Supply Chain Control Tower

Supply Chain Control Tower:

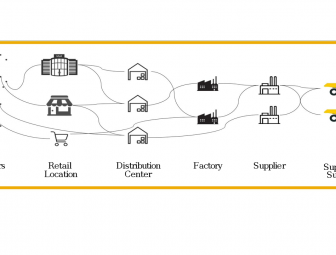

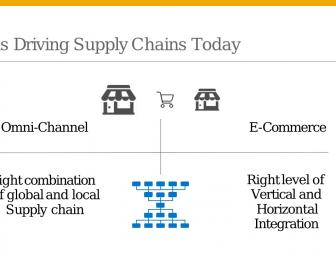

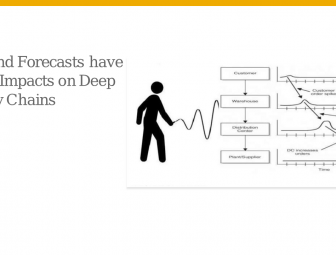

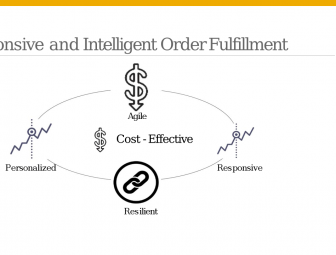

➤ The Complexity of the global supply chain is inevitable, however, developing collaboration, visibility, integration within the Value Chain – Vendor to business to Customer is the ultimate solution to mitigate this risk.

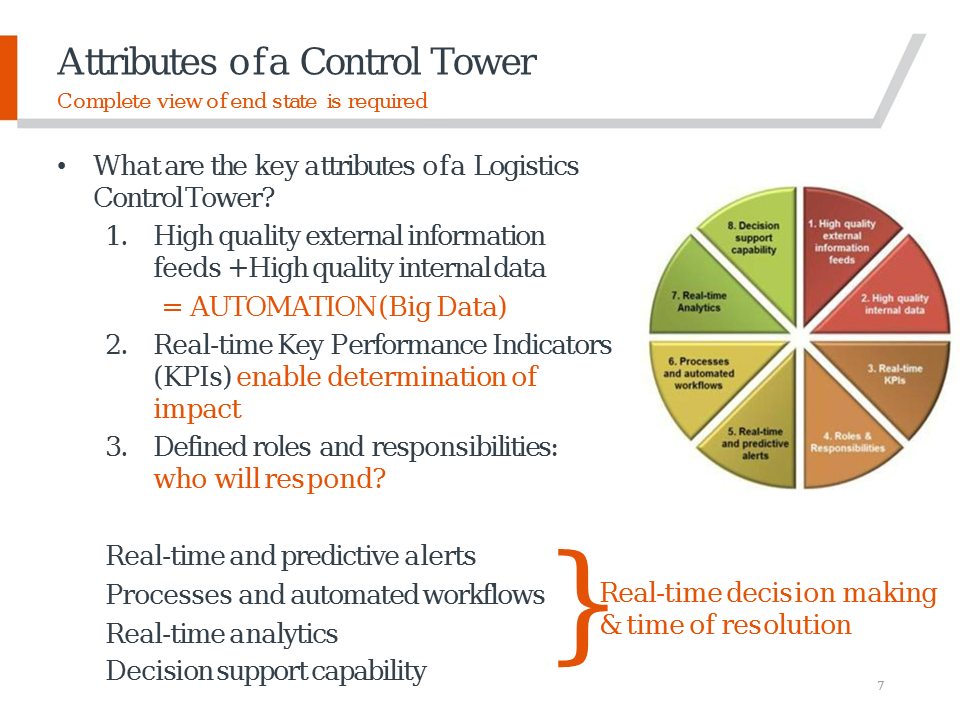

➤ Establishing your Supply chain Control Tower will enable your organization to collect, interpret and share real-time information; through a single platform; to detect and act to eliminate risks and seize the opportunity.

➤ Our competent consultants will guide you in implementing a Machine Learning solution effectively starting with an impact analysis and milestone execution.

➤ We at Chools guide organizations in executing solutions to sustain competitive advantage, drive world-class performance, customer satisfaction, reduce supply chain costs

Predicted Gains:

✔ 3-5% productivity savings out of Supply chain base spend.

✔ Optimizing operational performance

✔ Exceeding Customer expectations

✔ On-time deliveries at the lowest cost

✔ Eliminating Expediting costs and detention fines

✔ Reducing excess Inventory.

✔ Establish a platform that has the Capability of:

➤ Optimized Purchase order management

➤ Advanced shipment notification to optimize receiving, inspection and quality assurance operations

➤ Reveal unforeseen risks to be mitigated early

➤ Automated flow and integrated data system

➤ Vendor management system

Our Methodology:

➤ We Introduce collaboration, visibility , Integration within the Value Chain stakeholders through implementing the following strategies:

✔ Process continuous flow

✔ Just in time

✔ Dynamic sourcing

✔ Vendor management systems

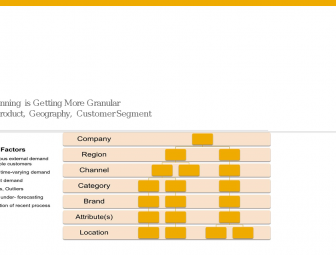

✔ Optimizing demand planning and forecast through S&OP implementation

✔ Optimization transportation payloads

Related Case Study

Case

➤ Chools was hired by 100 fortune Food and beverage company in North India to drive and develop its Productivity, Lean Six sigma, and supply chain excellence. SC control Tower was one of the strategies Chools adopted.

Act

➤ Chools Consultants conducted Supply chain assessments and impact analysis; leading the team in creating one single platform for the collaboration, integration and visibility creation of all the supply chain processes.

Results

➤ – $3MM annual productivity was achieved – 3% of supply chain base spend; delivered through reduction in transportation , excess inventory and over production , expediting fees and commodity purchasing costs

Supply Chain Control Tower - Case Study

Case

A food and beverage manufacturer with an annual production of 156MM Cases and 50MM NOPBT with 93% Market share; still suffered from Excess inventory in finished goods and Raw Material. Although this did not affect the sales revenue and meeting Market demand, yet, was a huge profitability opportunity and potential waste reduction.

Solution

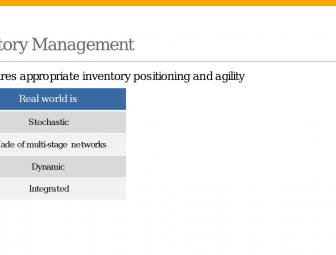

Our team of consultants after studying the process found that the Lack of integration of processes and coordination between all the stakeholders via a common ground and leveraging an automated tool is giving no visibility for the suppliers, Manufacturers, sales and distribution for the demand and the inventory.

Chools Consultants guided the manufacturer in executing the below solutions:

➤ Establish a control tower: One integrated single platform for Data sharing between all stakeholders.

➤ Optimize production line to have Process continuous flow

➤ Optimize the Raw Material warehouses Layout and space and setting the minimum and maximum amount to be ordered.

➤ Identify and qualify suppliers that could supply Just in time- Dynamic sourcing

➤ Establish a Vendor management systems

➤ Optimizing demand planning and forecast through S&OP implementation

RESULTS

The team increased their profitability by 10% through decreasing the waste and driving productivity from excess inventory holding cost. In addition, safety risks related to excess inventory were reduced.

Case

A Juice manufacturer with an annual production of 110MM Cases was not meeting the overall equipment effectiveness annual operating plan across three years on its major three high speed lines. The manufacturer hired Chools consulting to assist them in optimizing the processes to achieve their goals. Out team of consultants started with conducting a deep dive on the top losses on the production lines. It was found that the frequency of Changeovers is contributing to a 20% loss.

Solution

When analyzing the contributors to the increased frequency of changeovers it was found that the coordination between all the departments (procurement, suppliers, production, warehouses, sales and distribution) and the visibility to inventory and demand data via a common platform, and leveraging an automated tool for this is the reason.

Chools Consultants guided the manufacturer in executing the below solutions:

➤ Establish a control tower: One integrated single platform for Data sharing between all stakeholders.

➤ Optimize production line to have Process continuous flow

➤ Identify and qualify suppliers that could supply Just in time- Dynamic sourcing

➤ Establish a Vendor management systems

➤ Optimizing demand planning and forecast through S&OP implementation

RESULTS

The team met their OEE annual operation plan and increased it by 25 points. This reduced the $/case by 11%. This also reflected on the Moral of the crew with increasing the consistency and performance of the production lines.

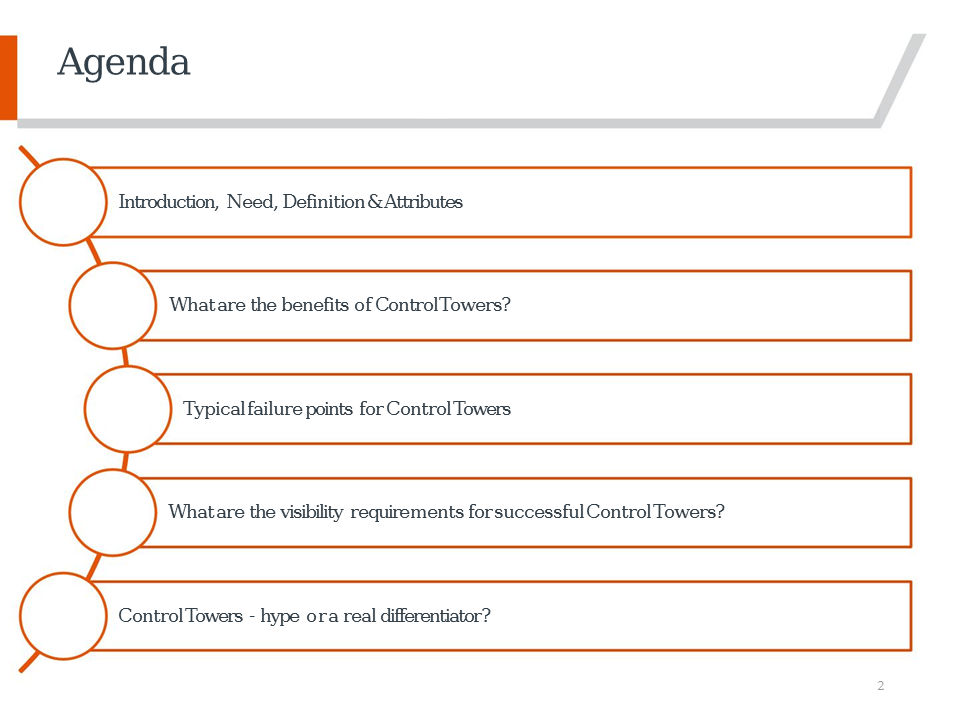

1. WHY DO YOU NEED A CONTROL TOWER

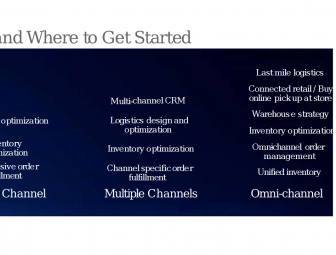

2. SUPPLY CHAIN OPTIMIZATION

3. SUPPLY CHAIN CONTROL TOWER PLANNING AND EXECUTION

4. SUPPLY CHAIN CONTROL TOWER DECISION MAKING