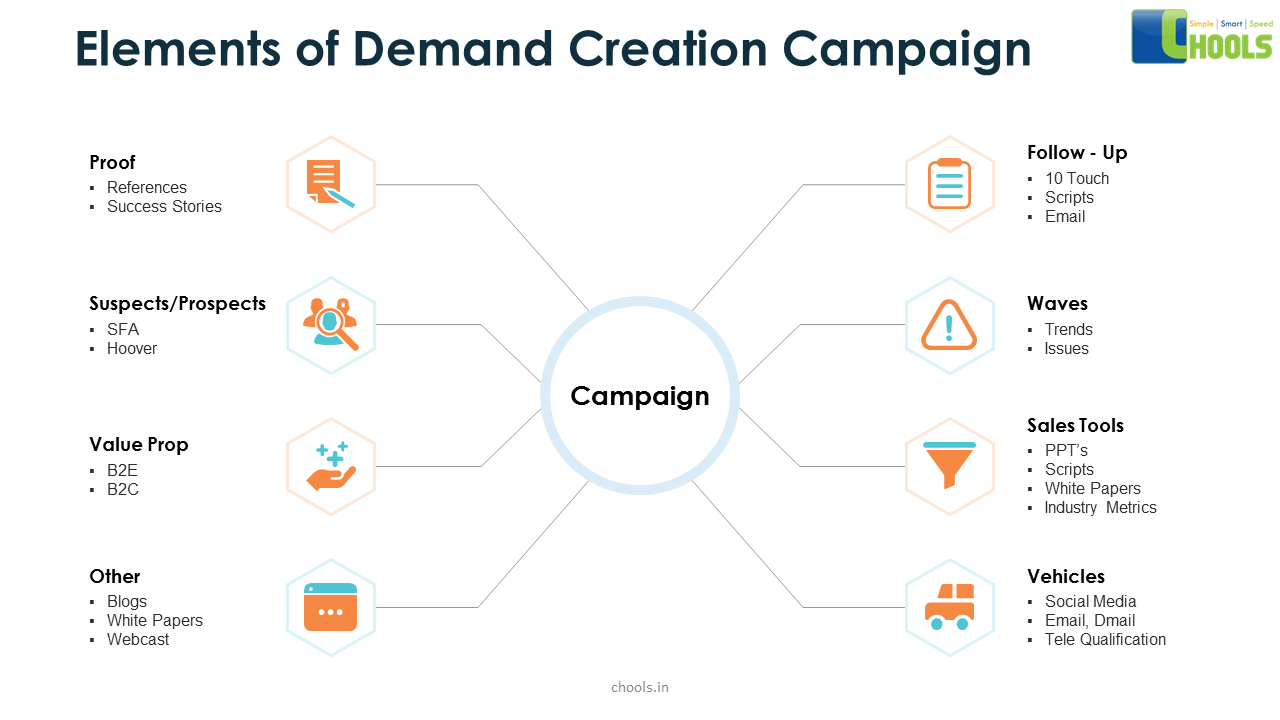

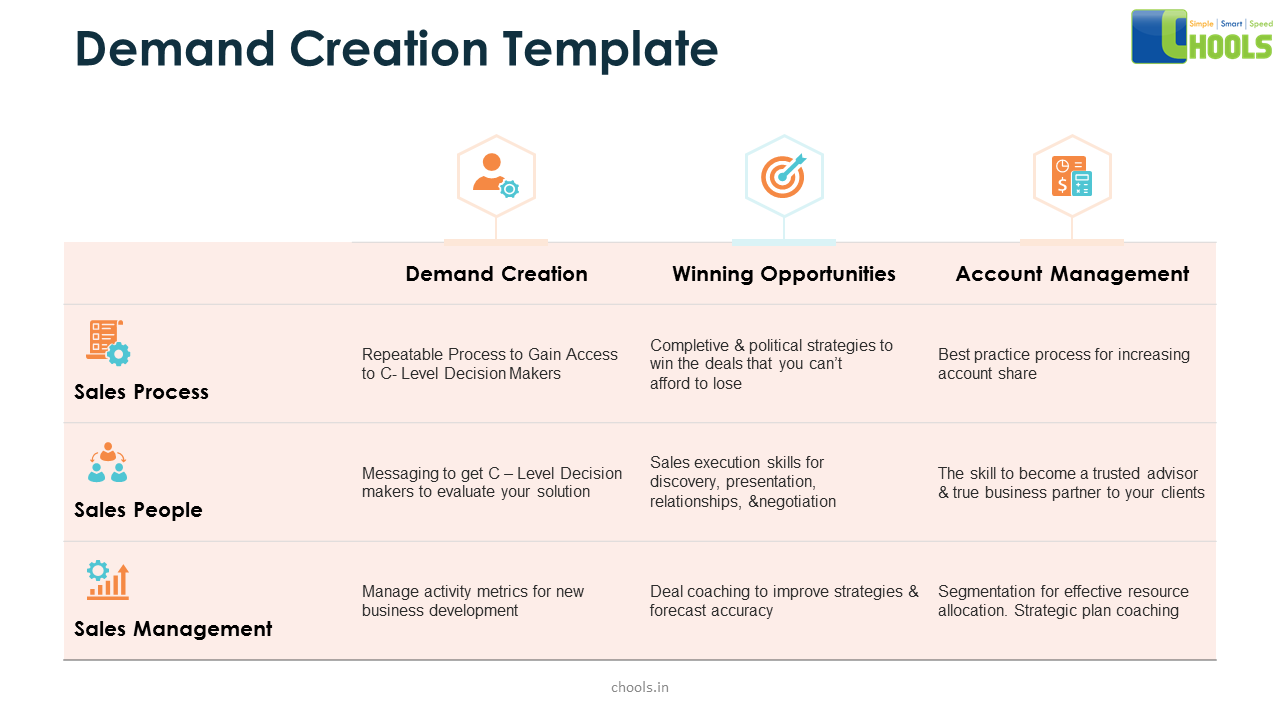

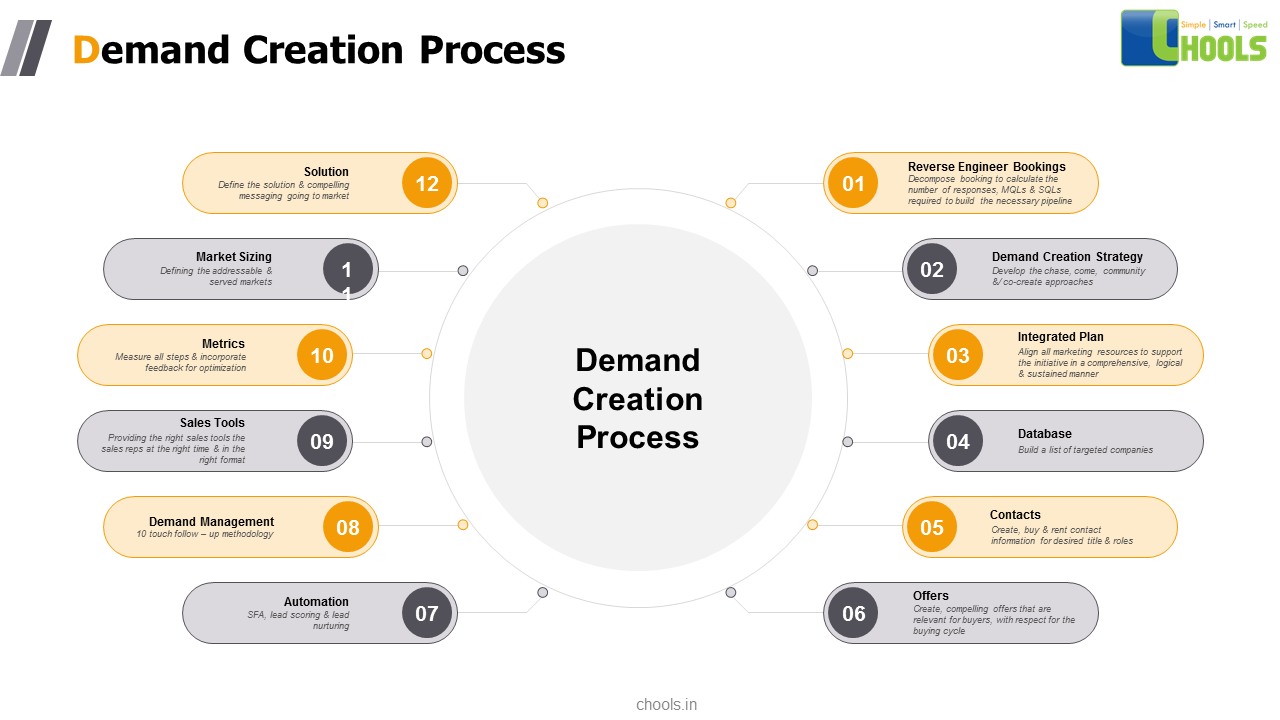

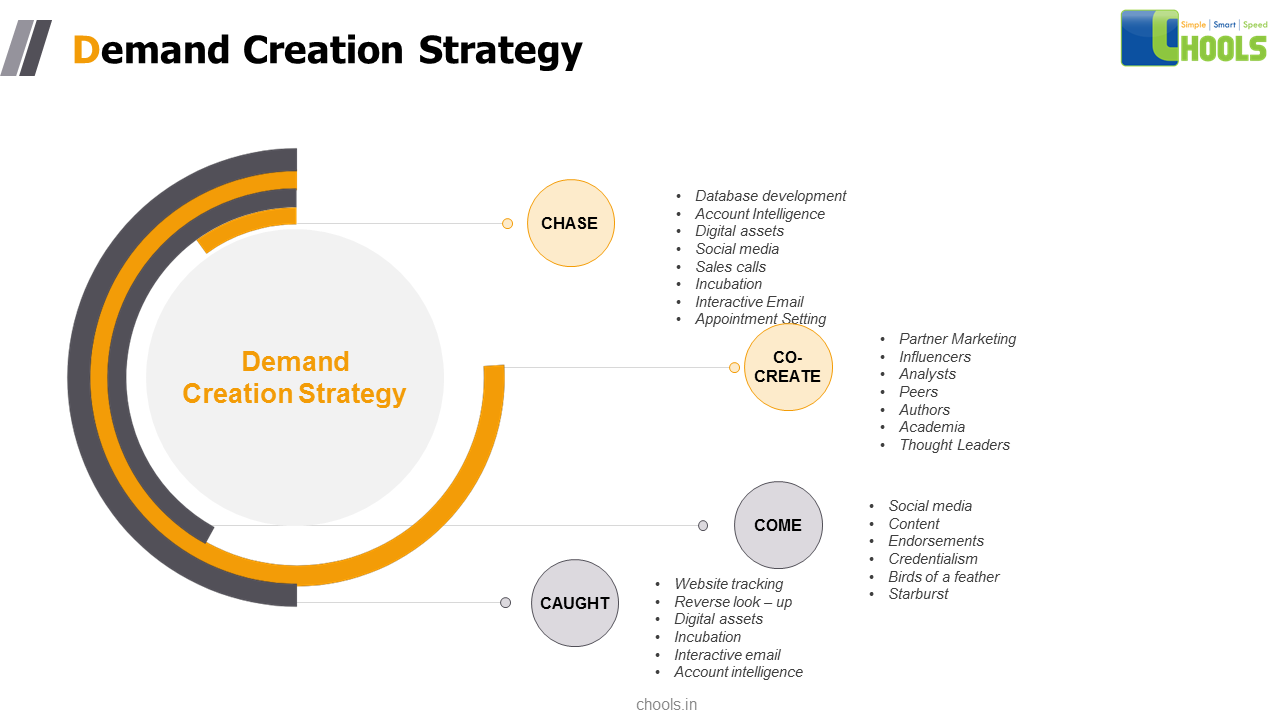

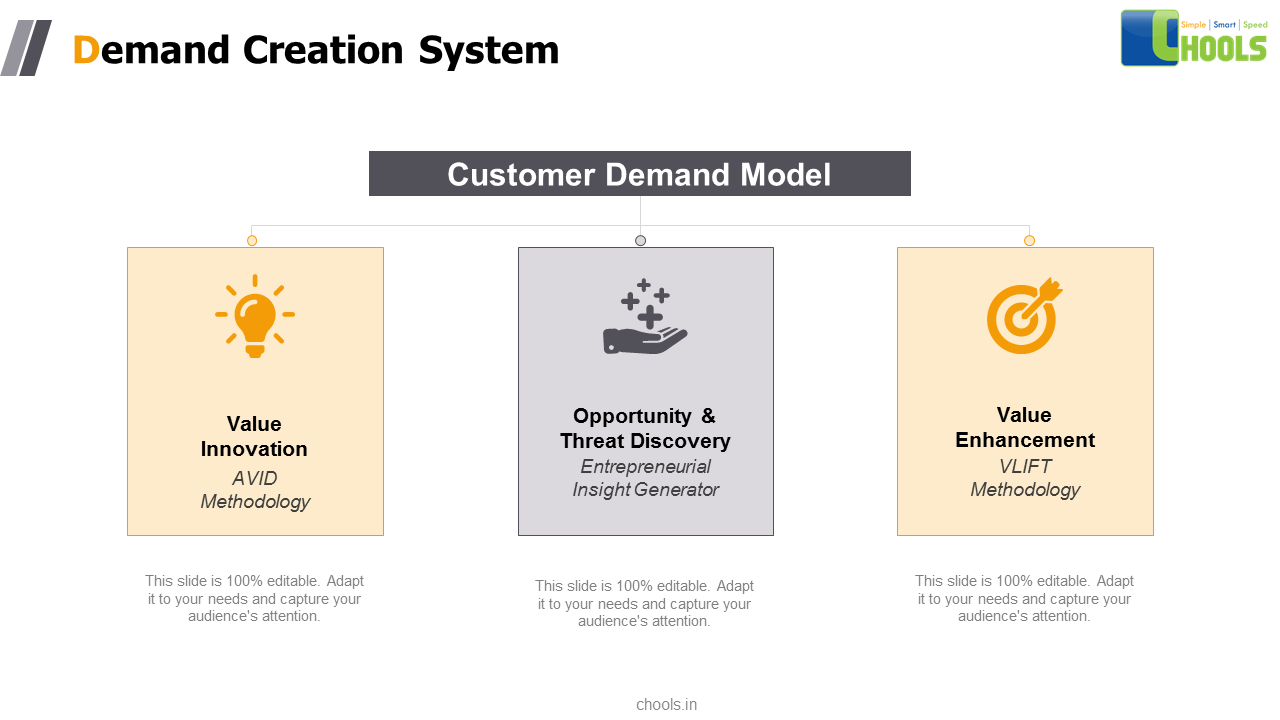

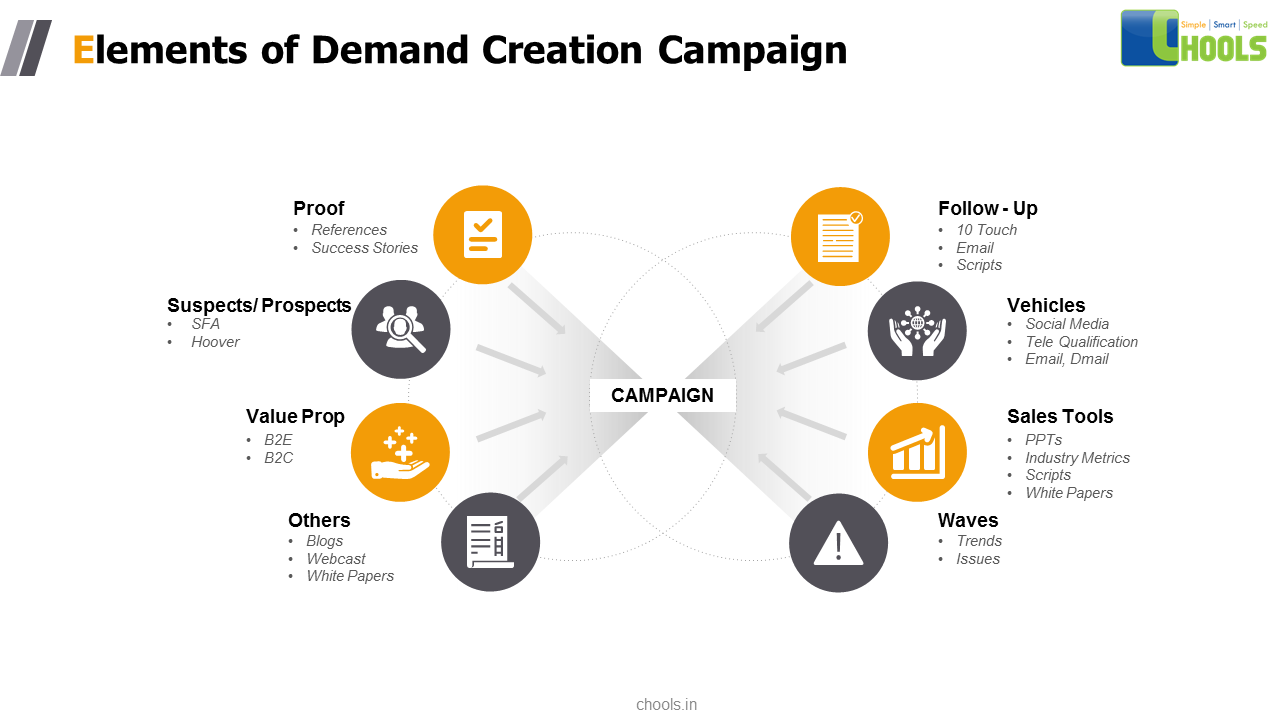

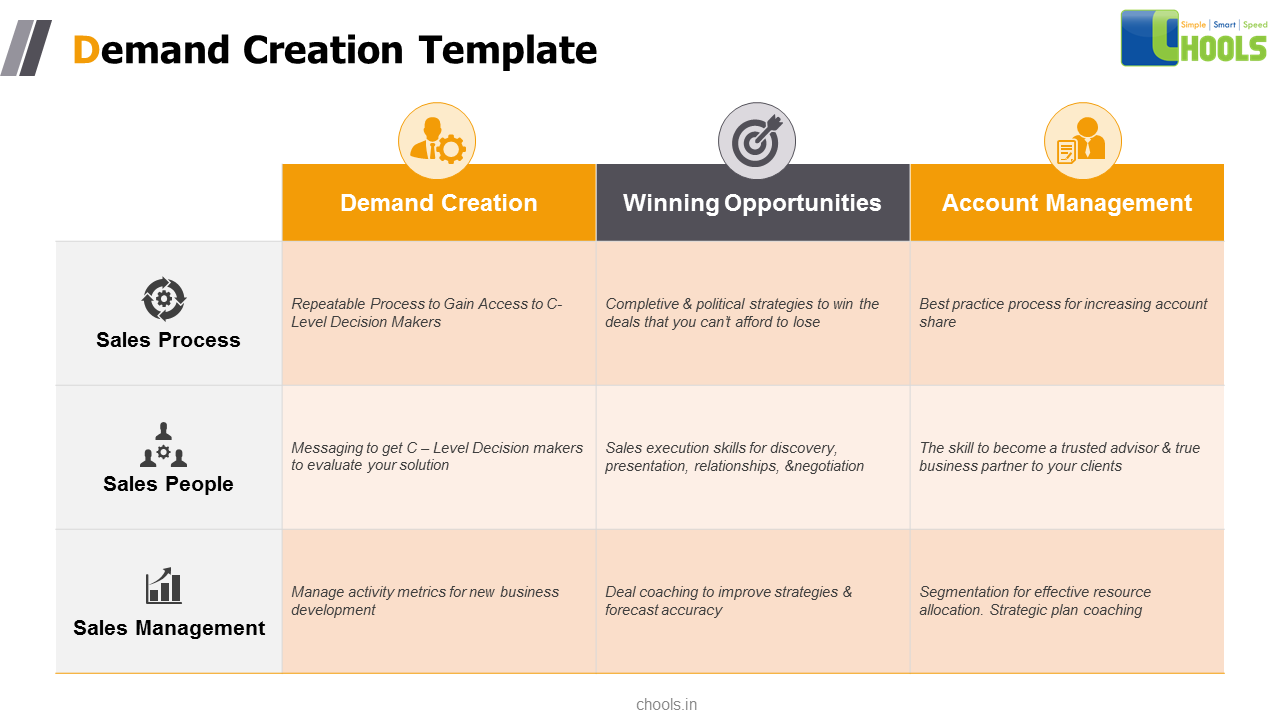

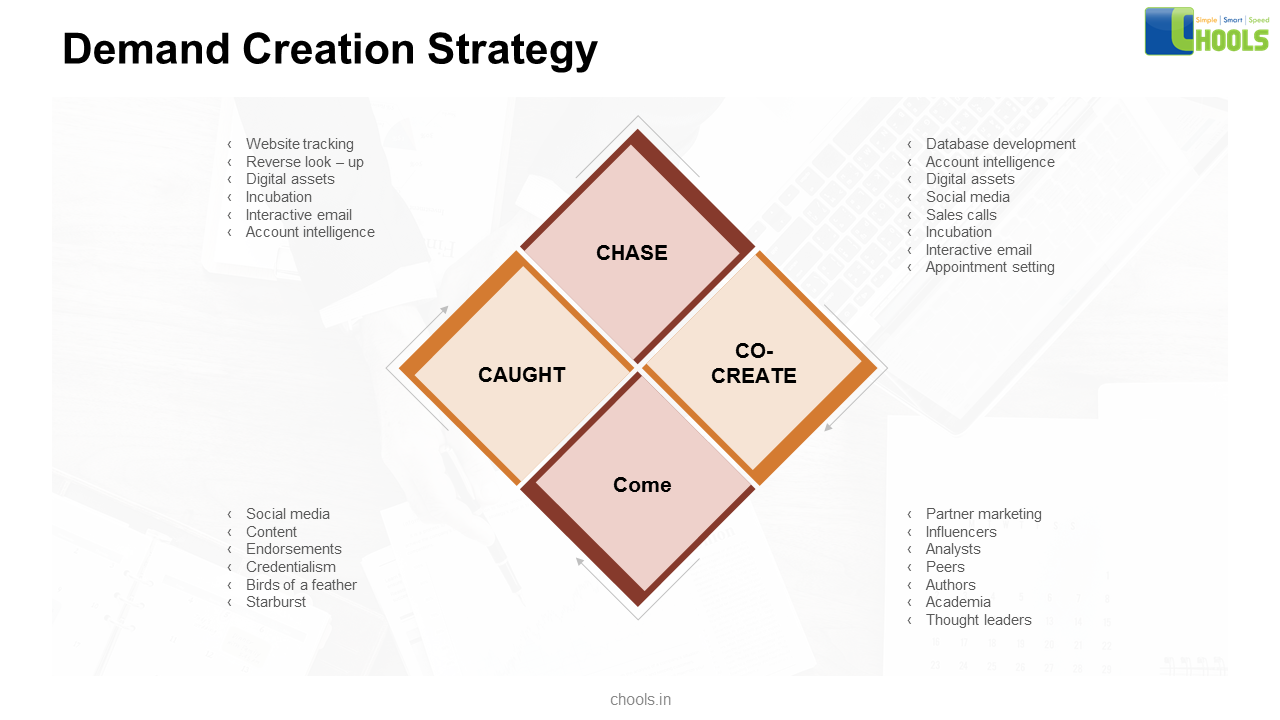

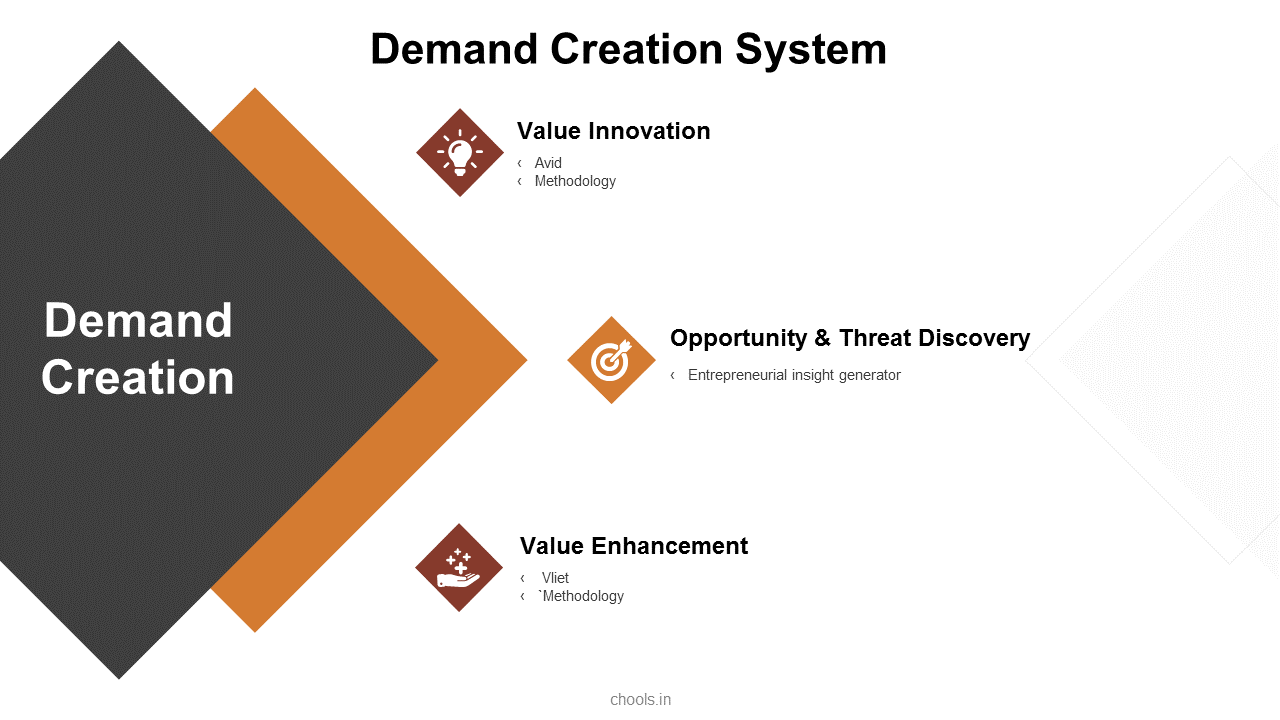

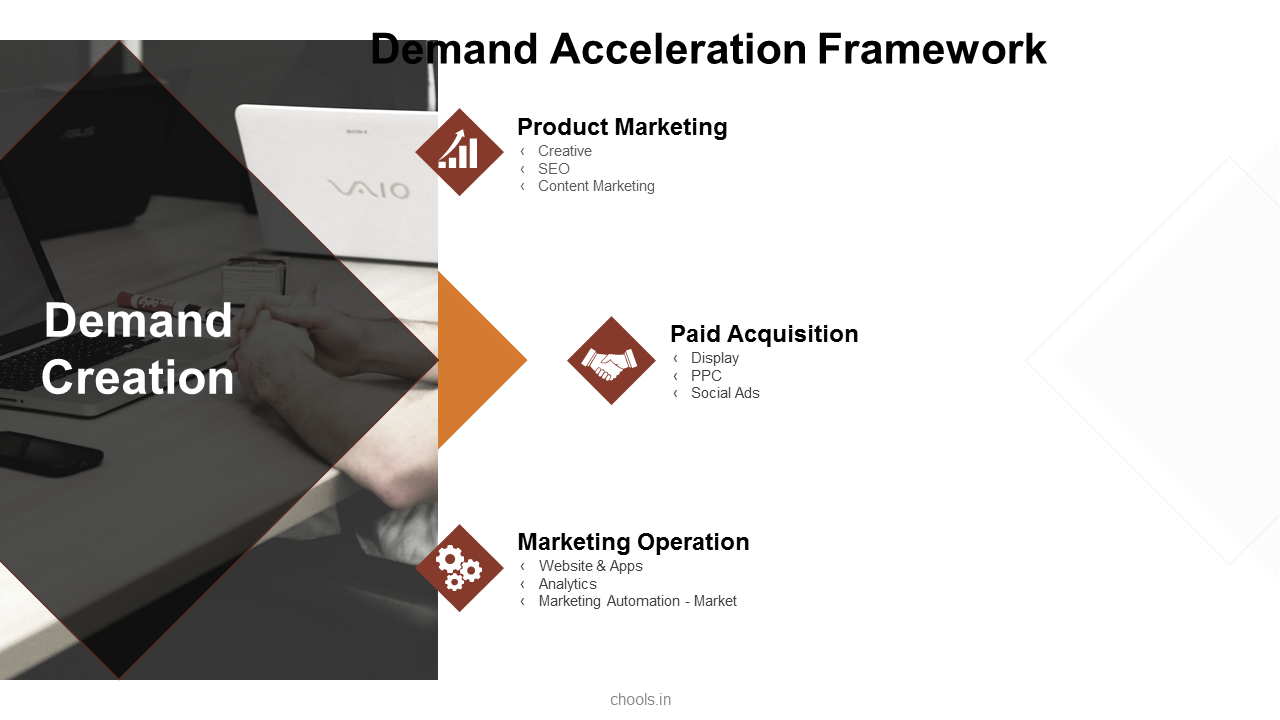

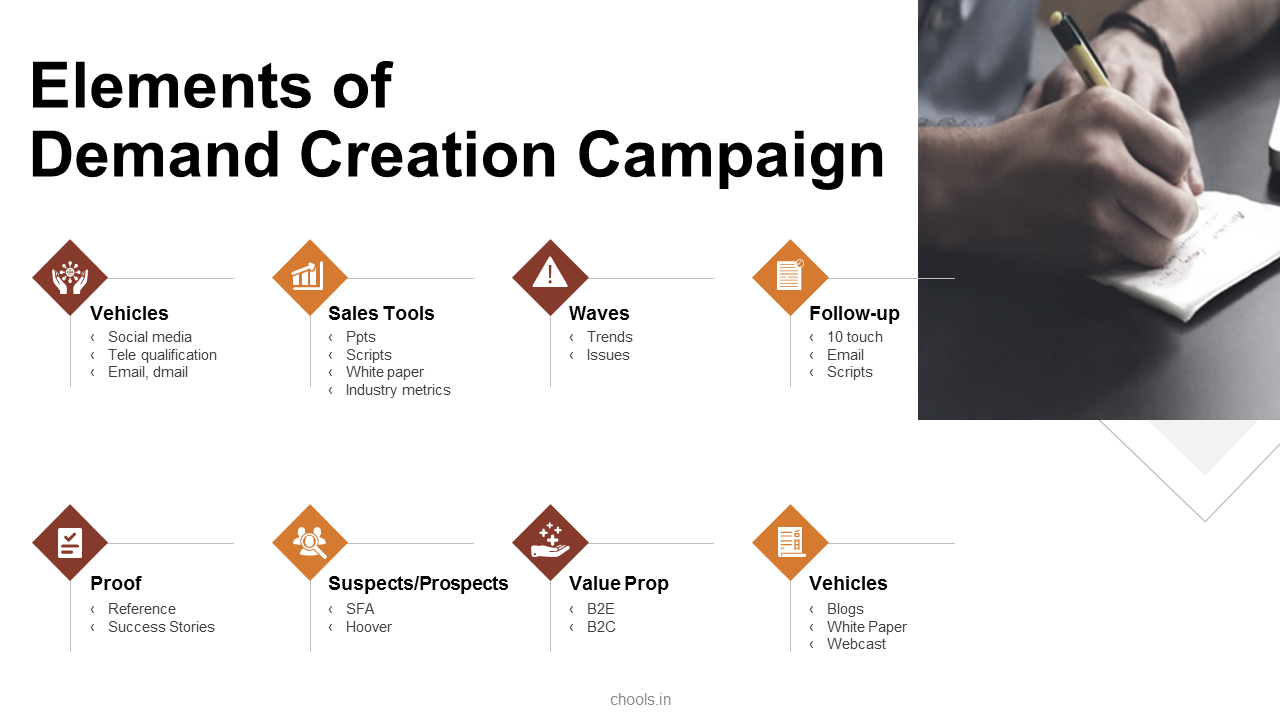

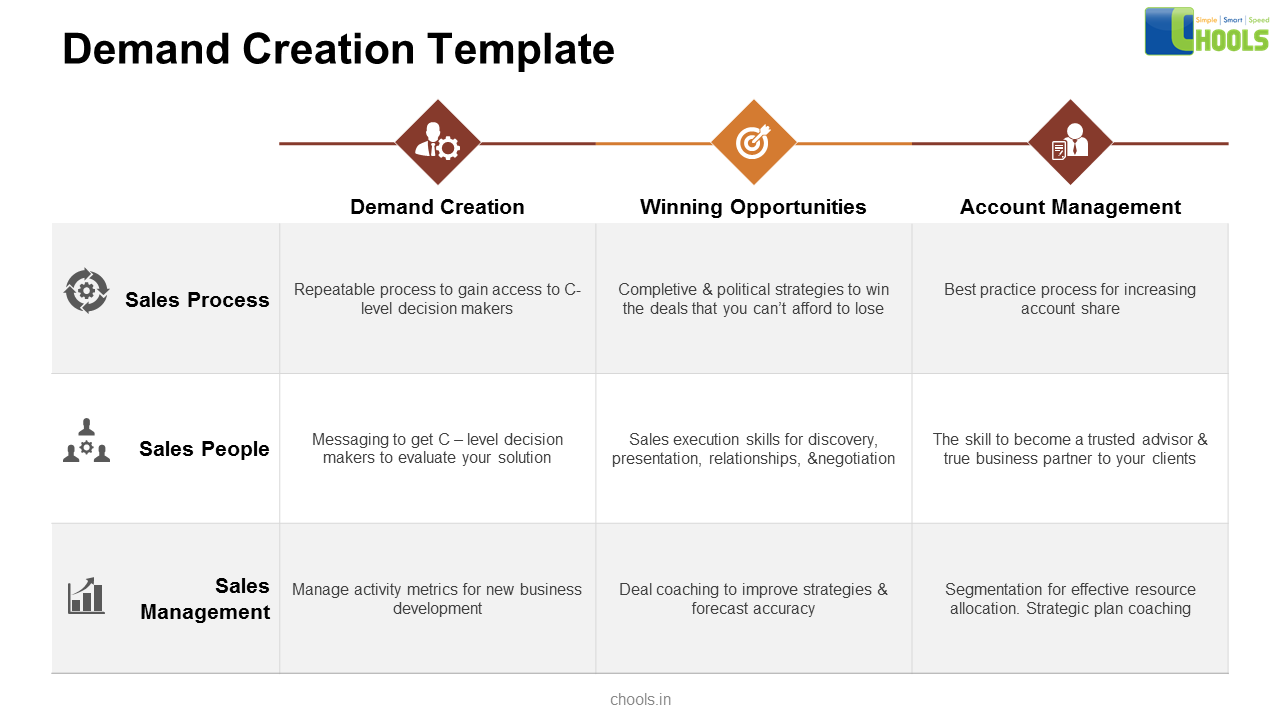

3. DEMAND CREATION

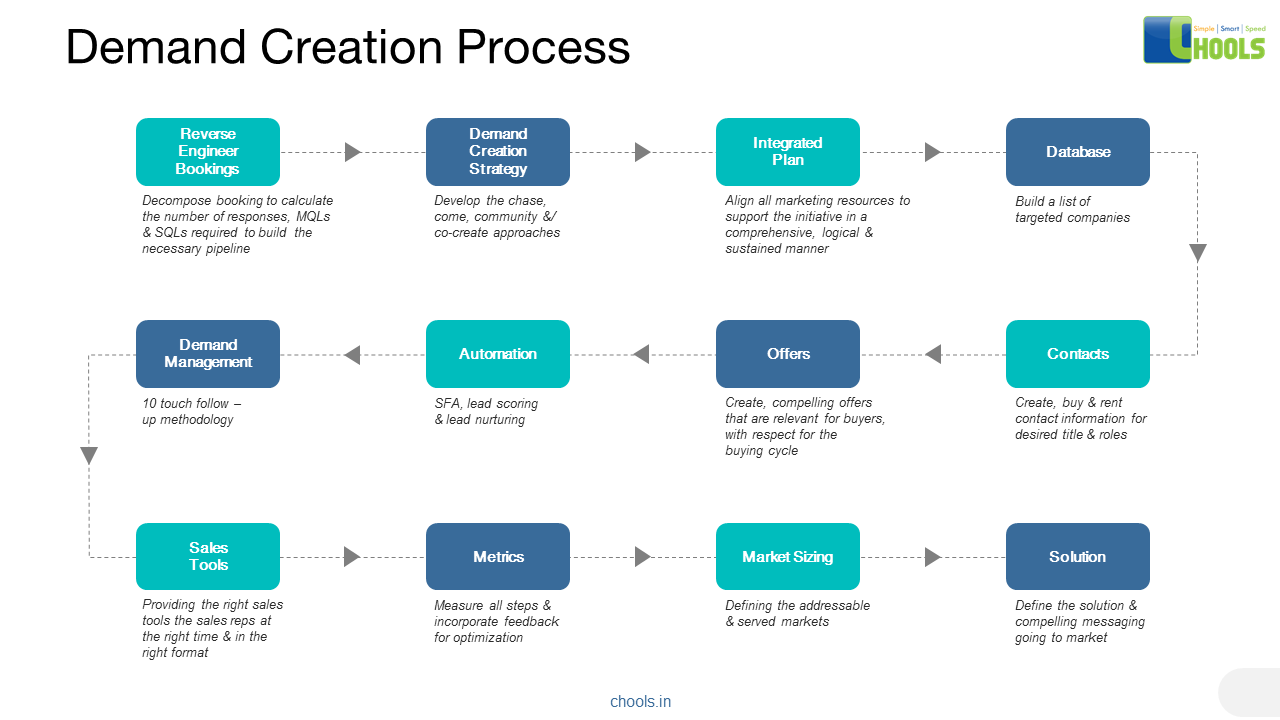

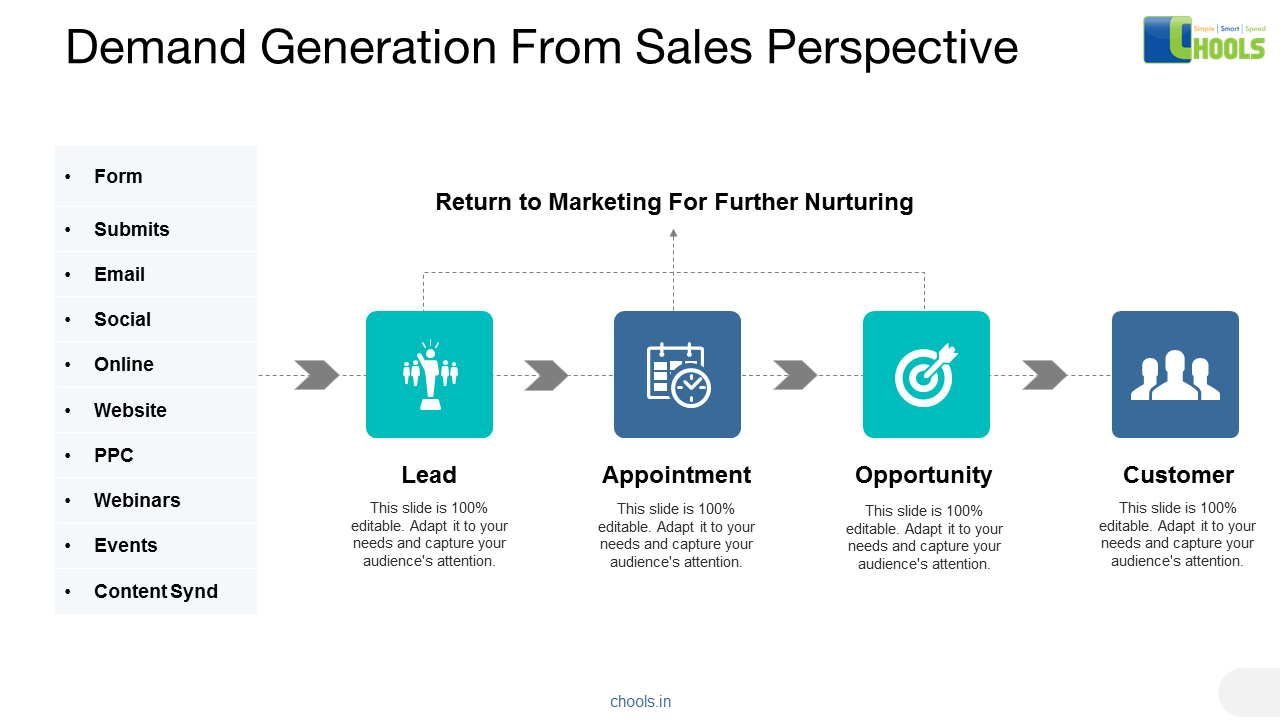

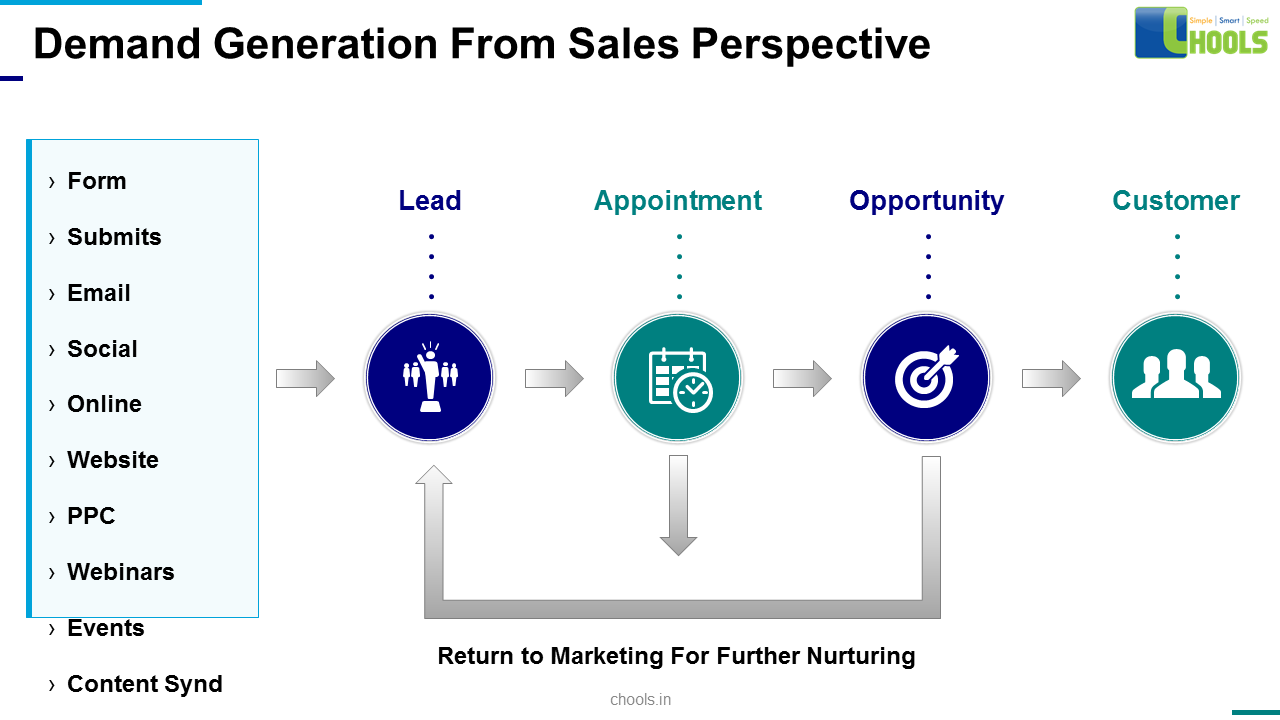

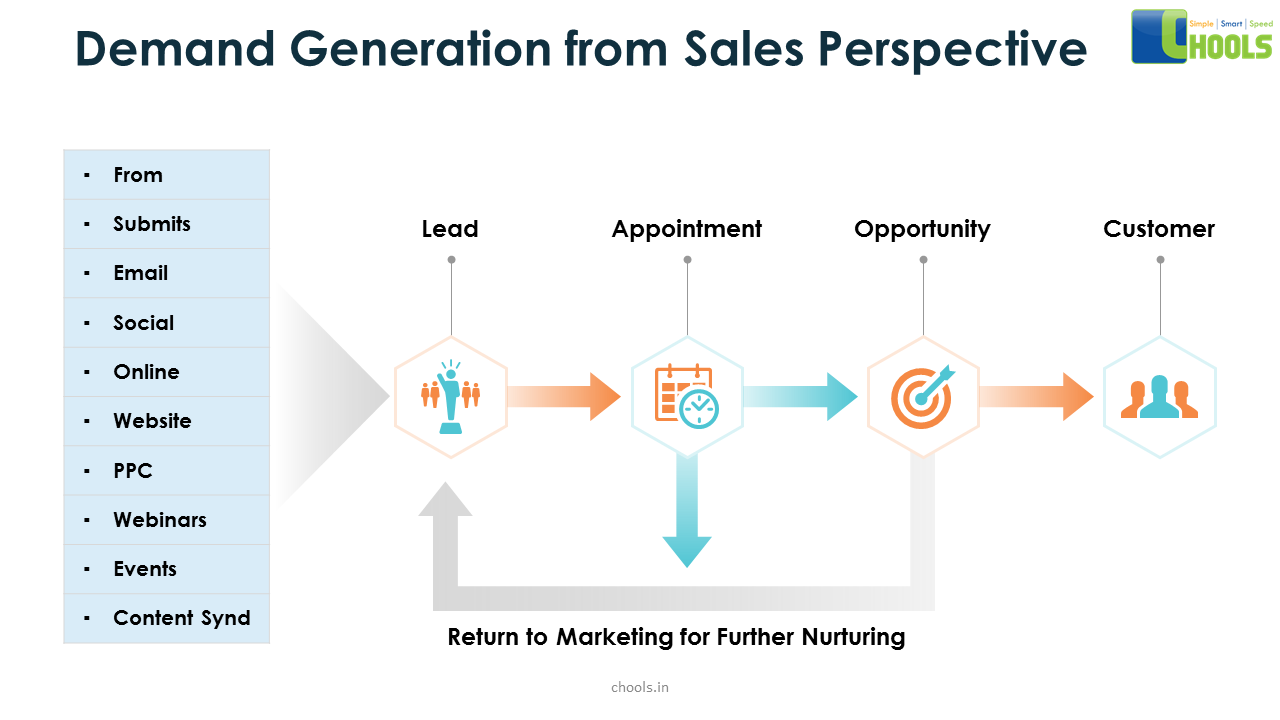

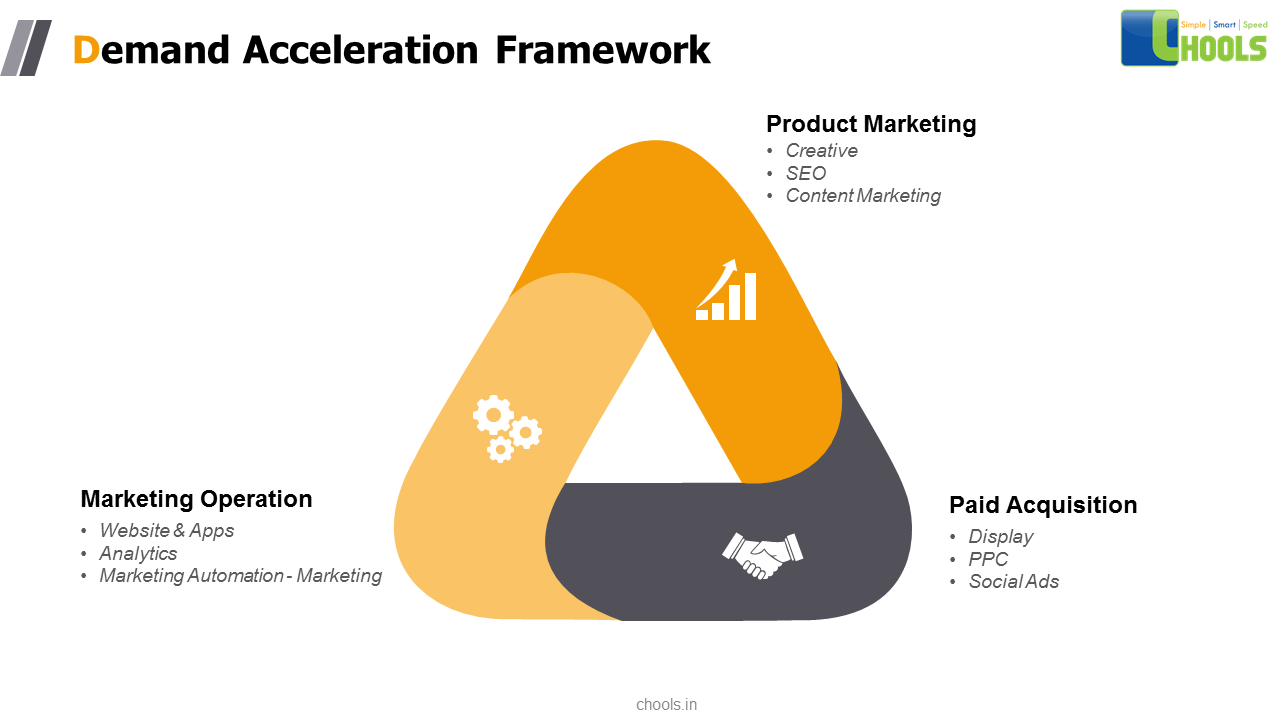

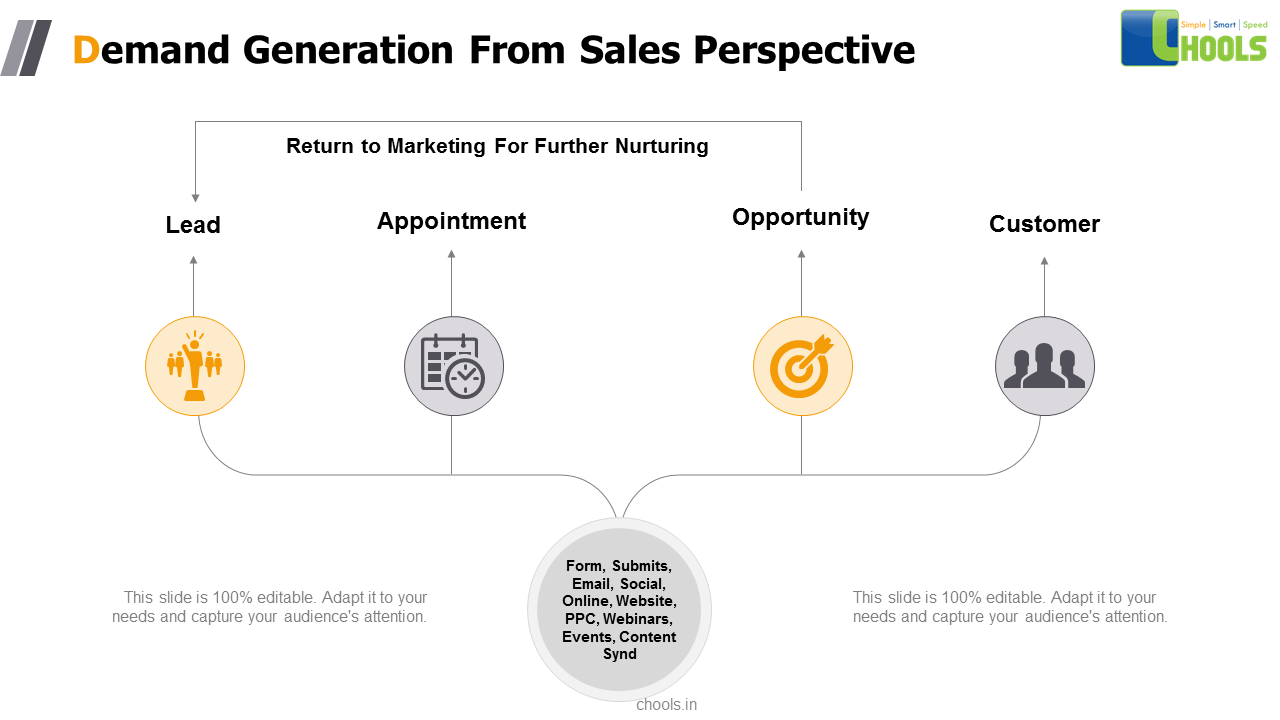

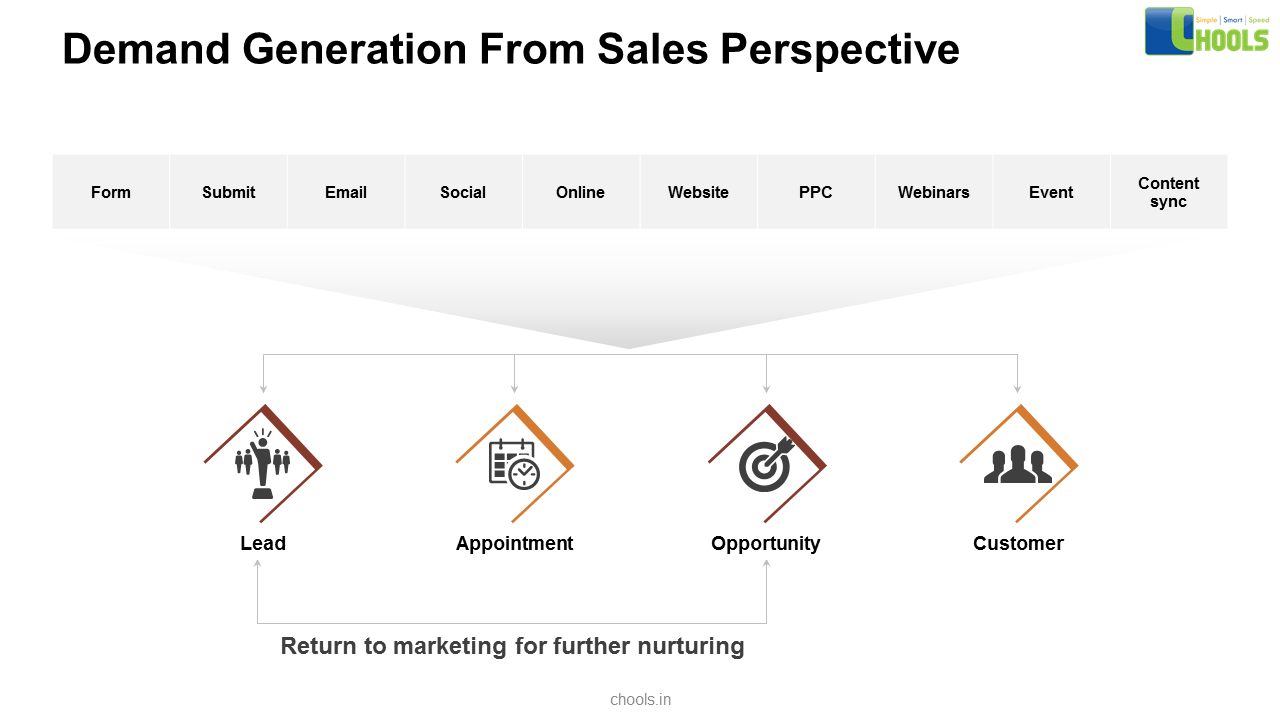

4. DEMAND GENERATION PROCESS

5. DEMAND GENERATION TECHNIQUES

6. DEMAND MANAGEMENT

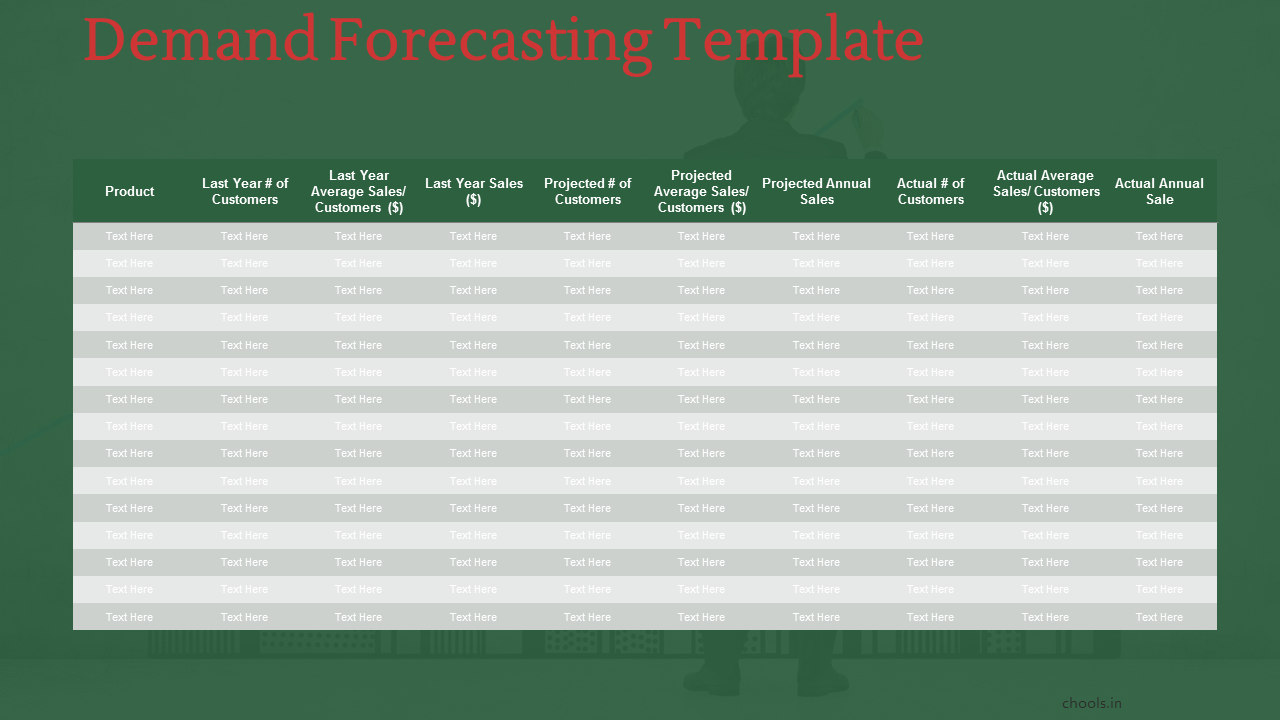

7. DEMAND PLANNING

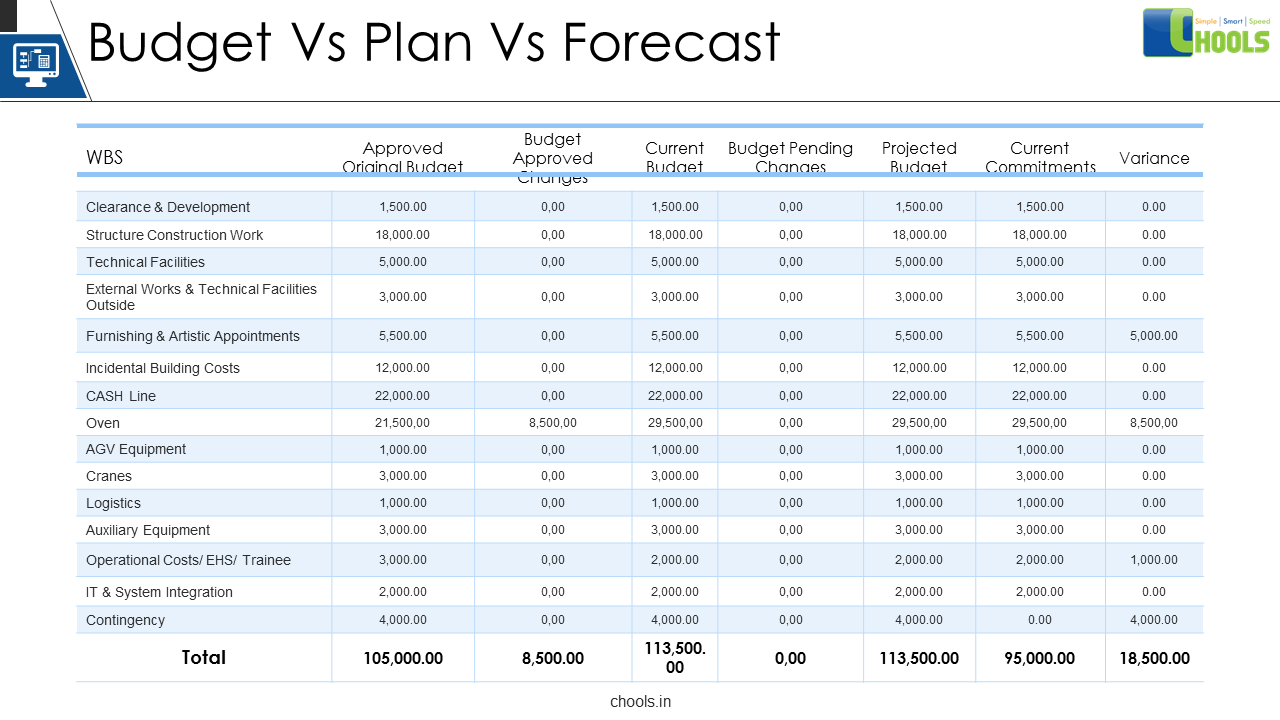

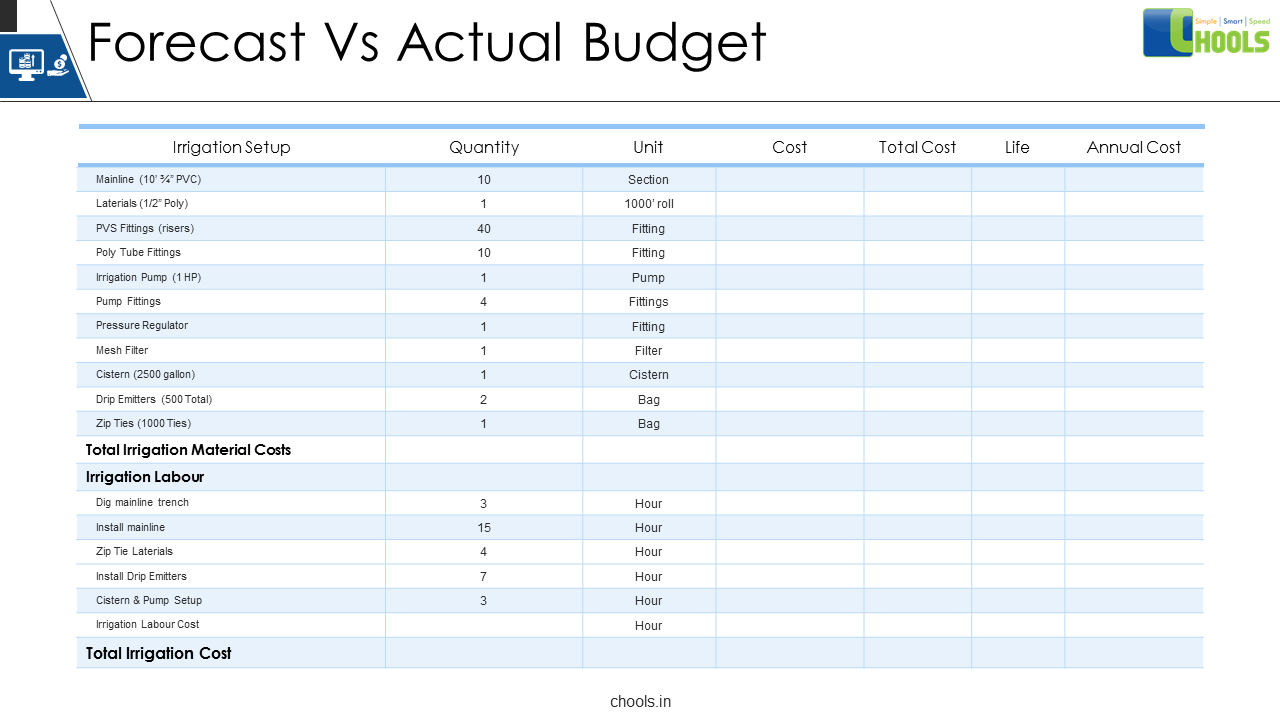

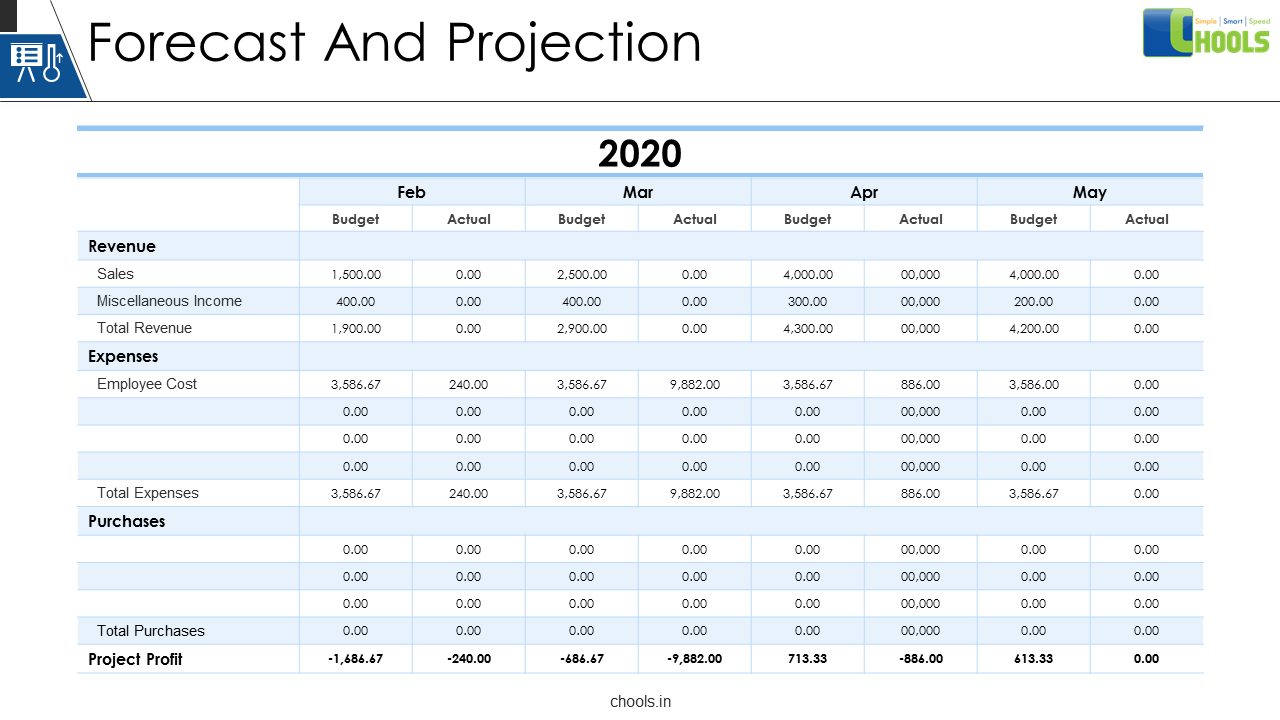

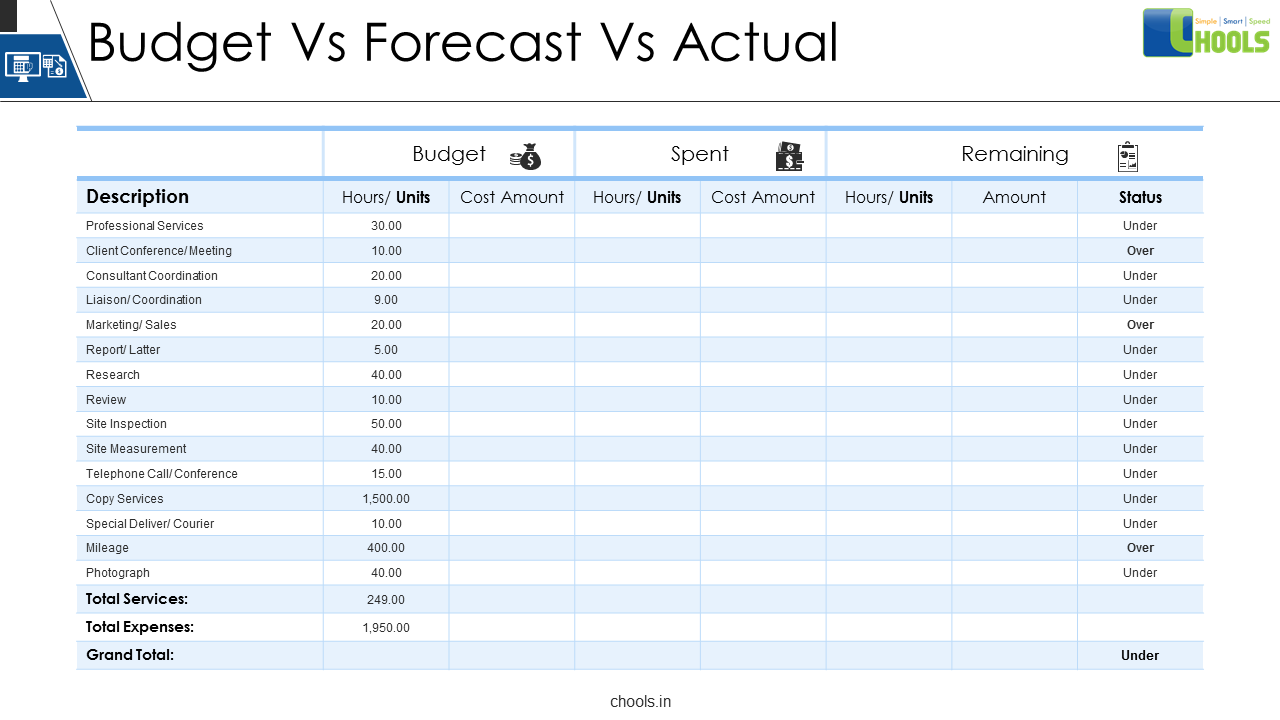

8. PLAN Vs. FORECAST

9. SALES & OPERATIONS PLANNING

10. SALES AND OPERATIONS PLANNING

11. SALES FORECASTING

12. CREATE A TEST DESIGN STRATEGY

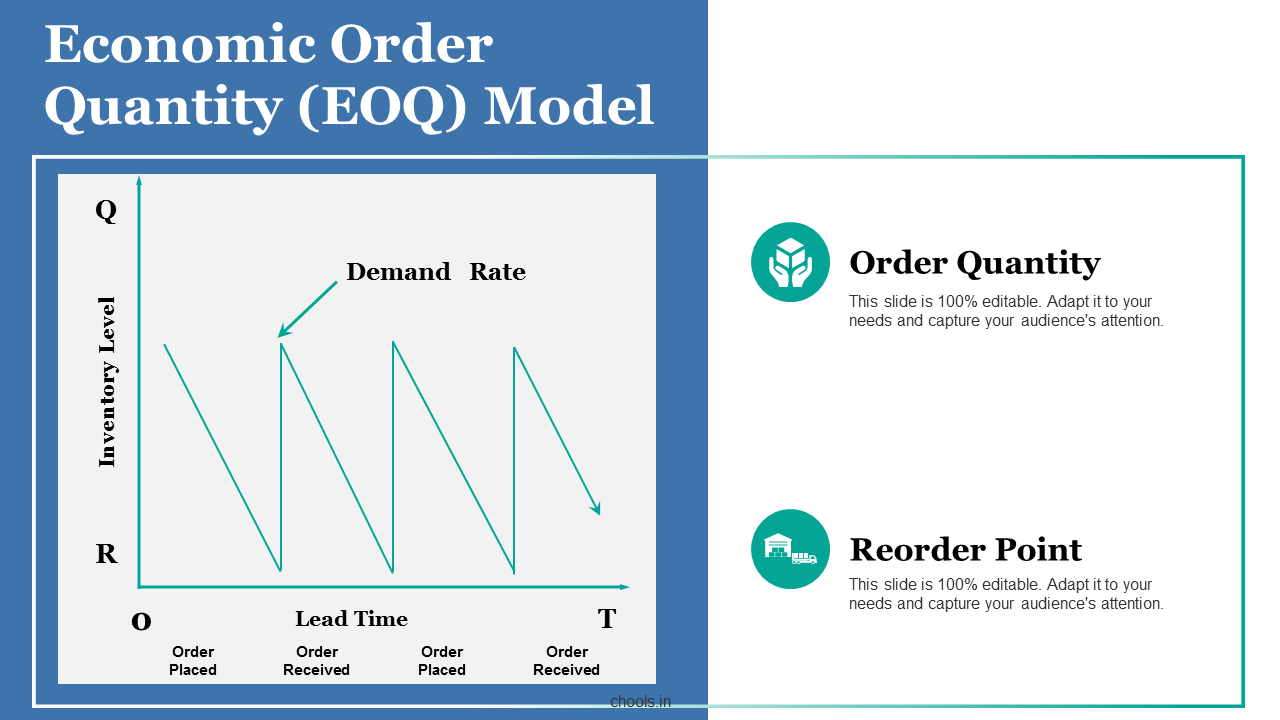

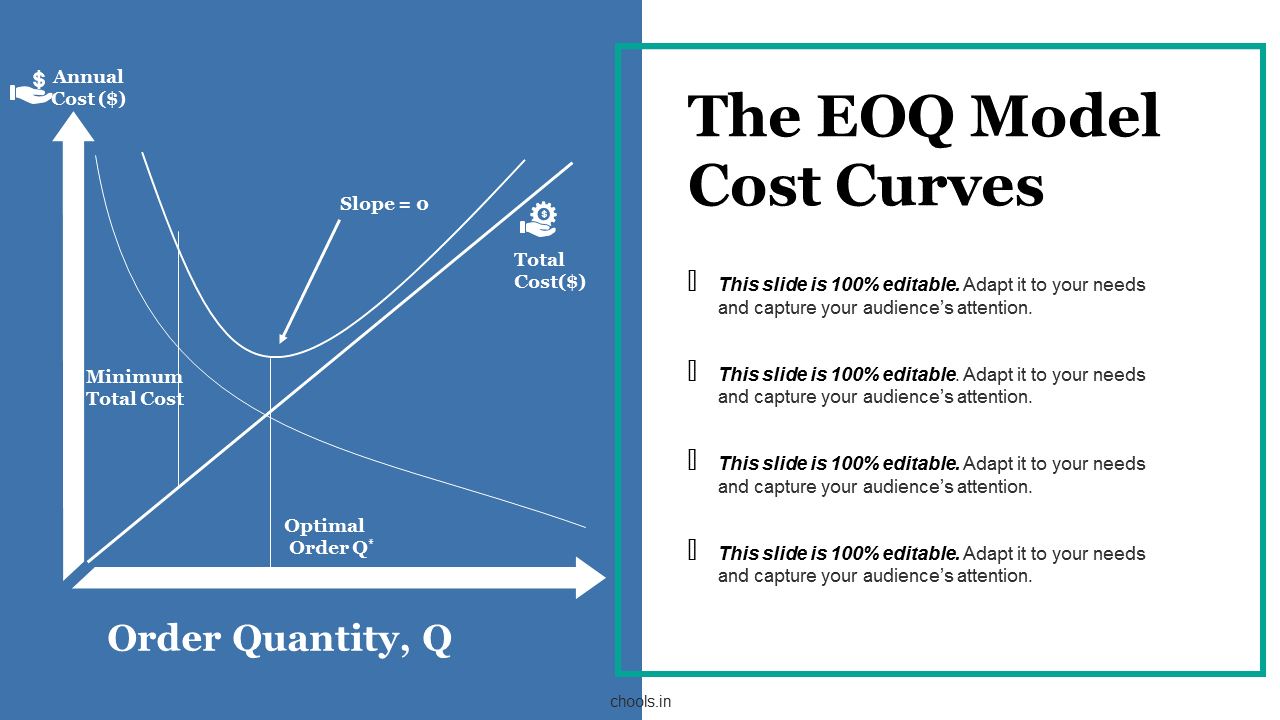

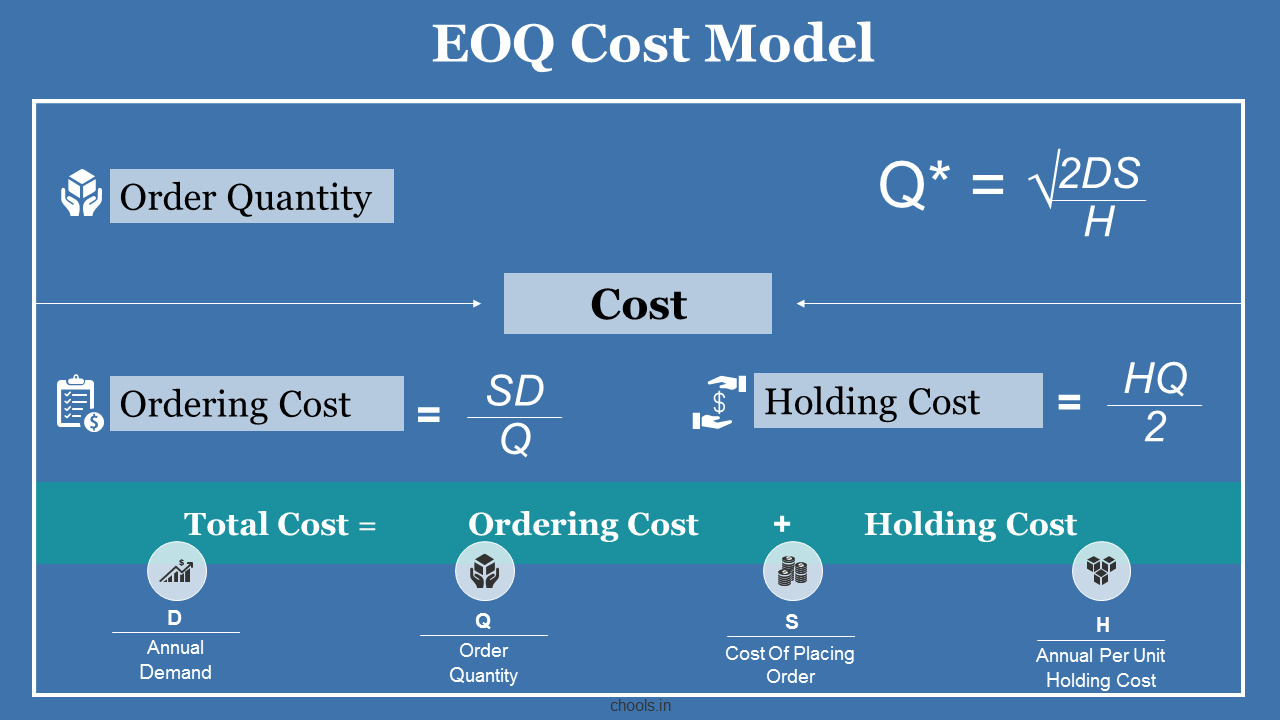

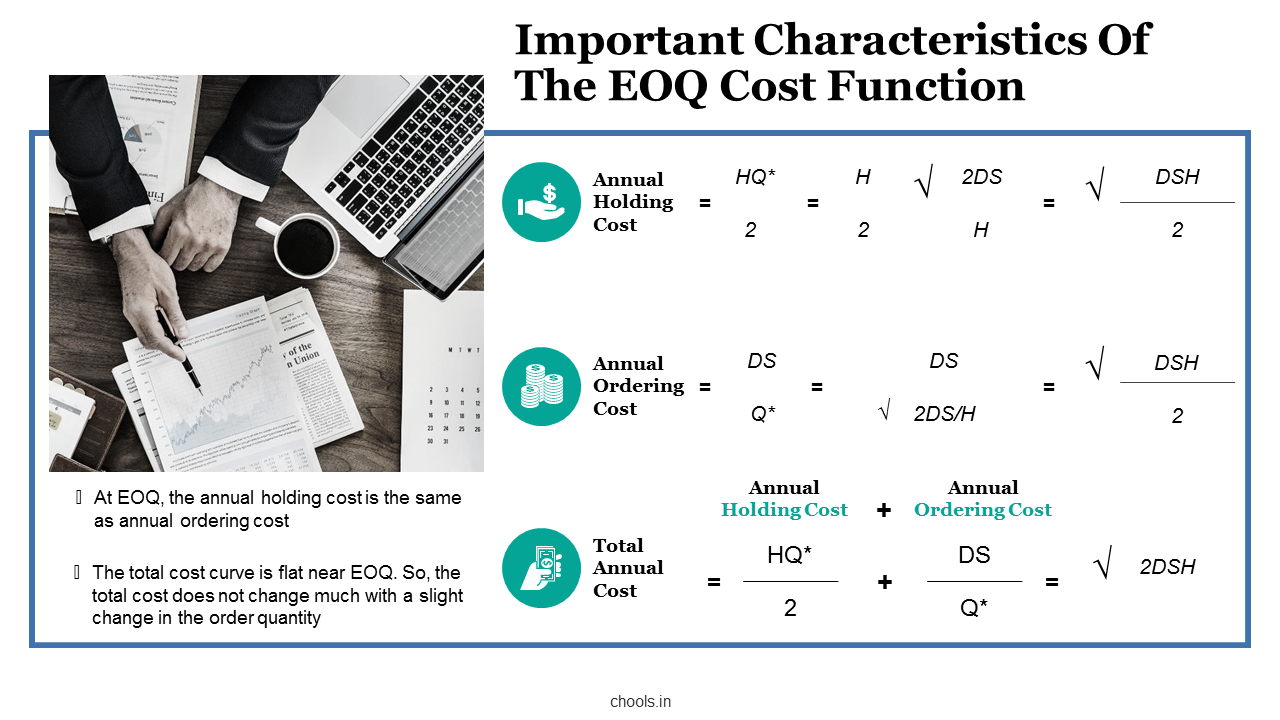

13. SUPPLY CHAIN ECONOMIC ORDER QUALITY MODEL

14. SUPPLY CHAIN MANAGEMENT DEMAND FORECASTING