Supplier Relationship Management

The Complexity of global supply chain is inevitable, however, developing suppliers and optimizing their value will diminish the entailed risks, and increase business profitability and revenue.

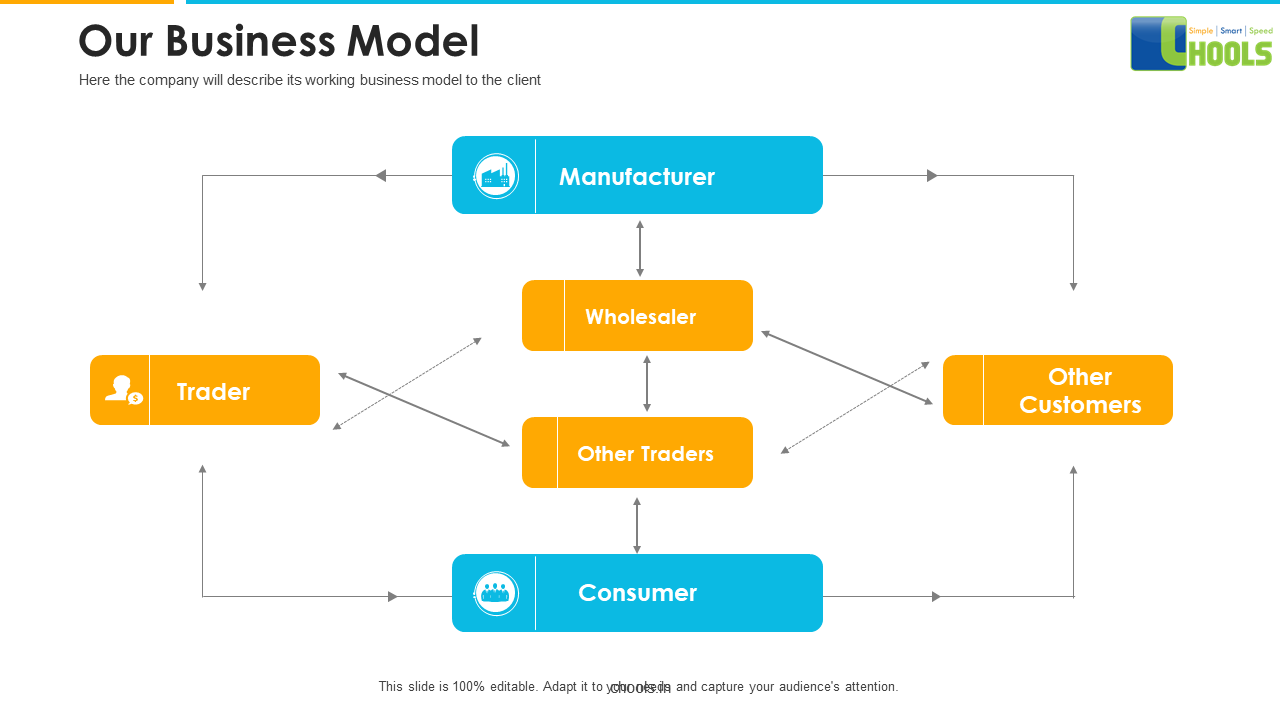

Whether your supplier is a manufacturer or a Vendor, a wholesaler or distributor, an importing source, a supplier either could become a reason for the growth of your business at scale or could form a bottleneck in your process.

We at Chools offer the SRM consulting service to lead your organization and provide you with the best practice tool to develop your supplier as your partner. The objective of SRM is to drive the highest value from your suppliers throughout the contract life cycle and to create a paradigm shift from a reactive SRM to a Strategic SRM.

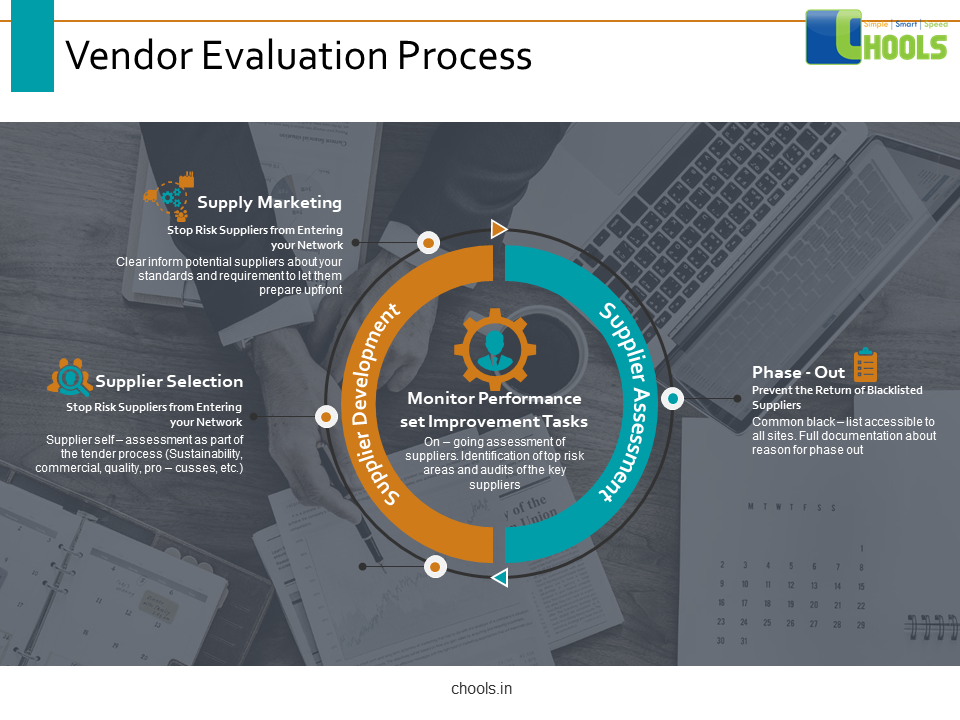

We will guide you in establishing the effective strategies to drive collaboration, visibility and integration within your supplier-partners Relationships through

➤ Developing Internal organization capabilities

➤ Developing the SRM strategies and processes

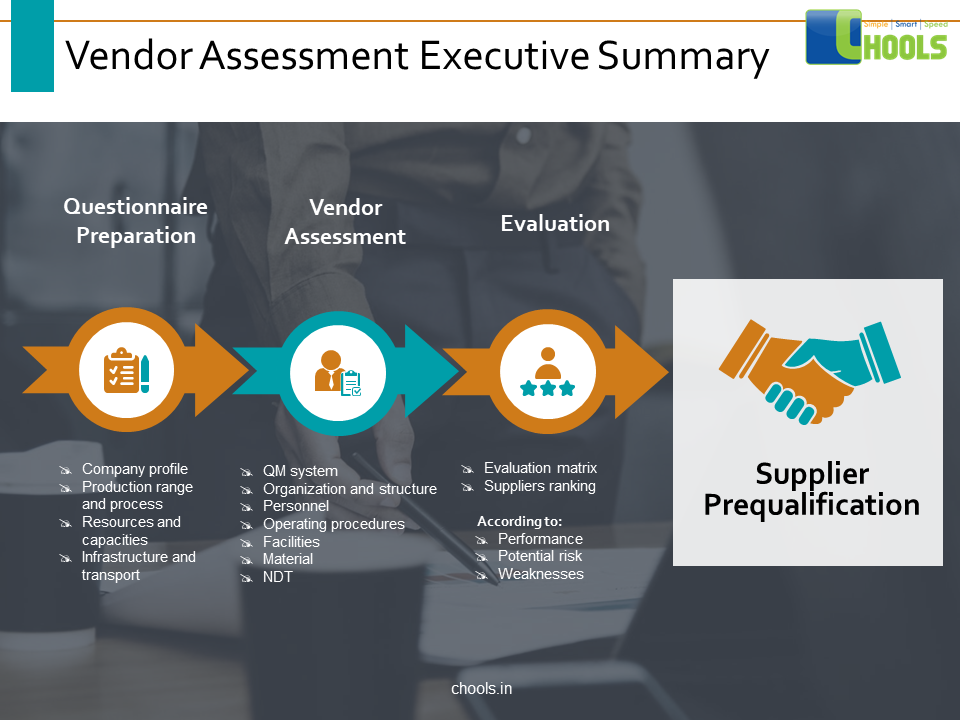

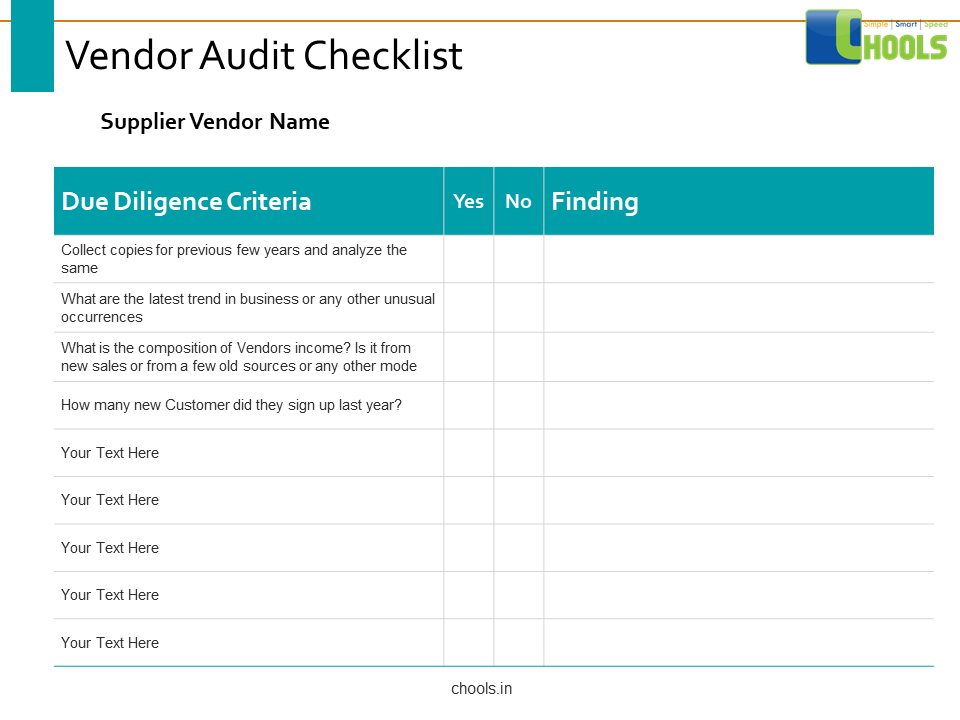

➤ Conducting Suppliers Assessments

➤ Develop or provide Advisory on establishing a SRM software -ERP

Predicted Gains:

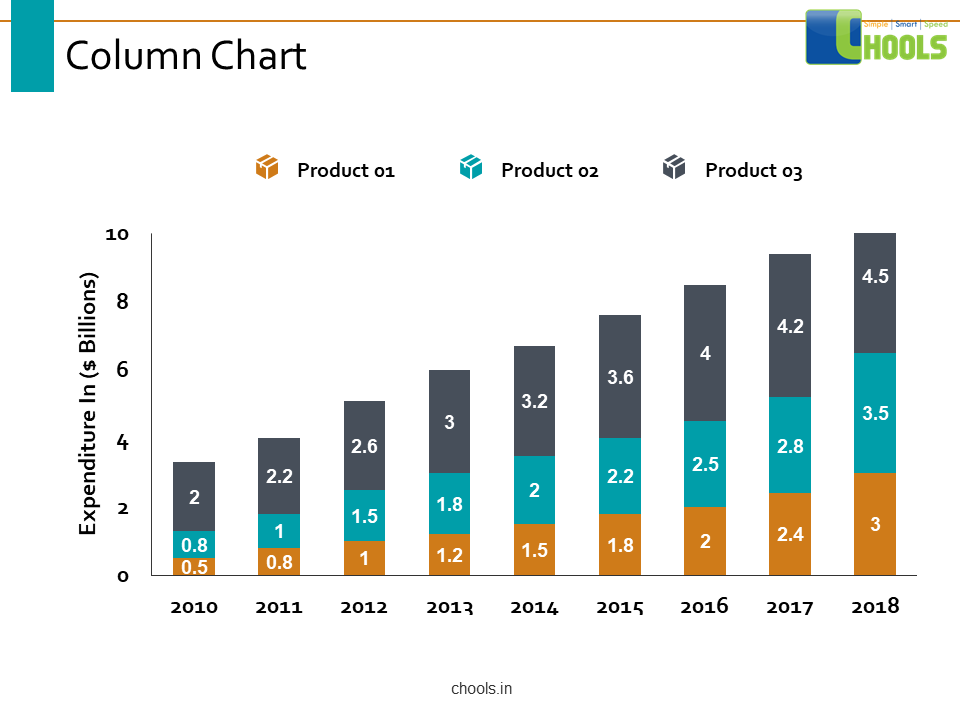

✔ 15-20% productivity savings out of Supply chain base spend.

✔ Optimizing operational performance /efficiencies by reducing Material Quality issues and late deliveries.

✔ Exceeding Customer expectations

✔ On time deliveries at discounted rates ( Economic Ordering Point)

✔ Eliminating Expediting costs and detention fines

✔ Reducing excess Inventory.

✔ Establish a Vendor management system

that has the Capability of:

✔ Optimized Purchase order management

✔ Advanced shipment notification to optimize receiving, inspection and quality assurance operations

✔ Reveal unforeseen risks to be mitigated early

✔ Automated flow and integrated data system

Our Methodology:

✔ Supplier Segmentation : Strategic vs. Tactical vs. Transactional

✔ Building Organization Supply Chain Strategy: e.g. global /parent company or subsidiary contracting.

✔ Creating a Vendor Management System to build the organization-supplier Collaboration-Visibility-Integration platform

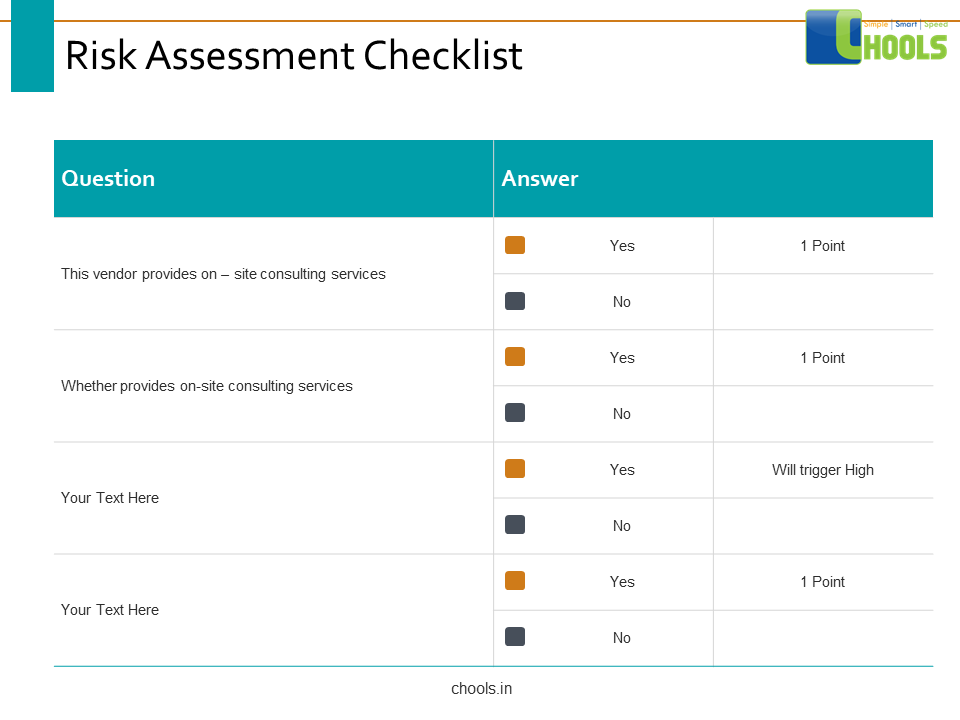

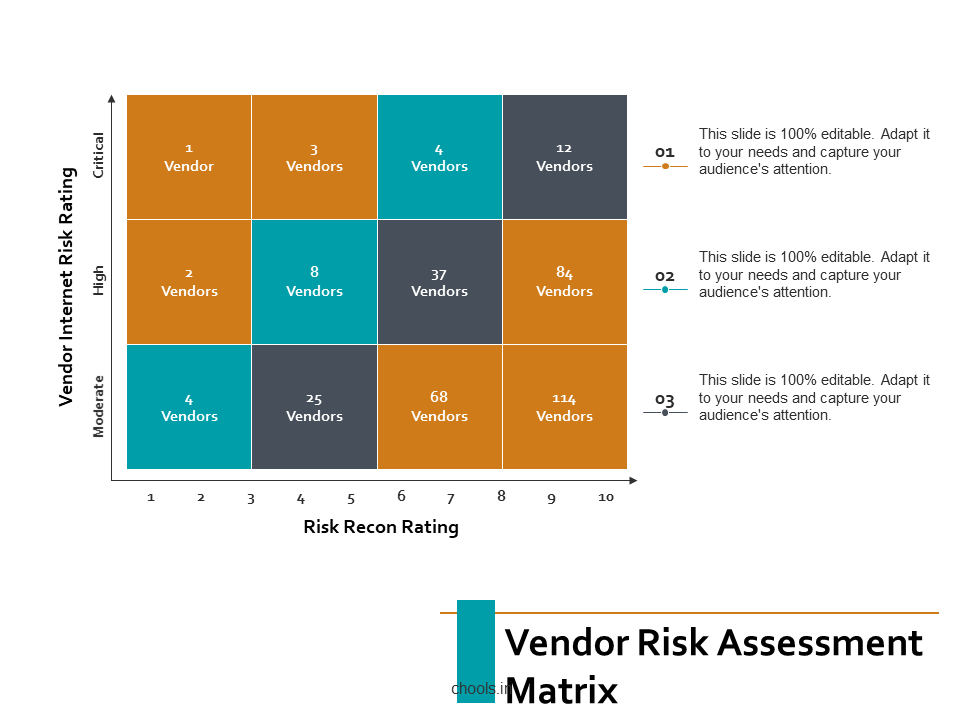

✔ Supplier Risk Assessment

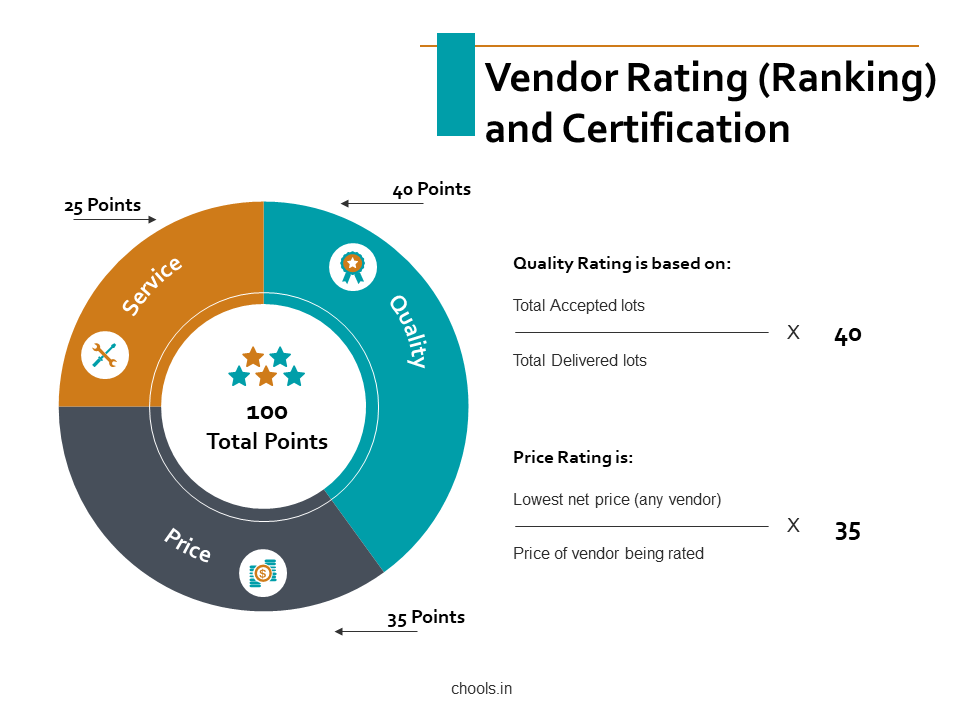

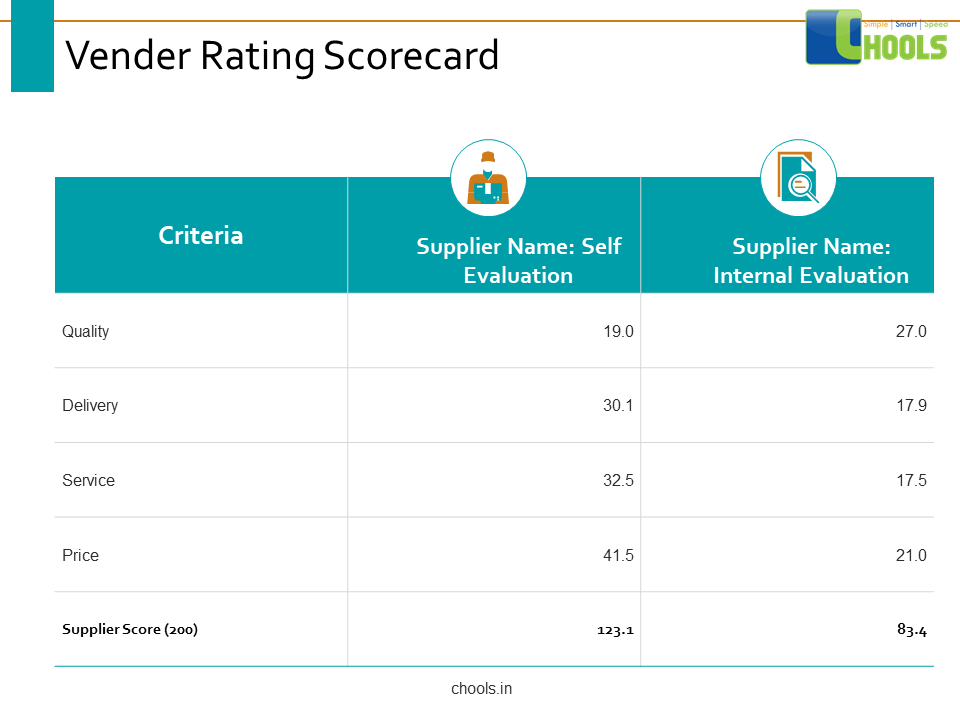

✔ Establishing a Supplier performance and Governance Management system Monitoring KPI’s: On time deliveries, Quality, etc. .

Related Case Study

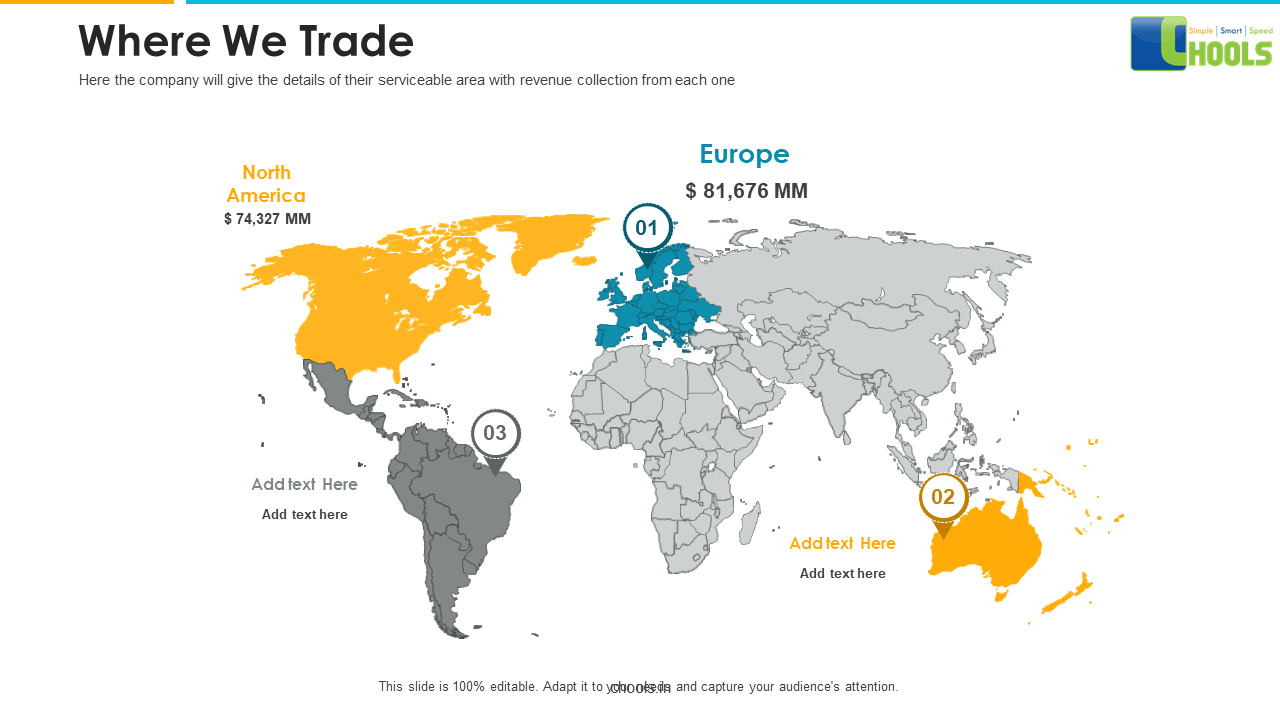

Case : Chools was hired by 100 fortune Food and beverage company in North India to drive and develop its Productivity, Lean Six sigma, and supply chain excellence. SRM was one of the strategies Chools adopted.

Act : Chools Consultants led the team in developing SRM ; through conducting Supplier Risk assessments, Developing internal capabilities , Supply chain Strategy , VMS, supplier performance management system

Results : – $3MM annual productivity was achieved – 3% of supply chain base spend; delivered through reduction in: transportation expediting fees and excess inventory costs, on time deliveries and reduced material quality issues improving operational efficiencies.

Supplier Relationship Management - Case Study

The Challenge

A well-known organization with a prominent reputation had no consistent method with respect to managing supplier relationships. The suppliers’ performance was inconsistent, and they varied across multiple sites. They had a limited understanding of the concerned processes. Their influence was weak over their supplier strategy. The inconsistent communication resulted in hindrance for other procedural operations. The unclear responsibilities caused a lot of confusion internally and there was an absence of emphatic accountability. There was no fixed parameter to measure the incremental value emerging out of the established relationship.

The Solution

Chools highlighted the critical role of business leadership when it came to initiating the Supplier Relationship Management initiative. We rolled out a systematic schedule for team workshops and category manager mentoring. The scope of the projects was displayed and the teams were formed. Relationship strategies were devised and approved. The strategies aimed at engaging the suppliers.

The Results

As a result of the sincere implementation of the strategies developed, several hundred opportunities were identified. The company achieved its strategic alignment. Their operational performance saw a significant improvement. The working relationships got strengthened. There was a fine balance established concerning power and dependency. Within a few months, 30% of the opportunities identified were set out for implementation.

The Challenge

A global industry involved in the world-wide business of food and beverage commodities desired to reshape their relationship with the suppliers to result in mutually benefitting win-win scenario. They aimed to reach a higher level of profitability along with the other party. In addition to that, the client was interested in gaining critical insights into the value creation framework, which would benefit the suppliers and customers. They were keen on identifying potential areas of risk in the value chain. With that, they looked forward to understanding the latest trends and recent developments in the markets.

The Solution

The Supplier Relationship Management Analysts at Chools initiated an in-depth multi-step research methodology. They included qualitative as well as quantitative assessments for catering to the client’s specific category requirements. We identified the scope and economic flows in the relationship. We also identified the value that was being created. We presented the observations to our clients.

With our study, the client gained insights regarding control points in the value chain. The portfolio analysis highlighted in this study displayed a clear representation of the qualified merits with possible prioritization of the opportunities.

The Results

The engagement resulted from the implemented Supplier Relationship Management Strategy aided the client in increasing the savings and boosting the revenue-generating opportunities. We offered the client valuable suggestions on the associated road maps and the ways of implementing the steps. We provided the insights to bring necessary organizational changes required to seize sizable opportunities.

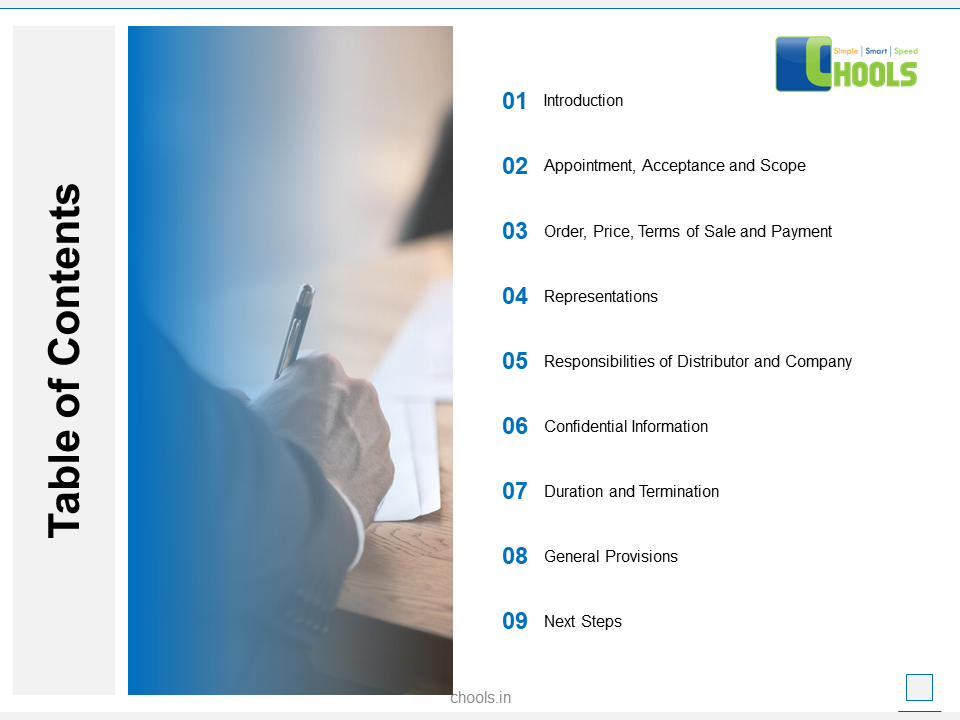

1. SUPPLIER EVALUATION

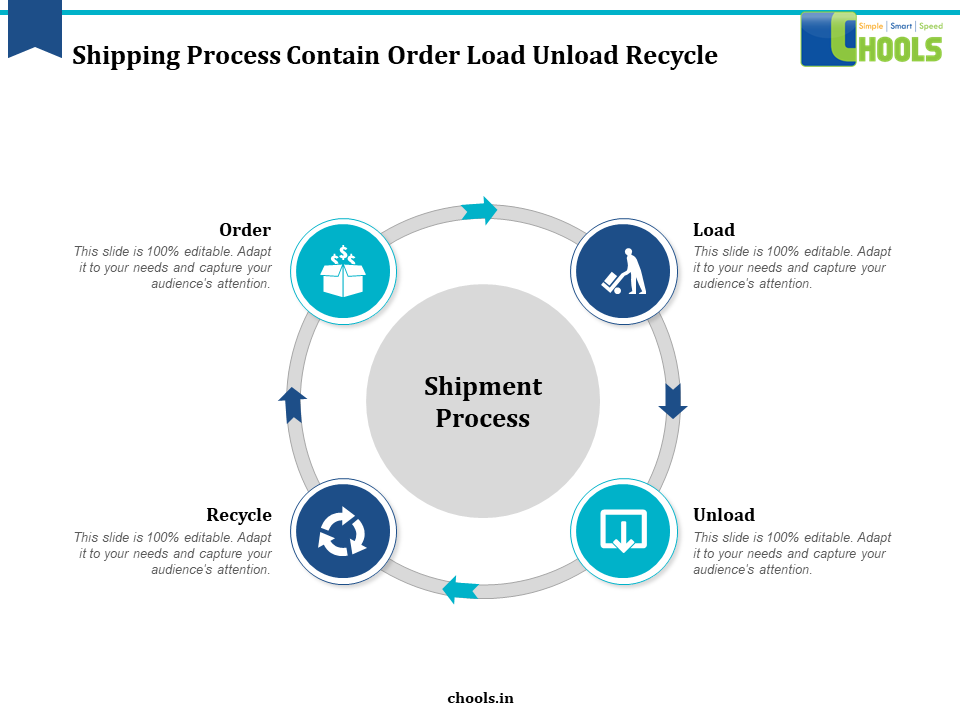

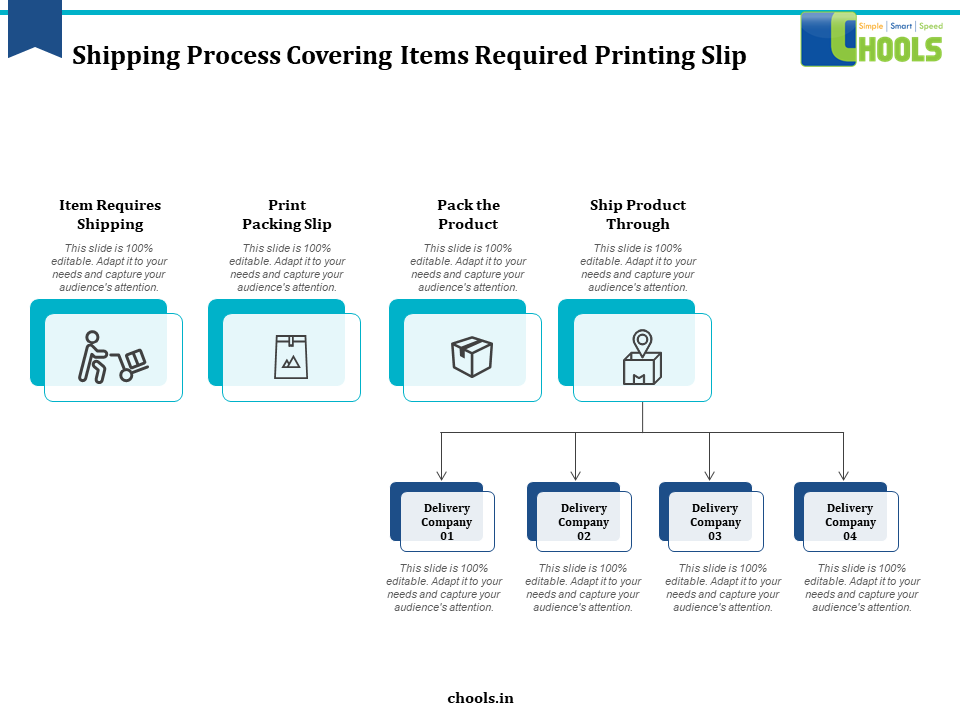

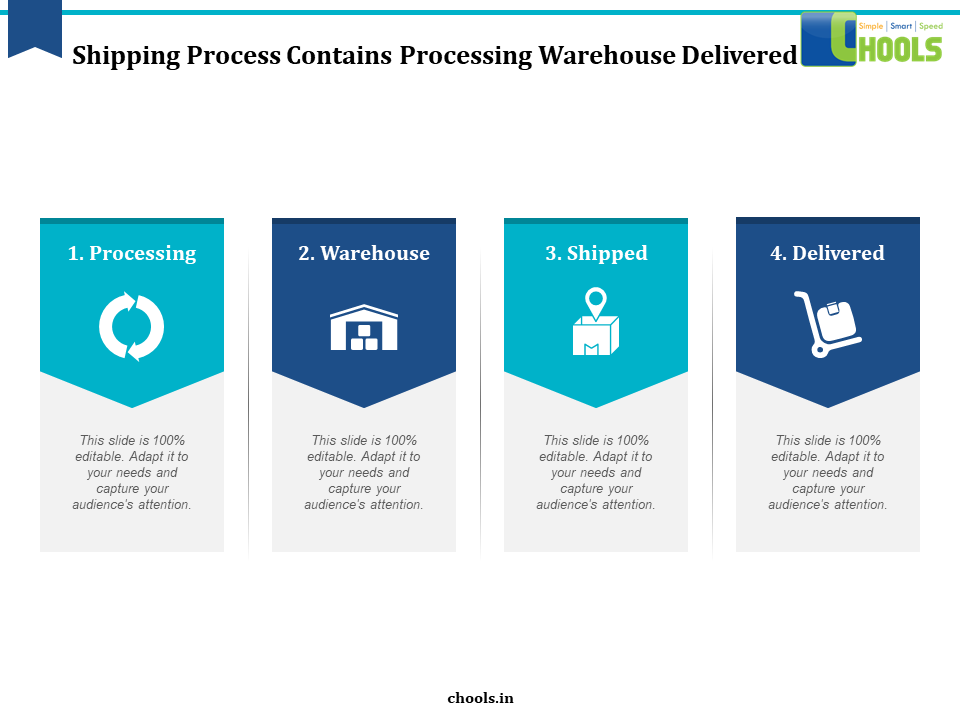

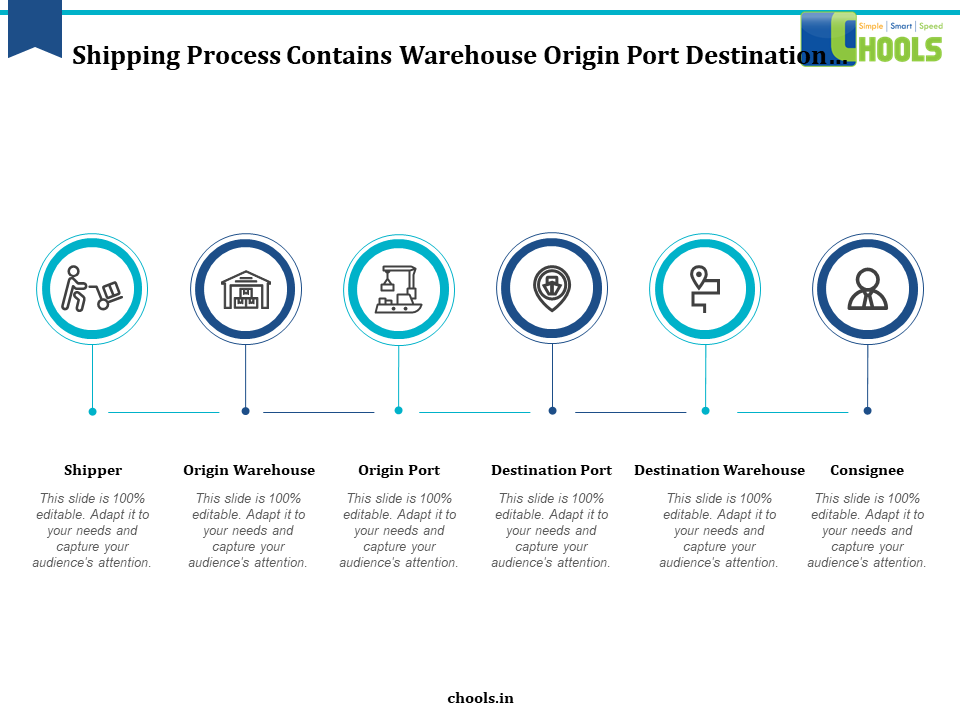

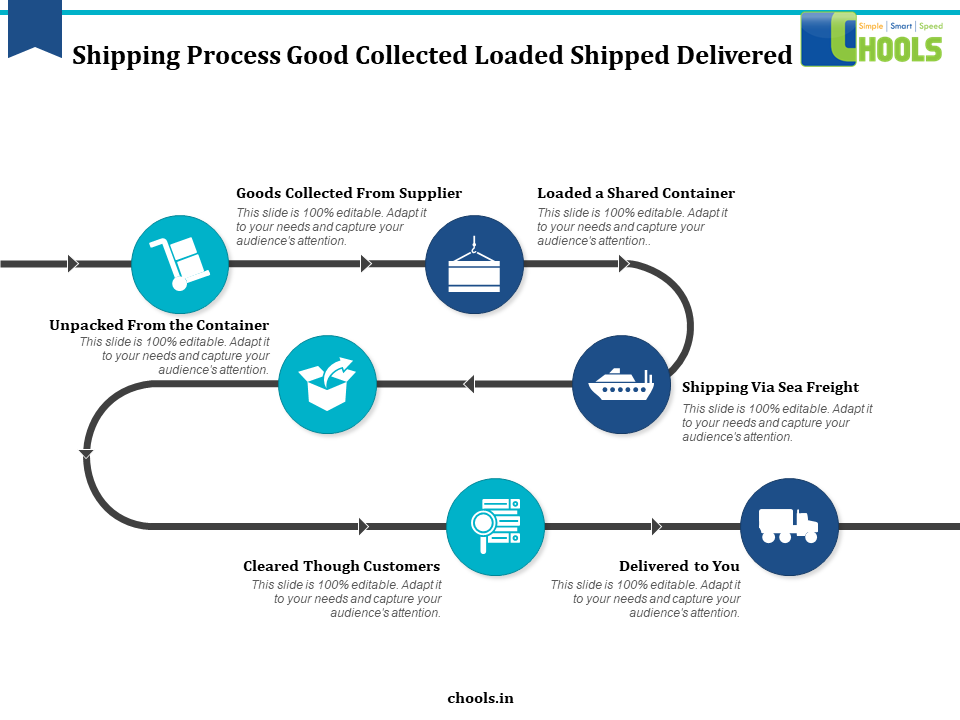

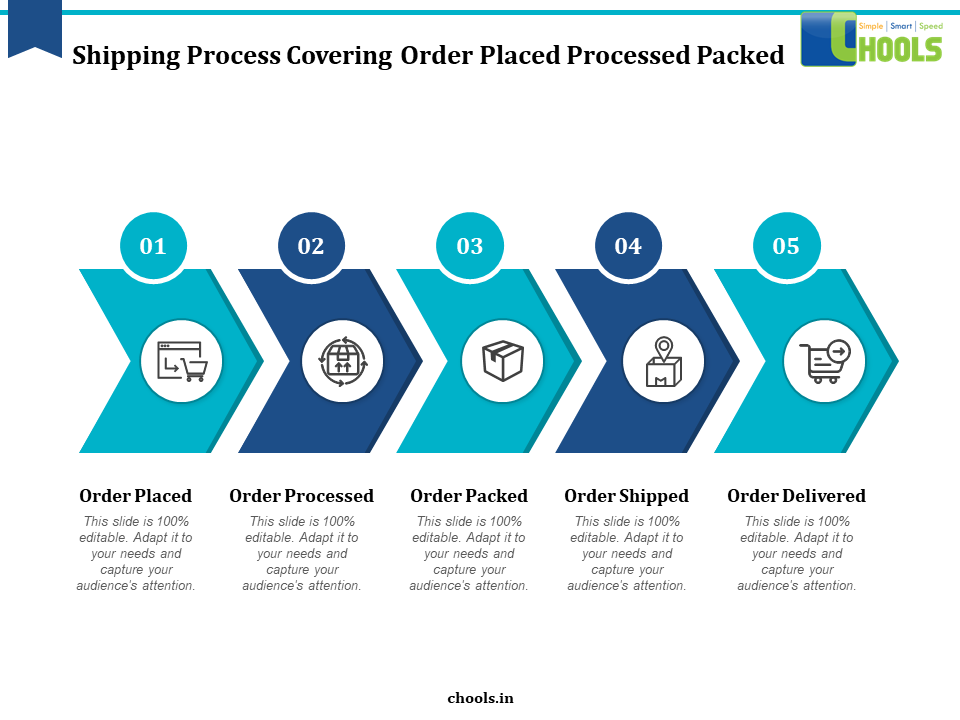

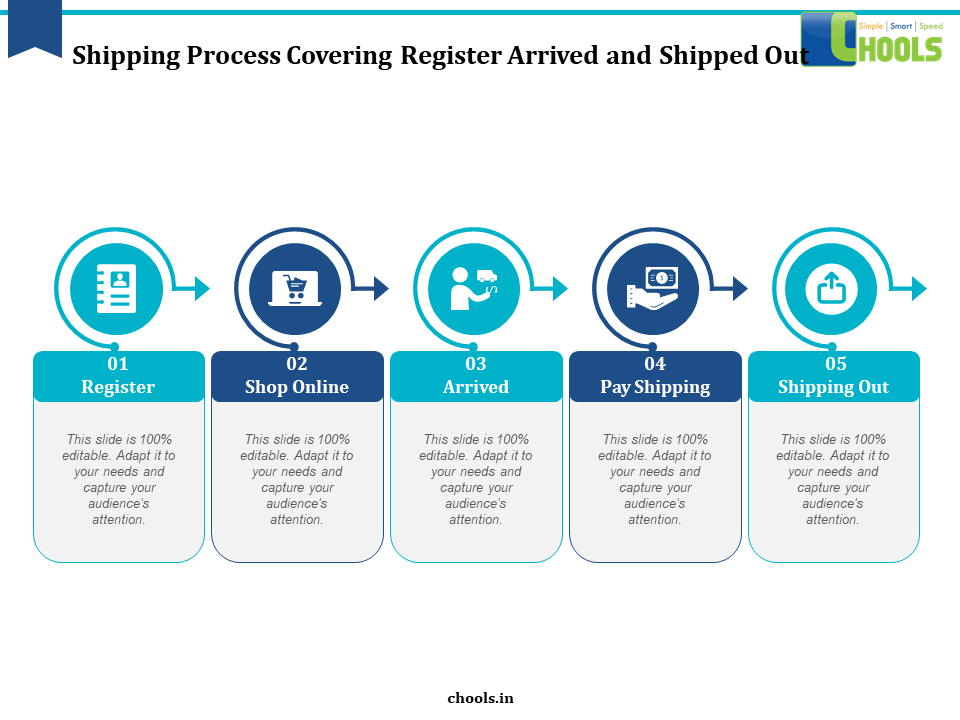

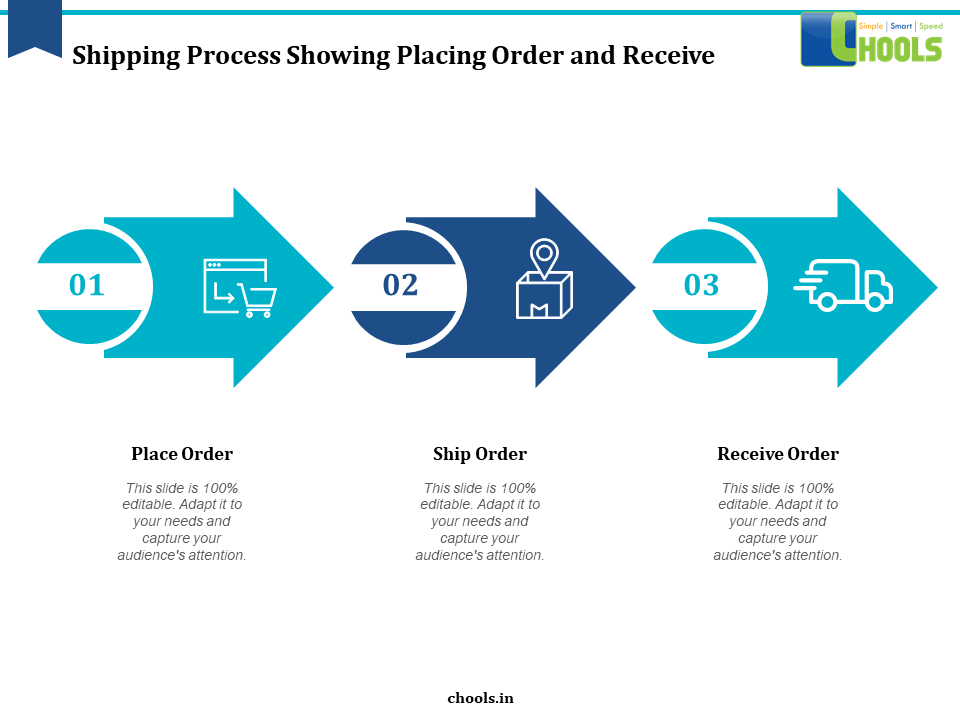

2. SHIPPING PROCESS

3. DISTRIBUTOR AND SUPPLIER AGREEMENT PROPOSAL

4. COMMODITY SUPPLIER COMPANY

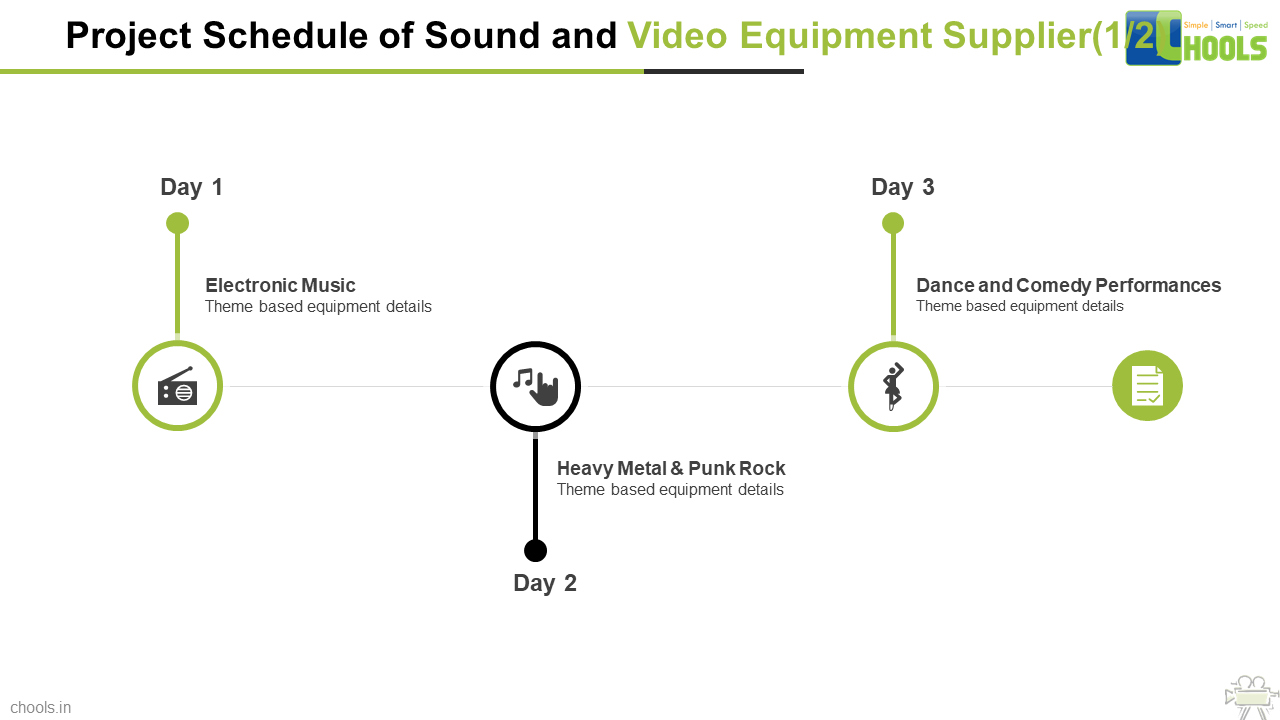

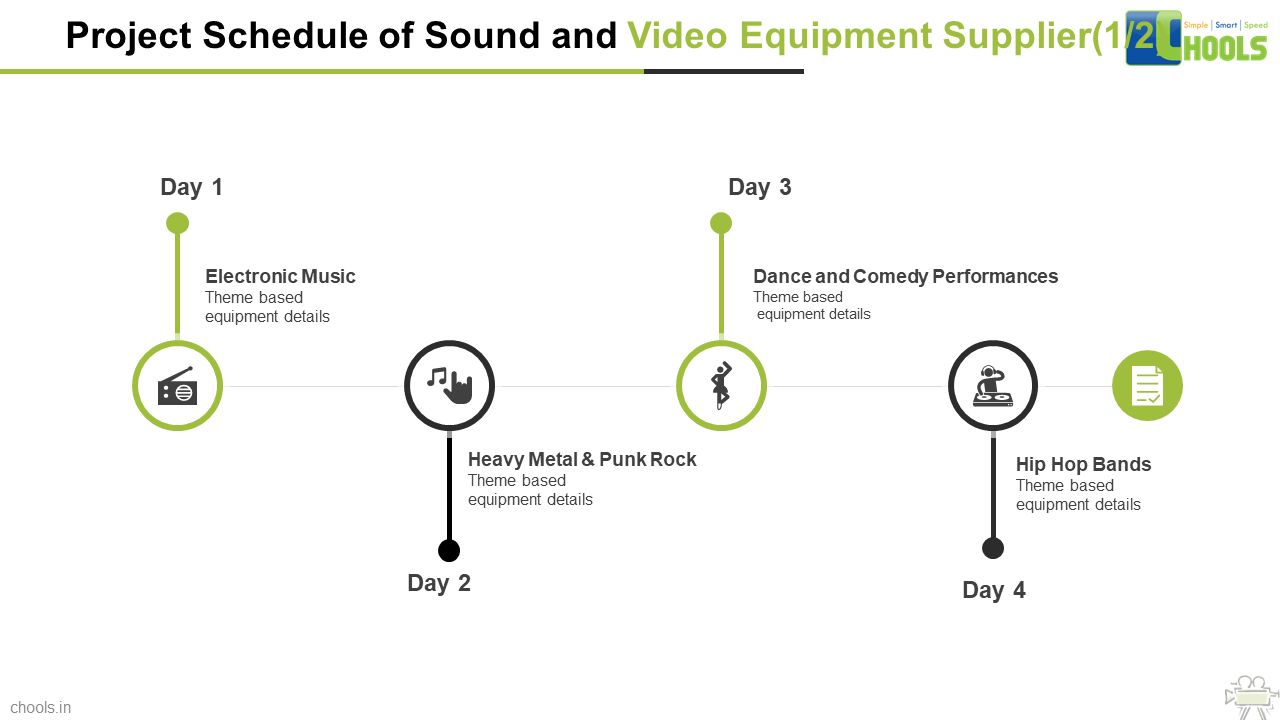

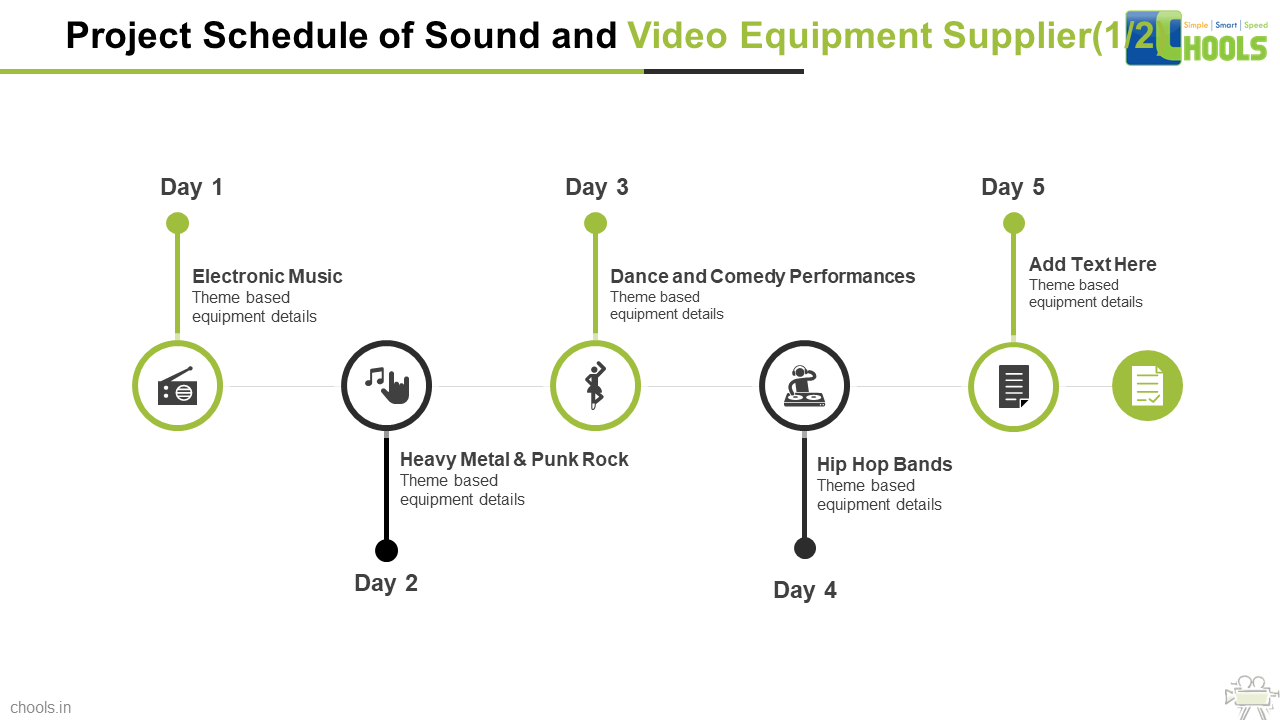

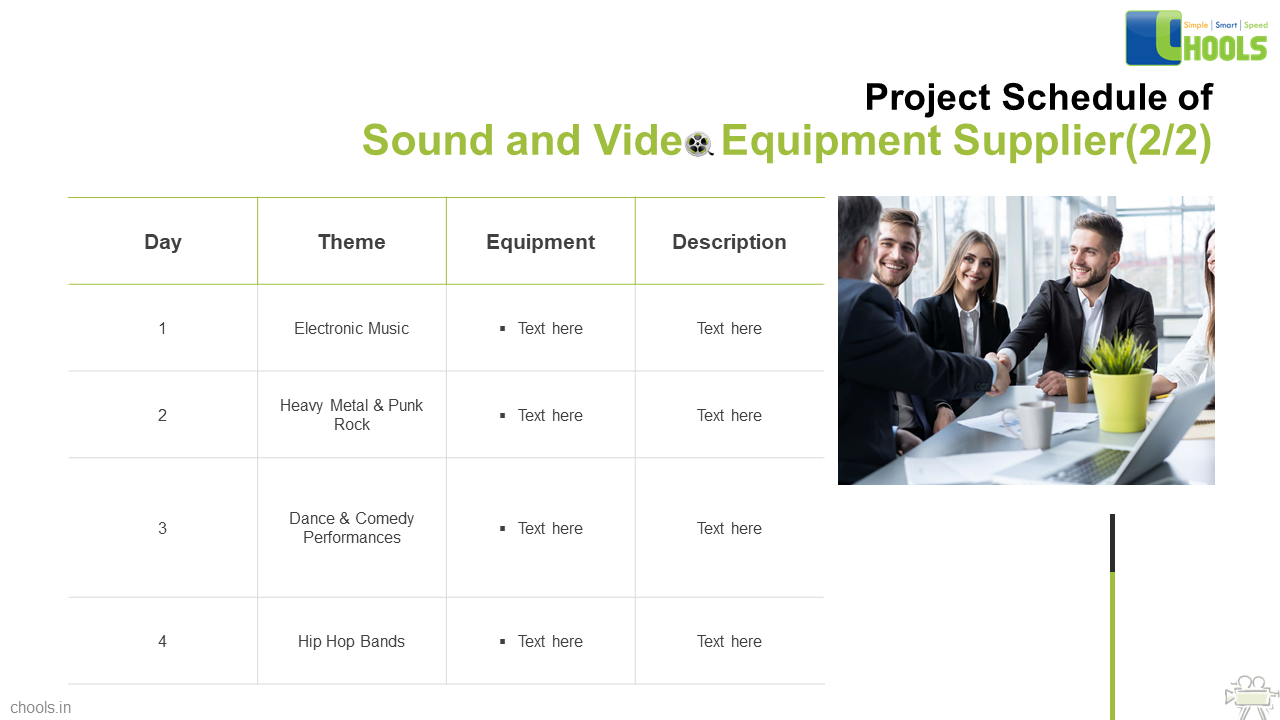

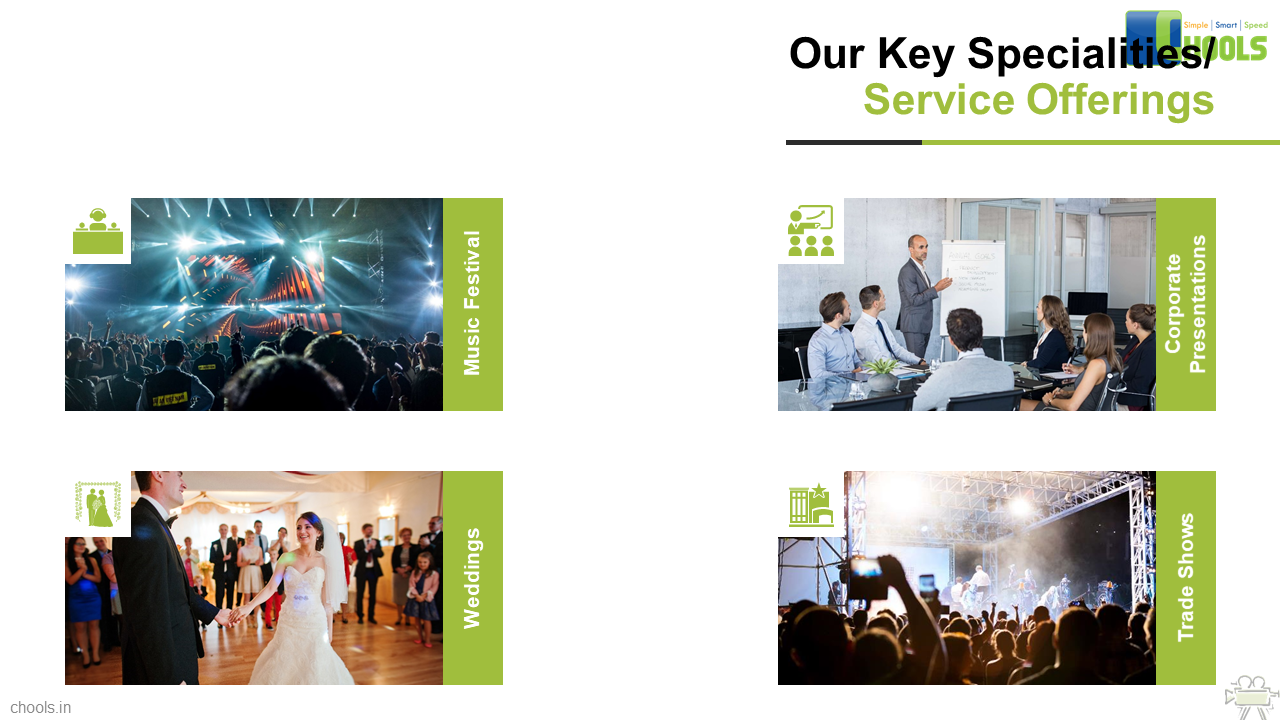

6. SOUND AND VIDEO EQUIPMENT SUPPLIER PROPOSAL