-

₹25000Add to cart

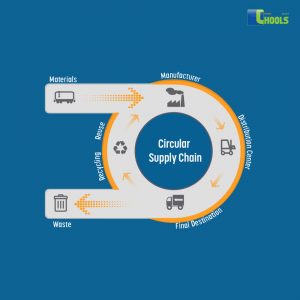

₹25000Add to cartThe global economy is a network of links and interlinks between products, services, information, logistics, finances, and the like. Isn’t it Fascinating to see how well these are linked together and function despite the complexities that the companies face? The mantra is – Supply Chain Management.

-

₹15000Add to cart

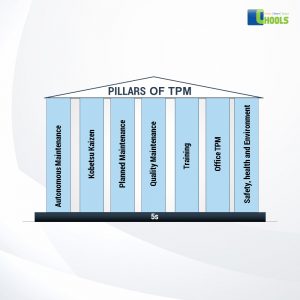

₹15000Add to cartAn organization that strives to achieve a production cycle without any breakdowns, and with smaller down time and lesser defects, will have to adopt this comprehensive approach called TPM (Total Productive Maintenance). TPM emphasizes and ensures the need for operators to maintain the equipment, which ultimately helps in operational efficiency of the equipment.

-

₹15000Add to cart

₹15000Add to cartThe success of a manufacturing process depends on how well the organization manages and utilizes the time, resources, and other facilities. Though it is nearly impossible to achieve 100% efficiency, it is possible to make the manufacturing time truly productive.

-

₹20000Add to cart

₹20000Add to cartCompetent business leaders enjoy strategizing. But fail to identify the required organization capabilities to effectively execute the designed strategies. Organization capability, in simple terms can be defined as skills, expertise and alignment of a company’s employees. From competencies at an individual level, to capabilities of the teams, their organization is critical, intangible assets that cannot be replaced.

-

₹20000Add to cart

₹20000Add to cartPlanned Maintenance. The third pillar of TPM. Its primary aim is to achieve zero breakdowns. Following a structured approach, it establishes a management system that emphasises on equipment reliability at an optimum cost. Including Planned Maintenance undoubtedly assures reduced breakdowns, reduced costs and improved efficiency.

-

₹20000Add to cart

₹20000Add to cartAutonomous improvement is one of the key distinguishing features of TPM. It is one of the most important activities when understood correctly. It needs to be seen as an improvement activity within TPM. Rather than production teams taking on maintenance activities.

- CONSULTING

- COURSES

- CORPORATE

- catechize

- CAREERS

- ADVISORY PANEL

- Logout

Hello!

We are happy to see you again!

Not a member yet? Register Now

Already a member? Login Now

Login to your account

Register to start learning

My Cart 0