Operations Excellence – The Best In The Business

“If you don’t appreciate your customer, someone else will…”

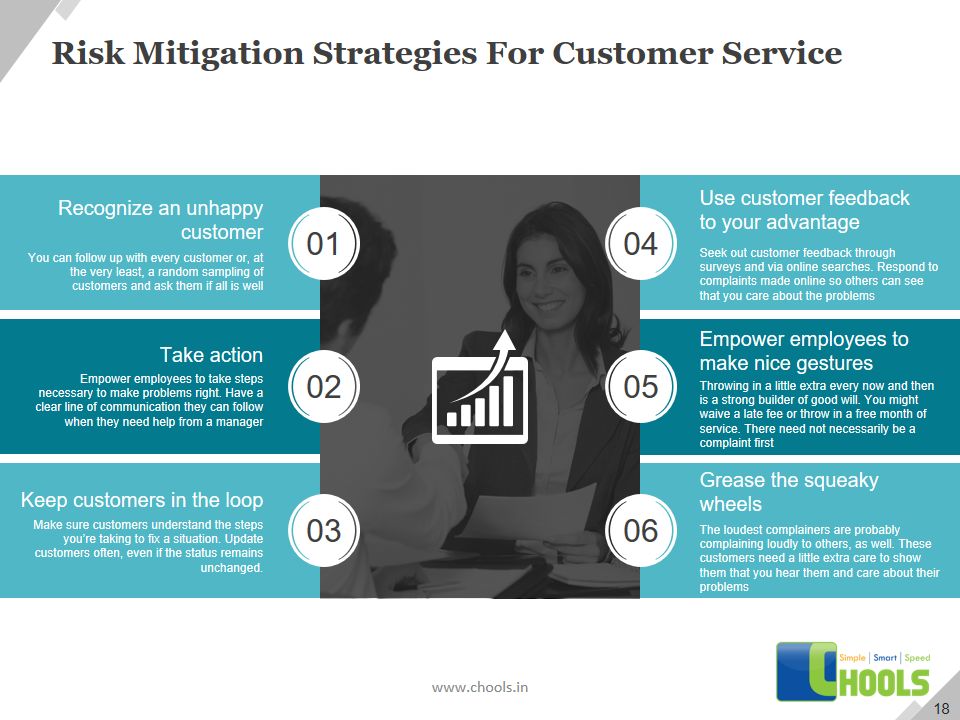

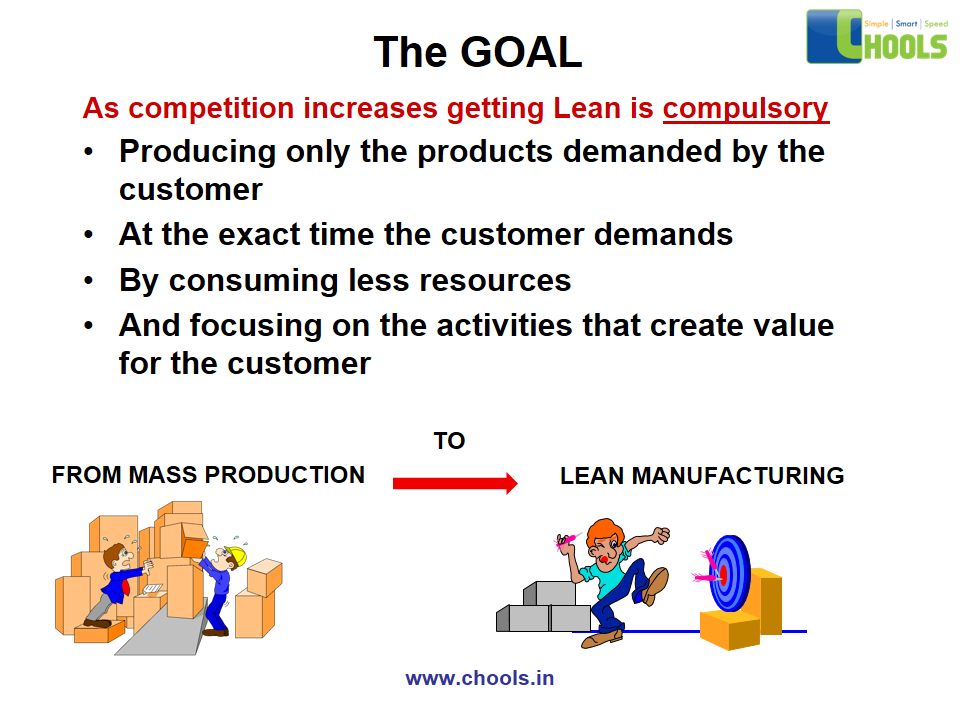

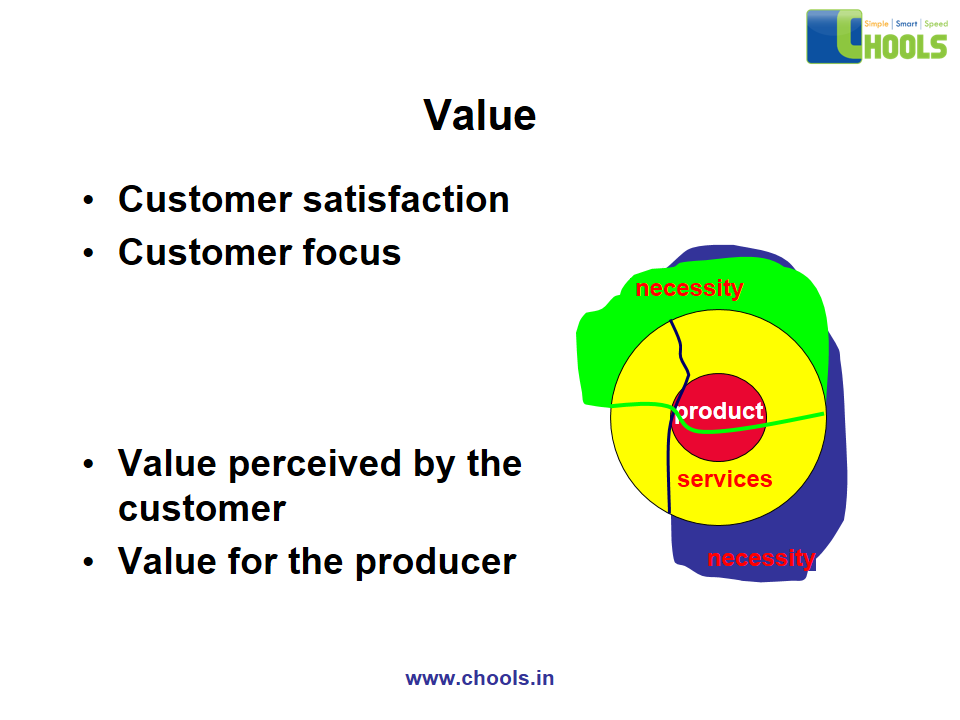

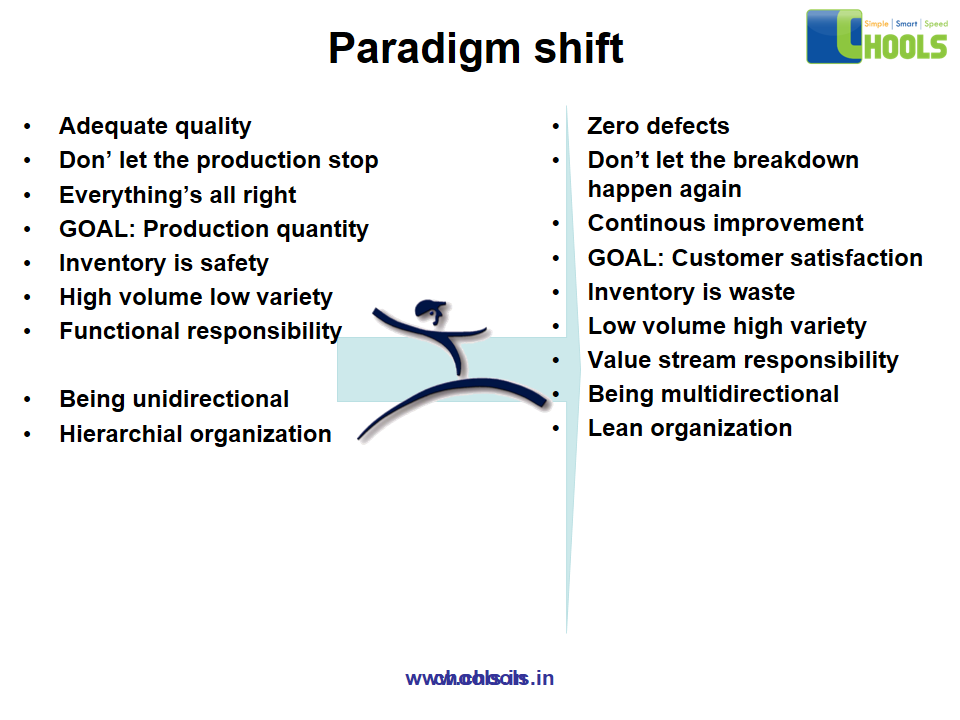

➤ In the present times of competitive business environments, Customer satisfaction is the key point that determines the success of a business. It decides the measure of customer loyalty, helps in identifying unhappy customers, and aids in attracting new customers.

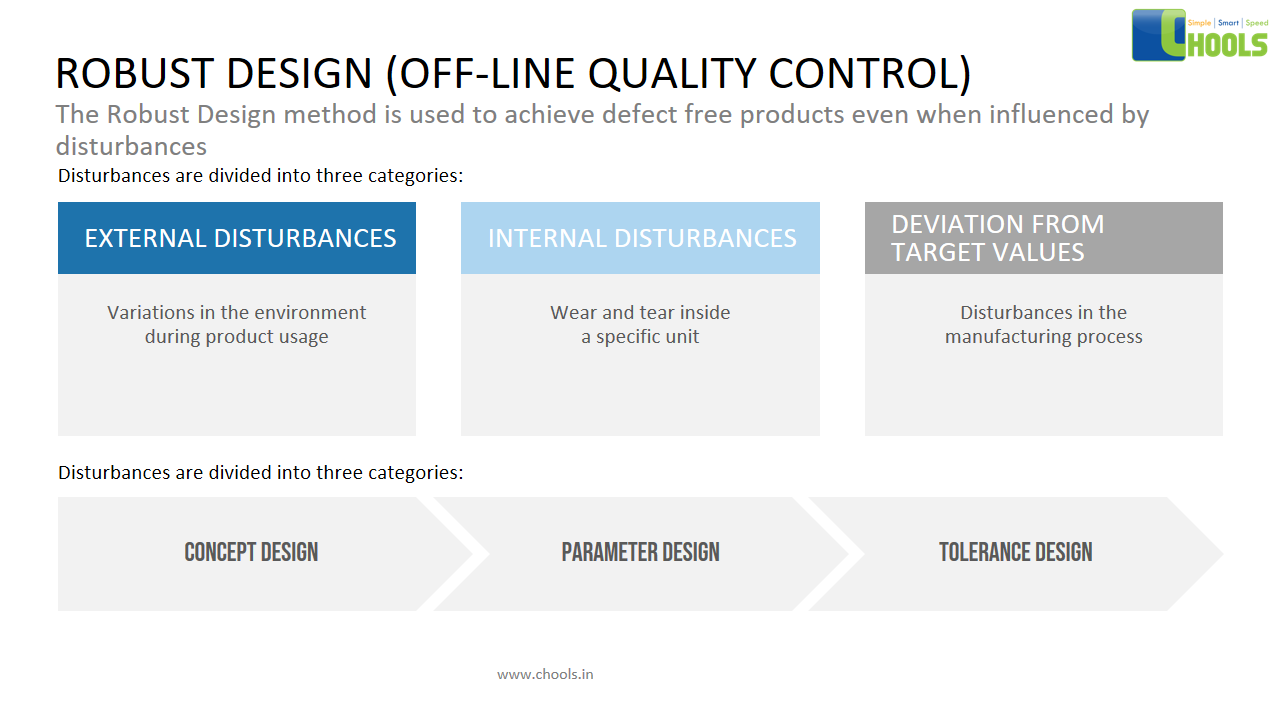

➤ Manufacturers keep facing never-ending challenges in trying to satisfy the customers’ needs and wants. Products must be of a desirable quality, have the right features, be priced right to retain the existing customers. To ensure customer loyalty, a manufacturer must keep reviewing the products and make the required changes to suit the changing needs of the customer.

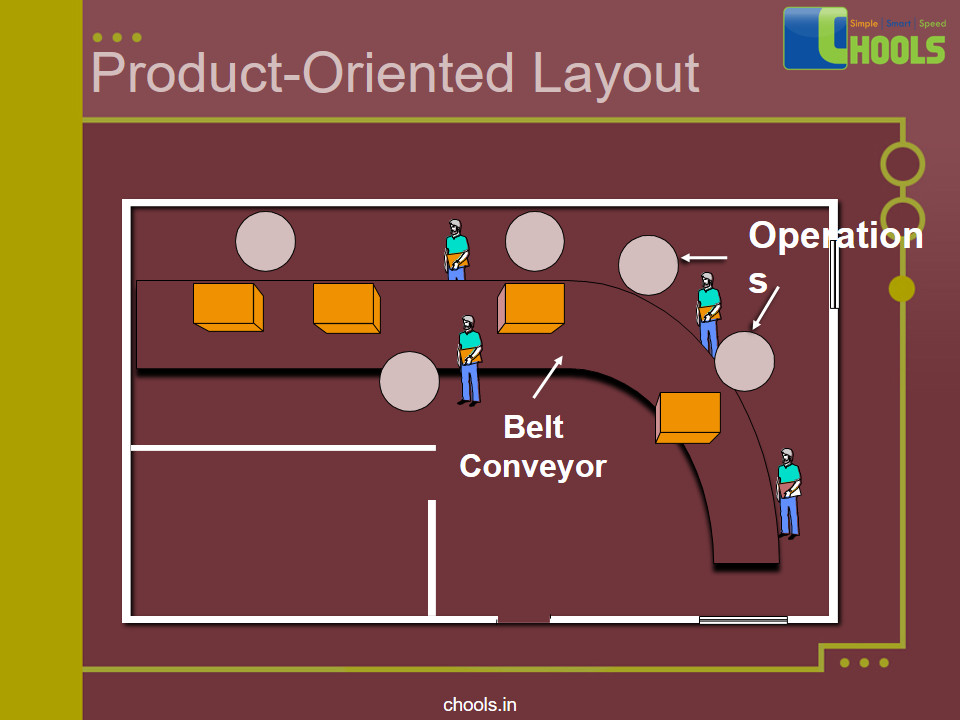

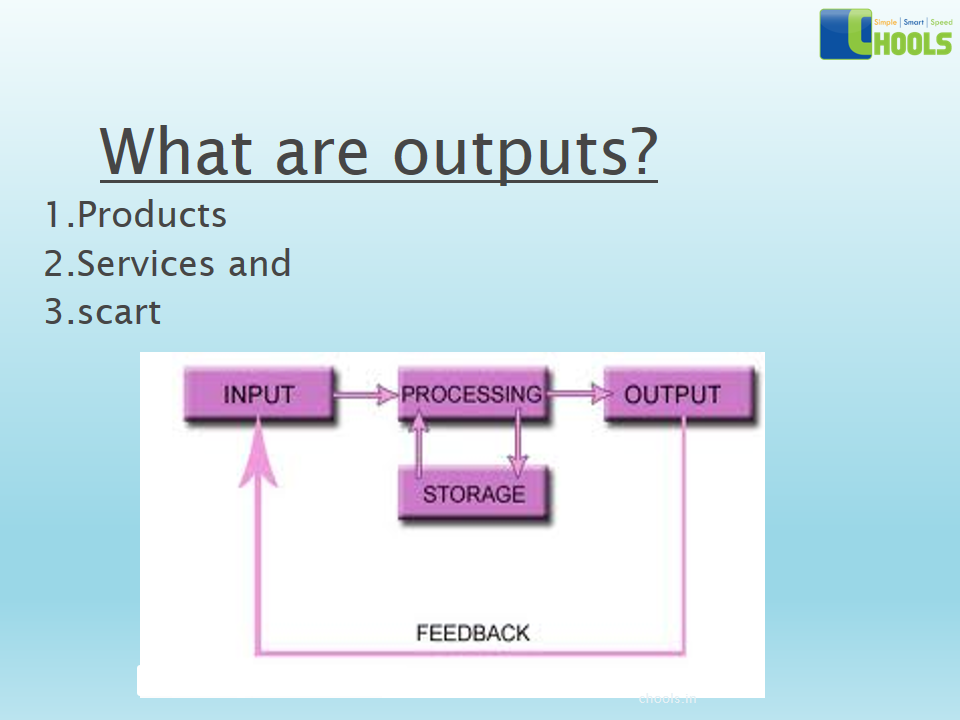

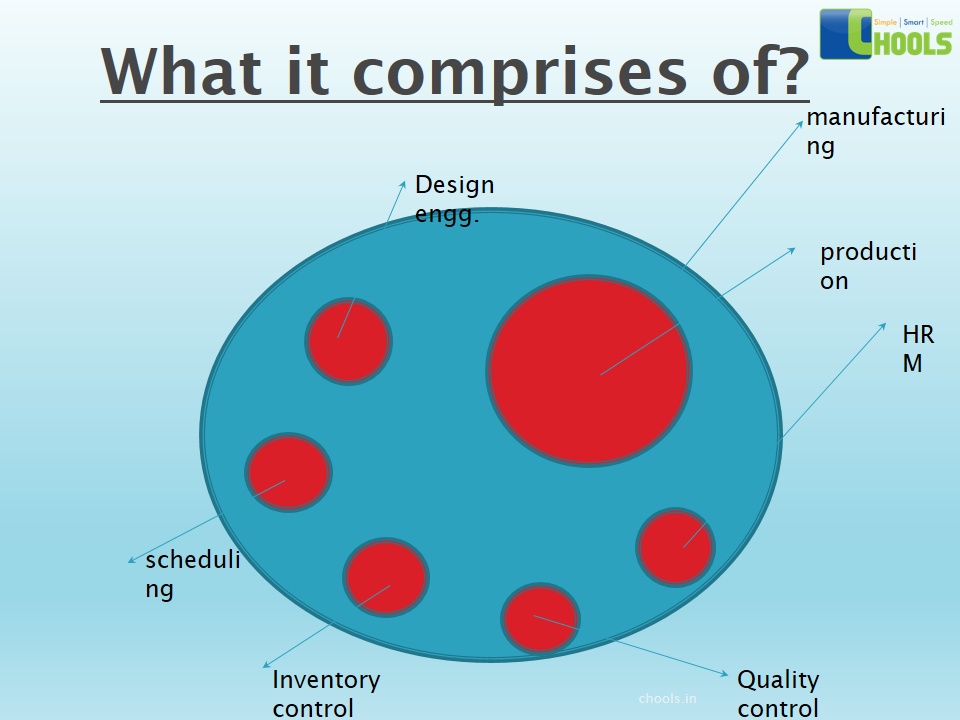

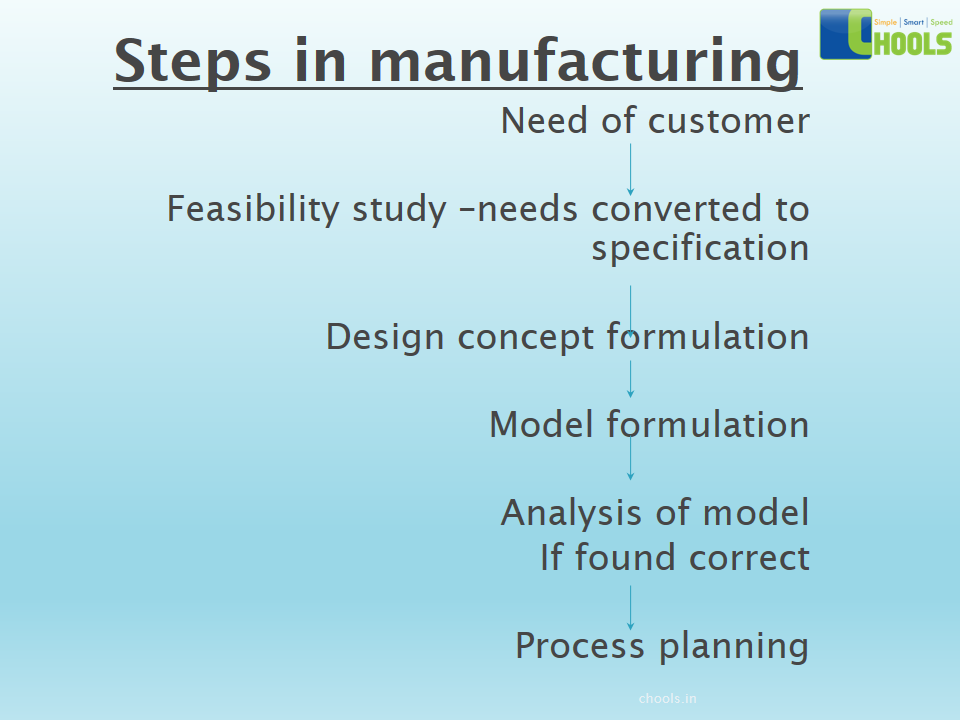

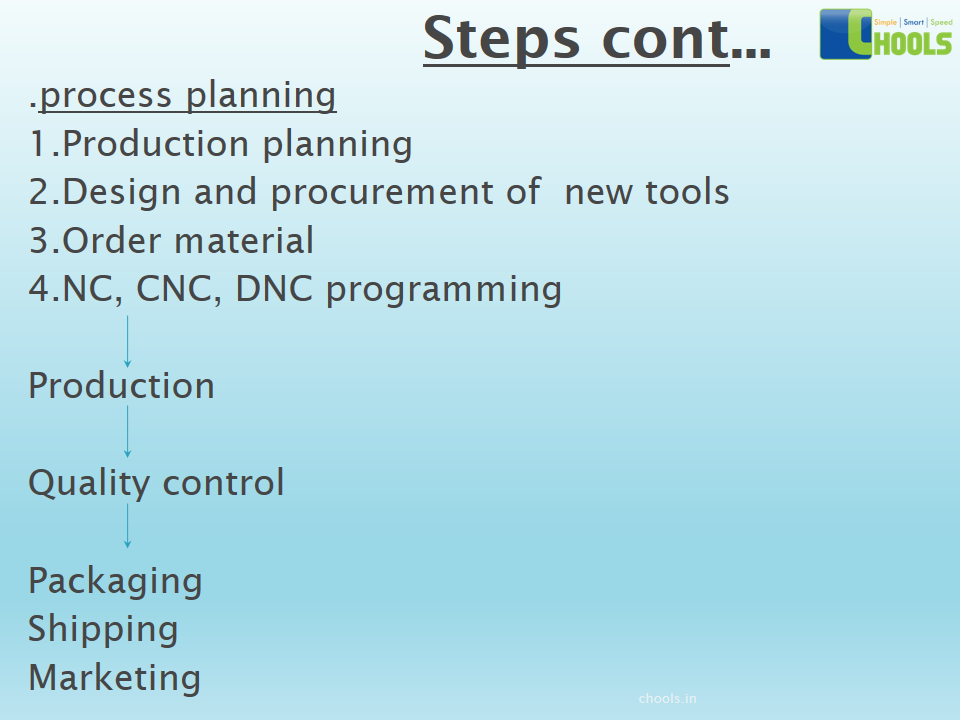

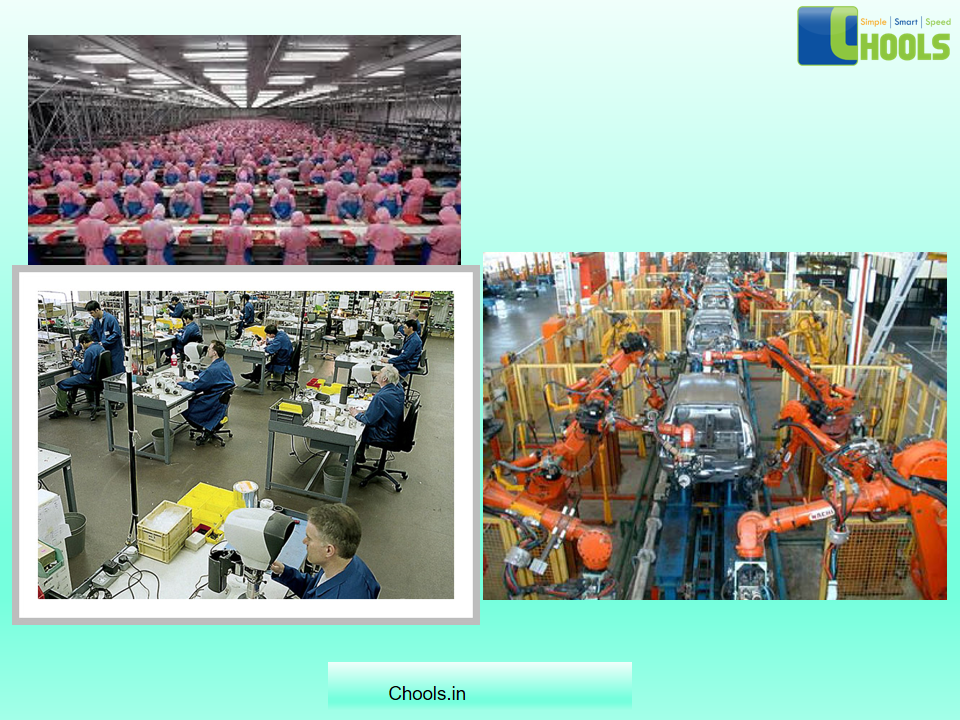

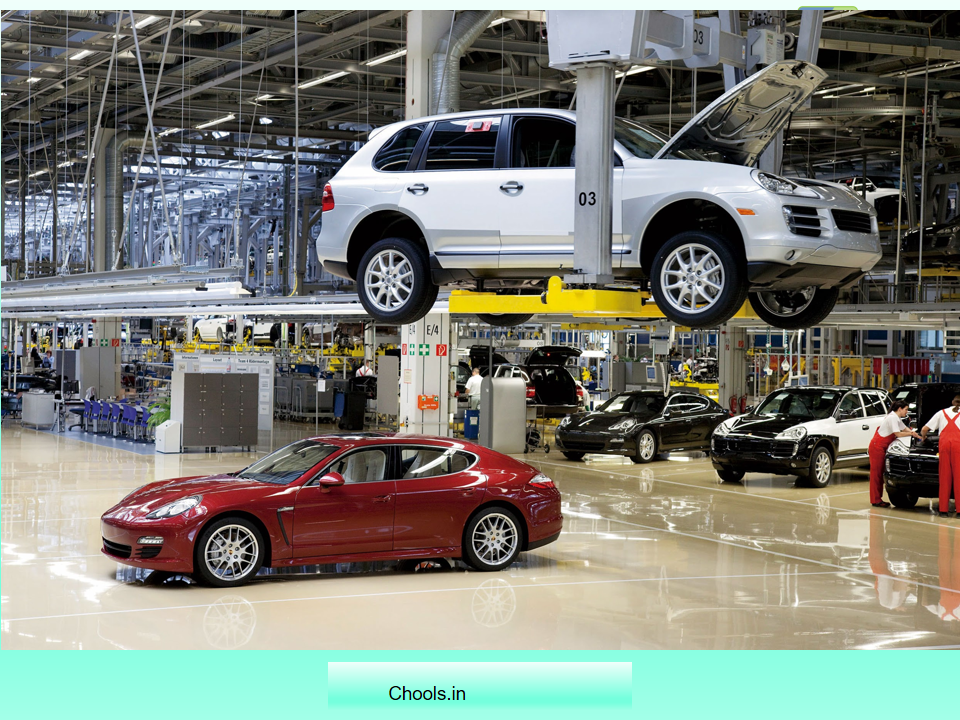

➤ Manufacturing operations is when people, process and equipment come in a single line to add value to the final product.

➤ When the manufacturing processes are placed rightly, it can provide the desired results which in turn would satisfy the customer demands and bring in new products to the market.

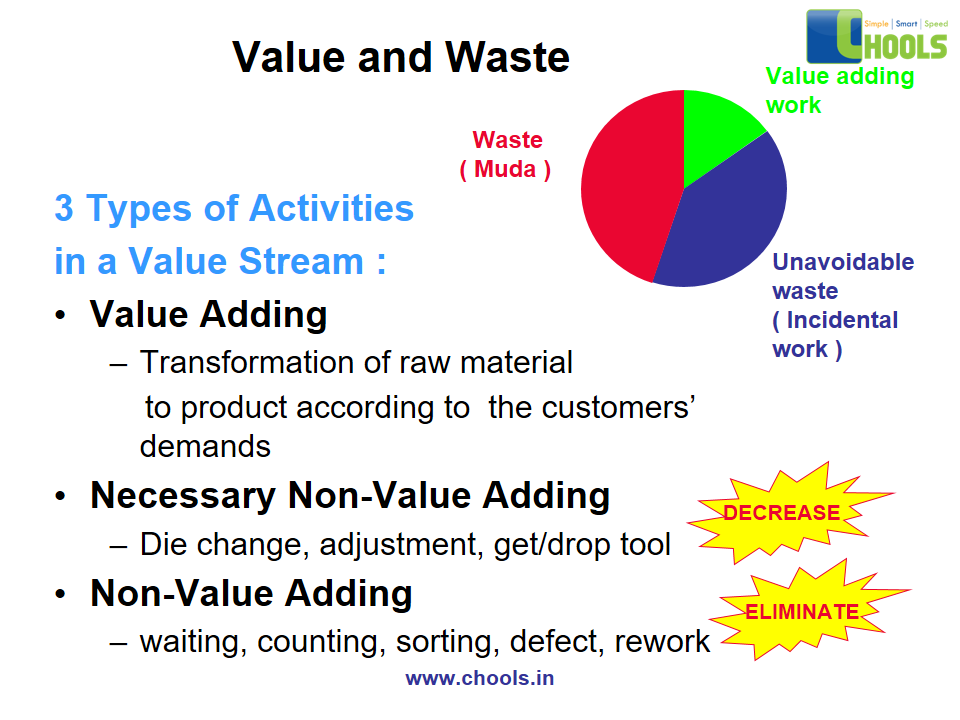

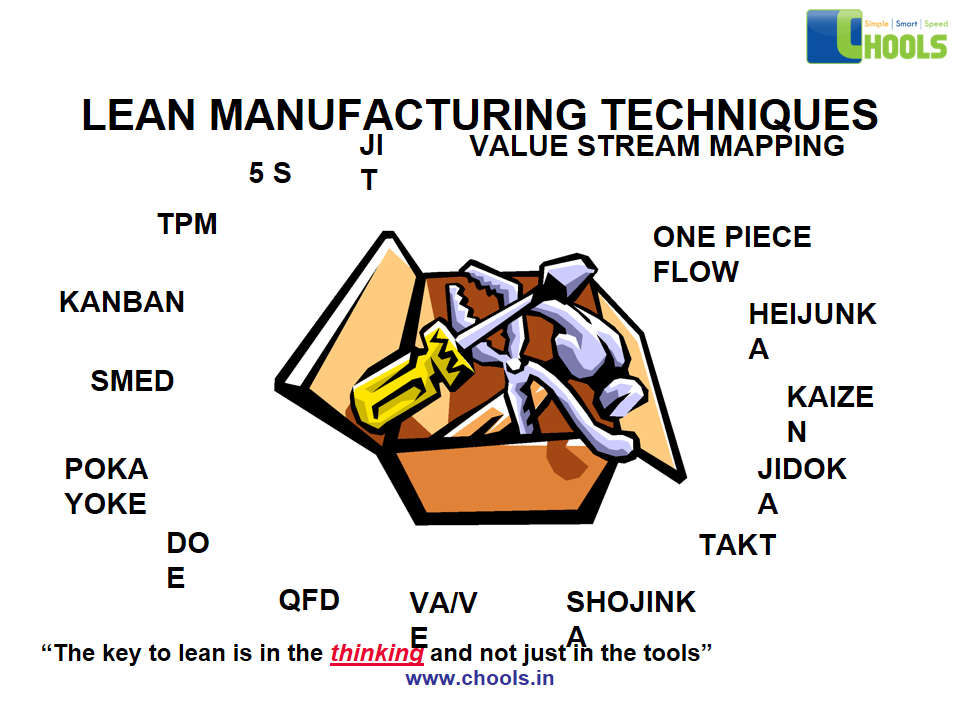

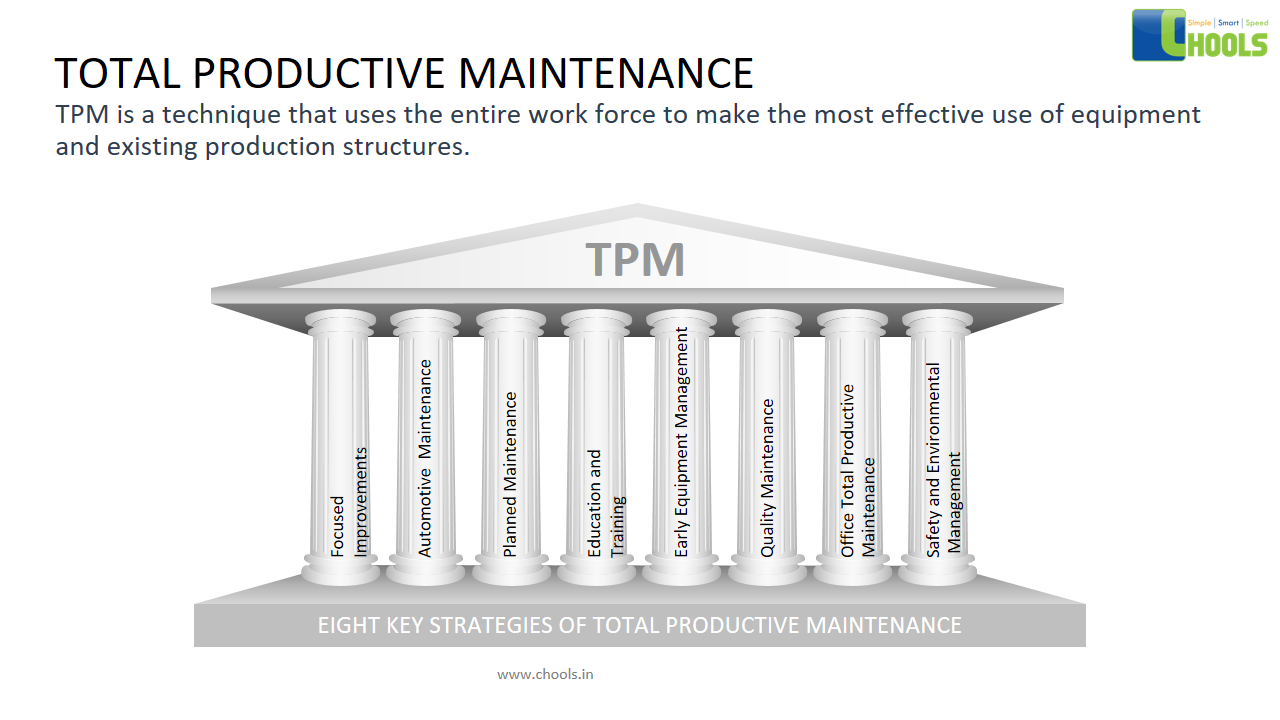

➤ Chools Consulting services advices and delivers end-to-end manufacturing initiatives. We motivate the cross-functional teams in your organization towards a common motto even when they have contrasting agendas. Our team of experts with their hands-on-experience in project management, blend in Six Sigma, TPM(Total Productive Maintenance), manufacturing leadership, and Lean Manufacturing to deliver the desired results faster, cheaper and in the best possible way.

The scope of our manufacturing consulting services extends to the following areas:

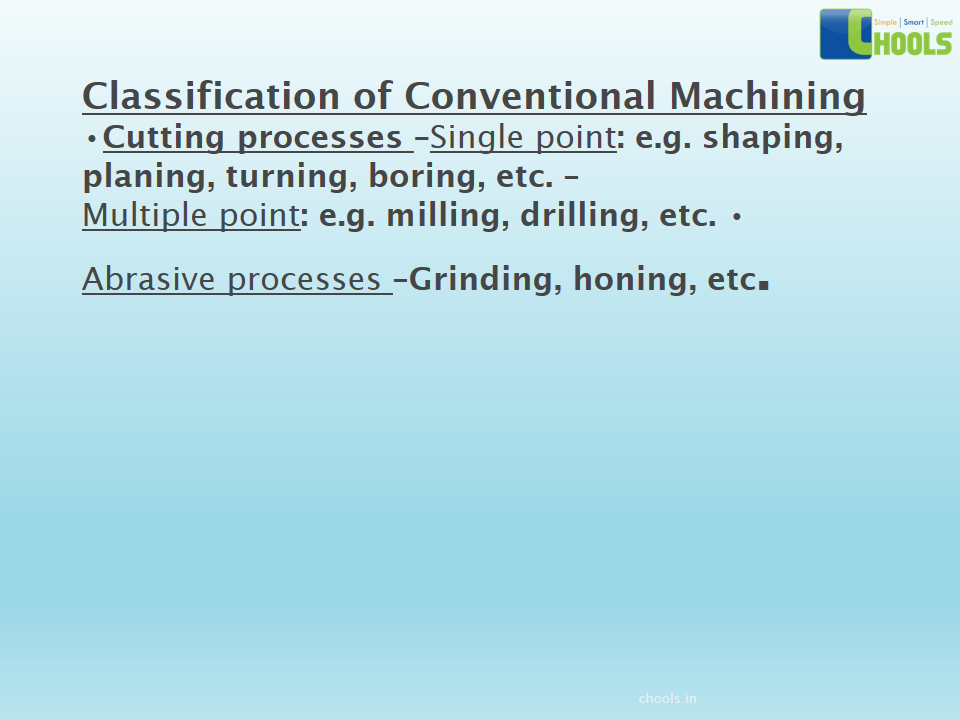

✔ Assessing the manufacturing model prevalent in the organization

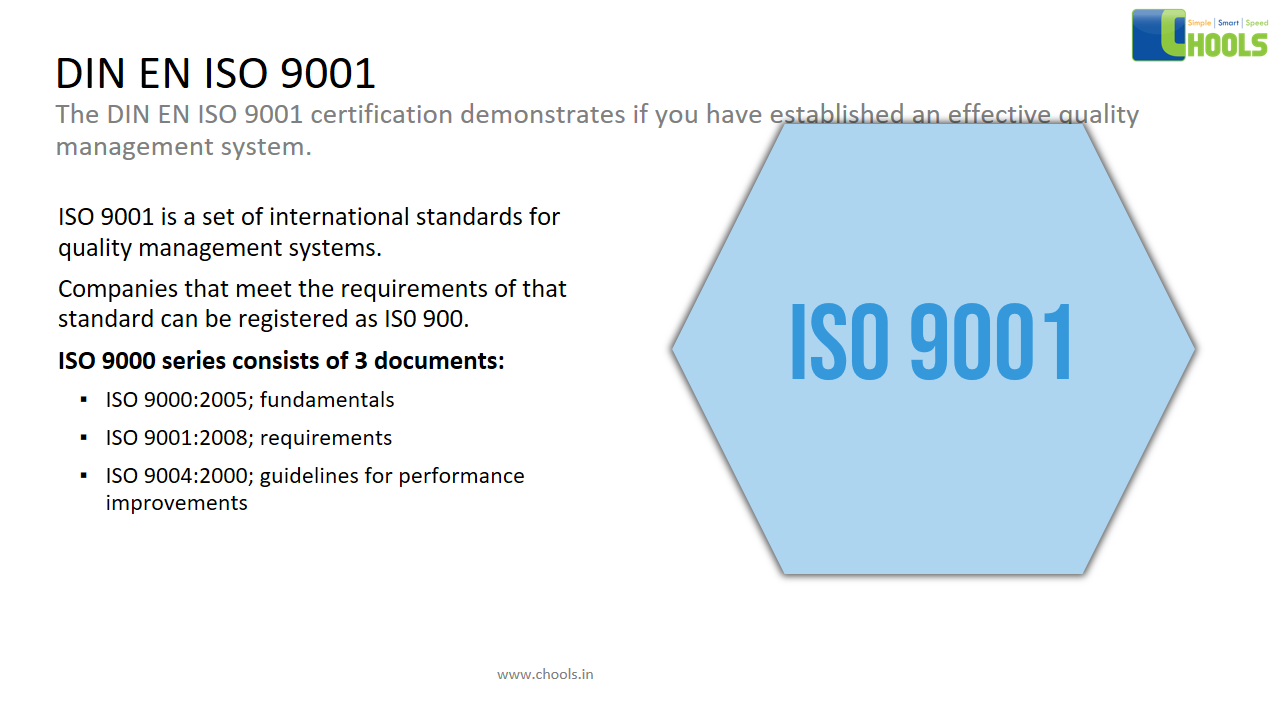

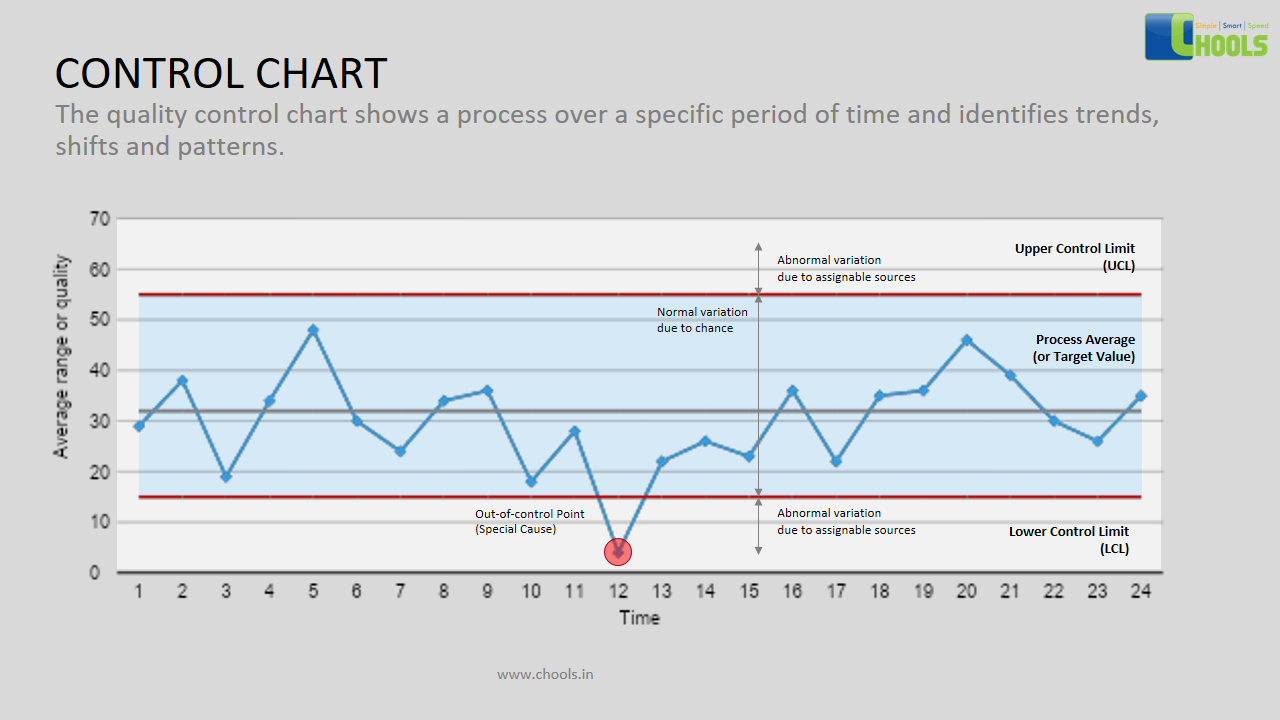

✔ Defining the QMS (Quality Management System)

✔ Bringing into effect Product Rationalization

✔ Installation of the required Equipment

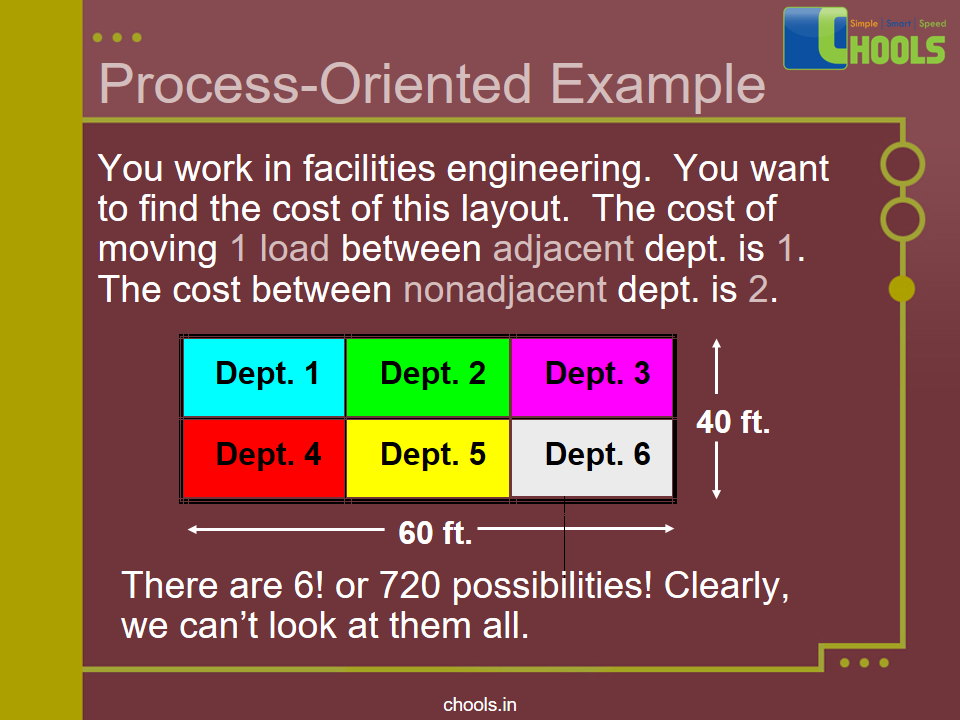

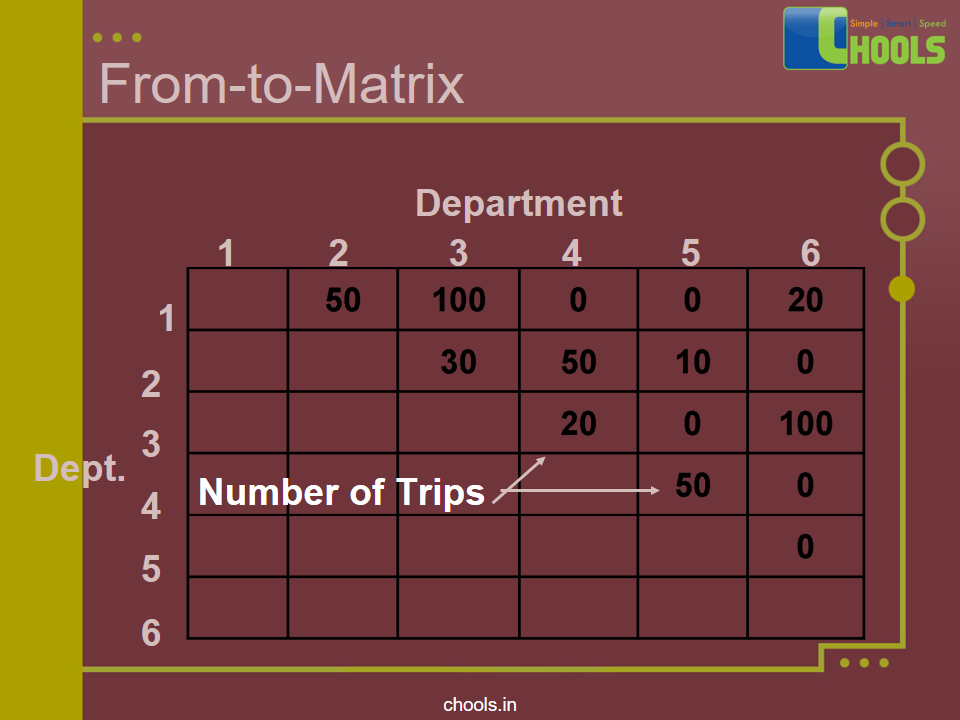

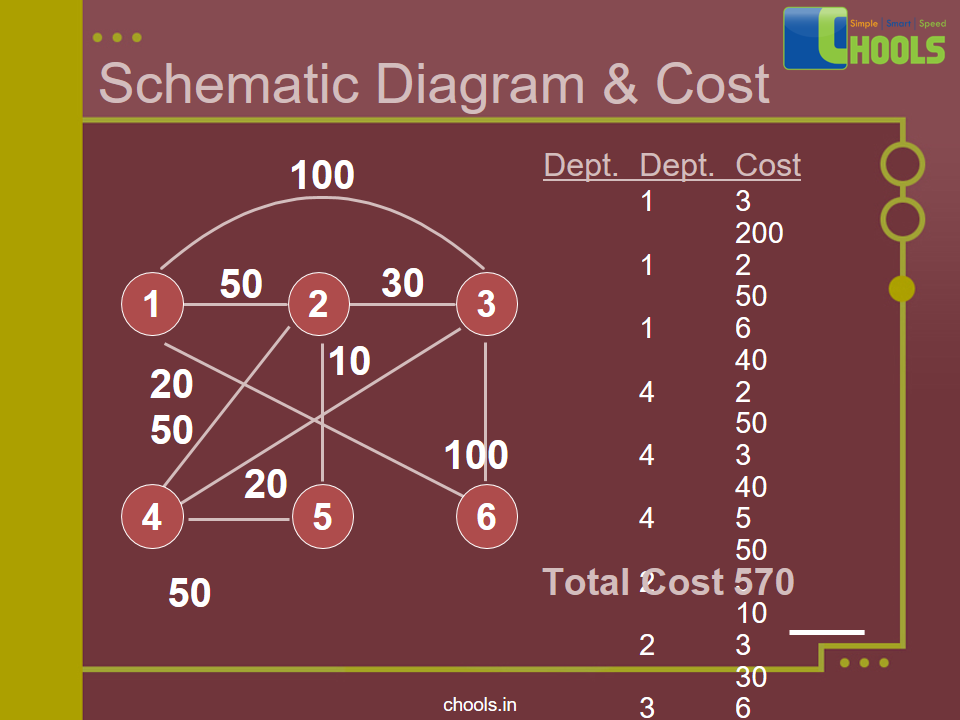

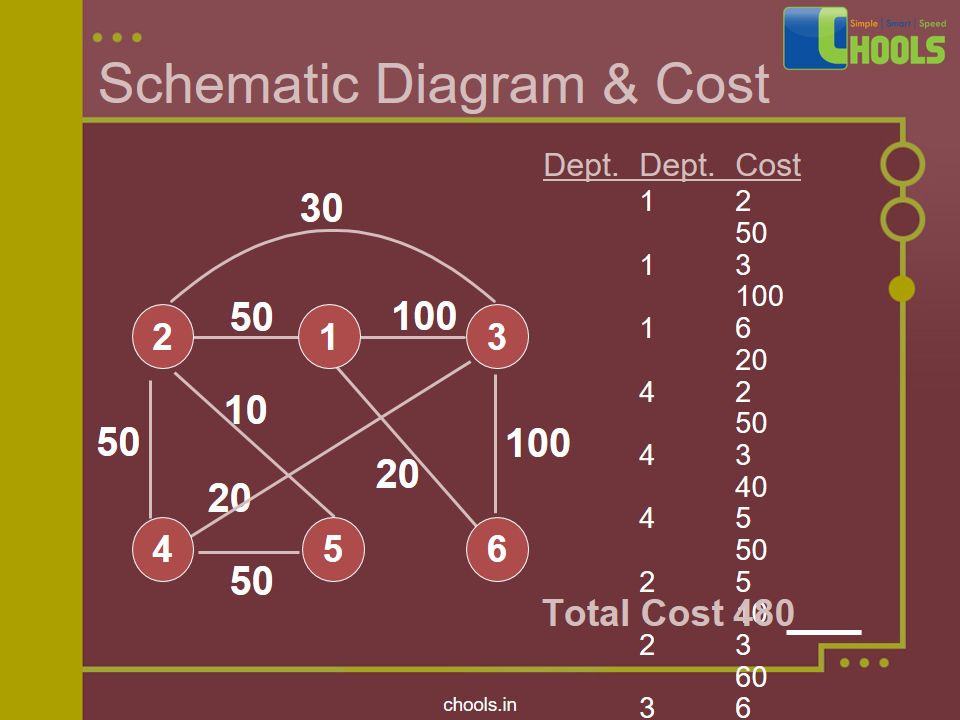

✔ The process of facility planning

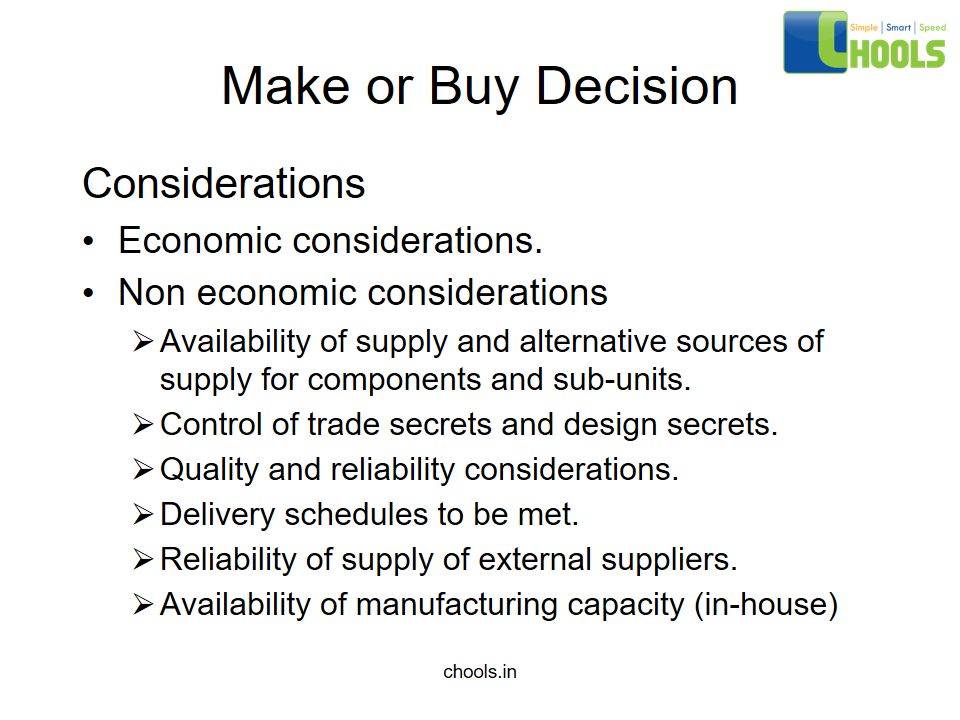

✔ Supply chain analytics and Cost cutting

✔ Optimizing the operations

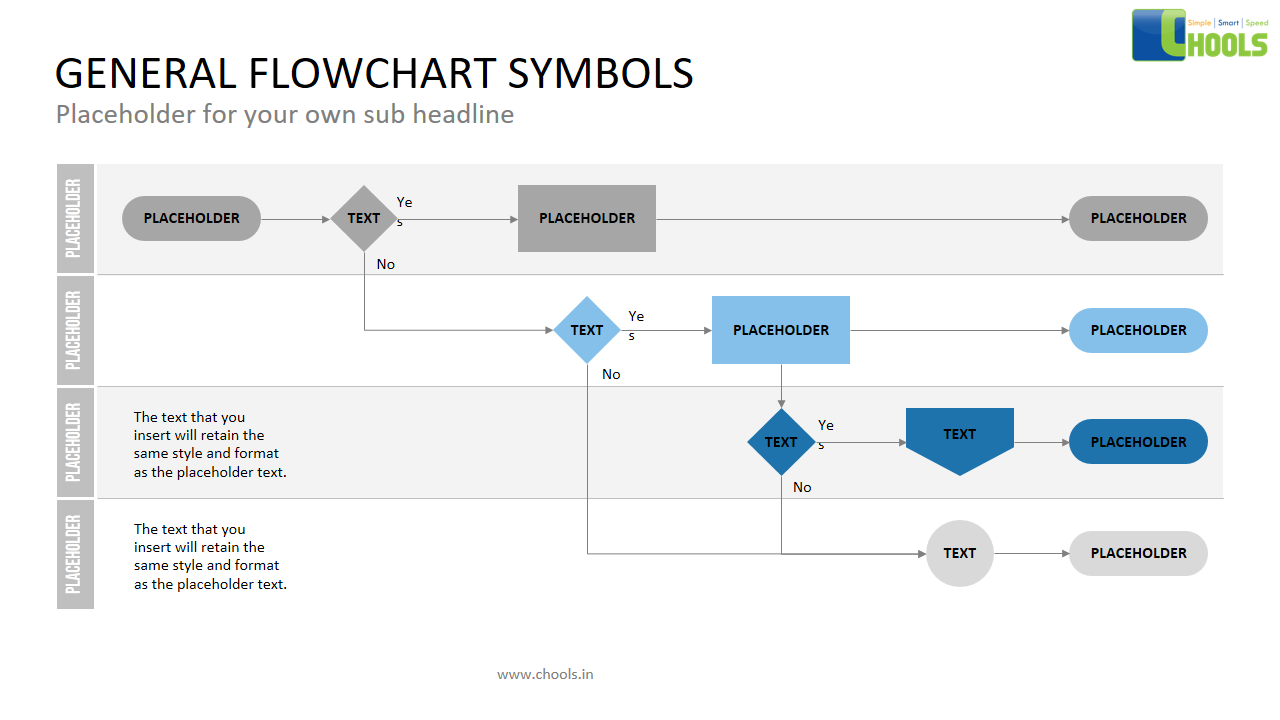

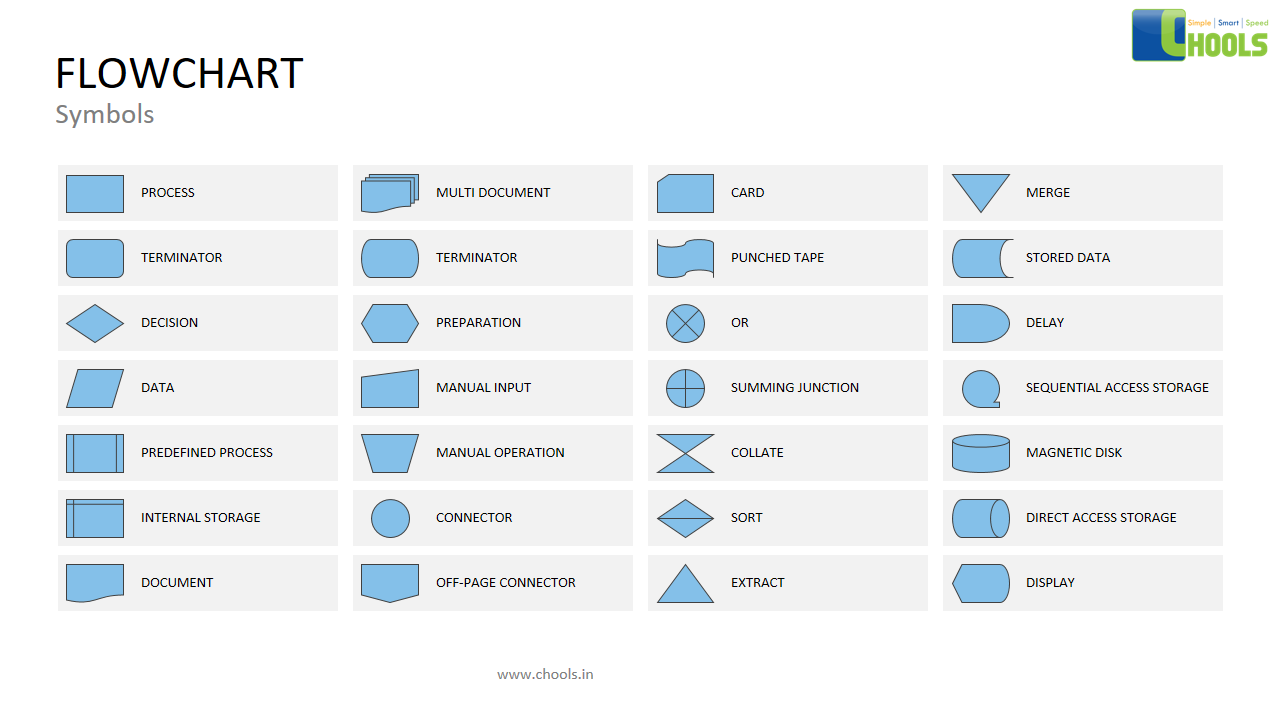

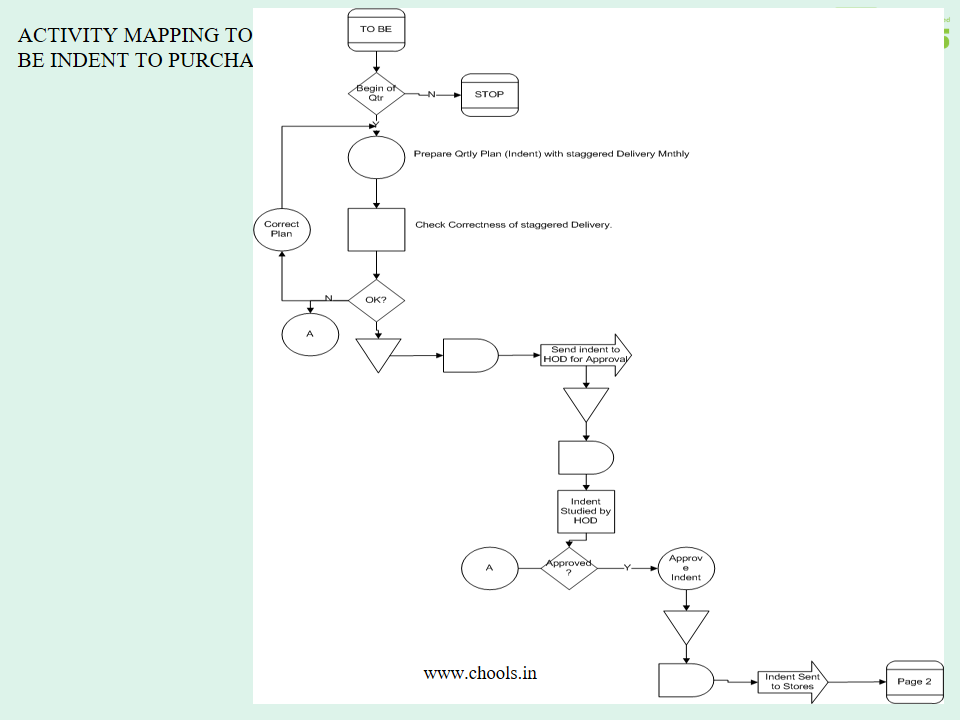

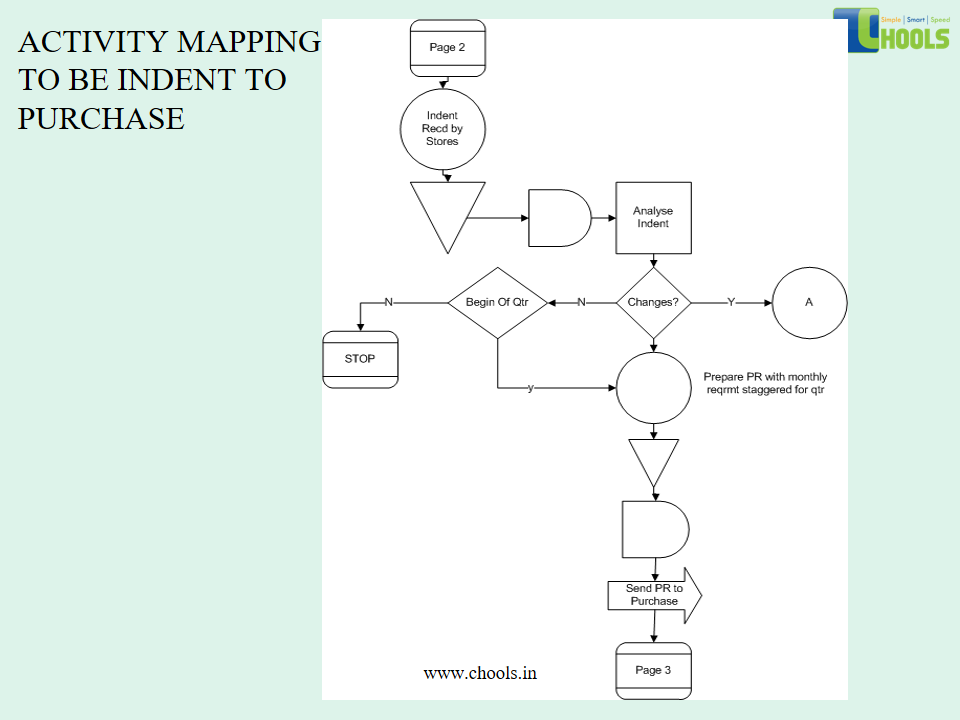

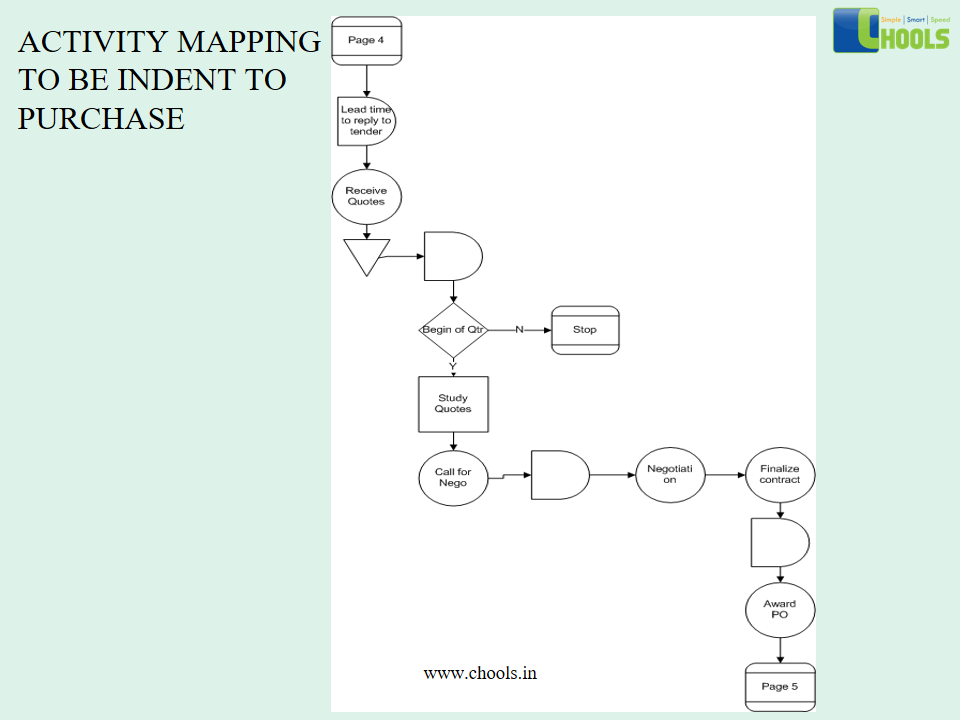

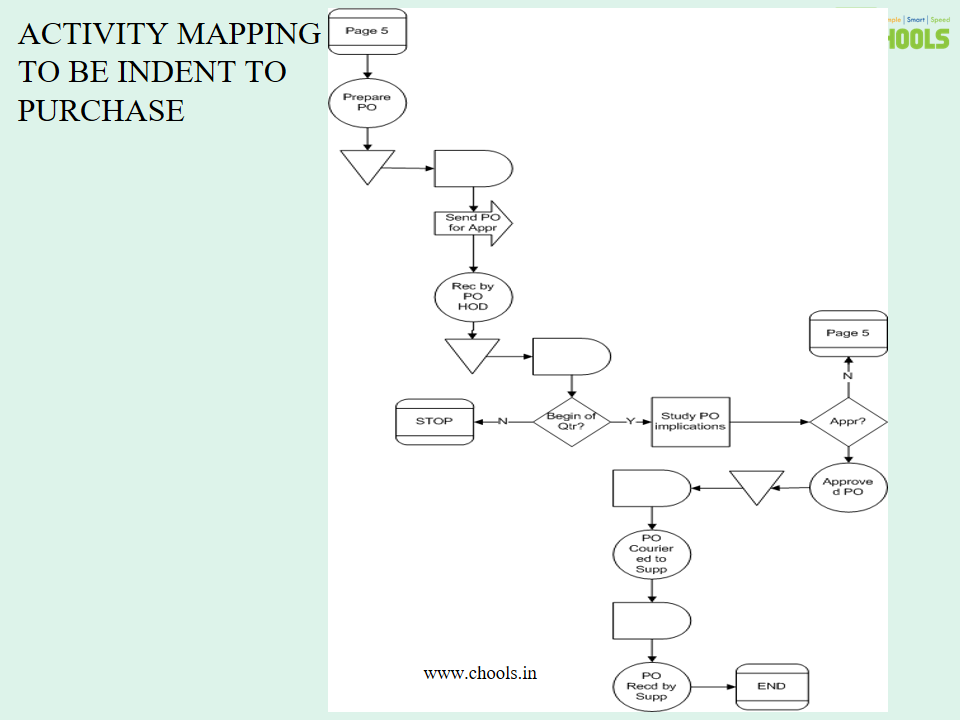

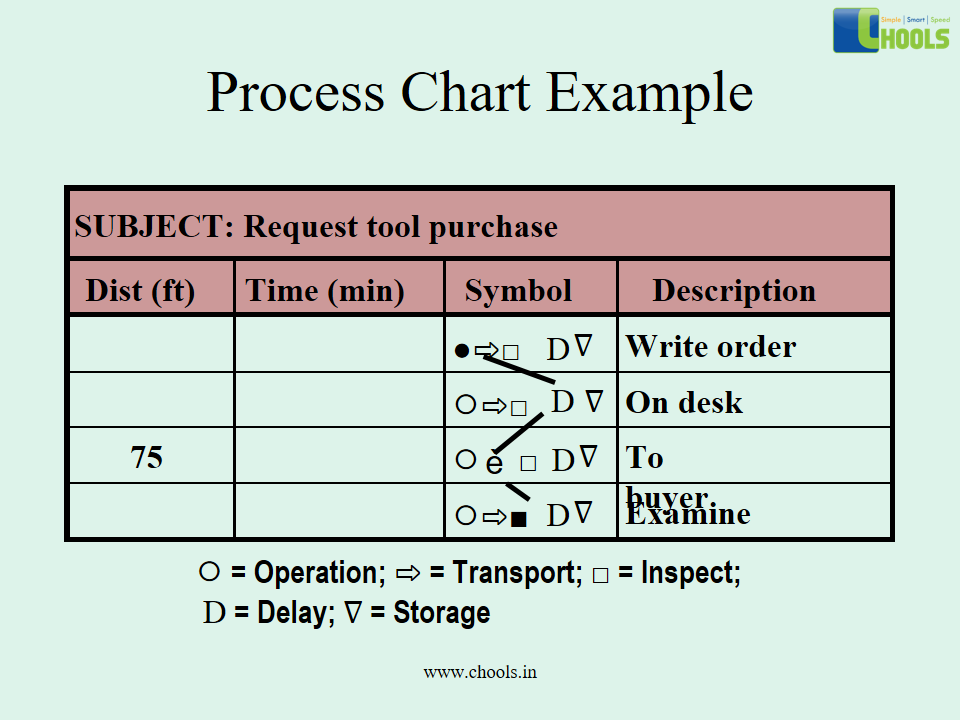

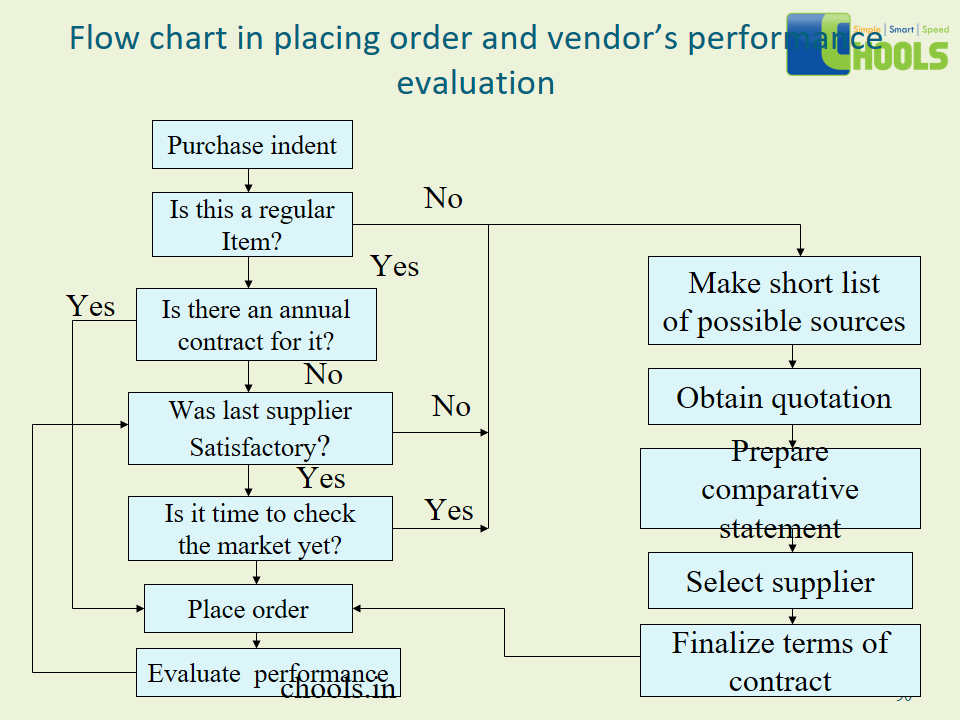

✔ Manufacturing process flow charts and workflow templates

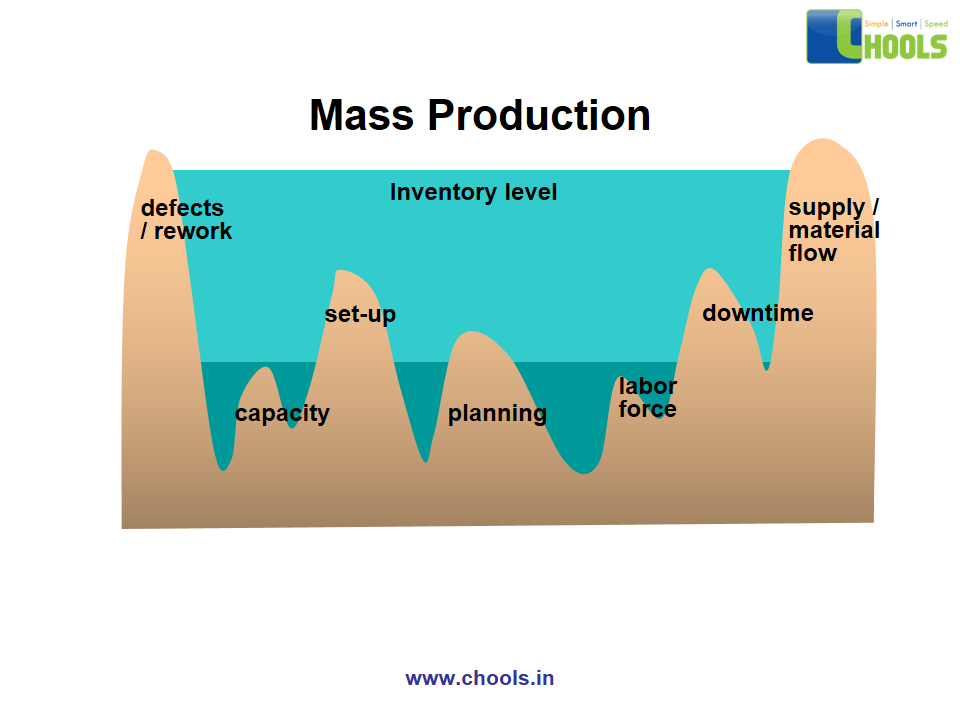

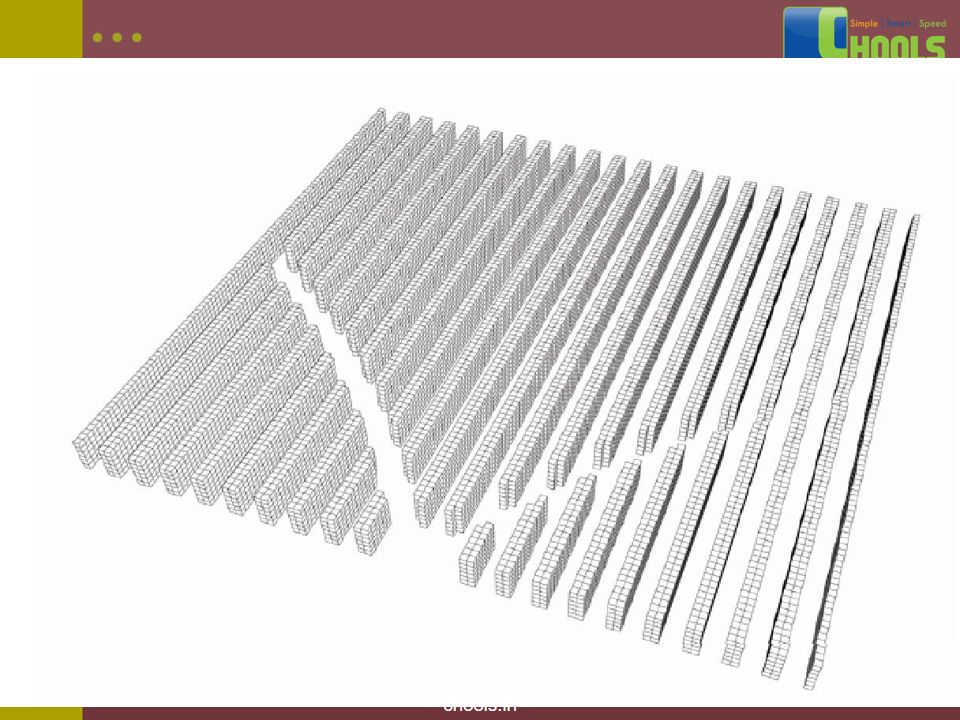

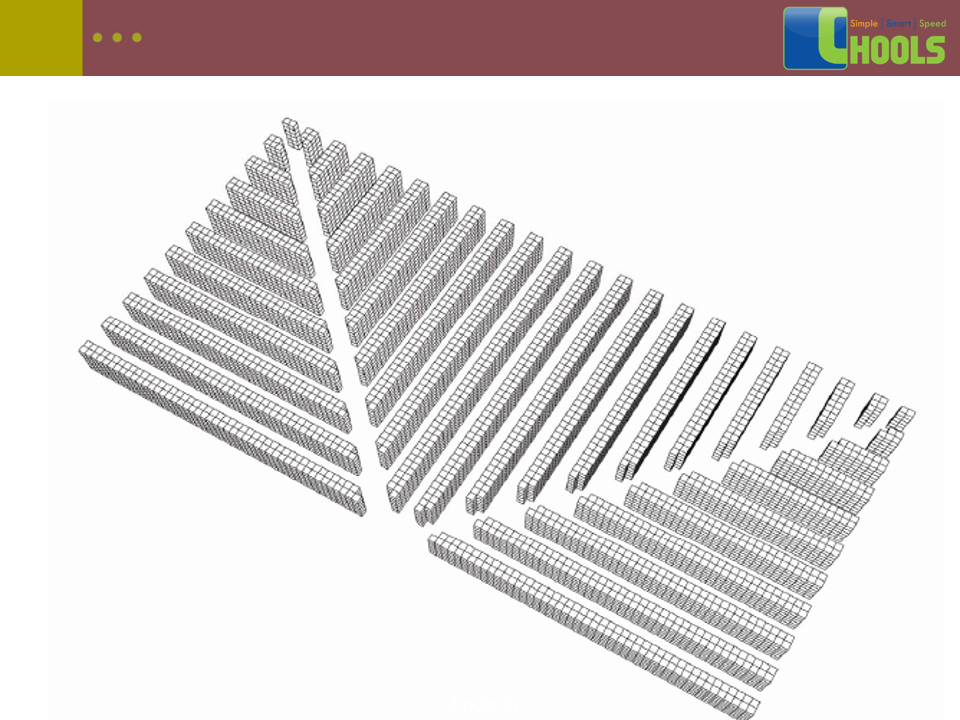

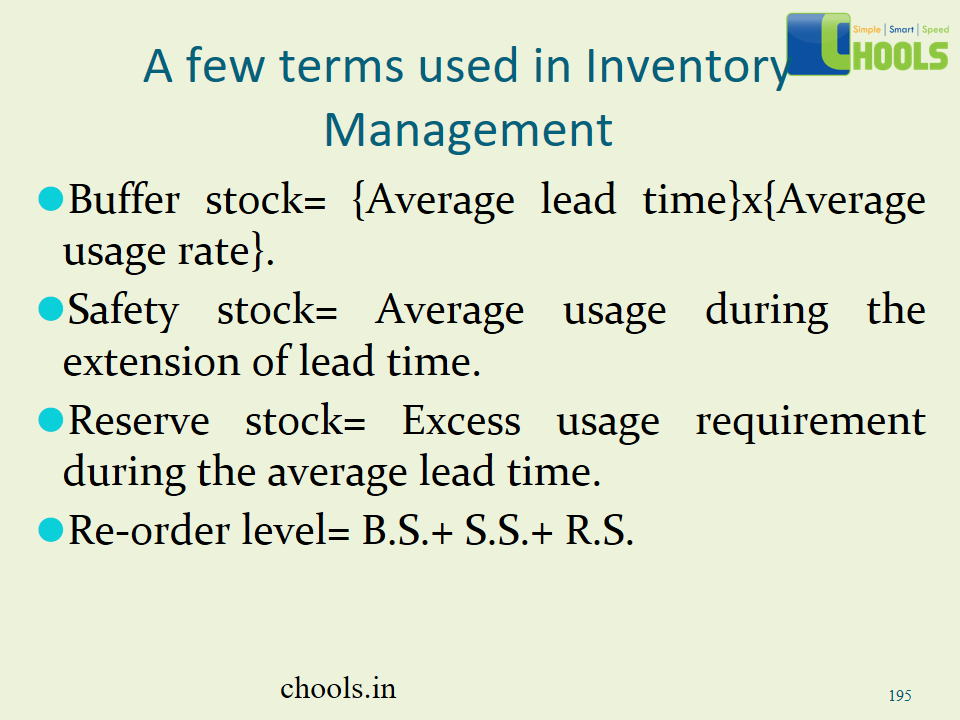

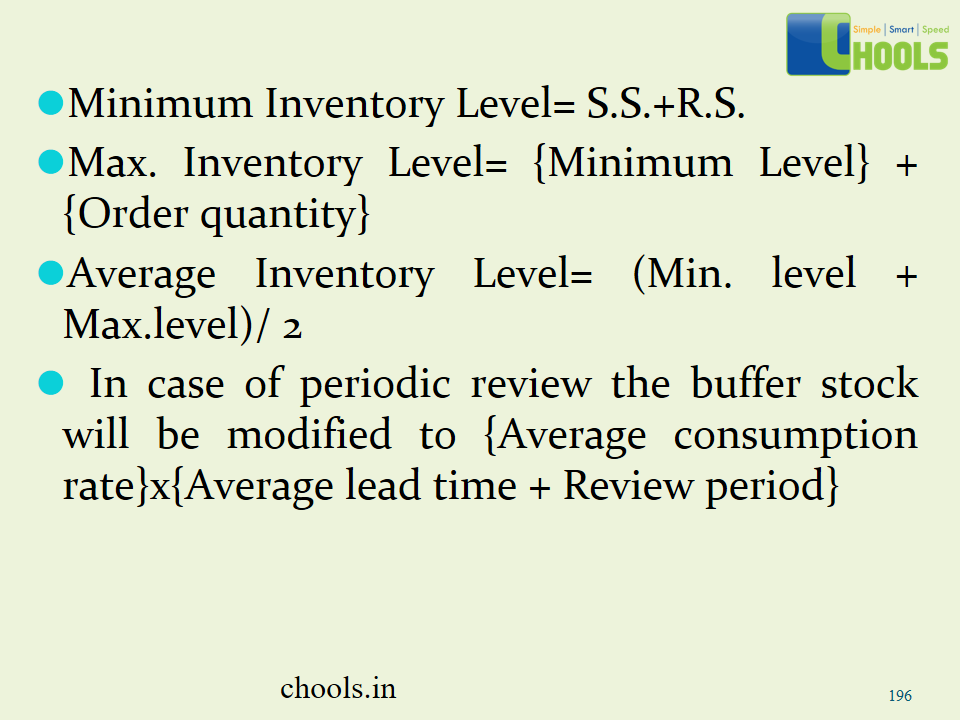

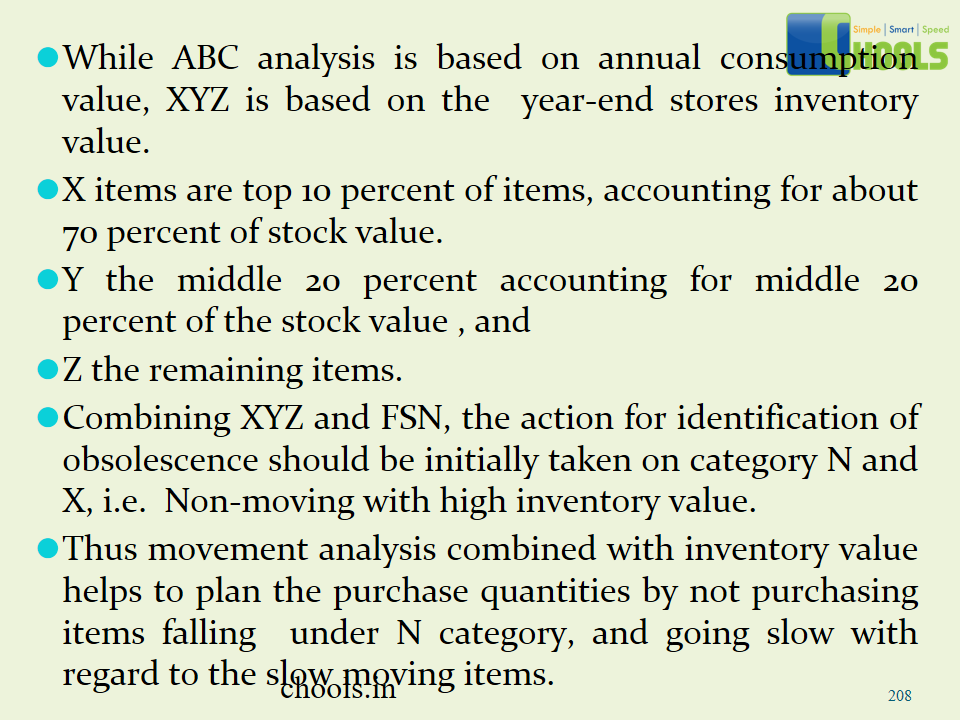

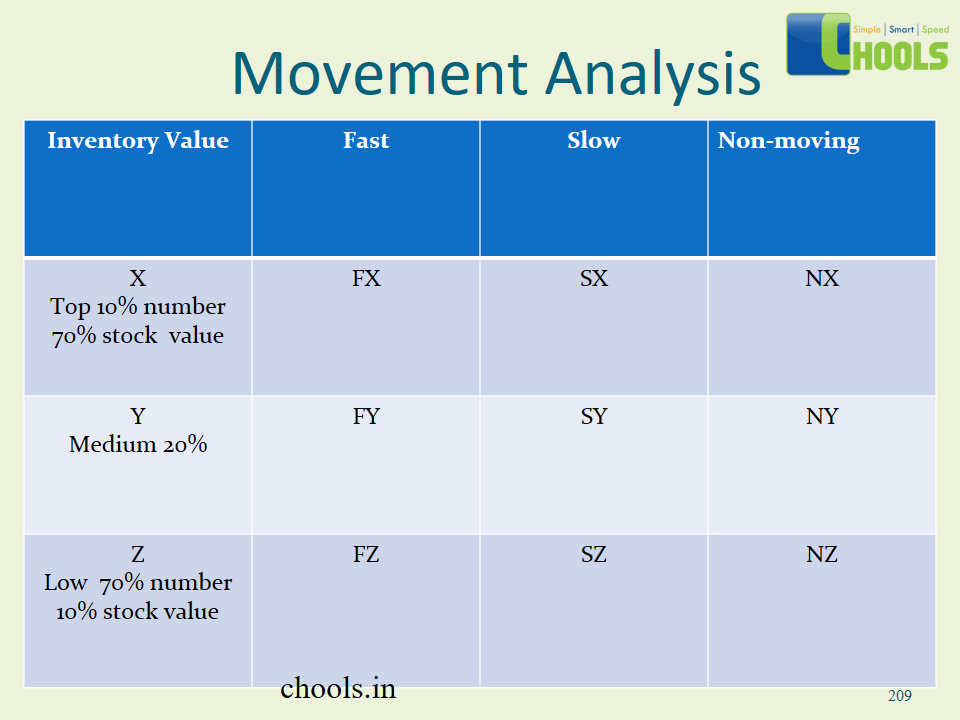

✔ Inventory management and control

➤ We at Chools Consulting, understand the challenges faced by the manufacturing industry. We have a dedicated team to help your growing business face the challenges, decrease costs, and optimize the supply chain to attain operational excellence.

Manufacturing Operations Consulting - The Best In The Business - Case Study

Problem –

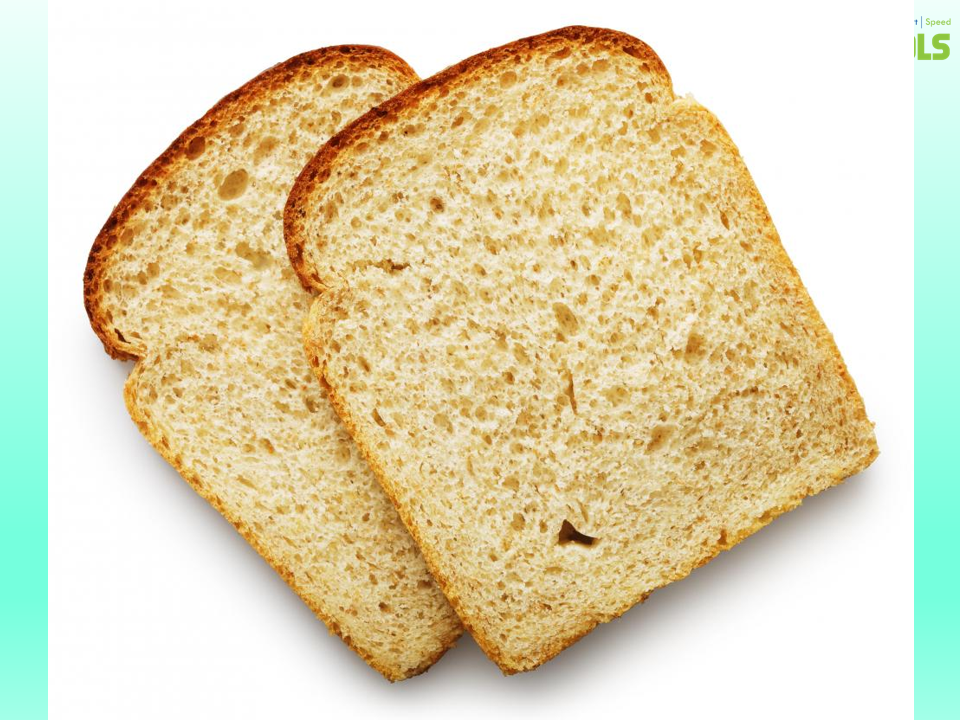

A company which was known for their premier offerings in Food and Beverages, was suffering from lost output, high amounts of rework and waste during assembly. The problem lay in the reductive process followed in the assembly line. Every item had to be picked up from the delivery belt, reoriented and fed back into it. A second component was taken from the delivery belt and kept on top of the first one, before it went for packaging.

There were 6 such assembly stations, each with 2 packing lines. The packing lines were set to run at 120 units per minute, but the feed rate was actually 108 units per minute.

This was attributed to assembly issues, and needed to be addressed immediately. In addition to this the operators’ morale was low, as they were simultaneously worried about the waste that was being generated, while being told by management to increase efficiency and keep costs down.

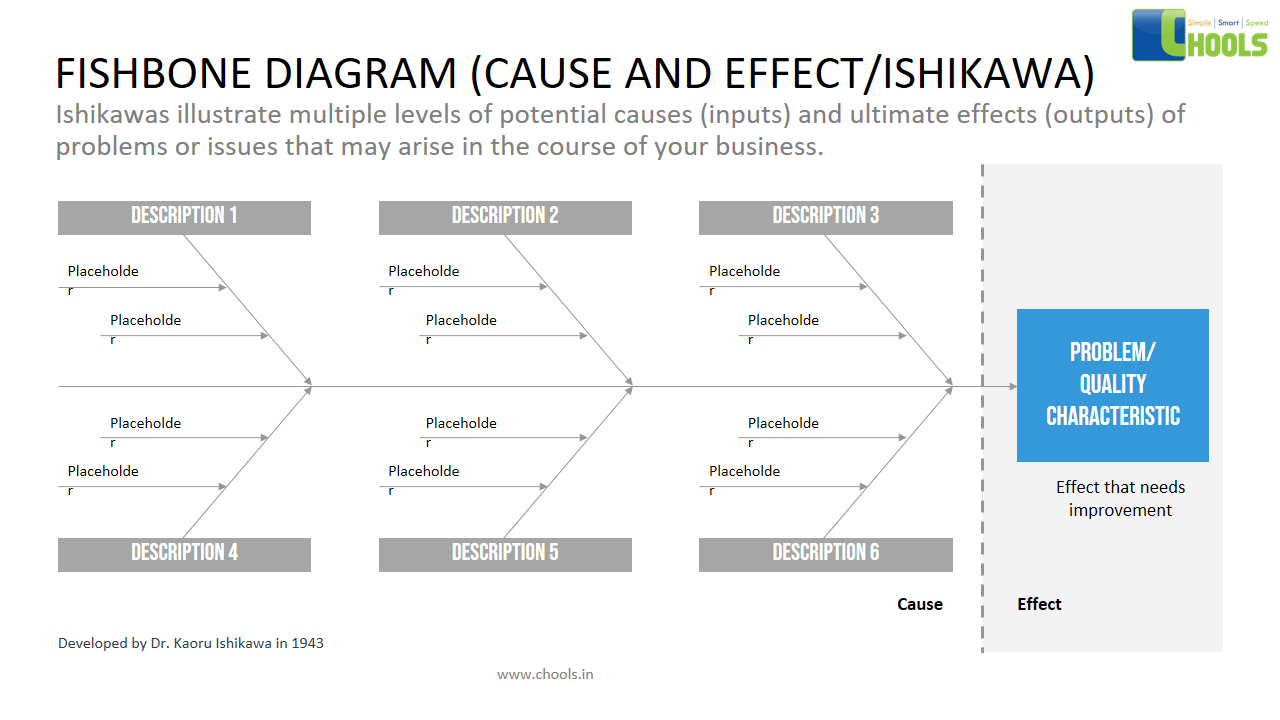

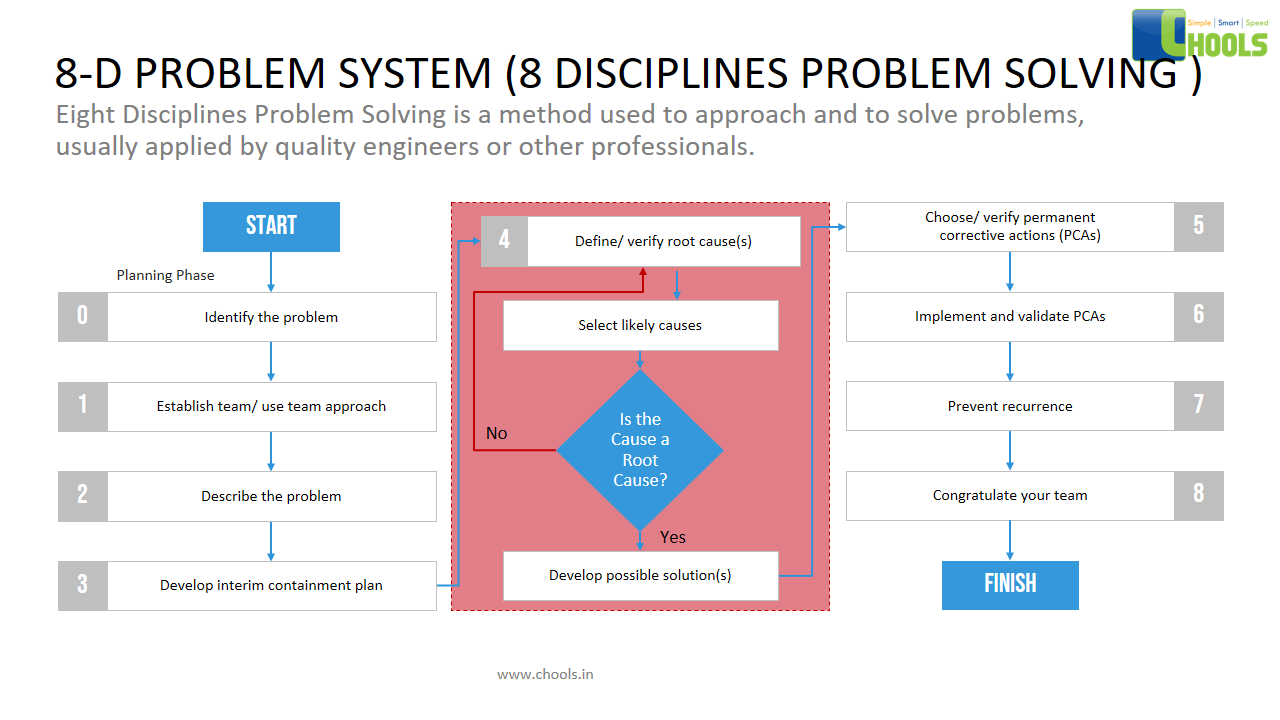

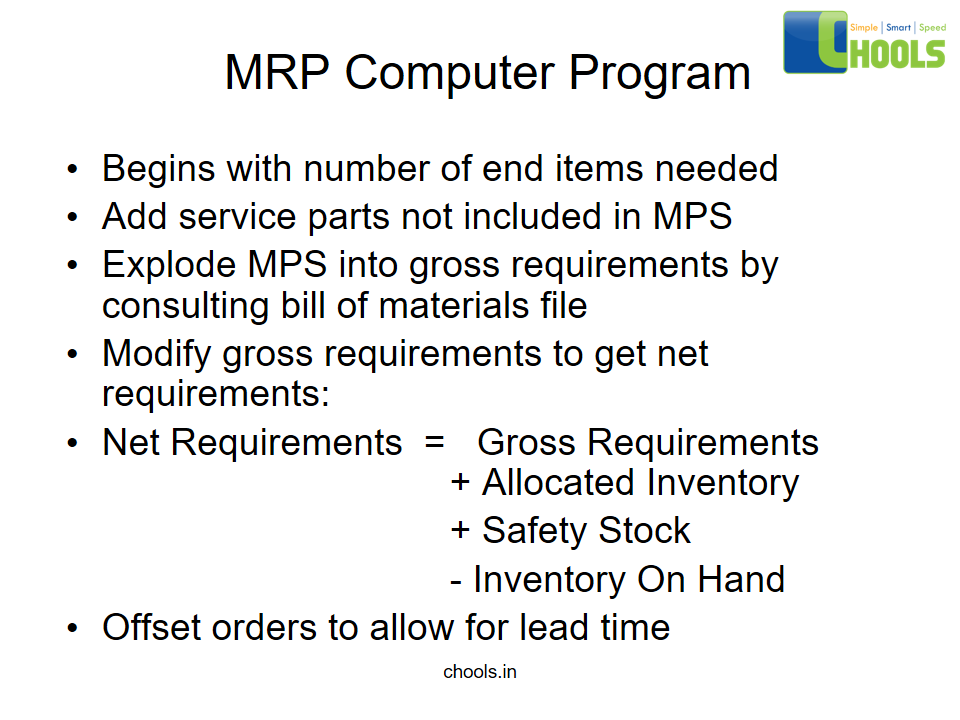

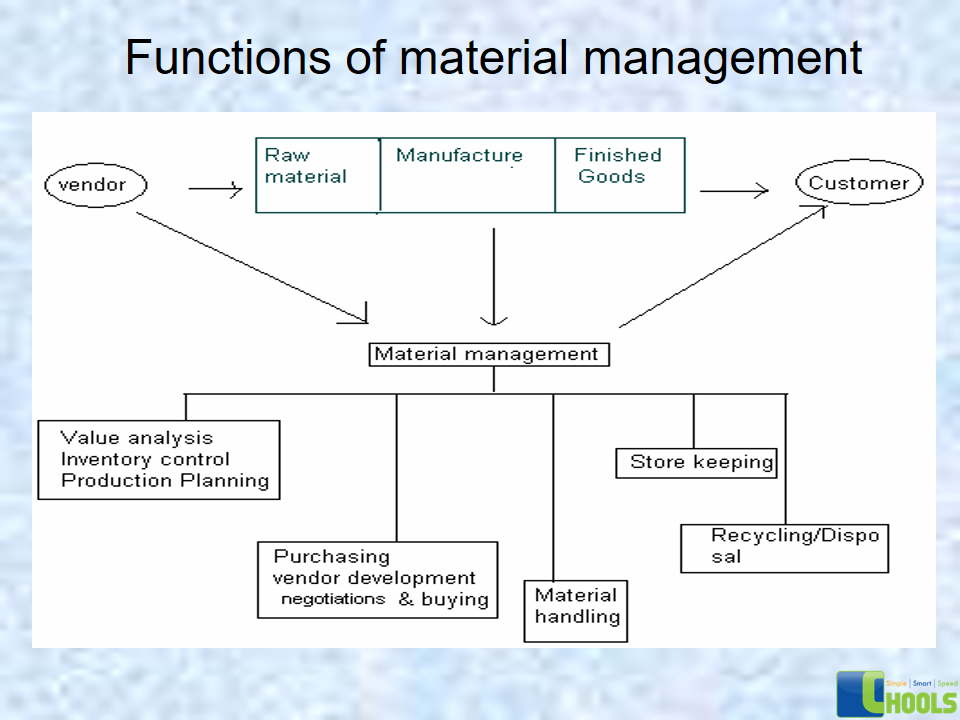

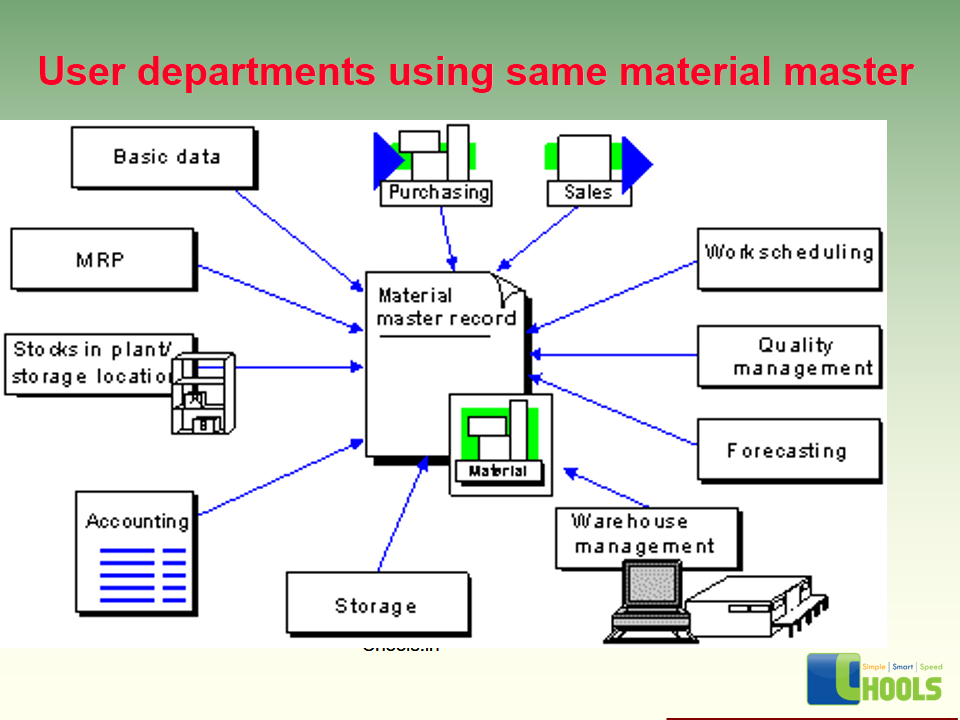

Some of the issues that were identified were –

✔ The pick and place robot was not accurately picking and placing the product.

✔ The product was being picked up, but before reorientation and delivery to the correct location, it was dropped off.

✔ Inaccurate placement of product.

Solution –

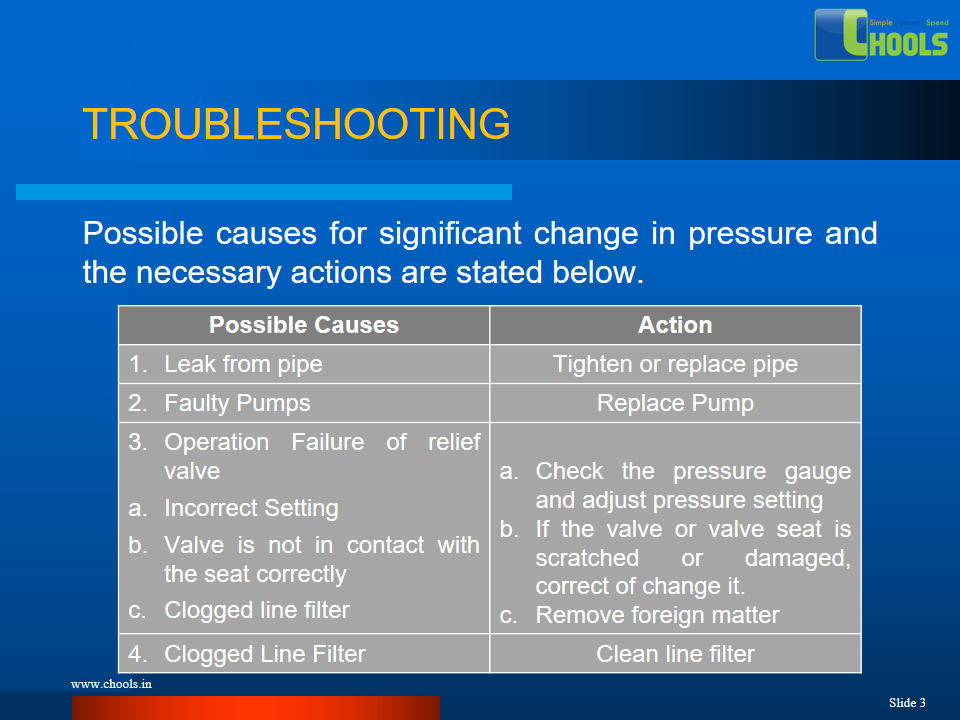

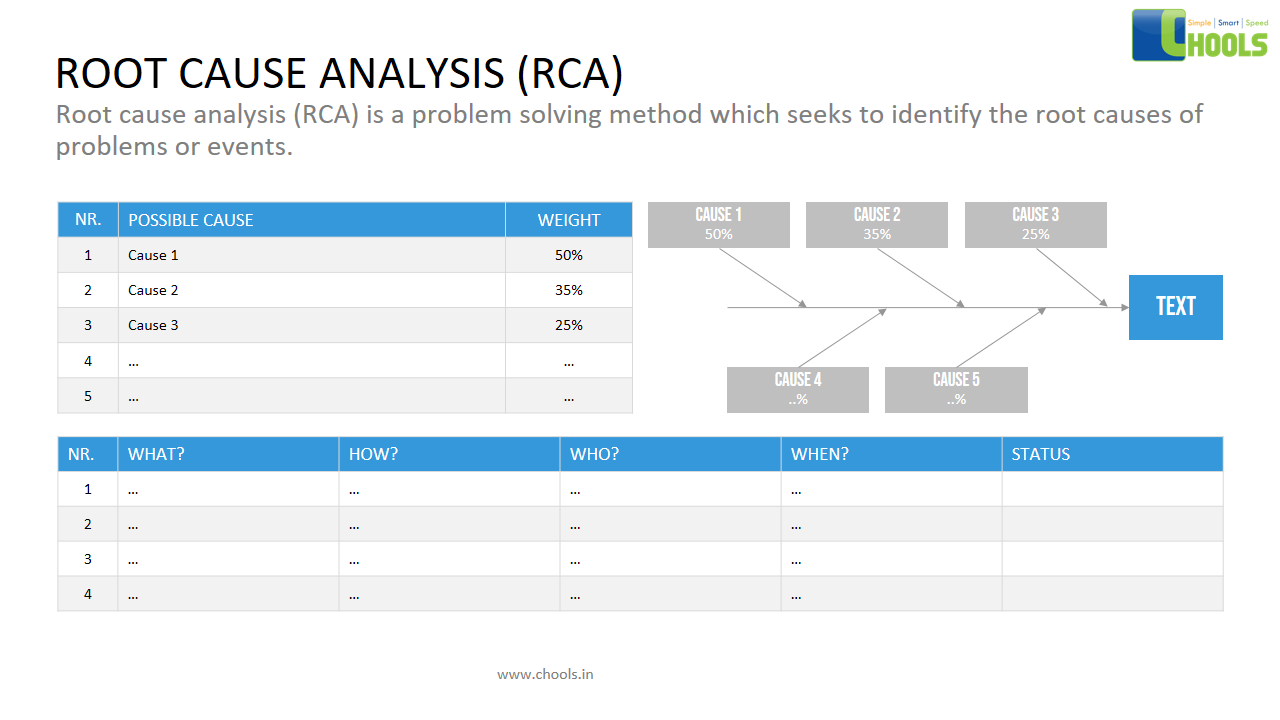

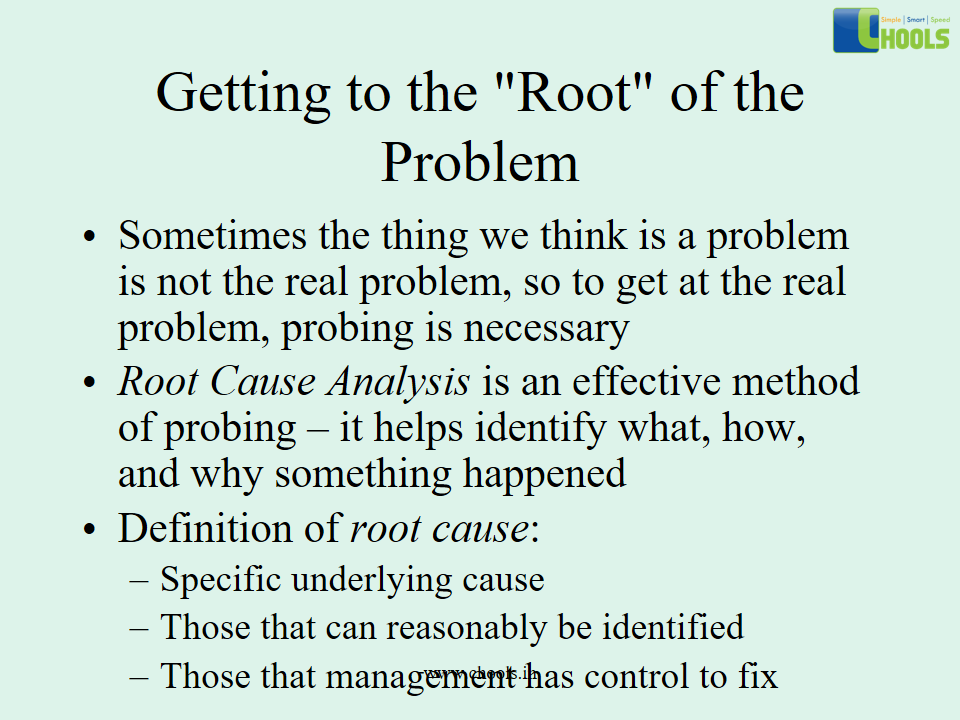

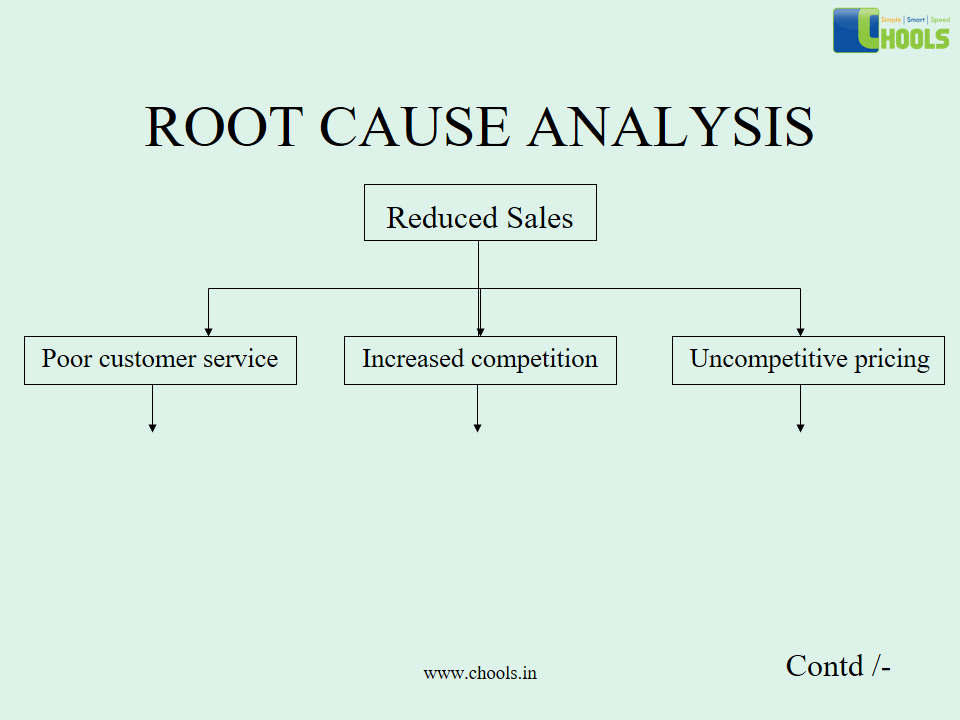

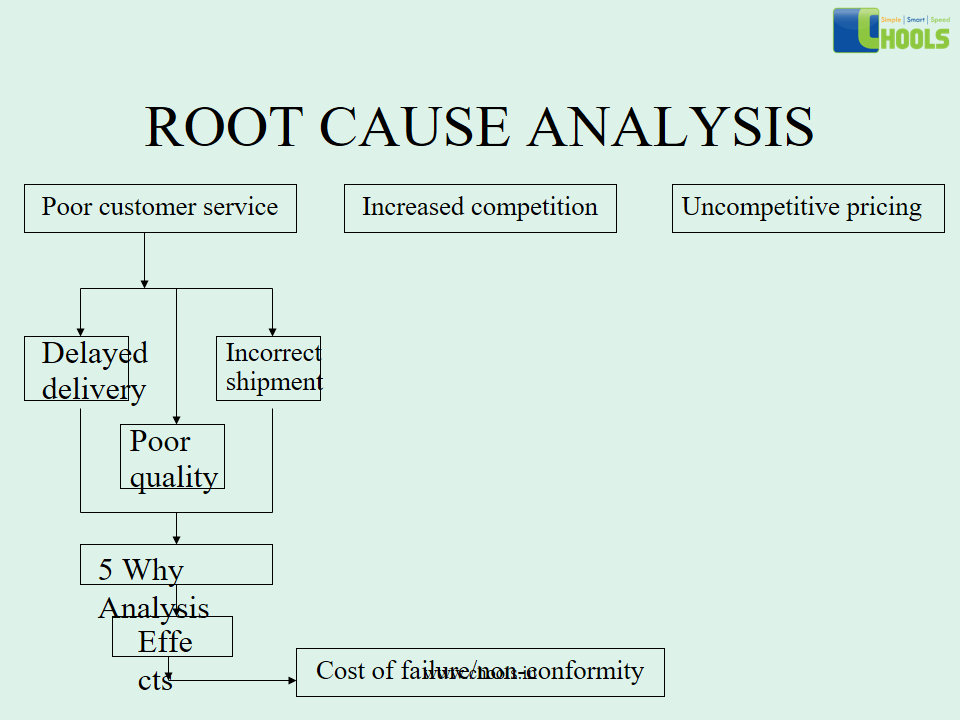

Insufficient vacuum at the picking head of the pick and place machines was identified to be one of the problems. A faulty control valve was another. Some of the root causes that were identified were.

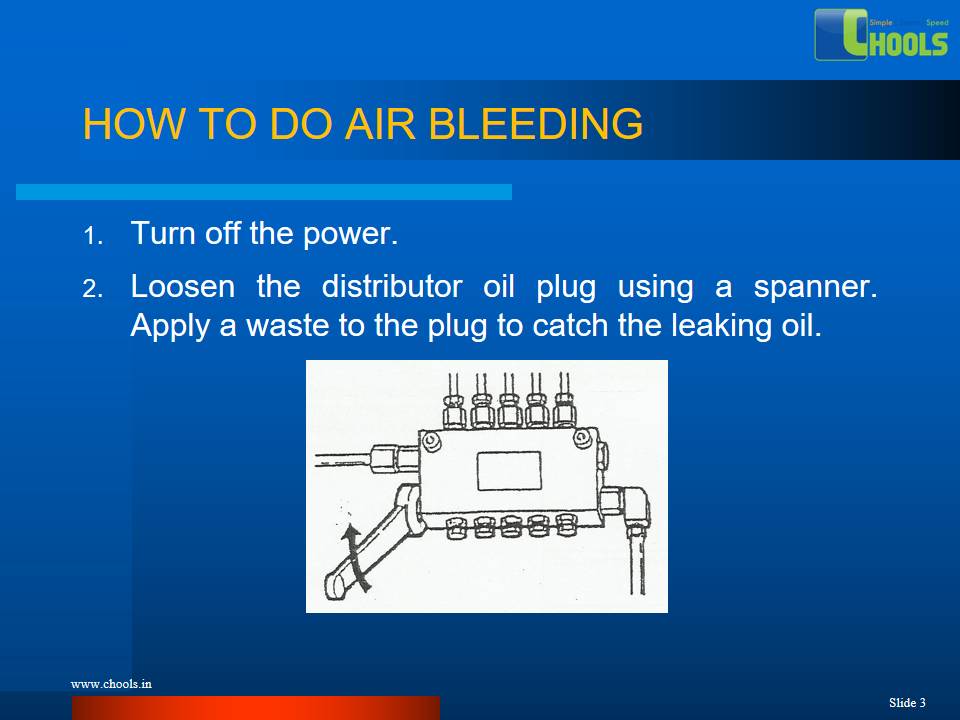

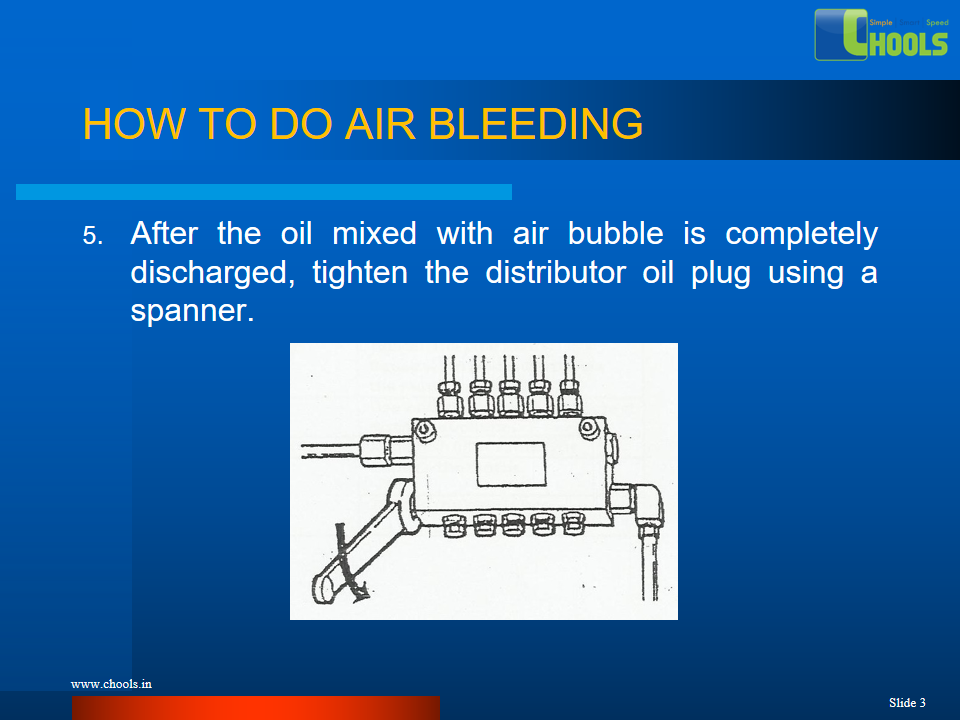

✔ Gaps in the pipe work.

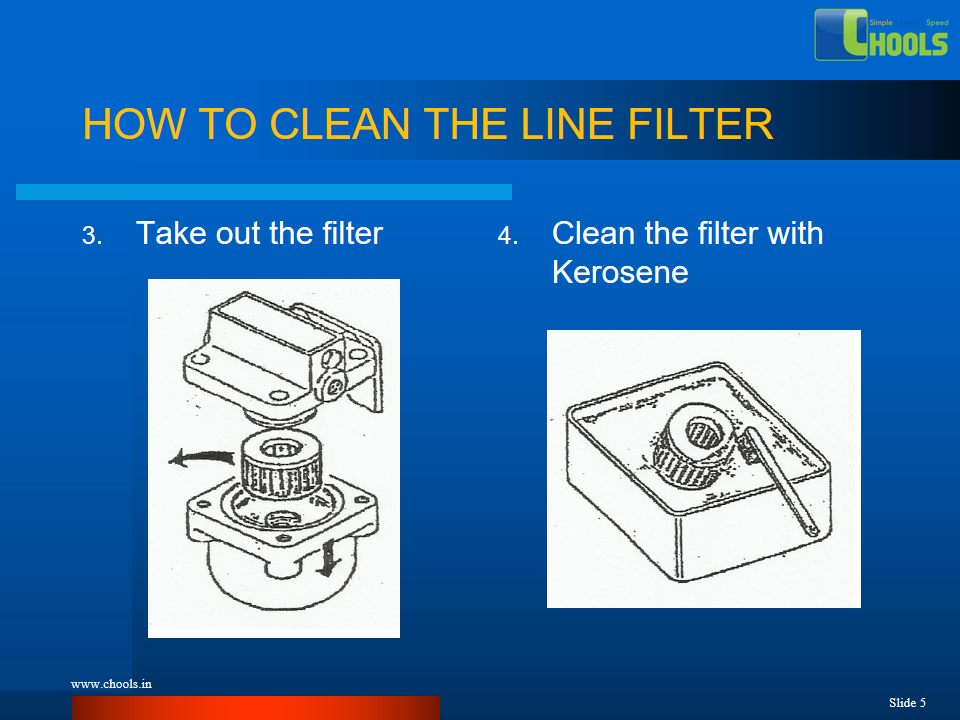

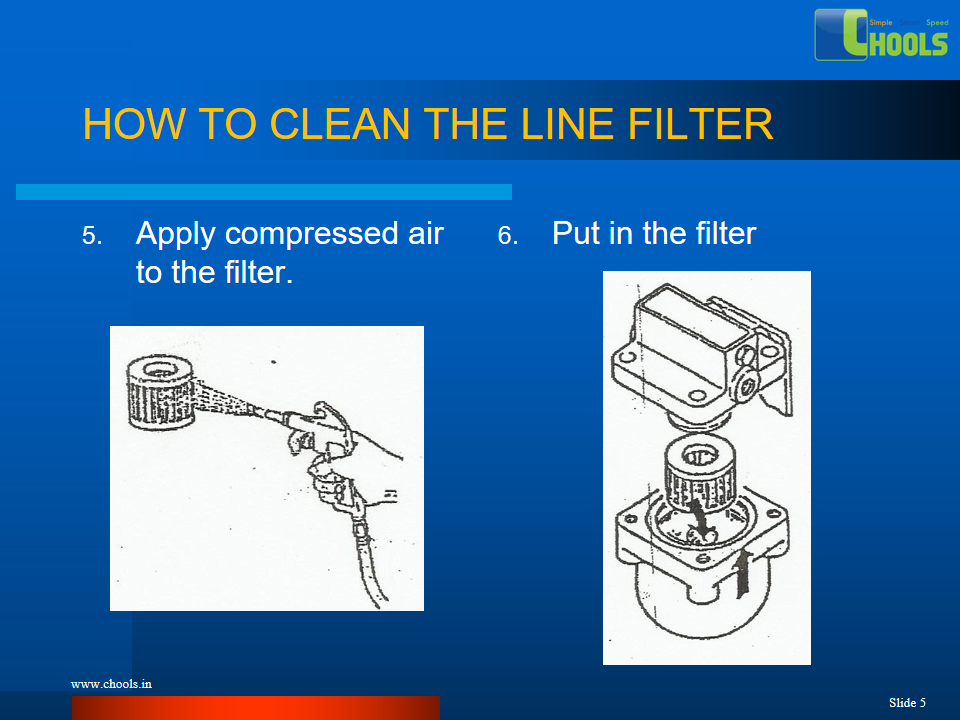

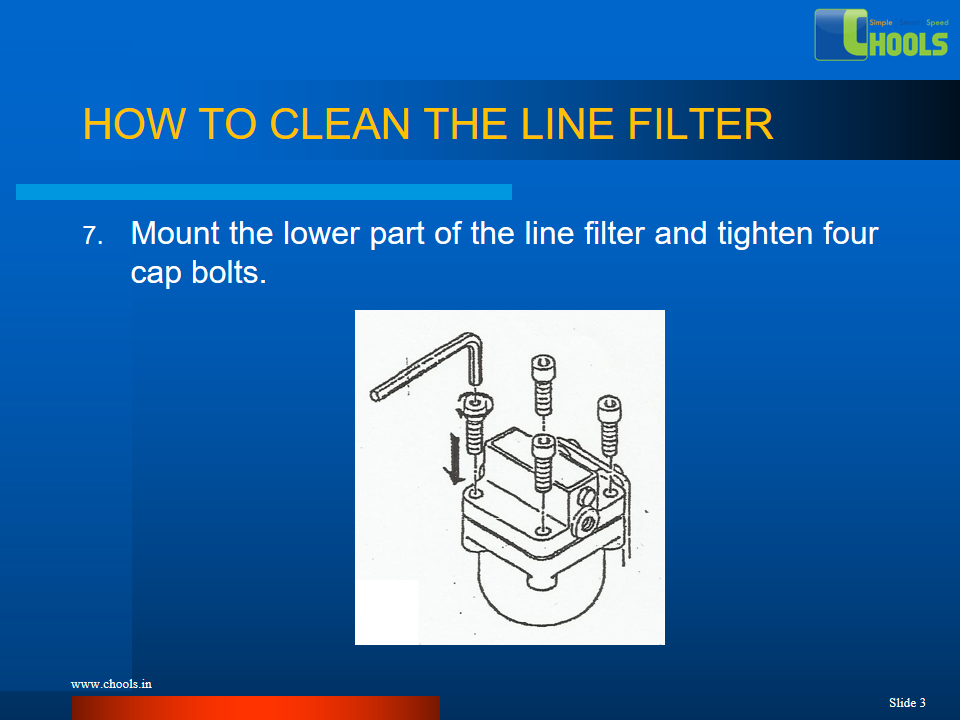

✔ Dirty Filters

✔ Damaged Suckers

✔ Insufficient amounts of Vacuum being generated.

After tightening several loose connections in the vacuum pump, a significant improvement was seen in the overall functioning of the plant. Still, there was scope for improvement.

The damaged suckers throughout the delivery line were replaced with fresh, working ones.

It was found that the operation of the vacuum generator was hampered due to a faulty control valve, which was swiftly fixed.

Result –

A 16 % increase in speed of the pick and place machines, and increased speeds of 42 units per minute.

The Challenge

➤ The client was a global leader in FMCG Packaging sphere. The applications and technologies utilized by the company were integral in the development of their products, which were launched into major markets.

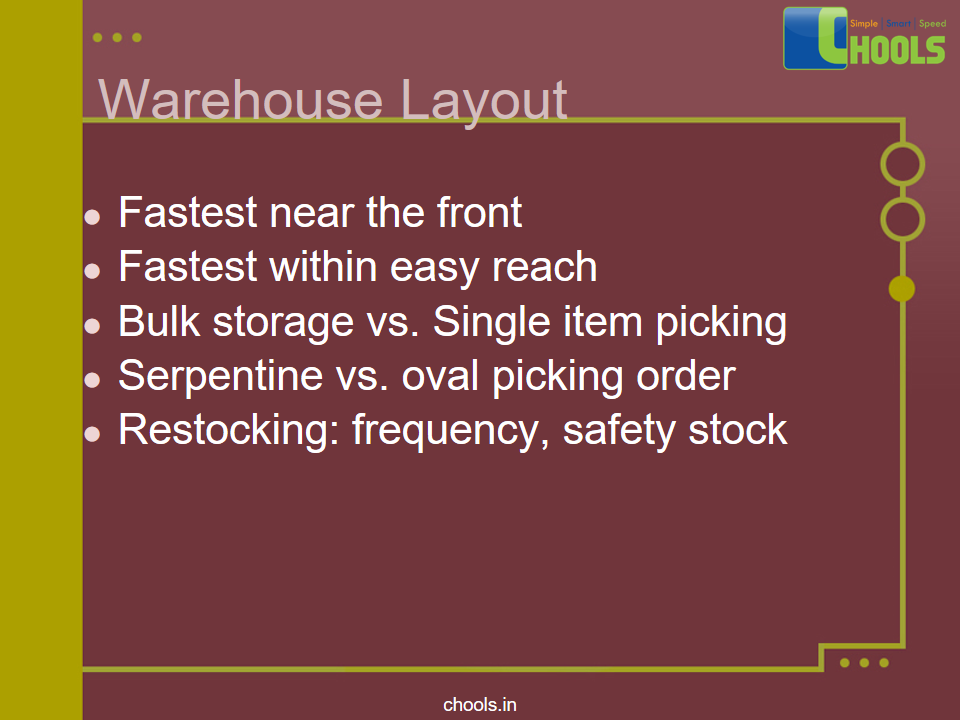

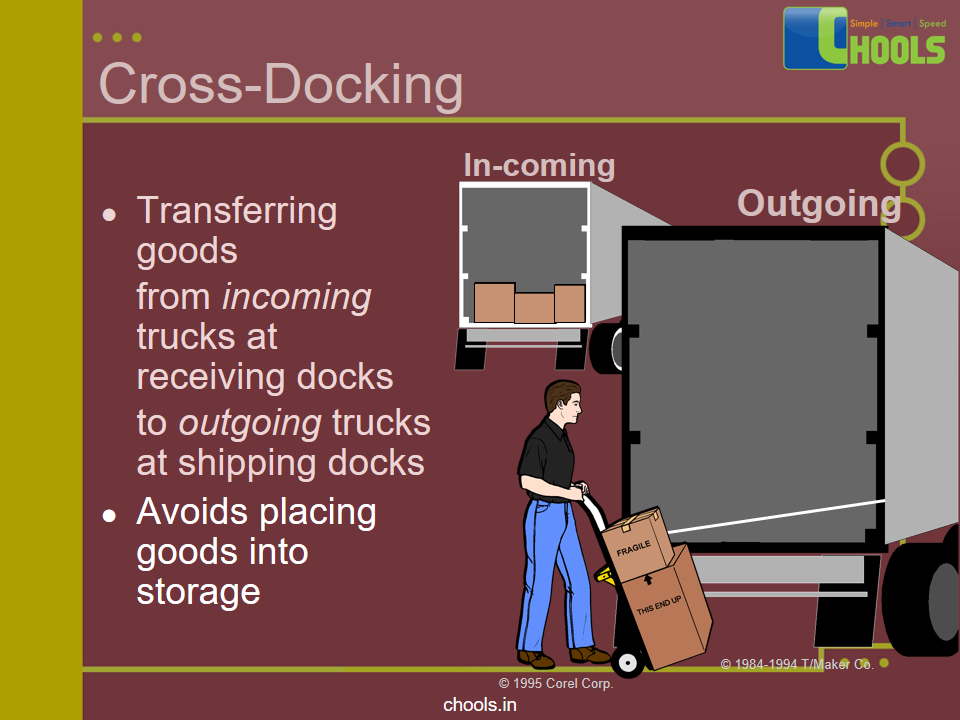

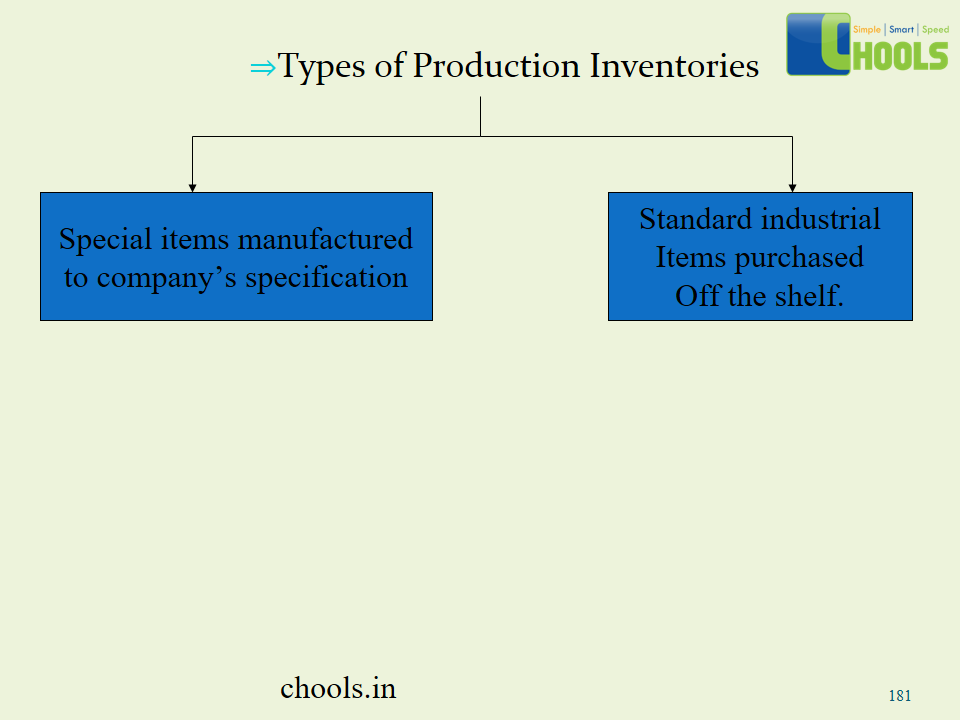

➤ The company was looking to validate and optimize the raw material and finished goods inventory, across manufacturing plants and the concerned distribution warehouses.

Production capacity constraints had to be considered, and the related inventory policies had to be redesigned.

The Solution

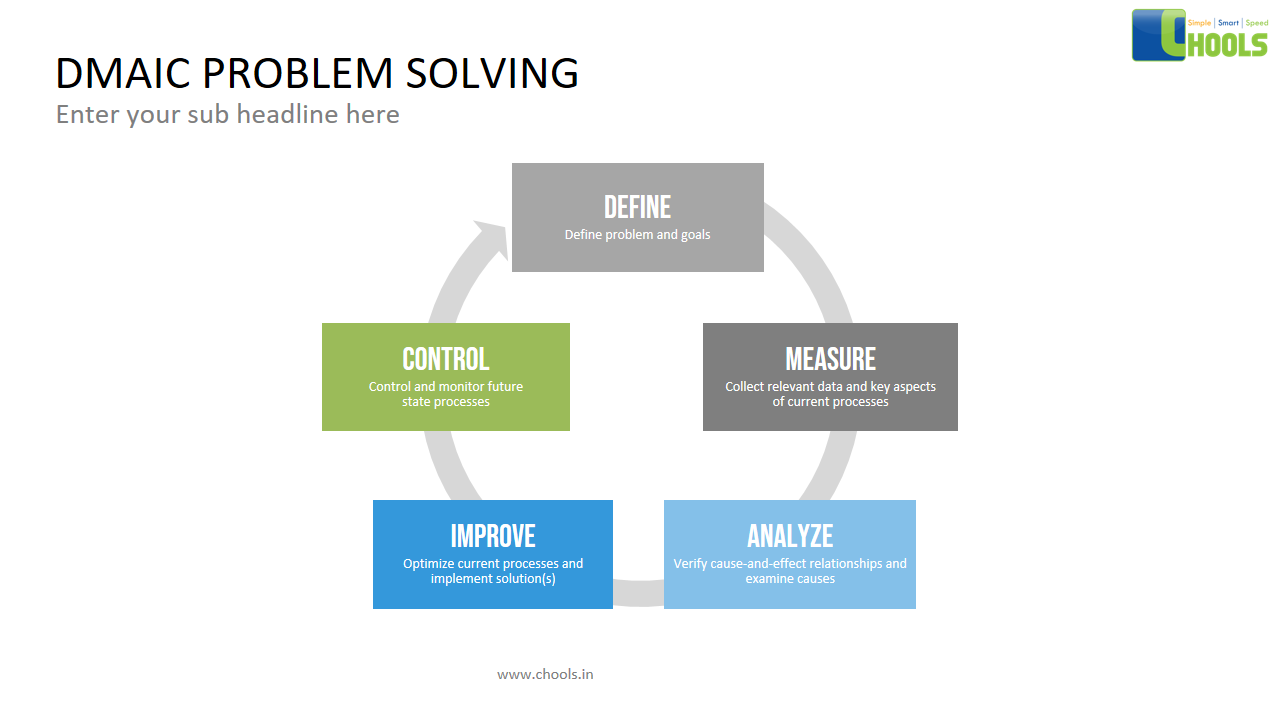

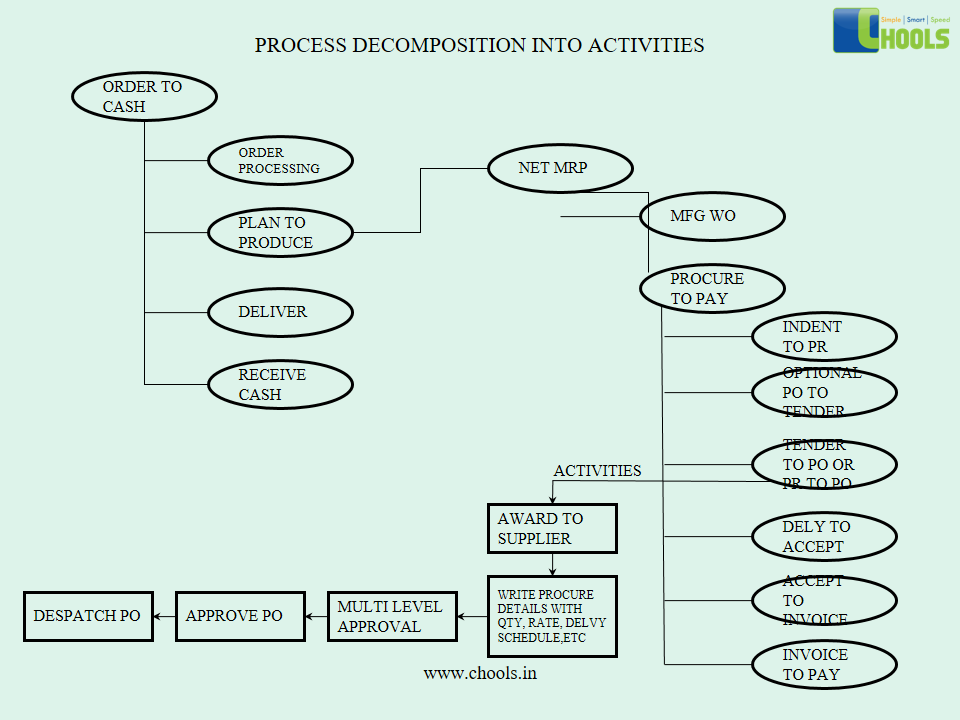

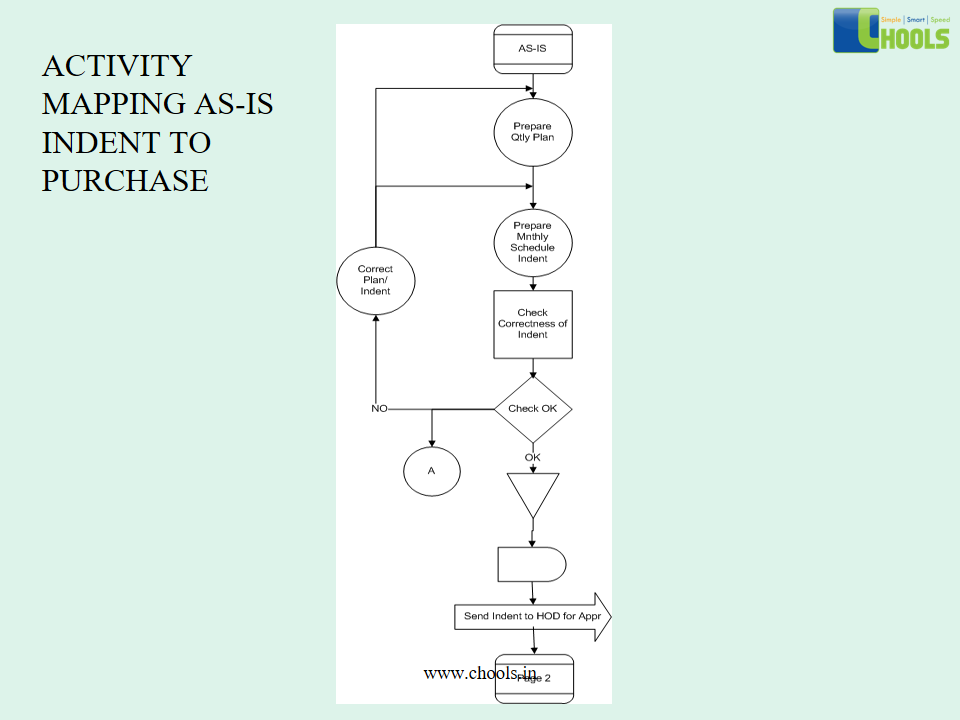

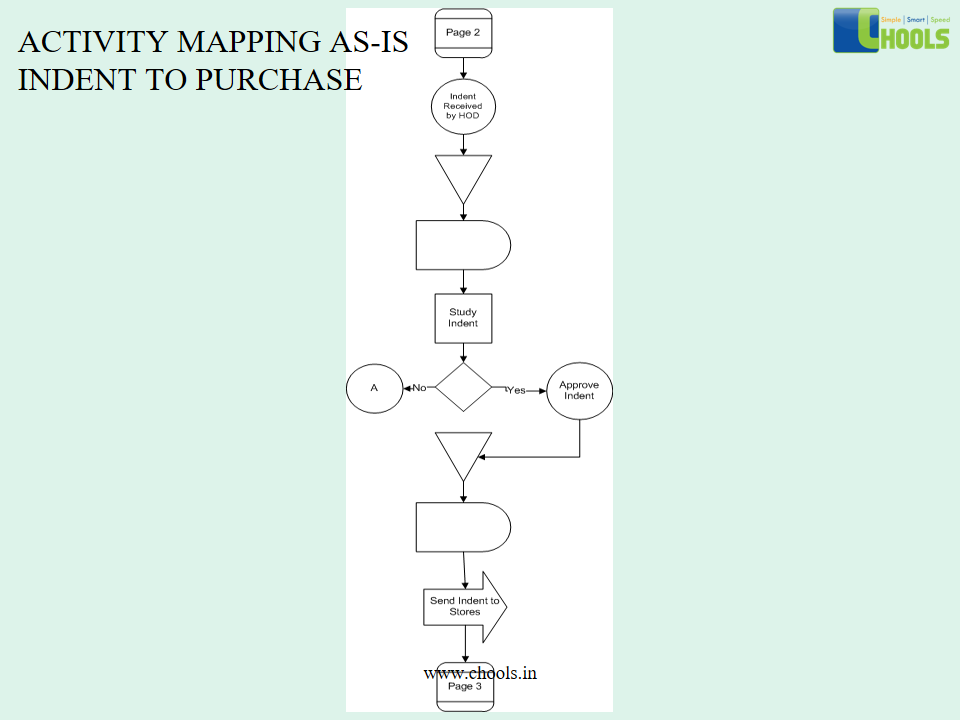

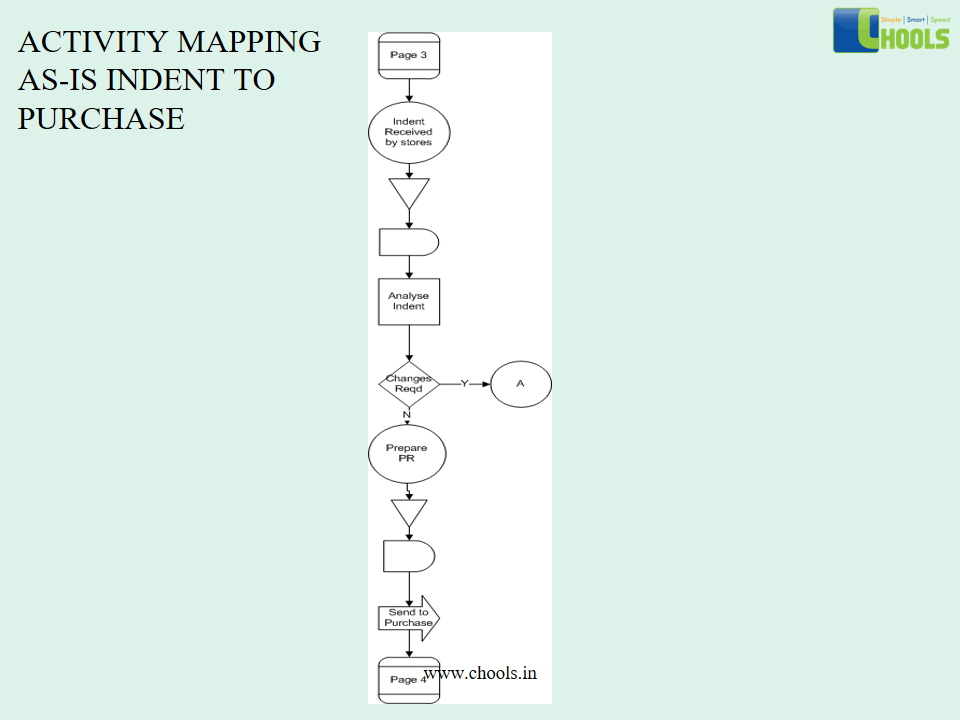

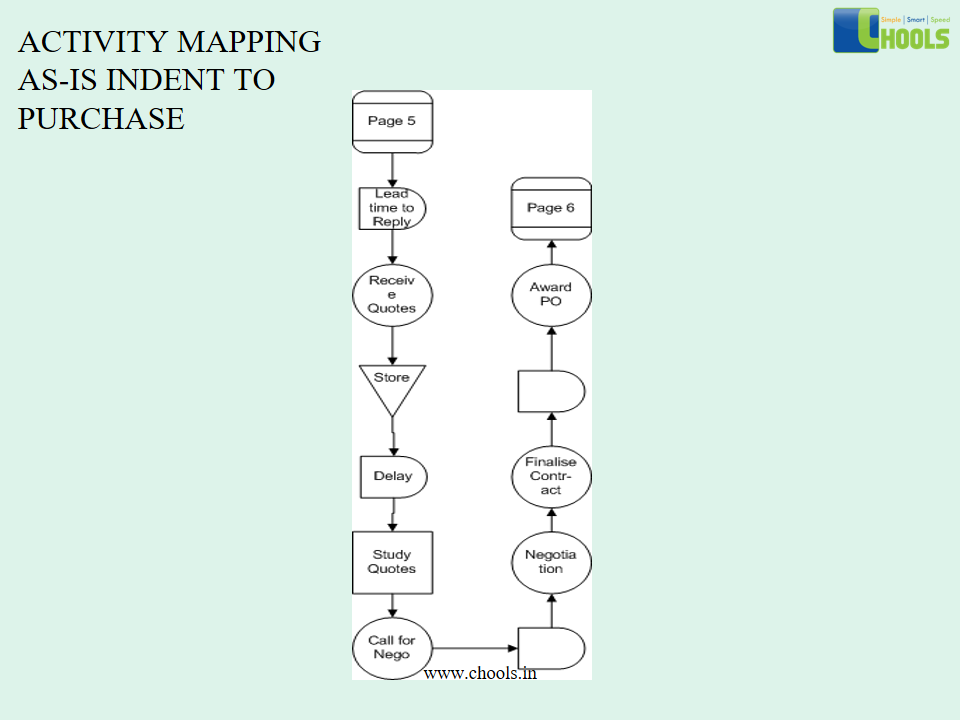

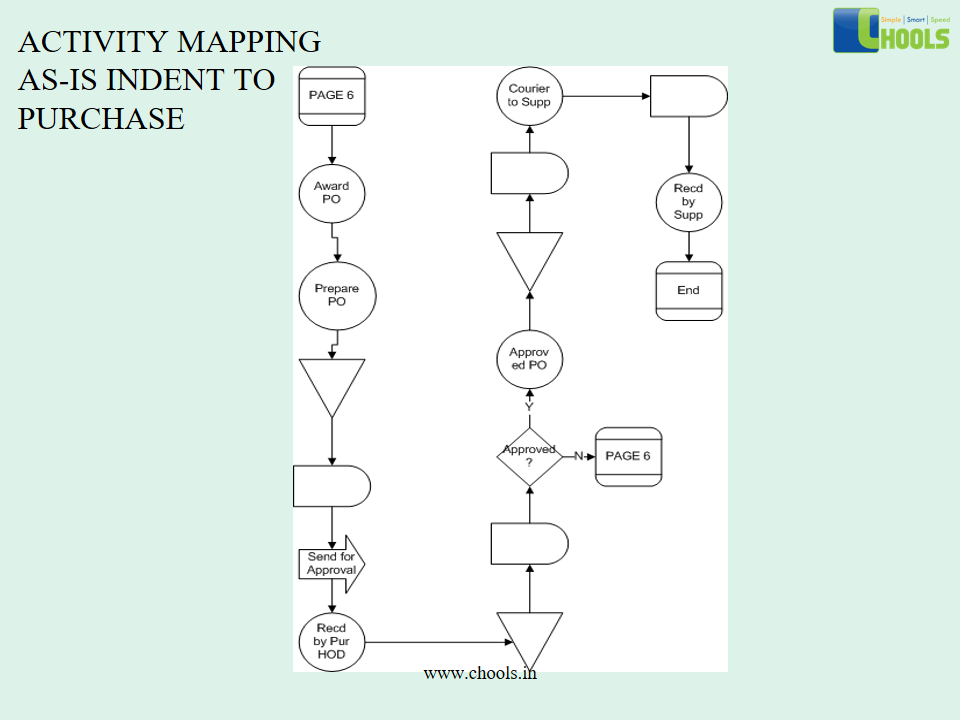

➤ Chools initiated As-Is Process Mapping and the Gap Analysis. Current inventory planning processes were diagnosed. Procurement and Material management were addressed. Sourcing lead times and related constraints were identified.

➤ Concerning the baseline of the current service levels, Order to Delivery Cycle was ensured and Reliability-Flexibility definitions were used in measuring customer satisfaction.

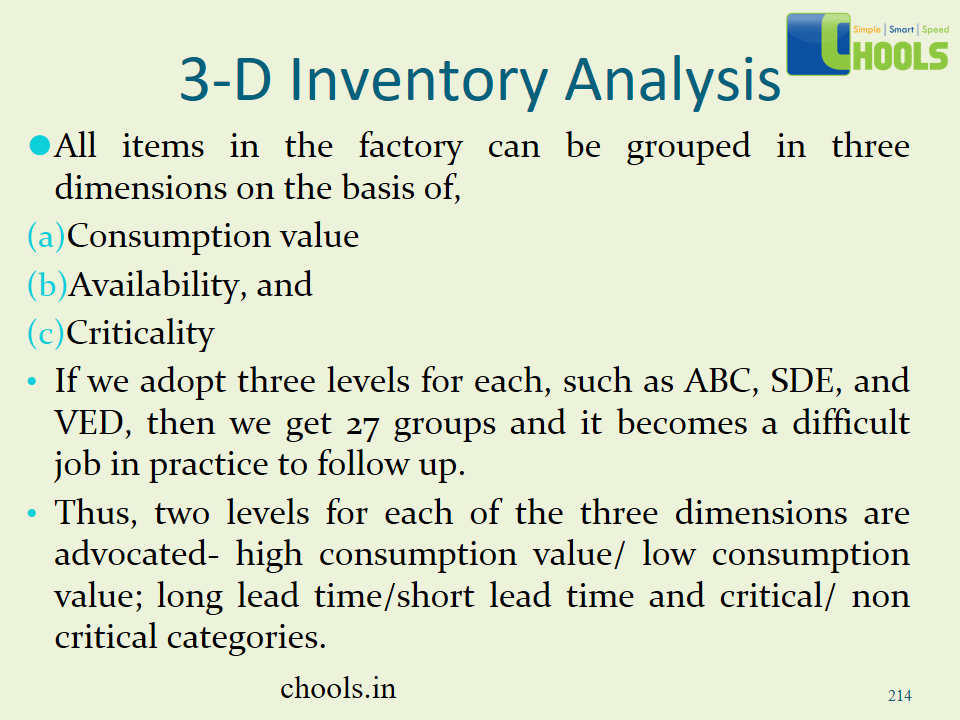

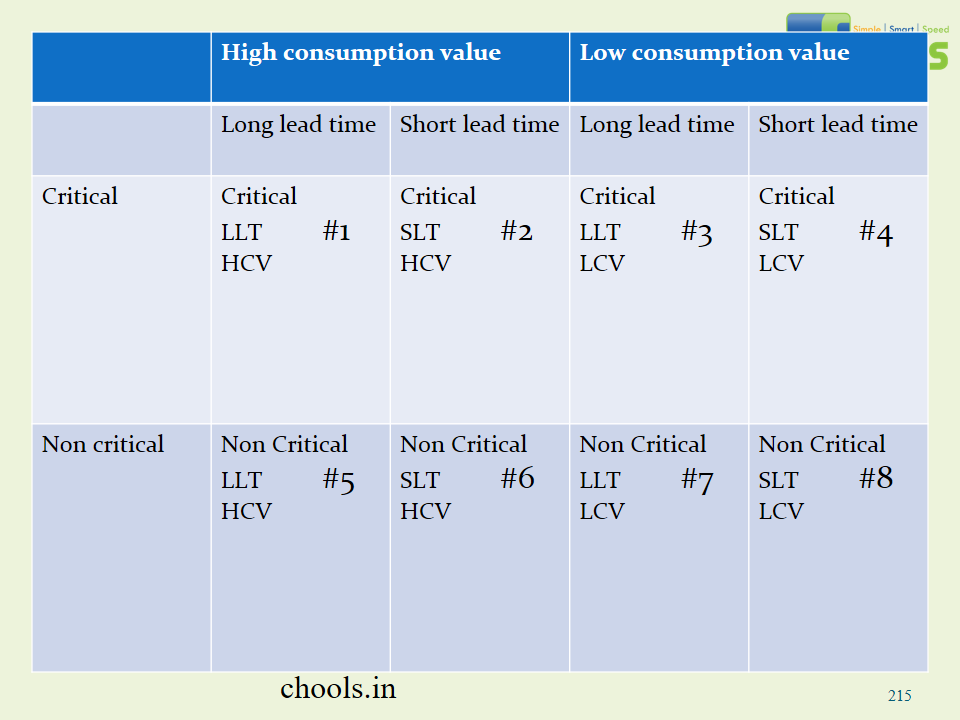

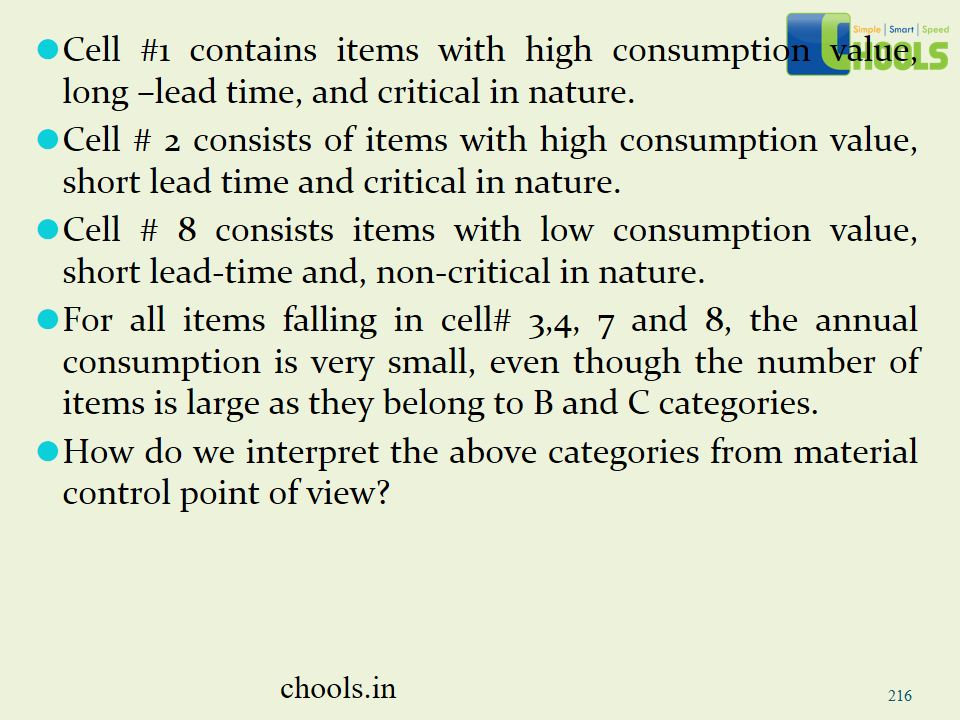

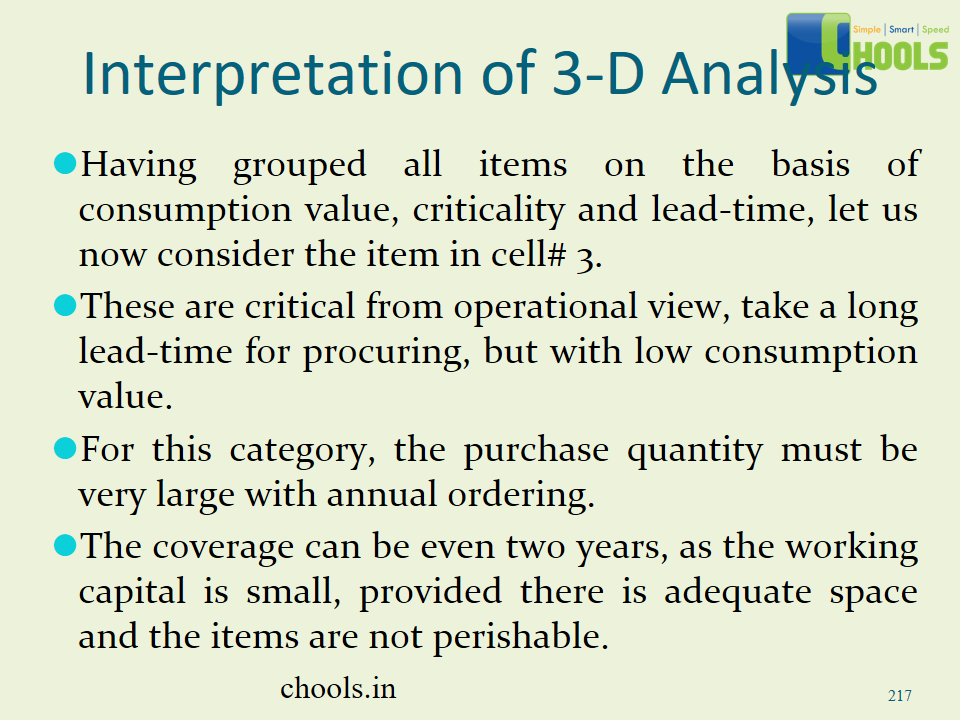

➤ We included Multi-Dimensional Categorization in Inventory Design. The Inventory Model devised was integrated with Demand Cleansing, Outlier Correction and MQQ Constraint Building. We developed a Stocking Policy Decision strategy. The service levels were extensively reviewed.

The Result

✔ The inventory model was designed based on the company’s specific business needs. It accurately catered to the service level requirements, considering sourcing and production capacity constraints.

✔ The solution significantly improved the categorization of SKUs. There was an improved focus on materials for which the inventory norms were defined. That led to the balancing of the stock, within the same capital requirement.

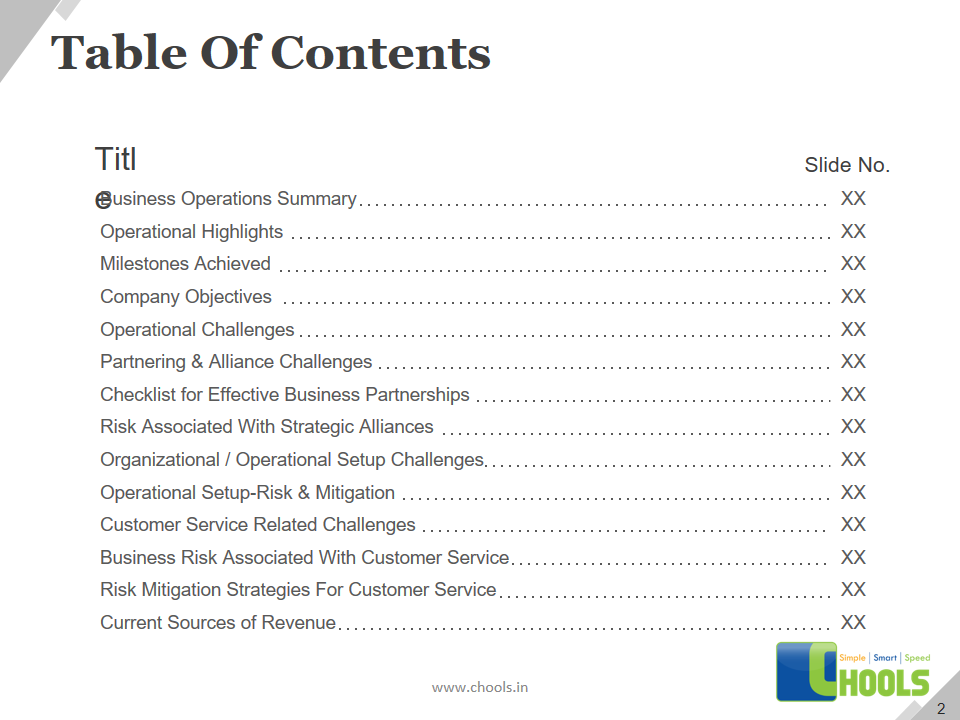

THE BEST IN THE BUSINESS – TEMPLATES

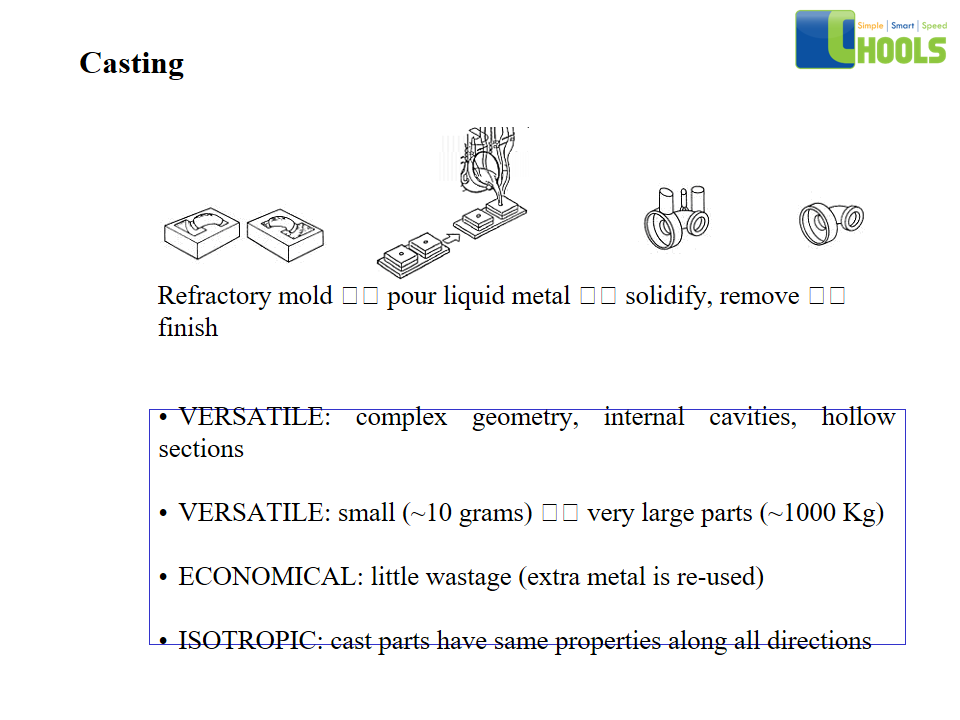

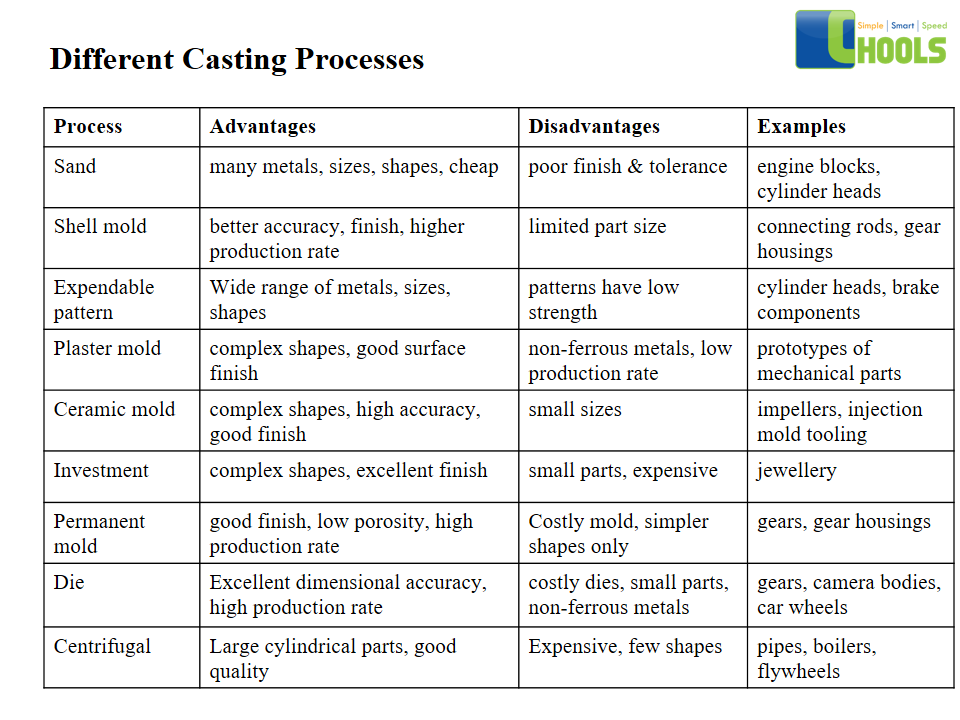

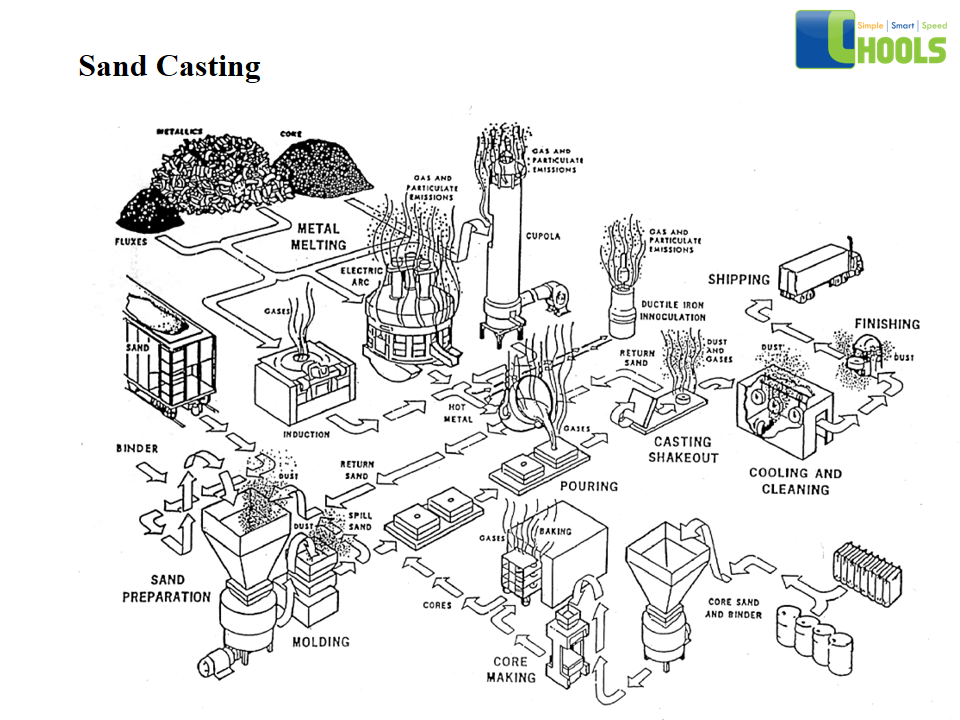

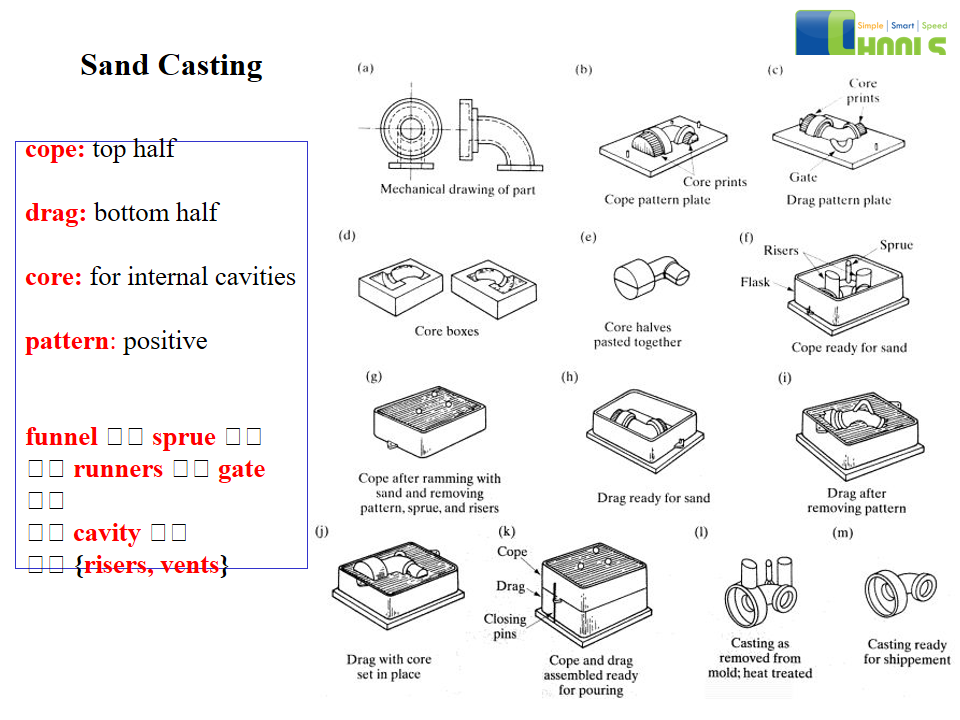

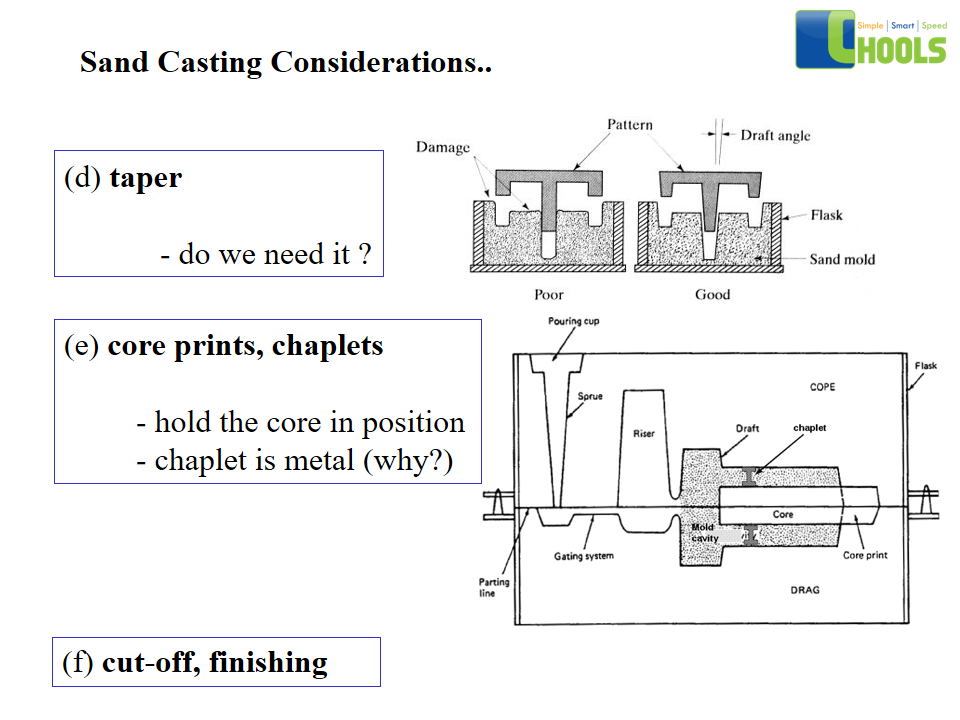

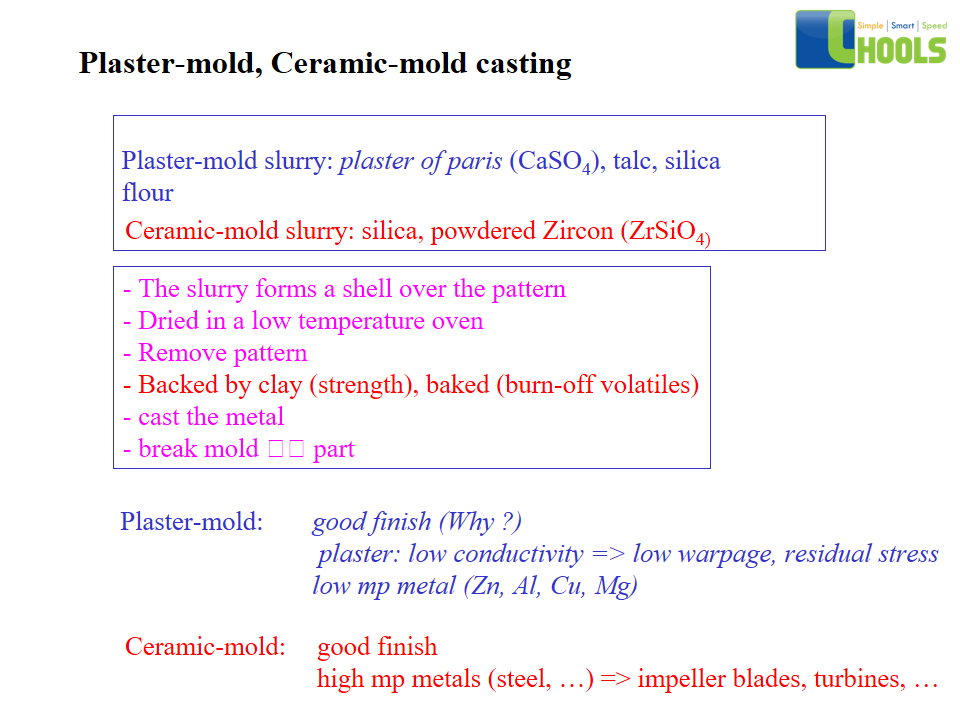

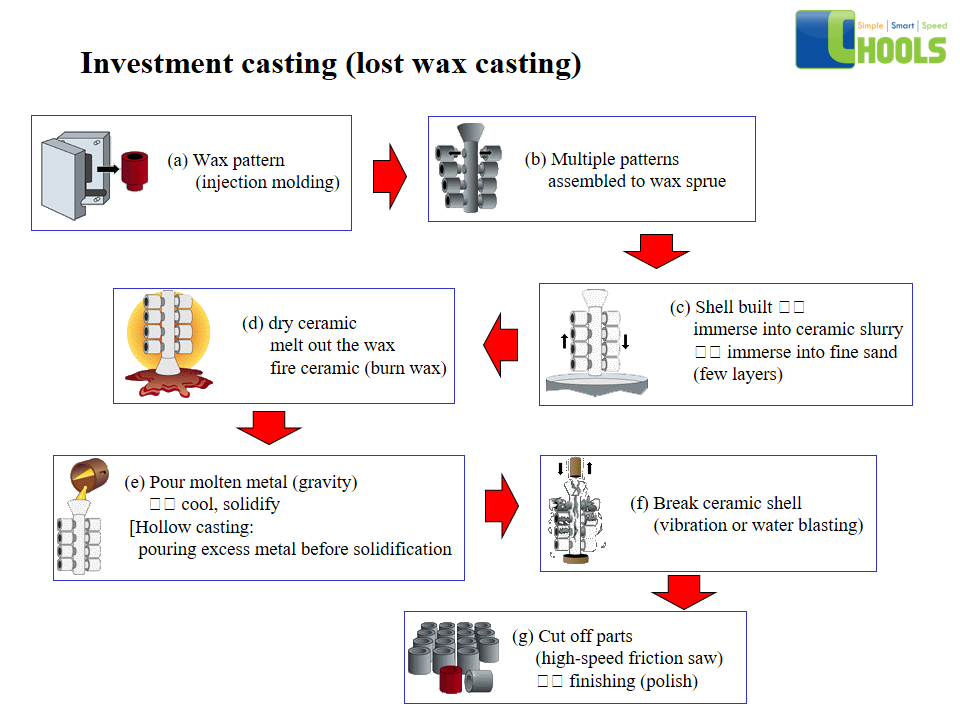

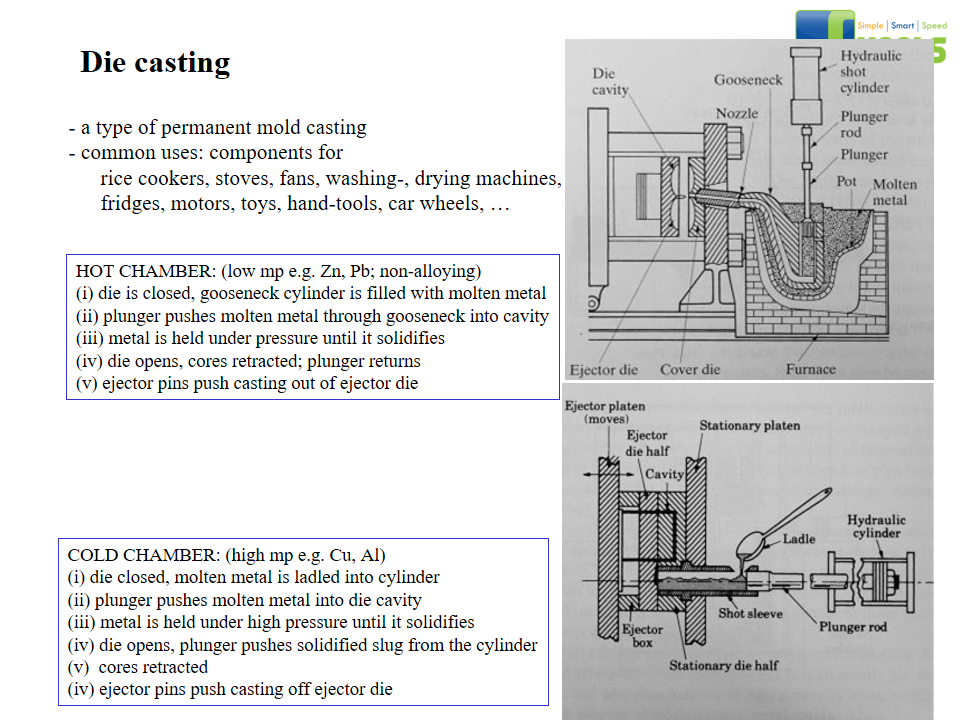

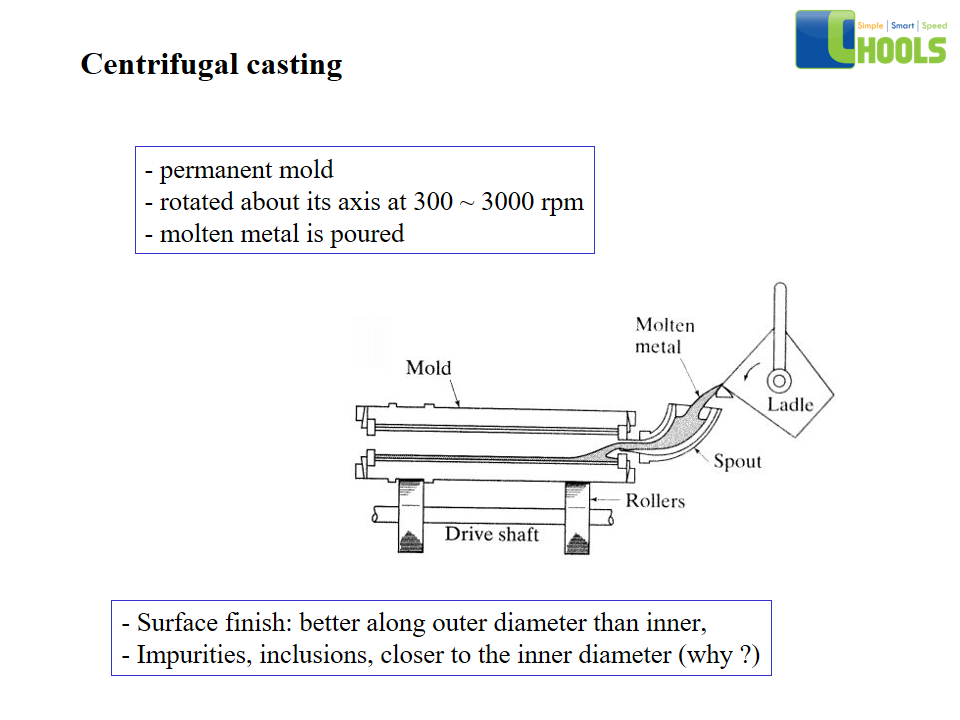

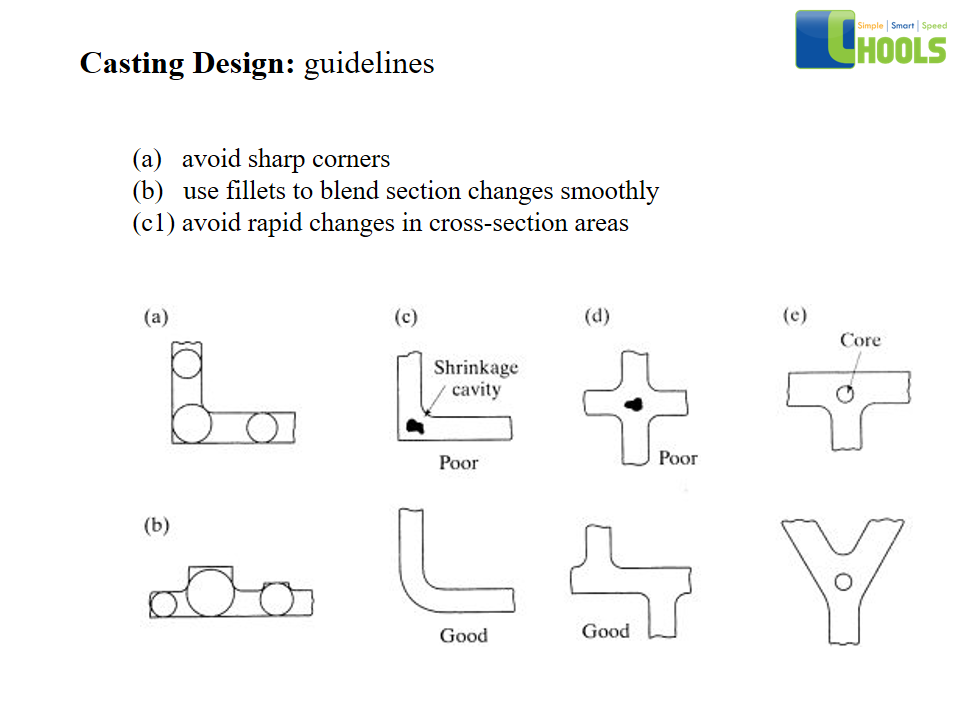

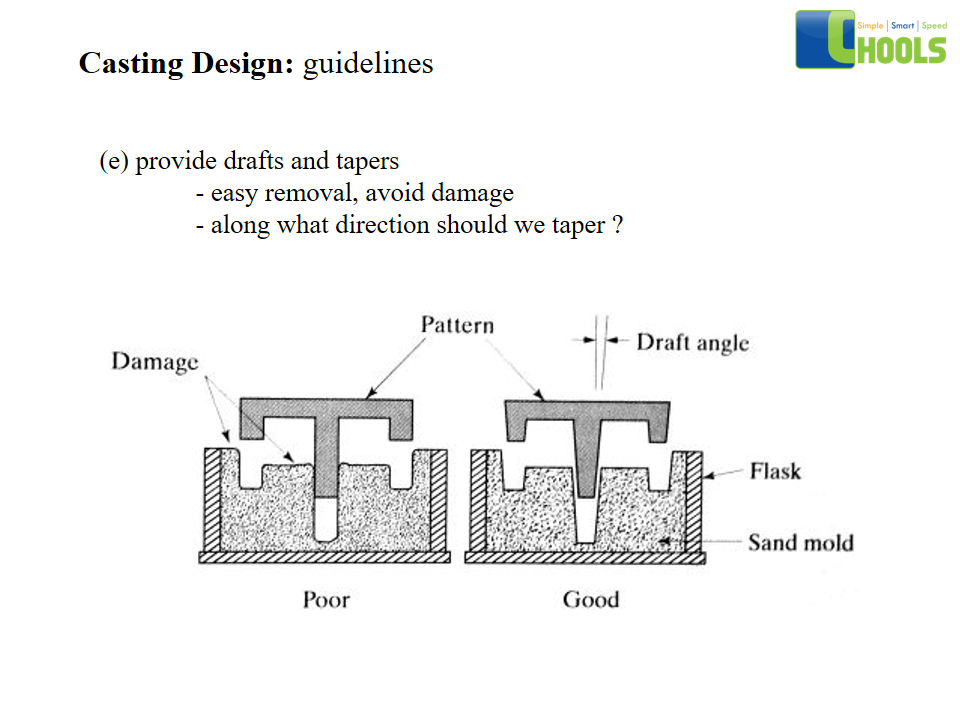

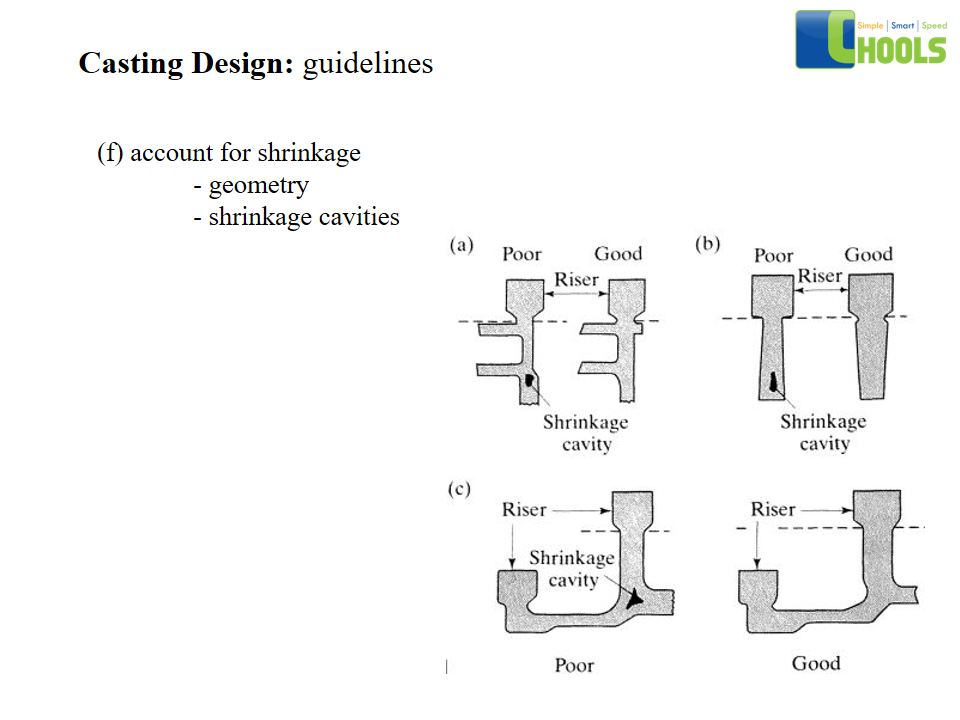

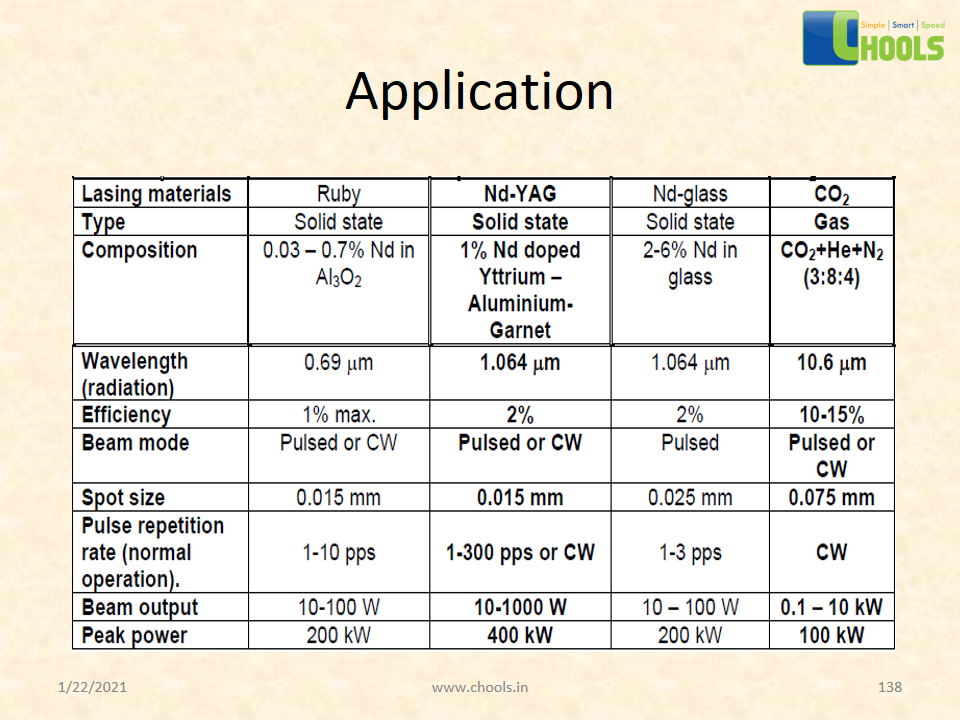

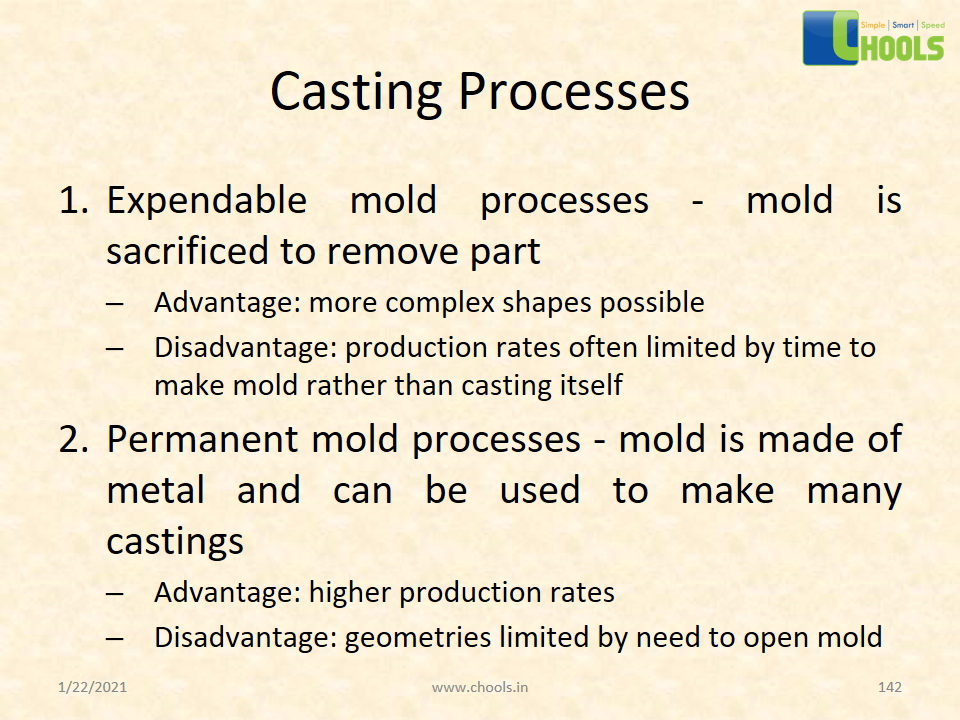

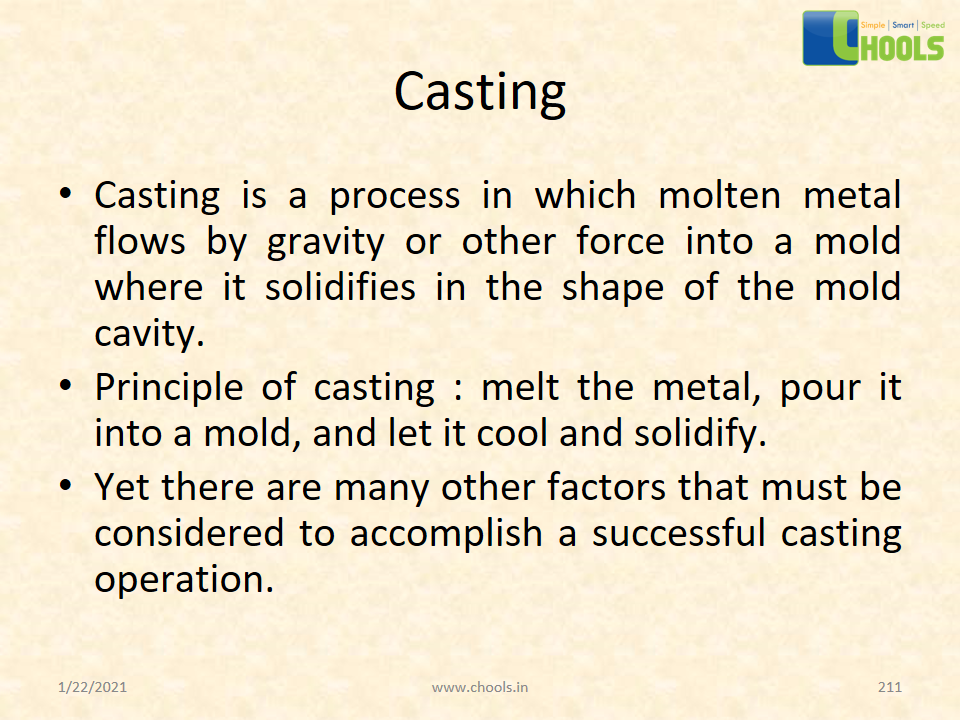

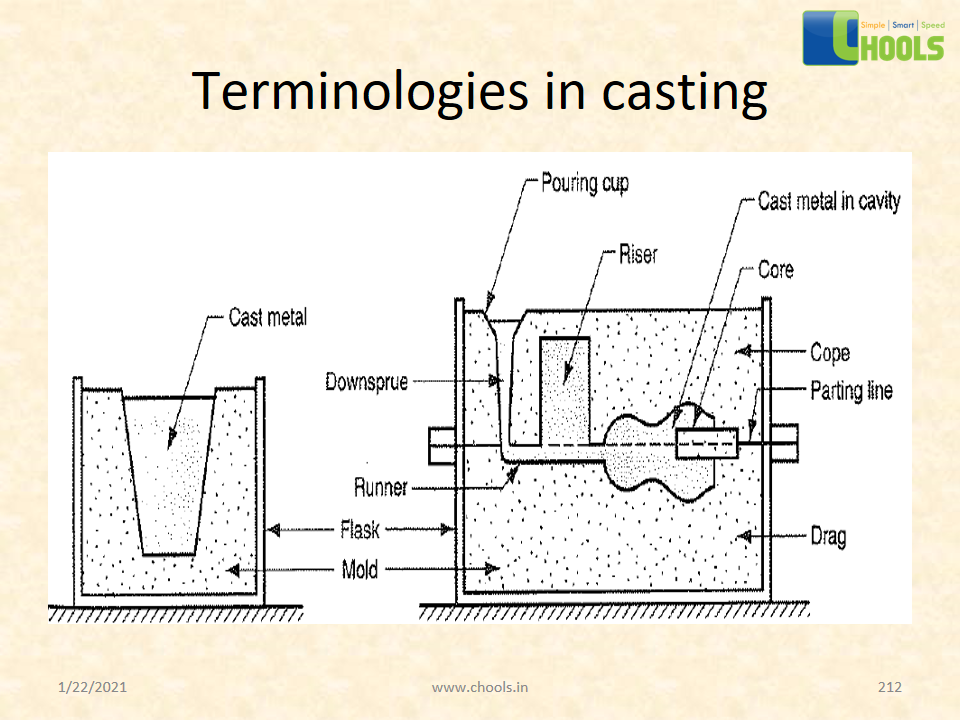

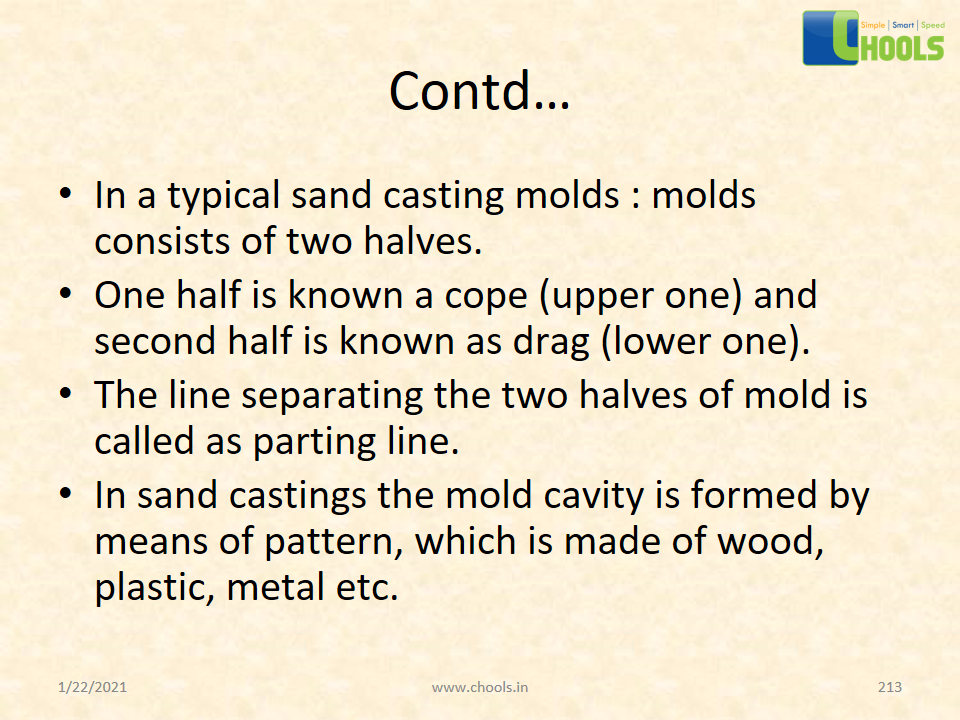

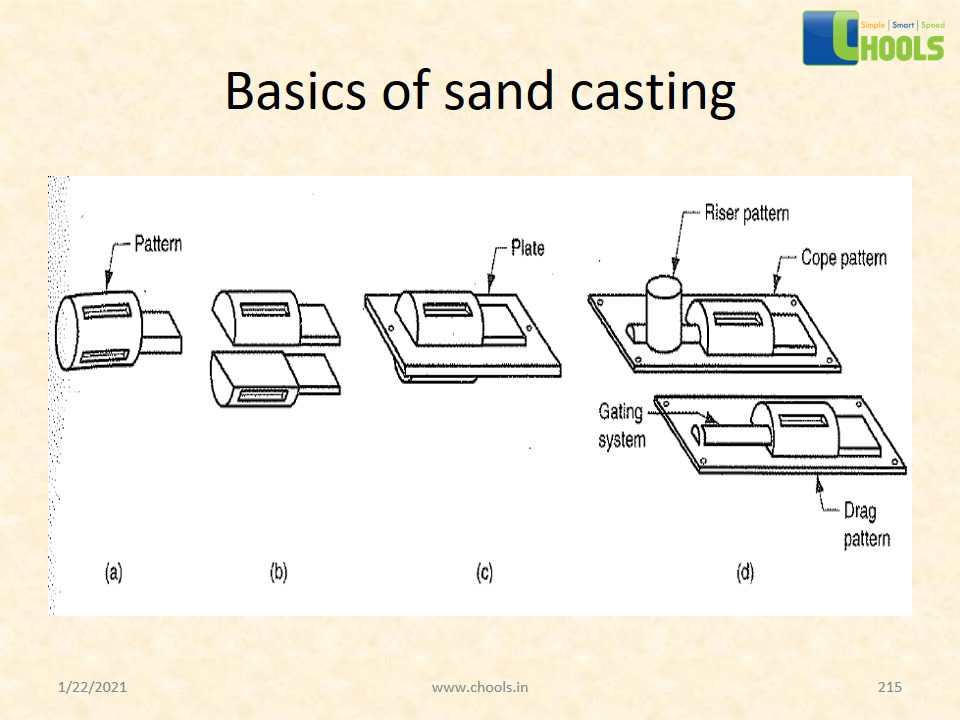

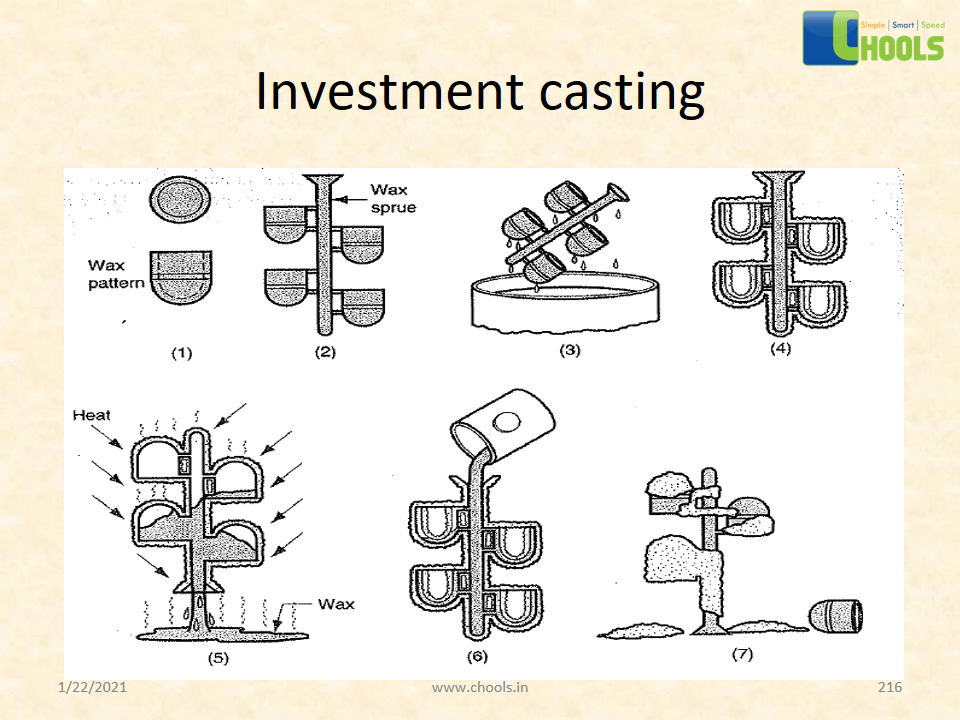

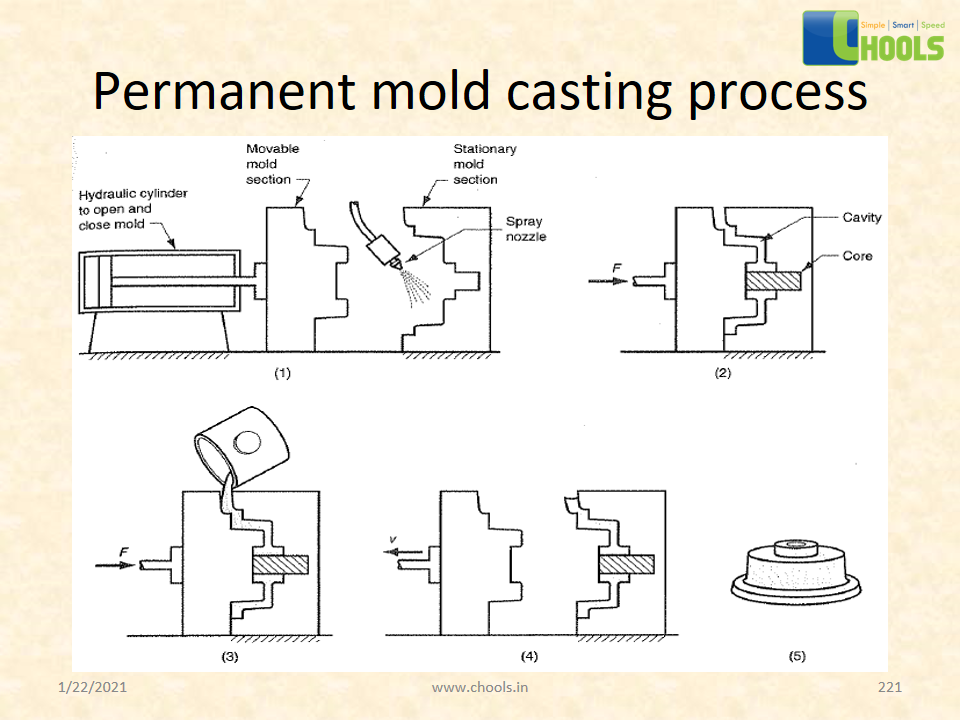

1. METAL CASTING PROCESS

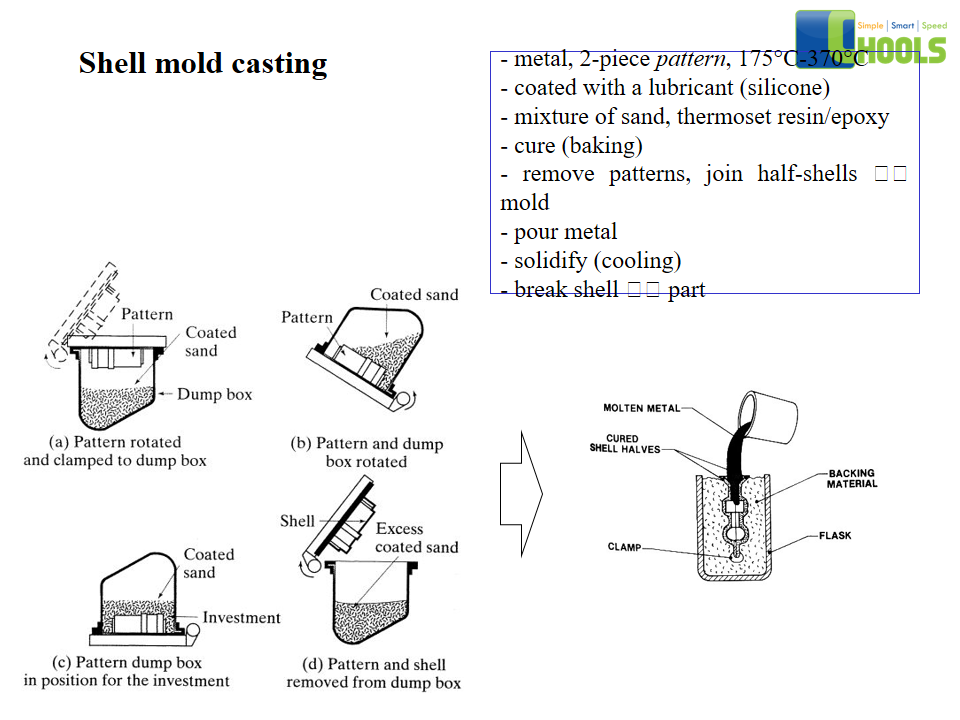

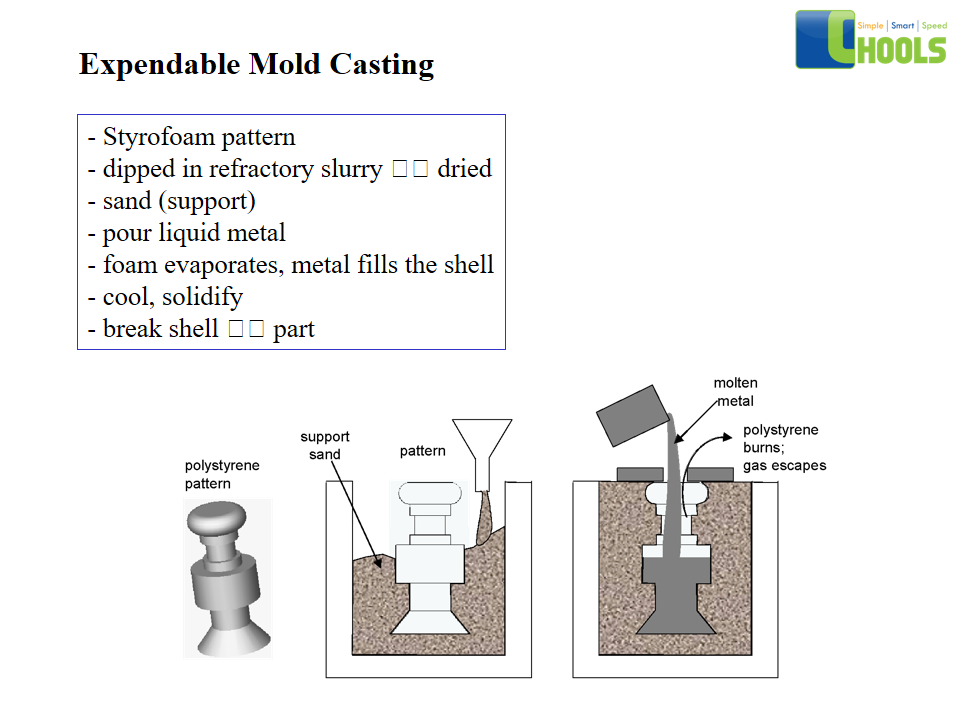

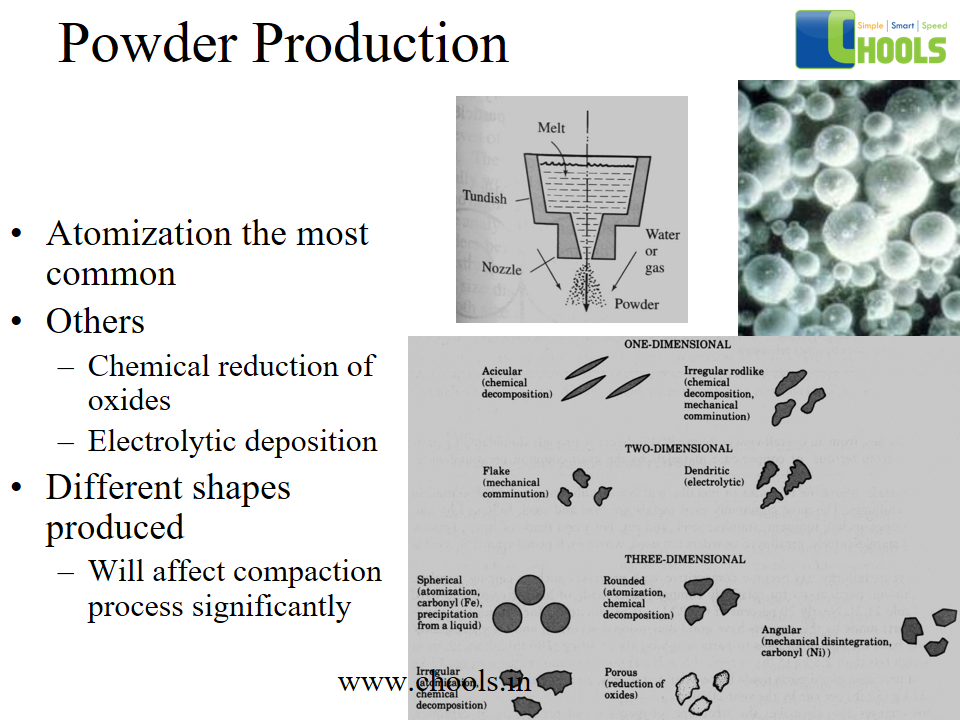

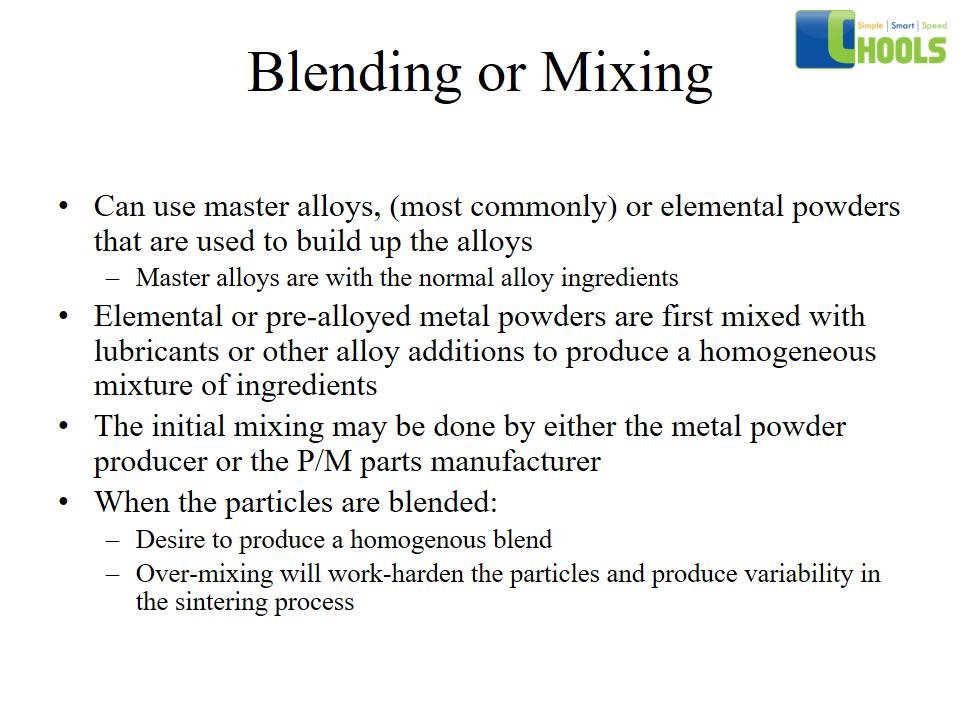

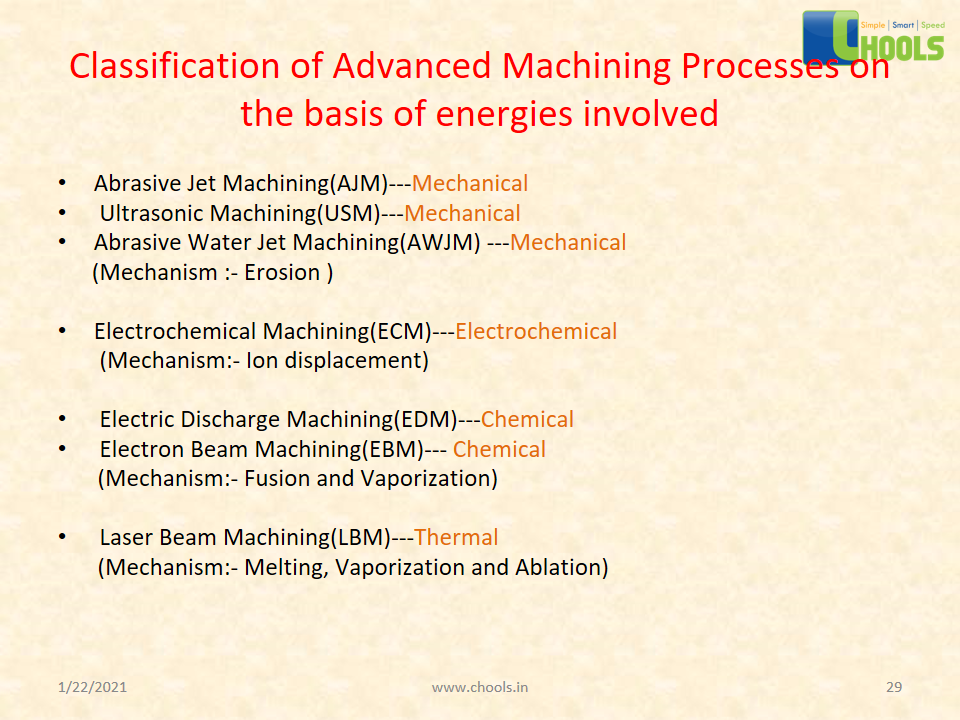

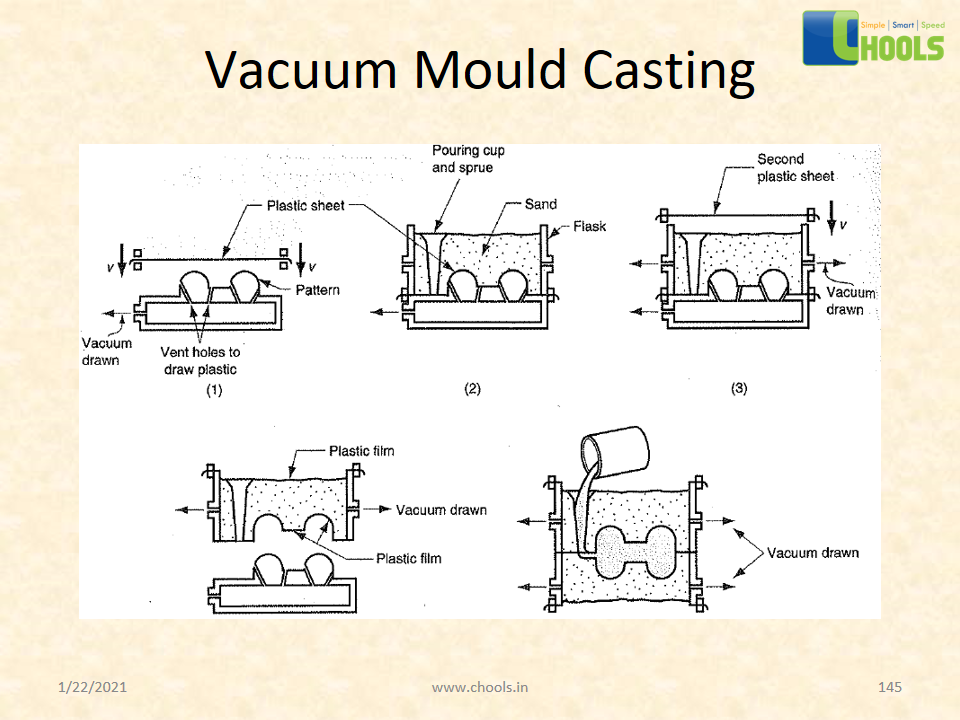

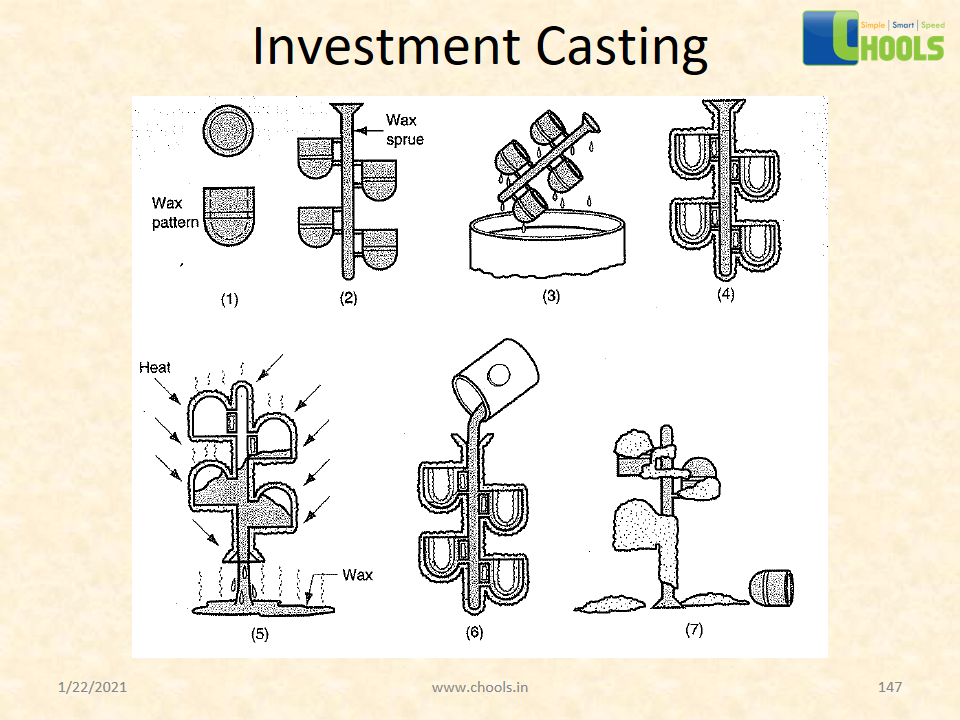

2. ADVANCED PROCESSES

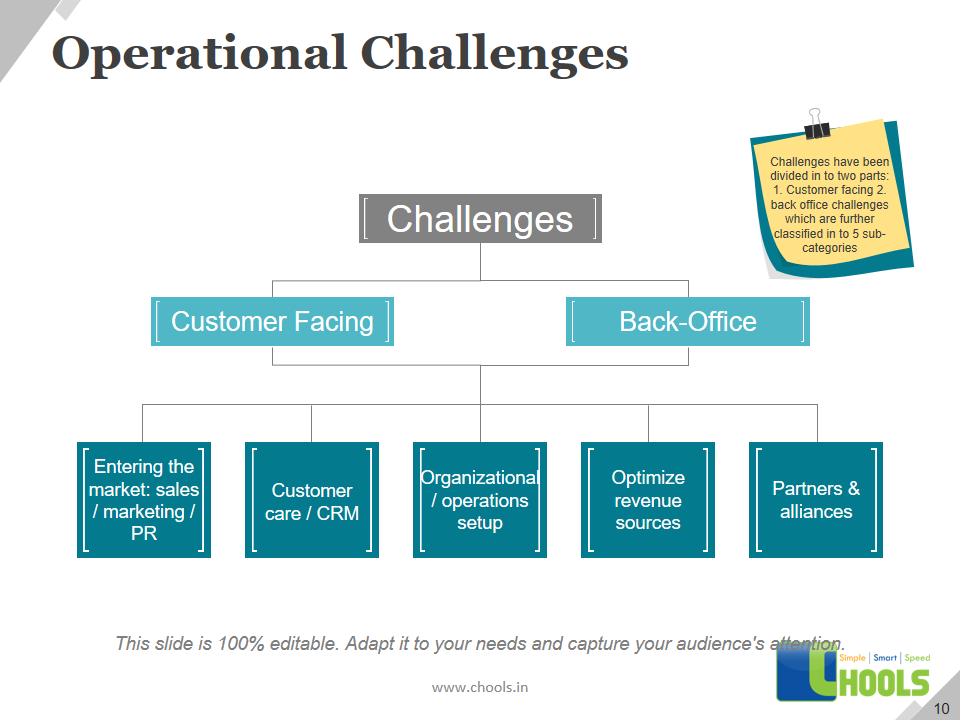

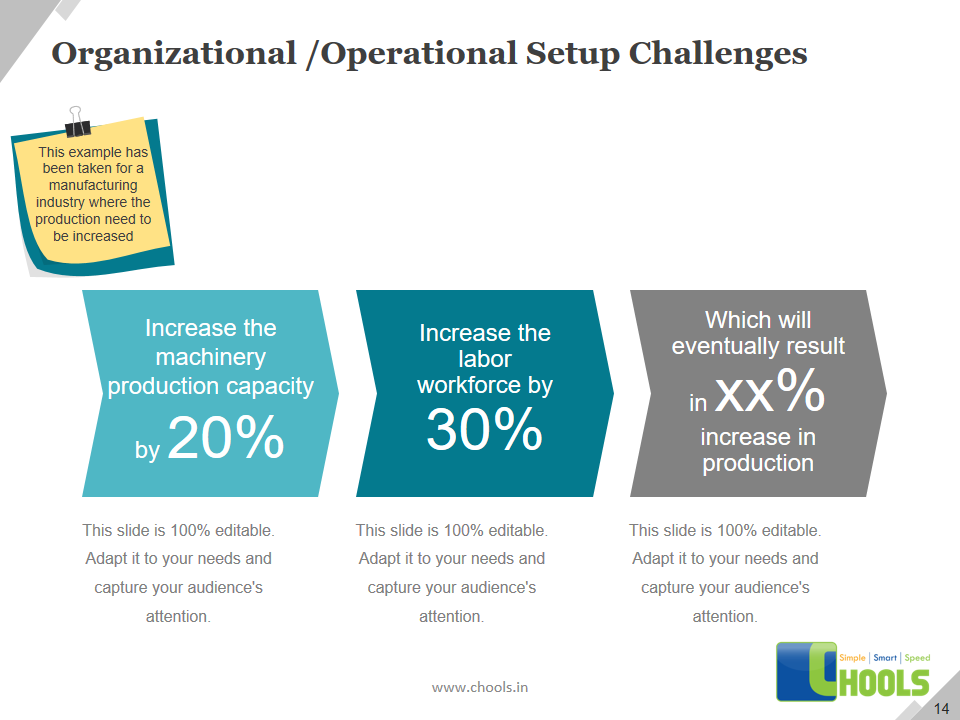

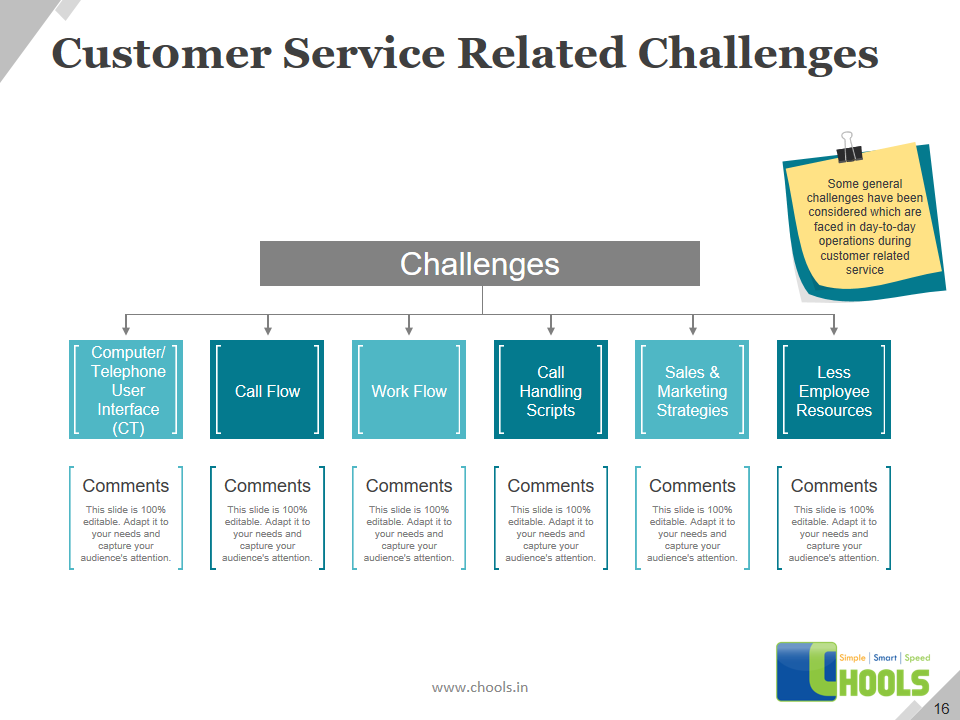

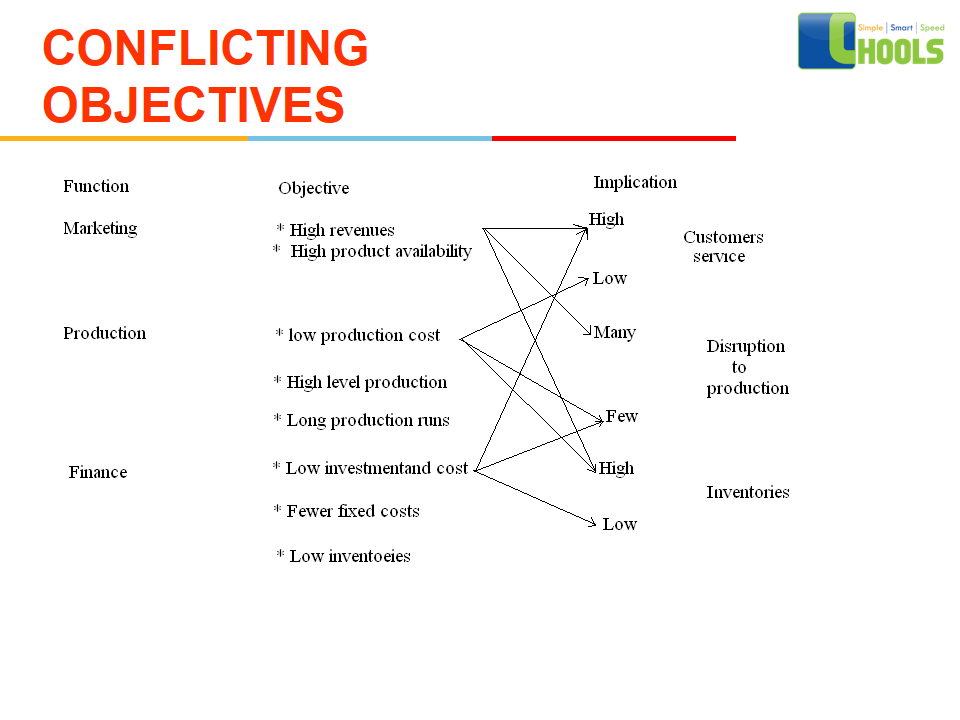

3. BUSINESS OPERATIONAL CHALLENGES

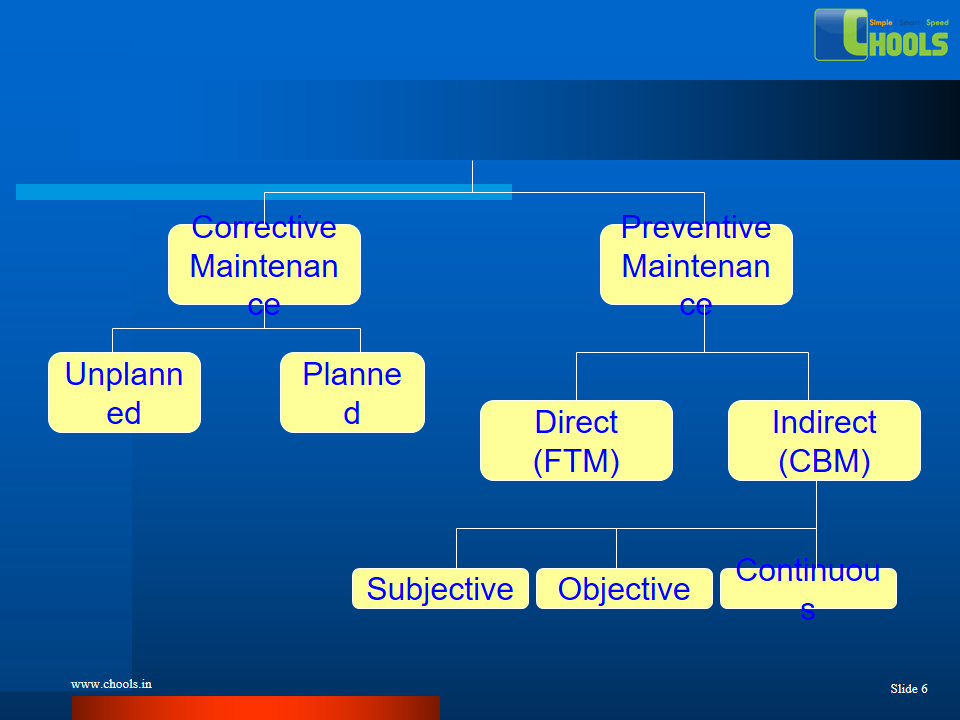

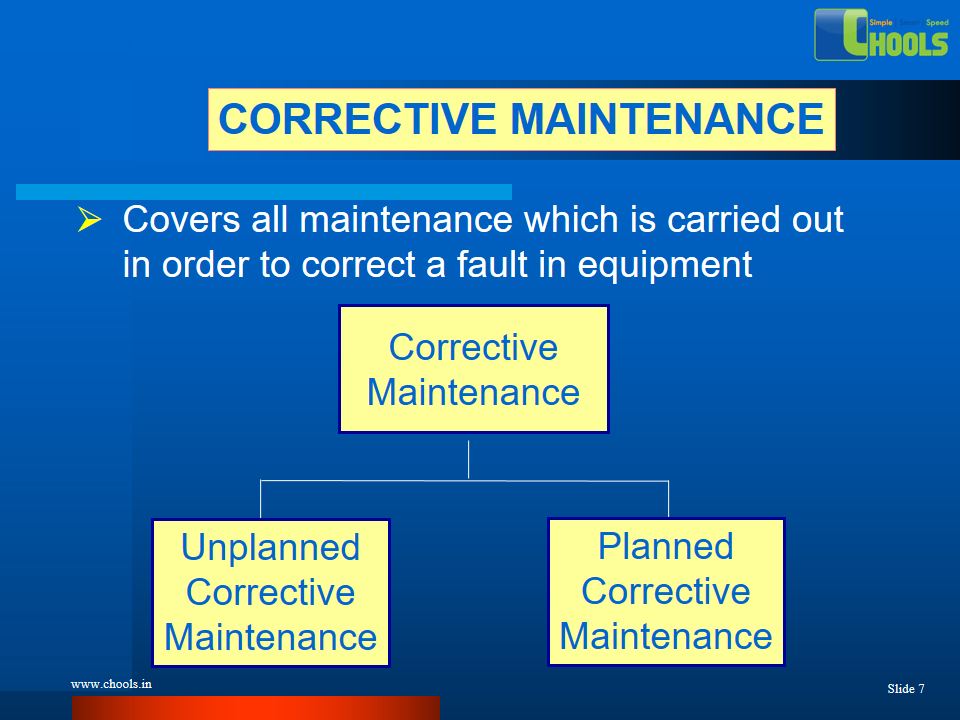

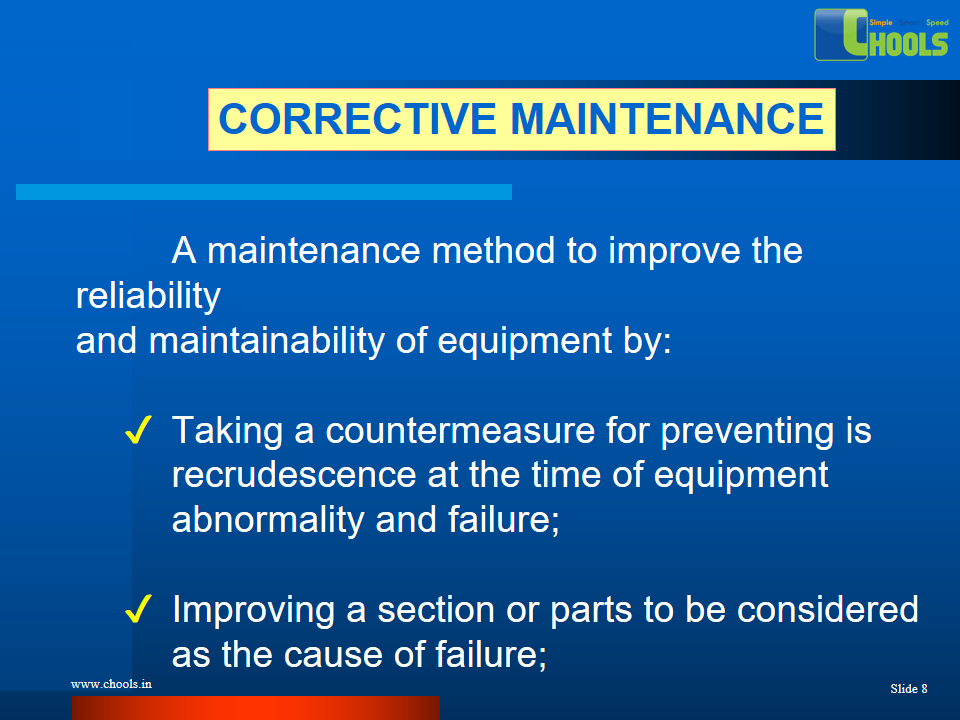

4. PREVENTIVE MAINTENANCE

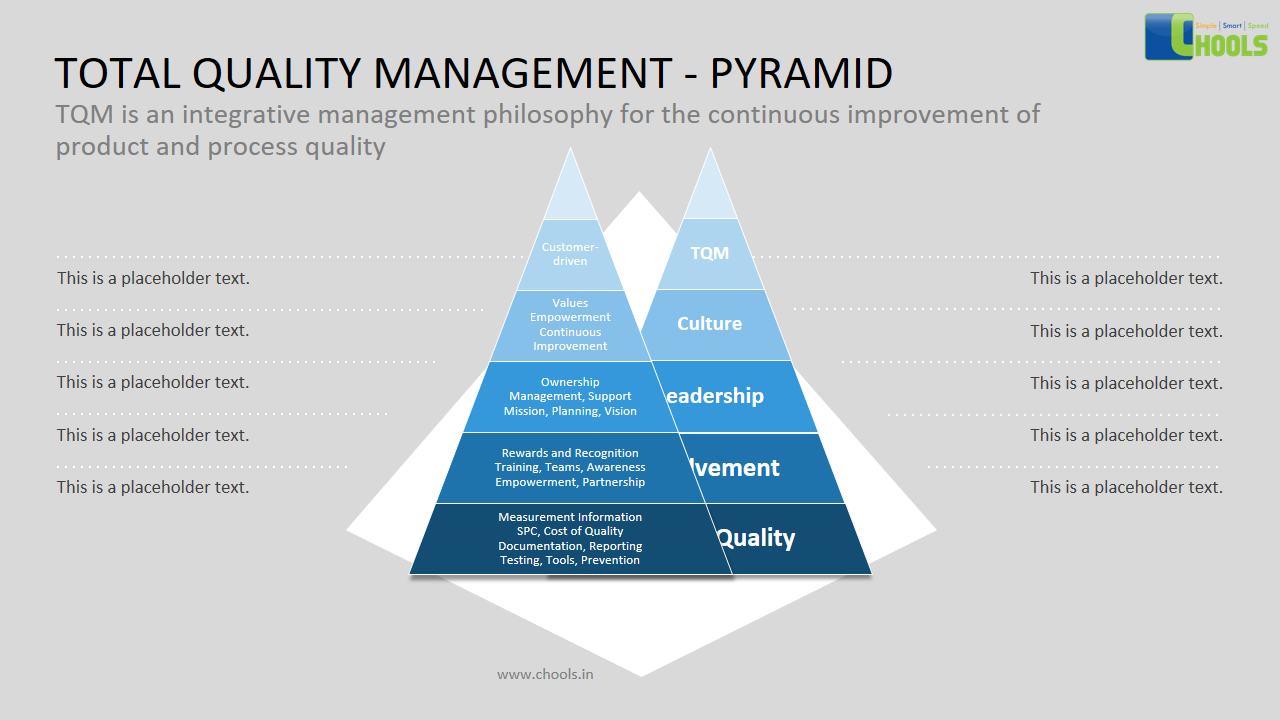

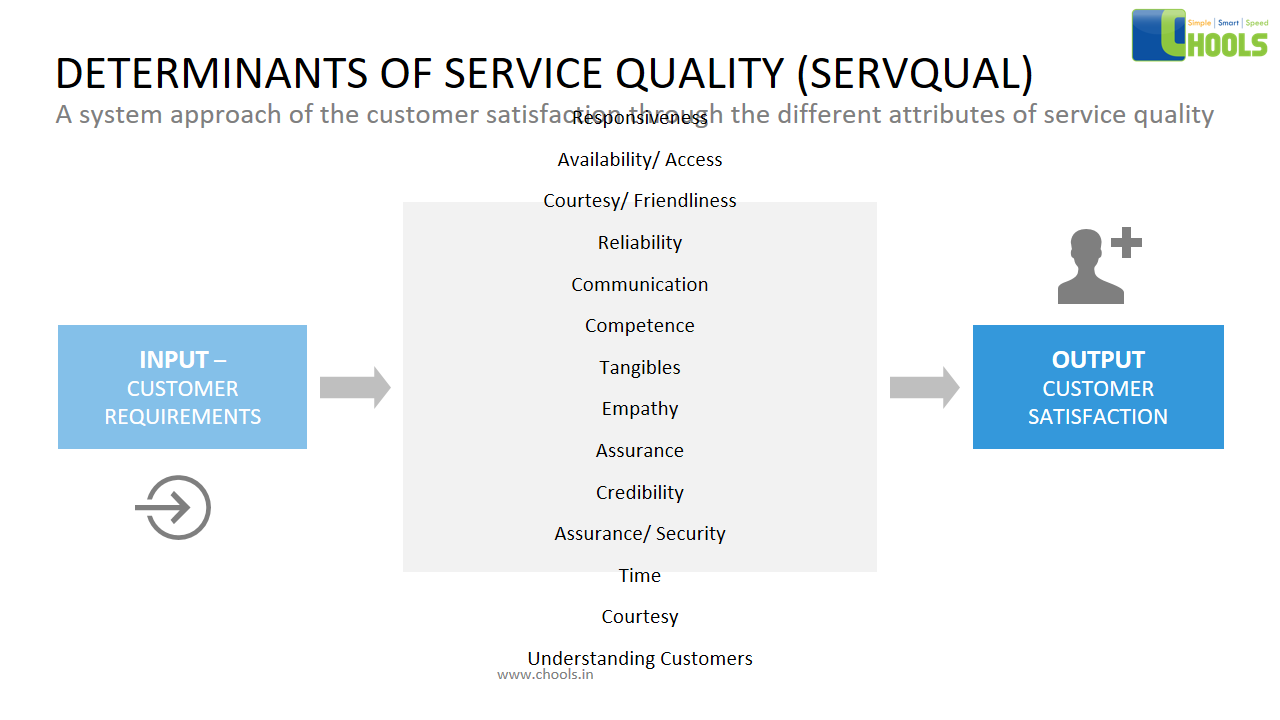

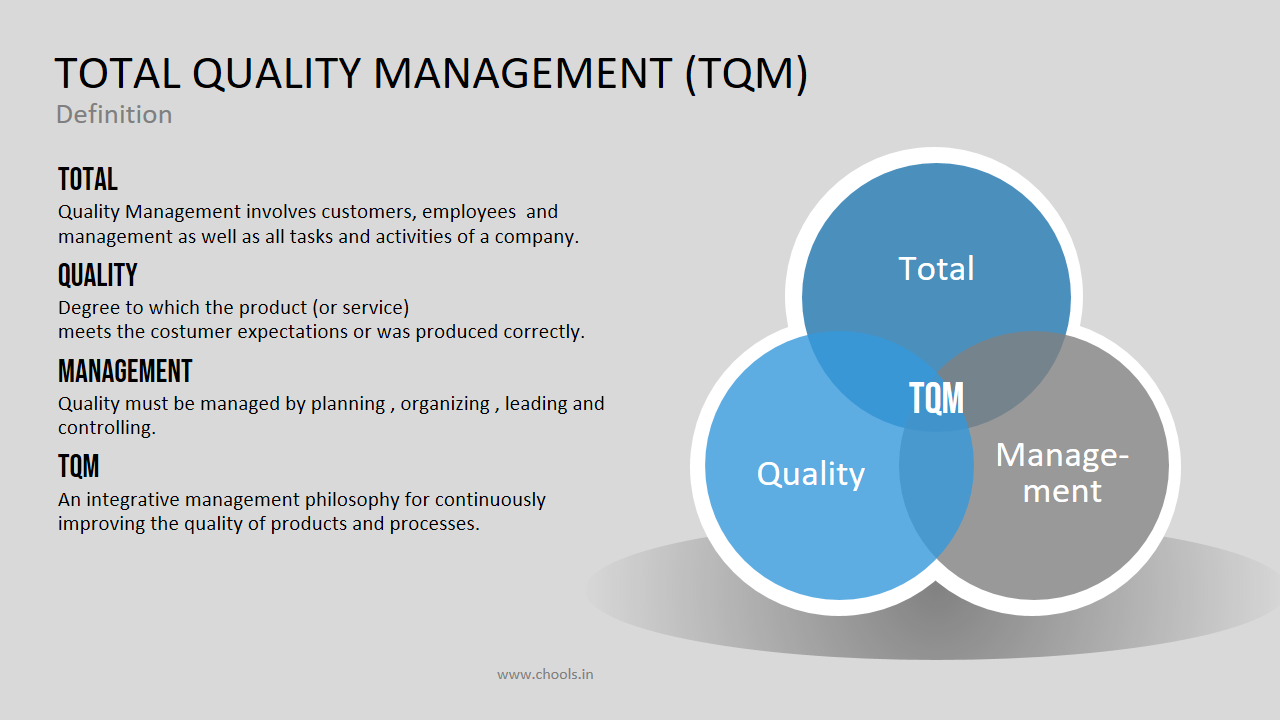

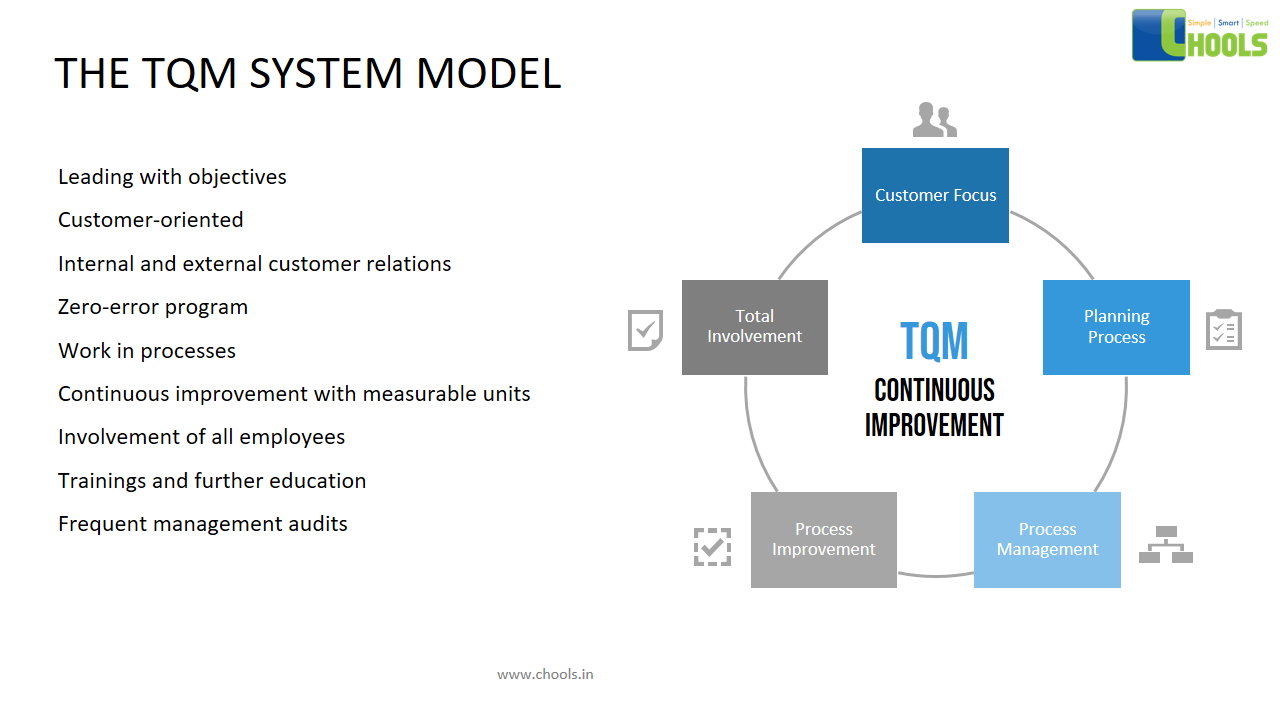

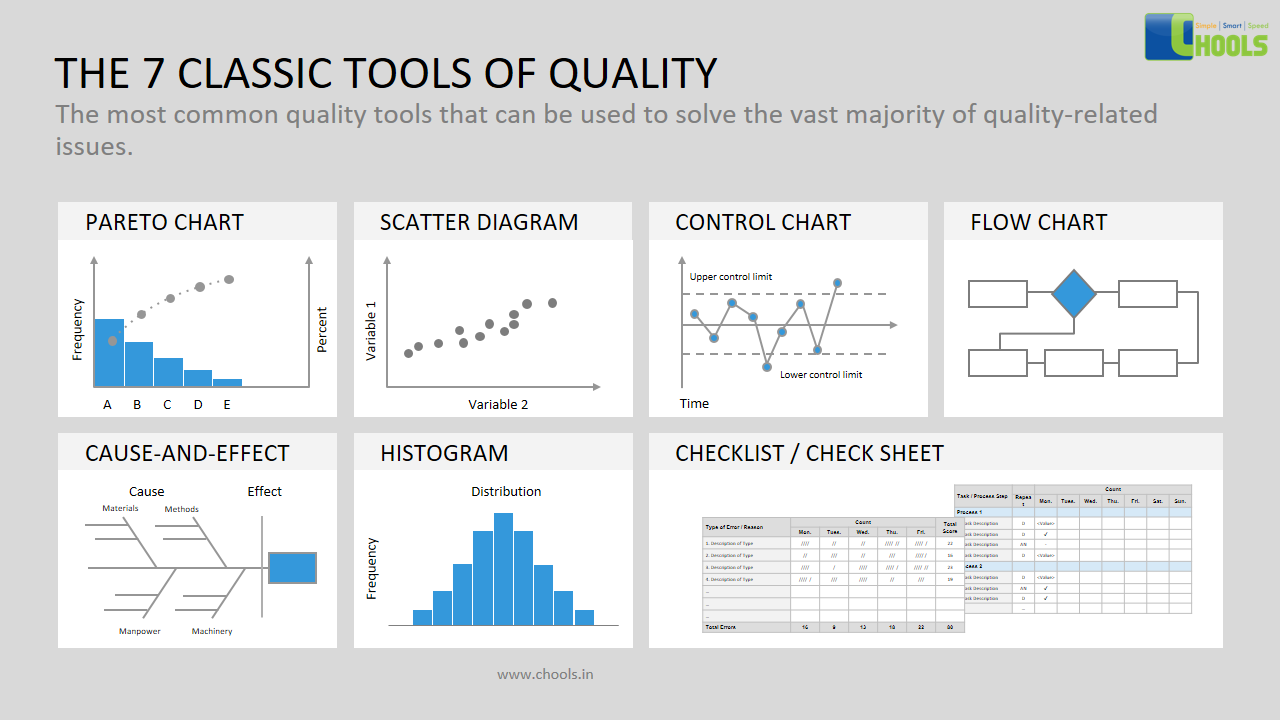

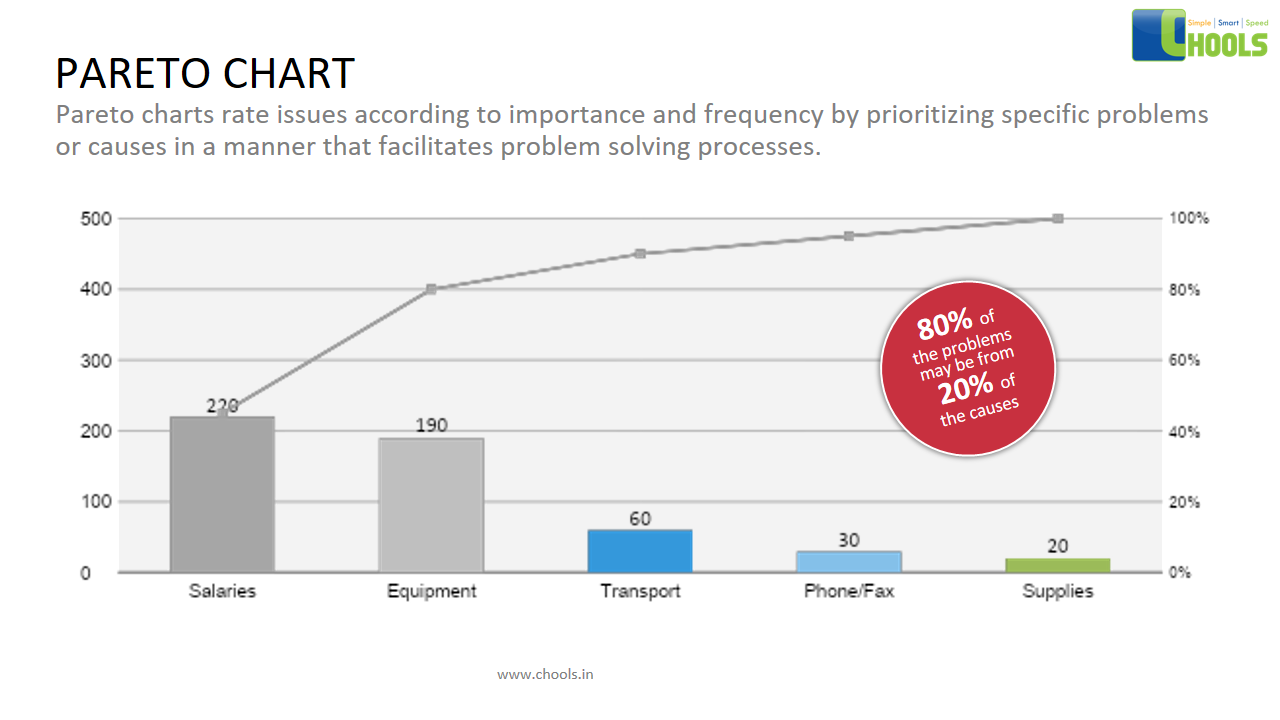

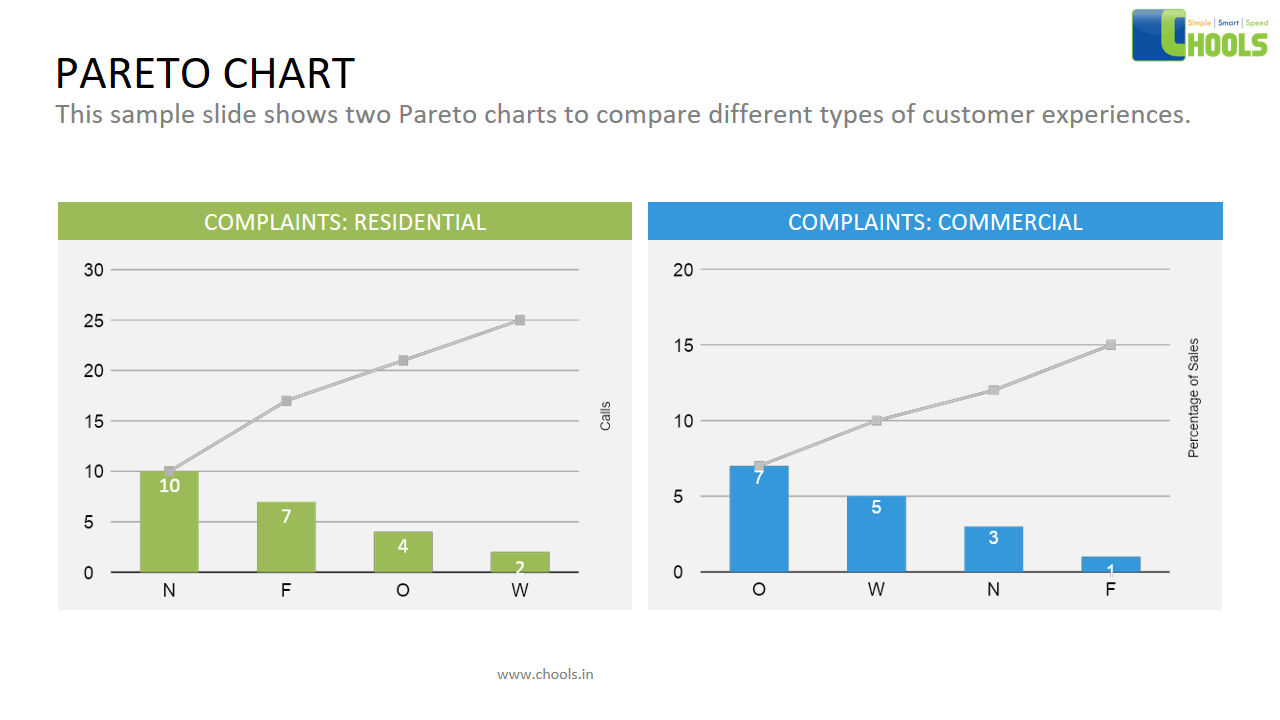

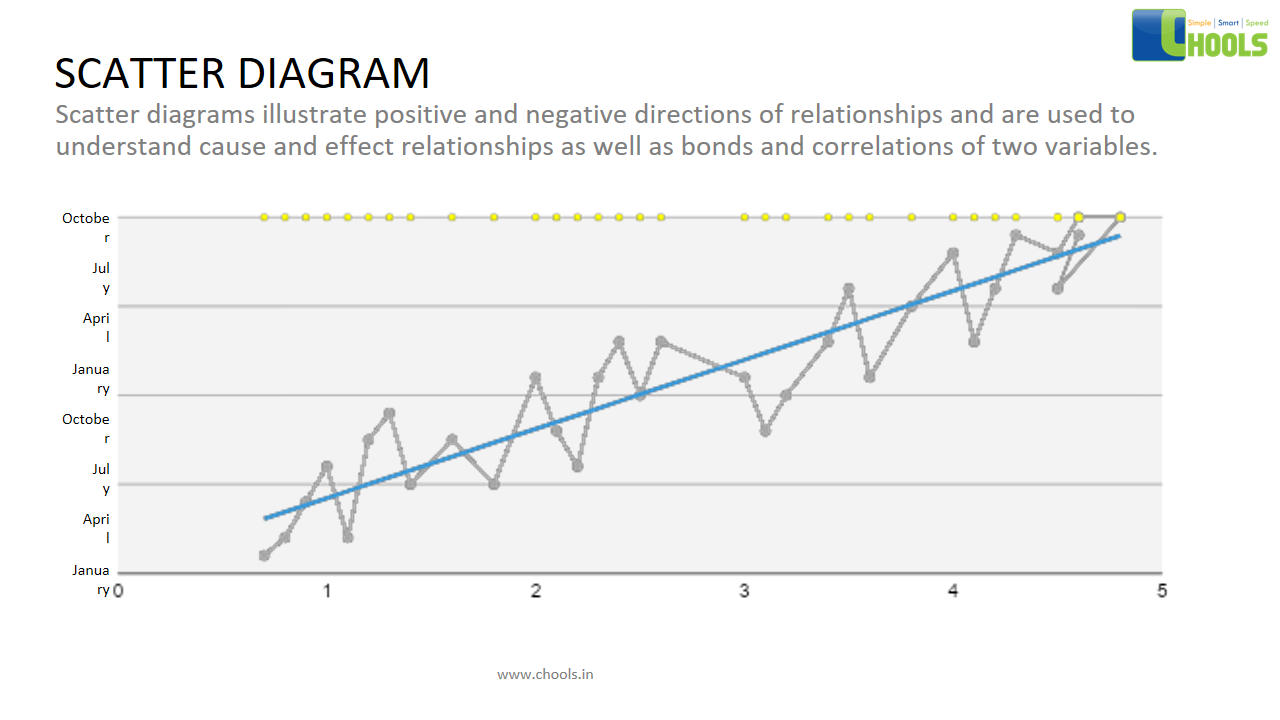

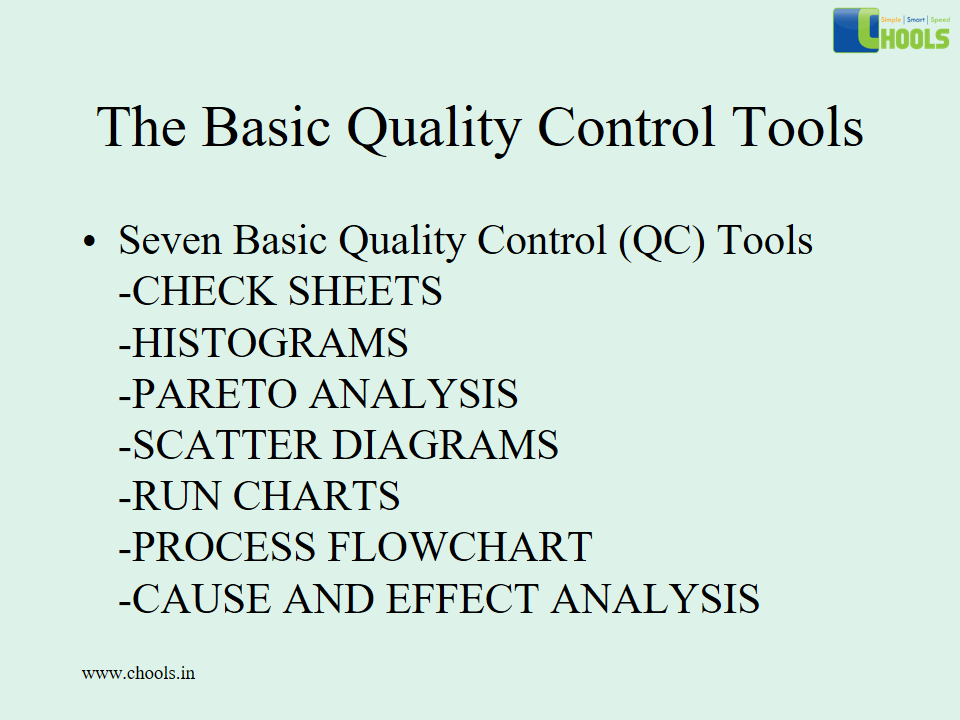

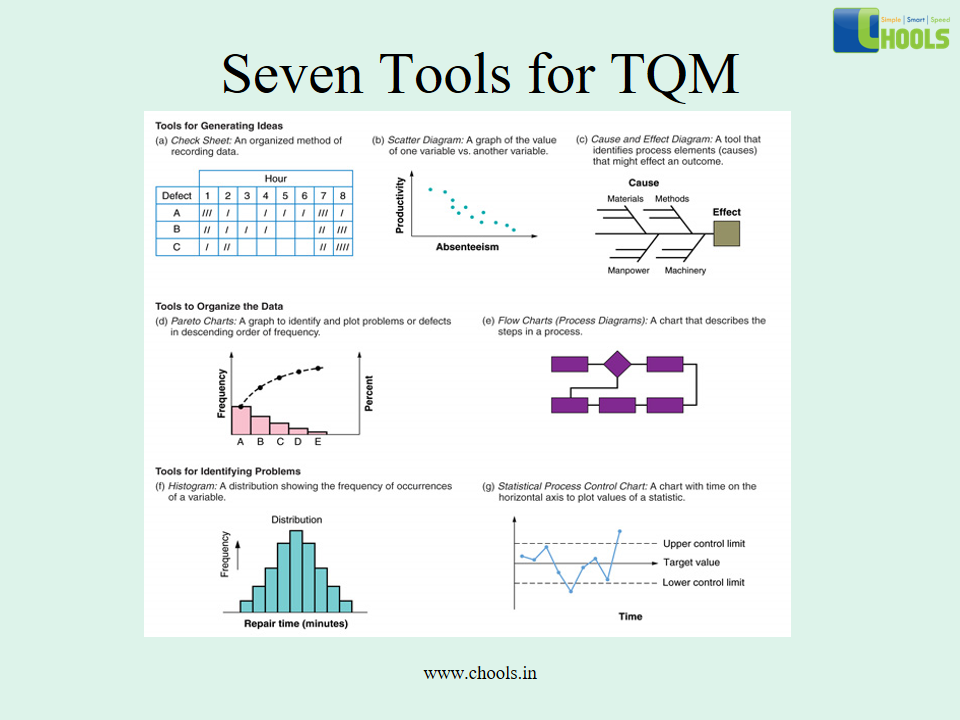

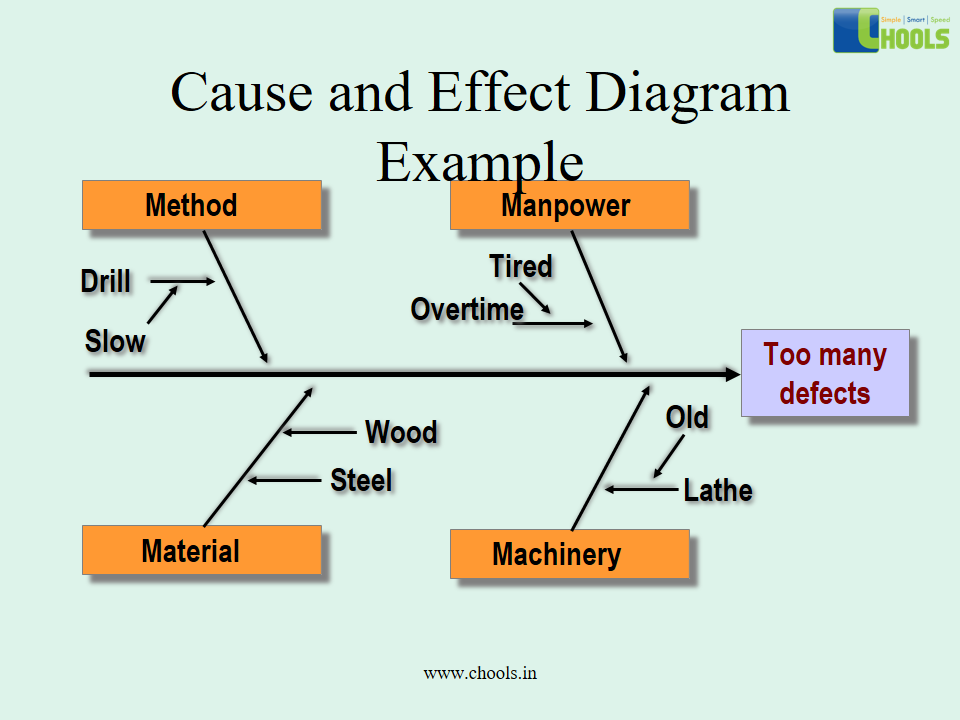

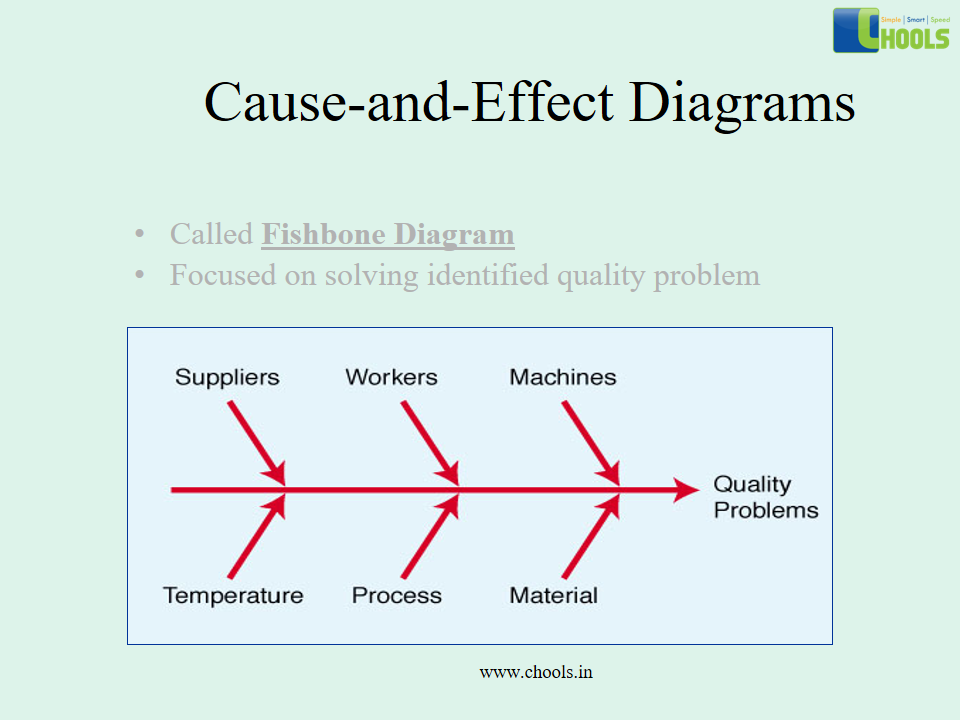

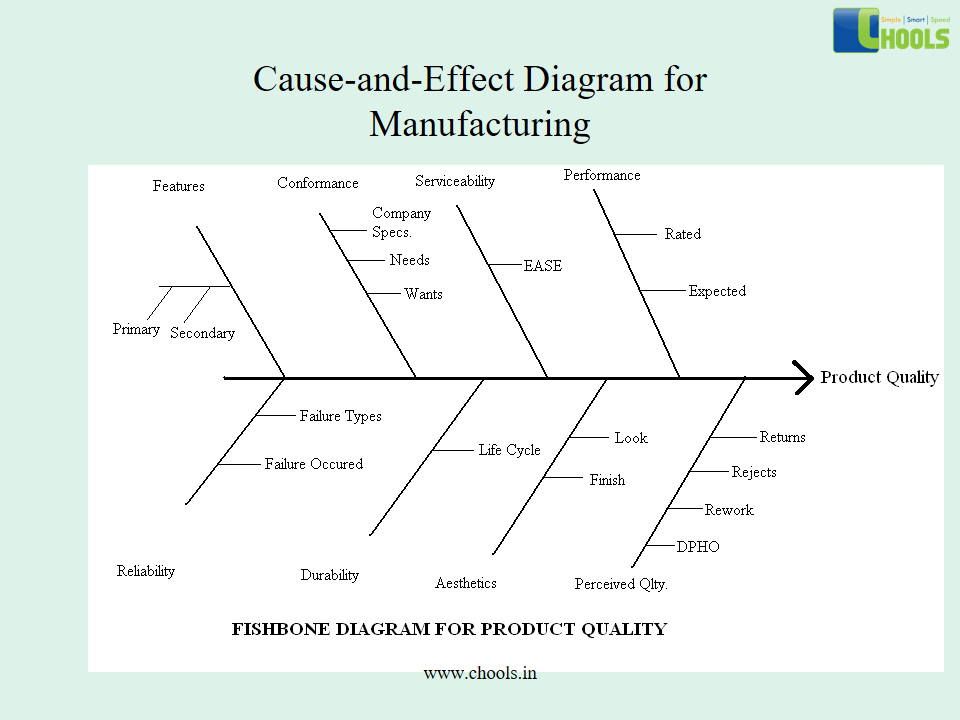

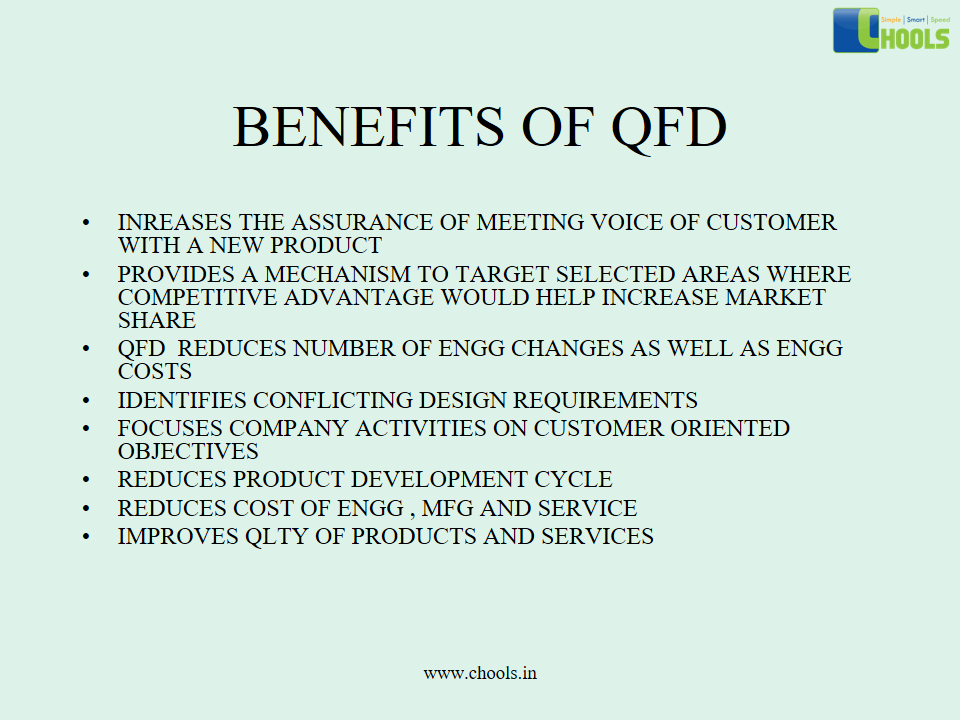

5. TOTAL QUALITY MANAGEMENT – TOOLBOX

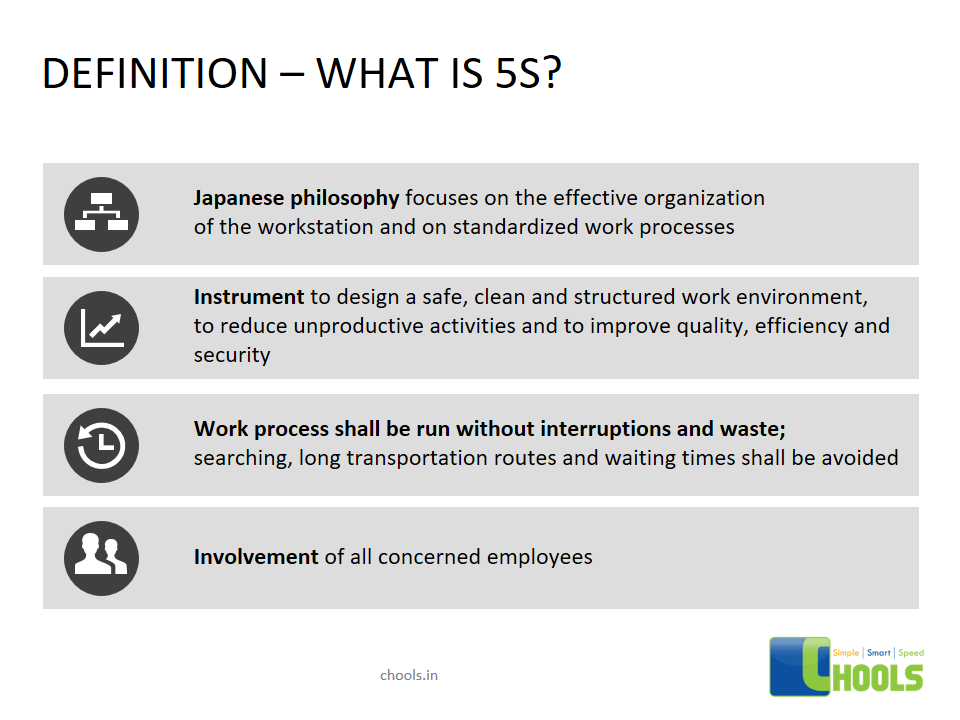

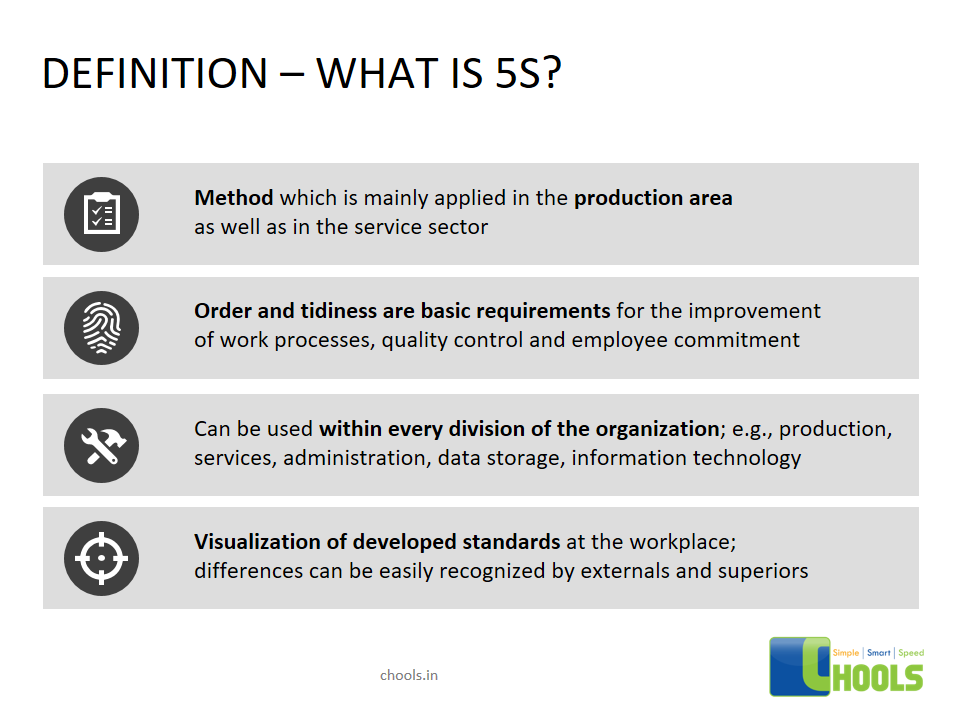

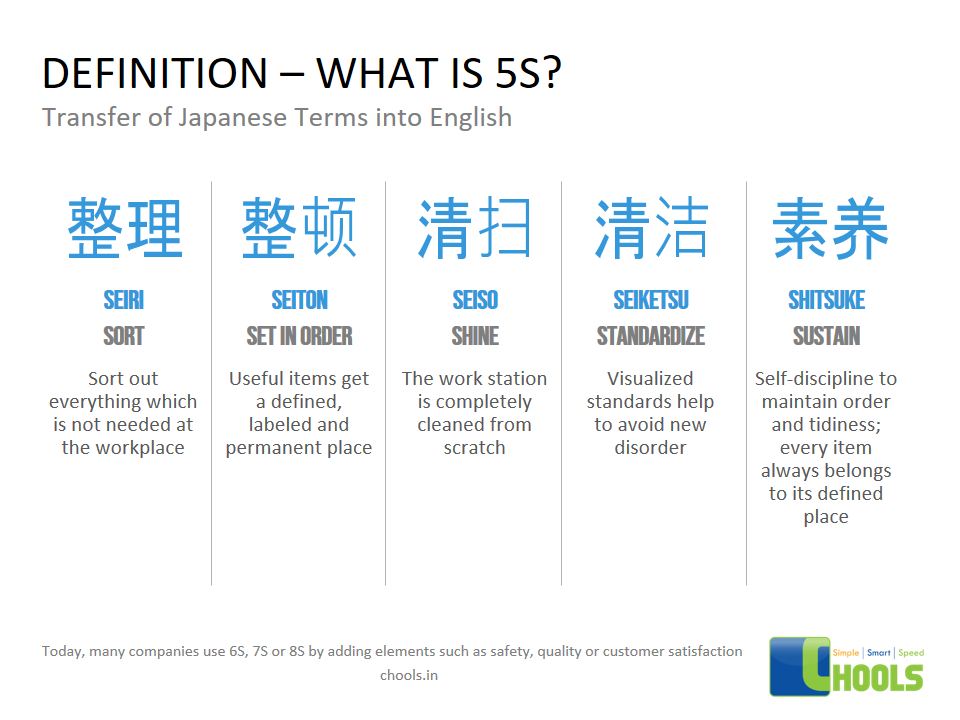

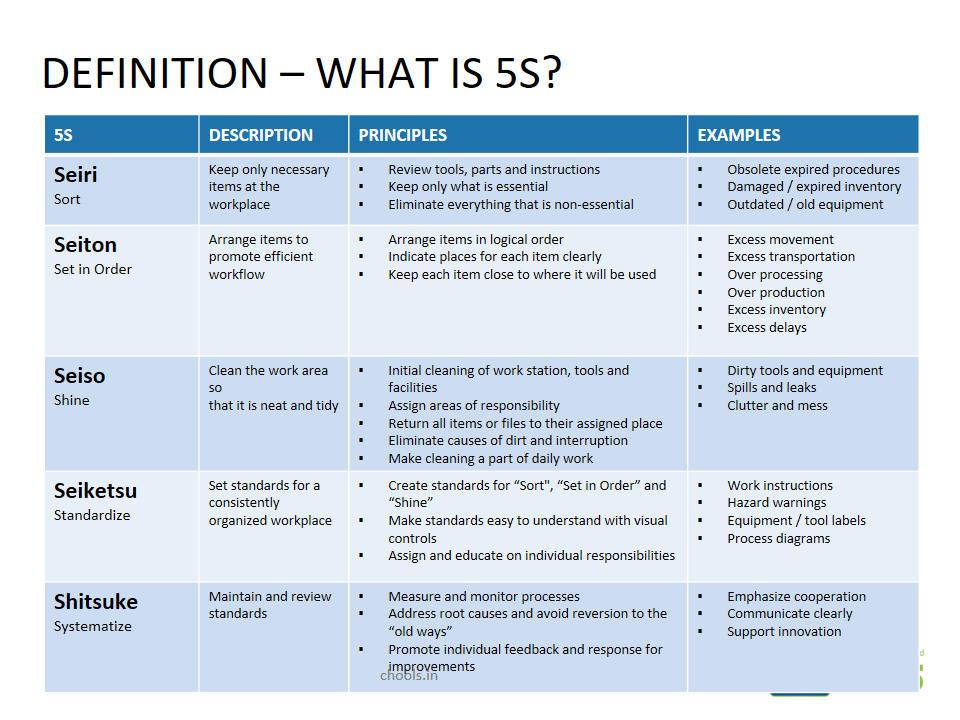

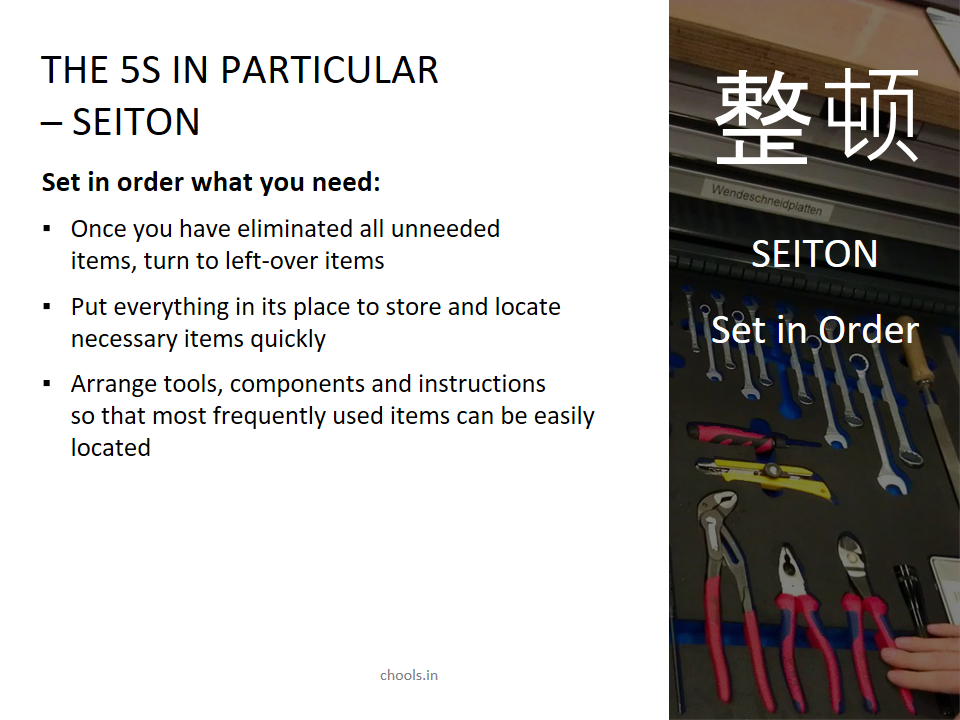

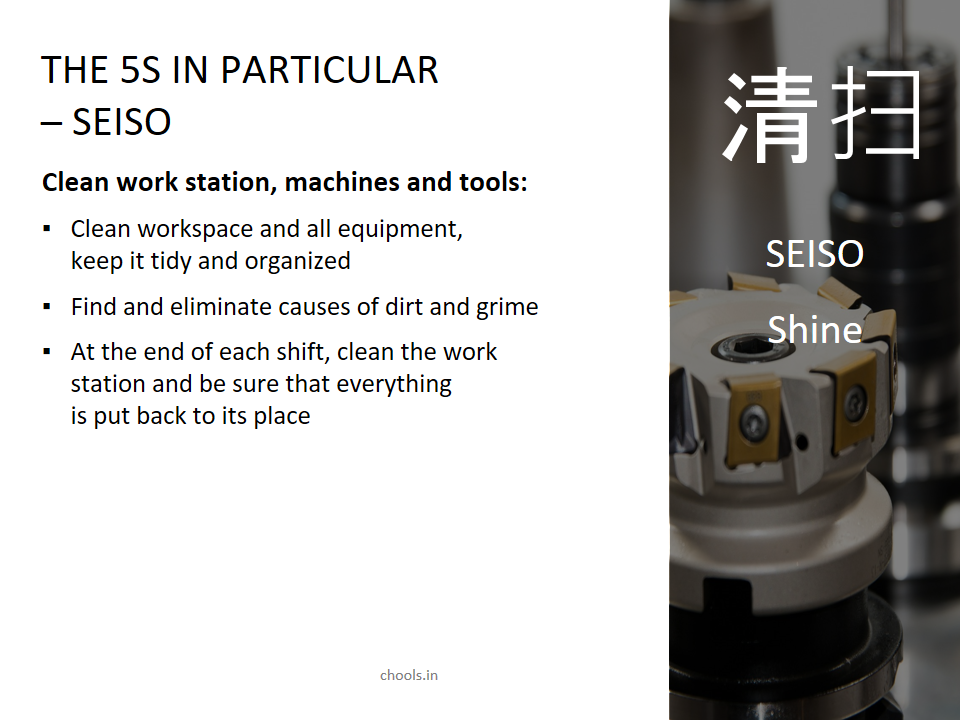

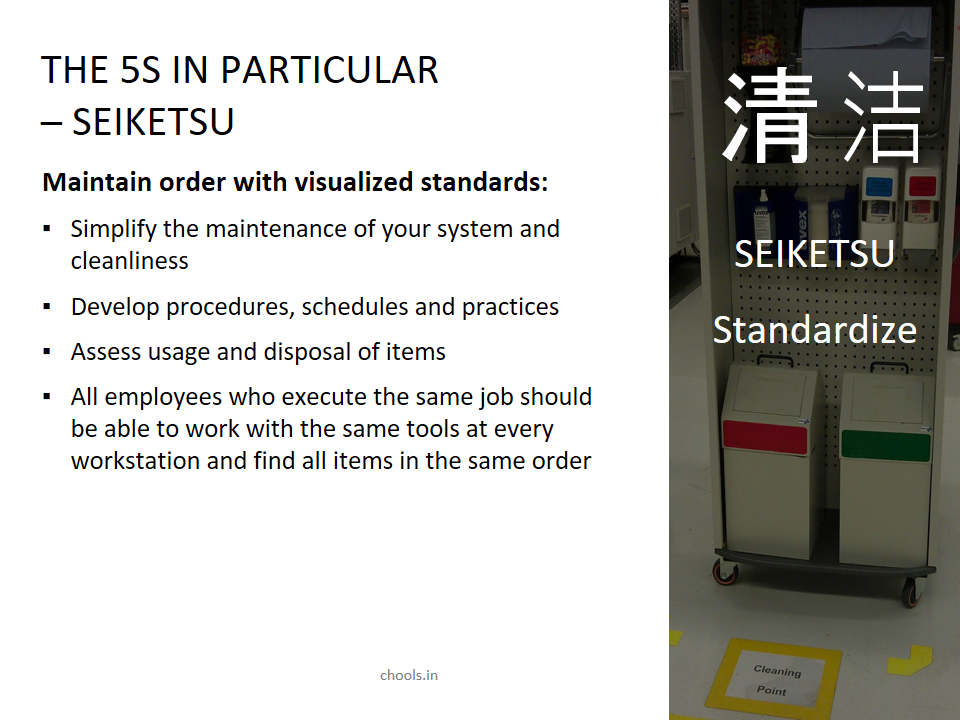

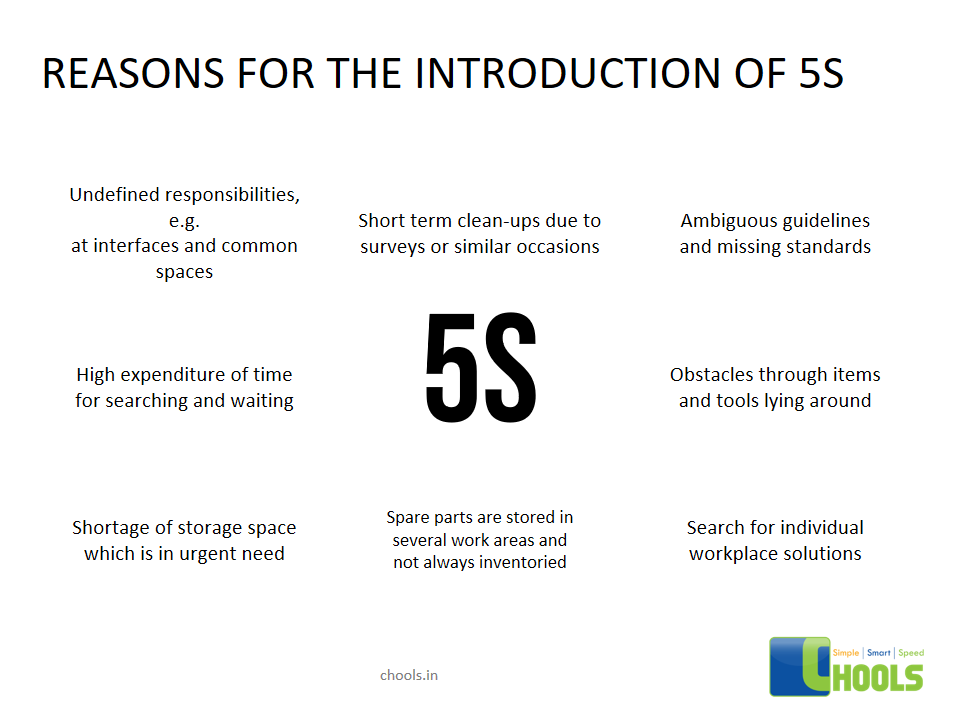

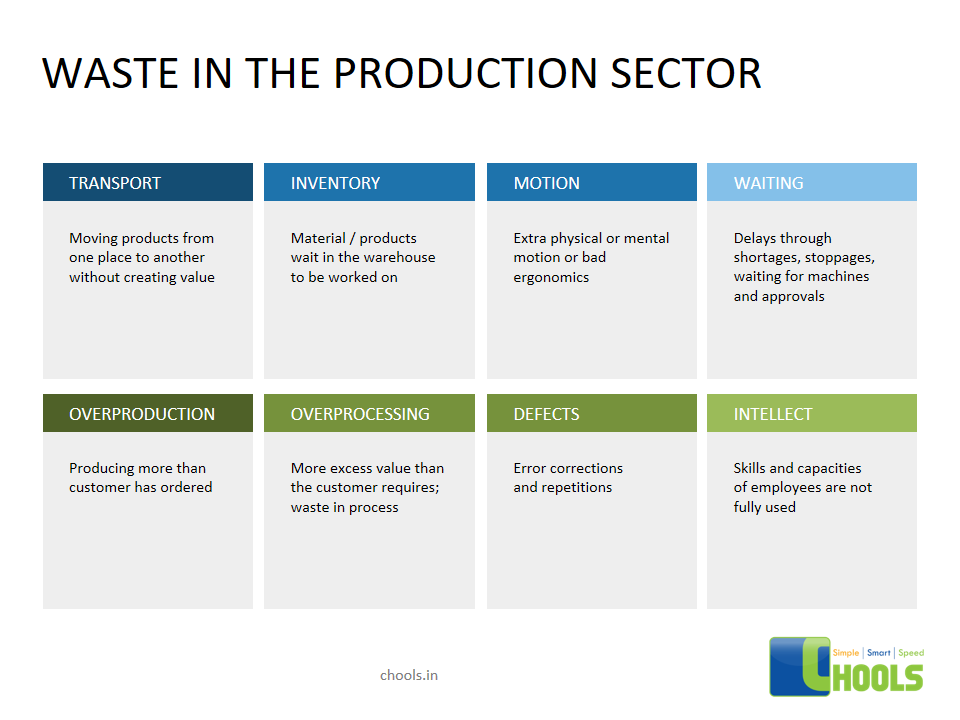

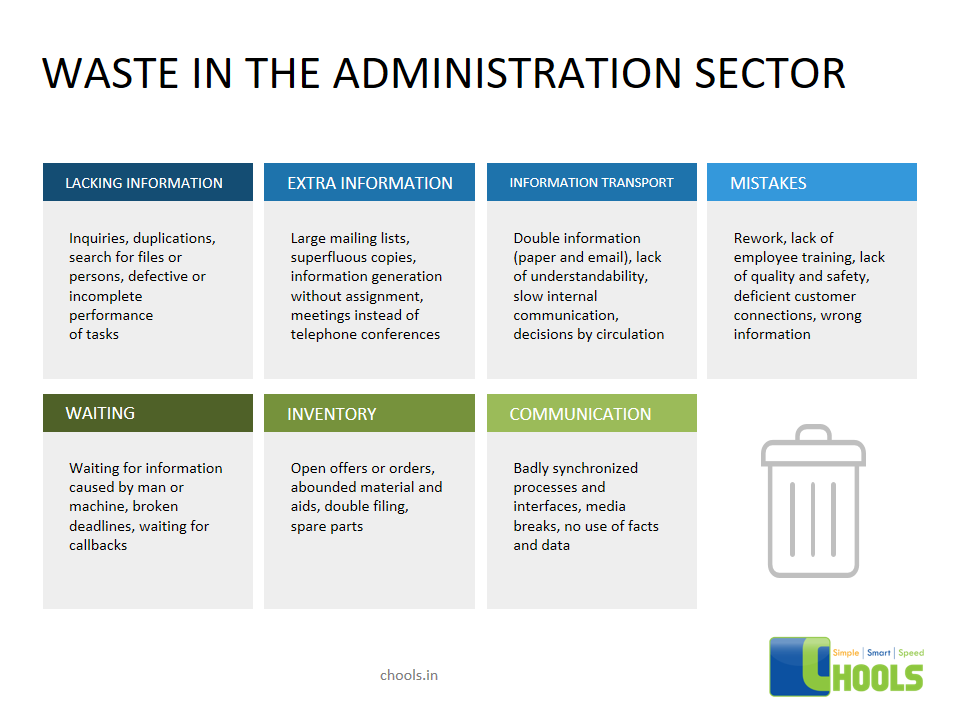

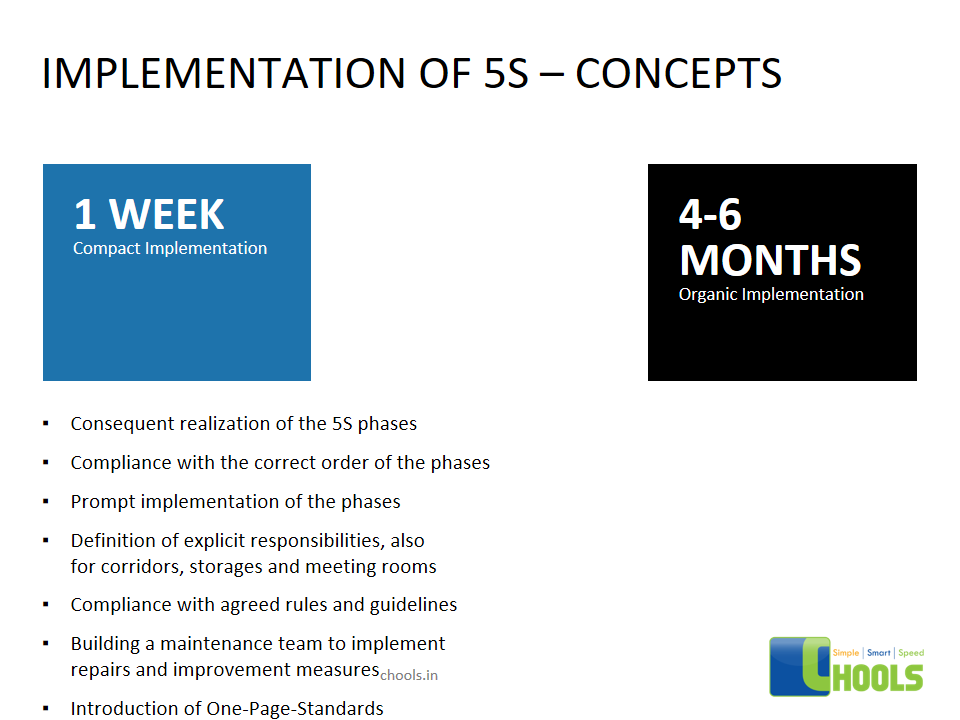

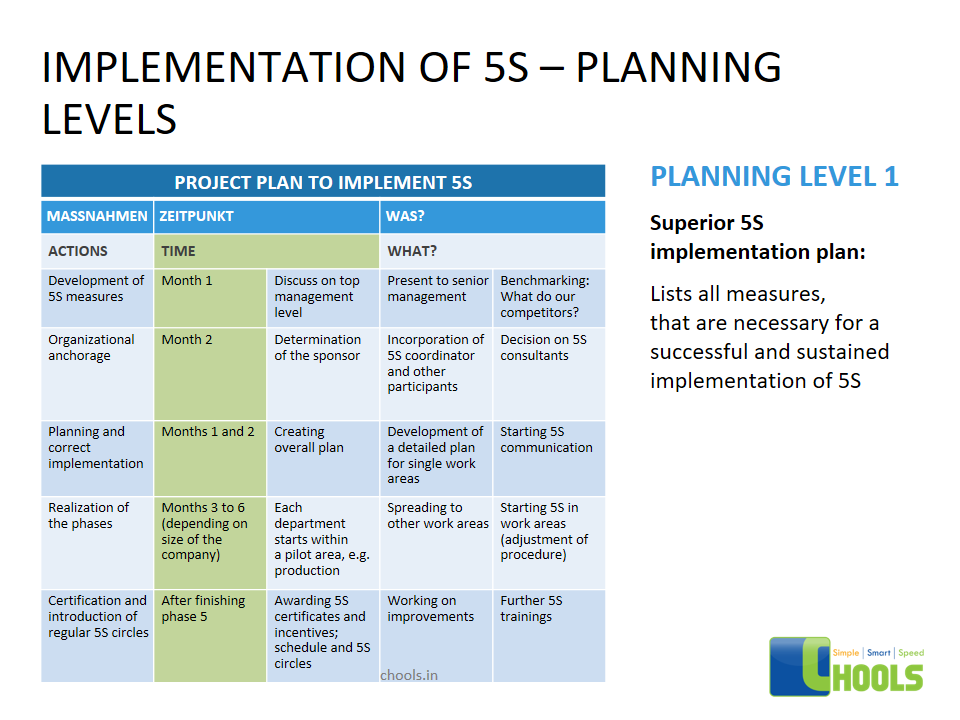

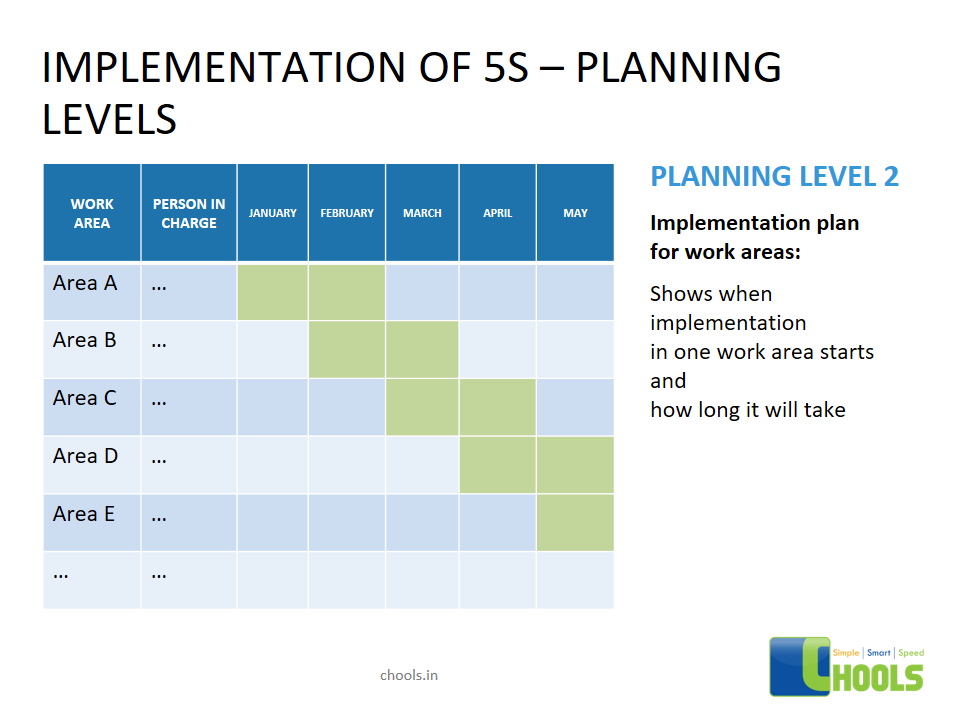

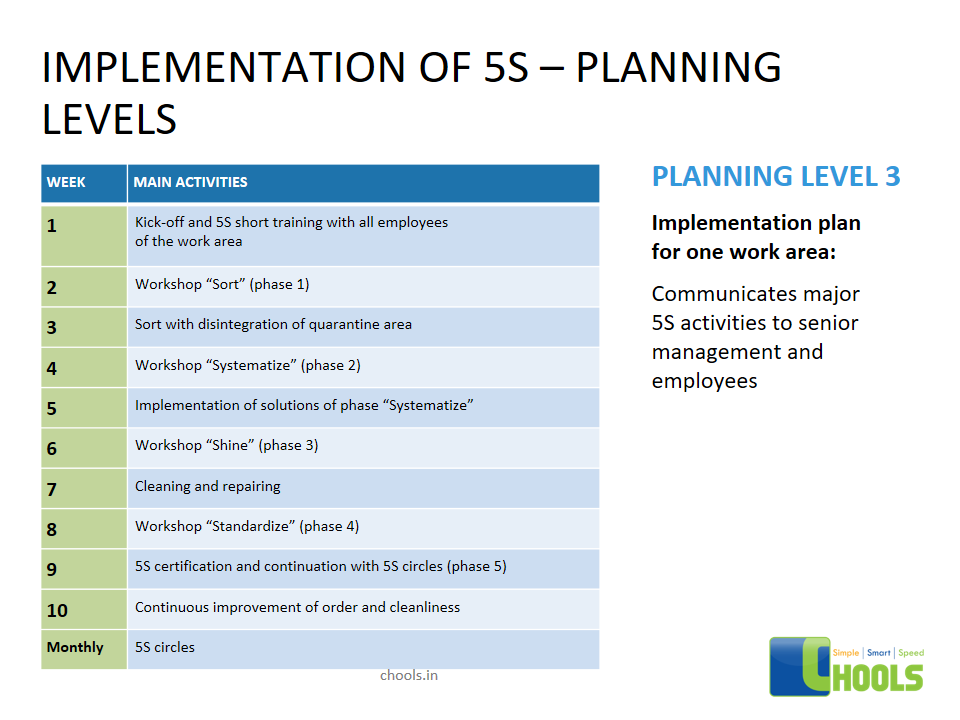

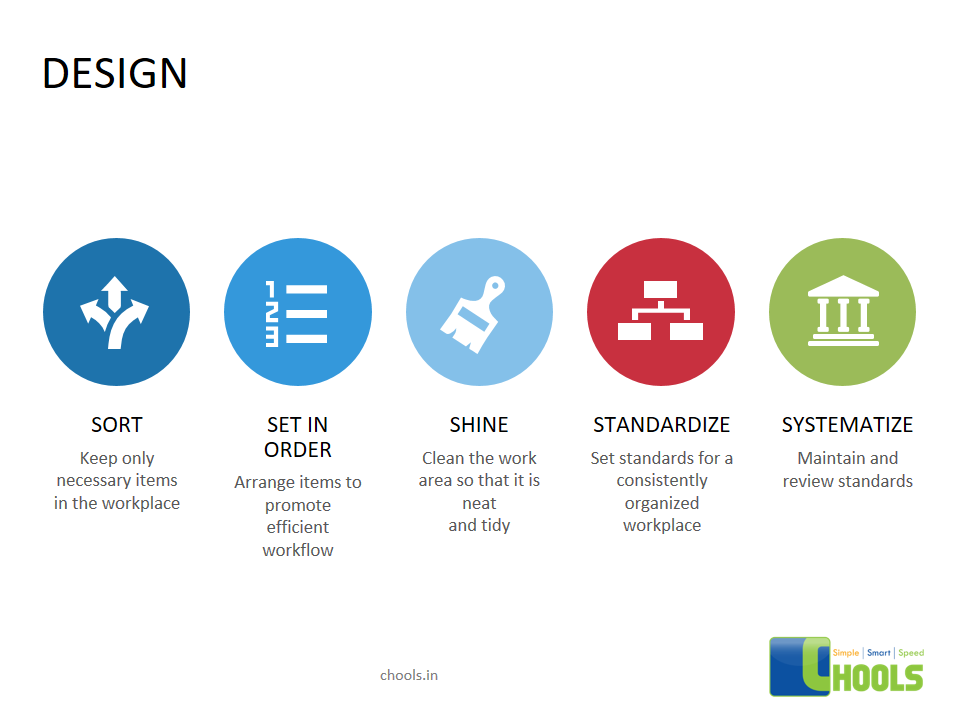

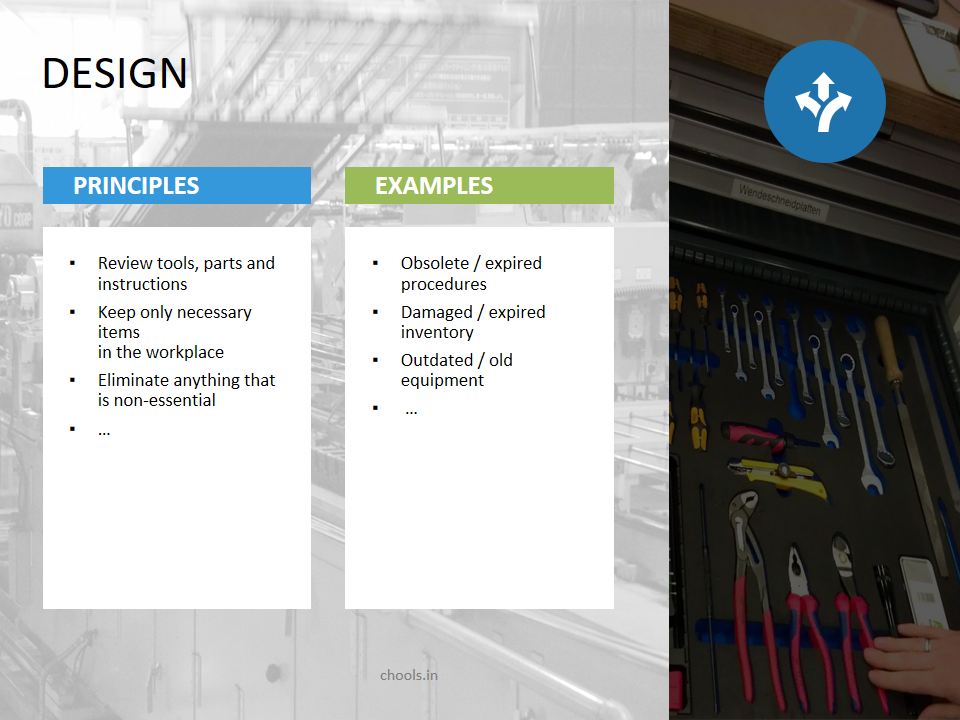

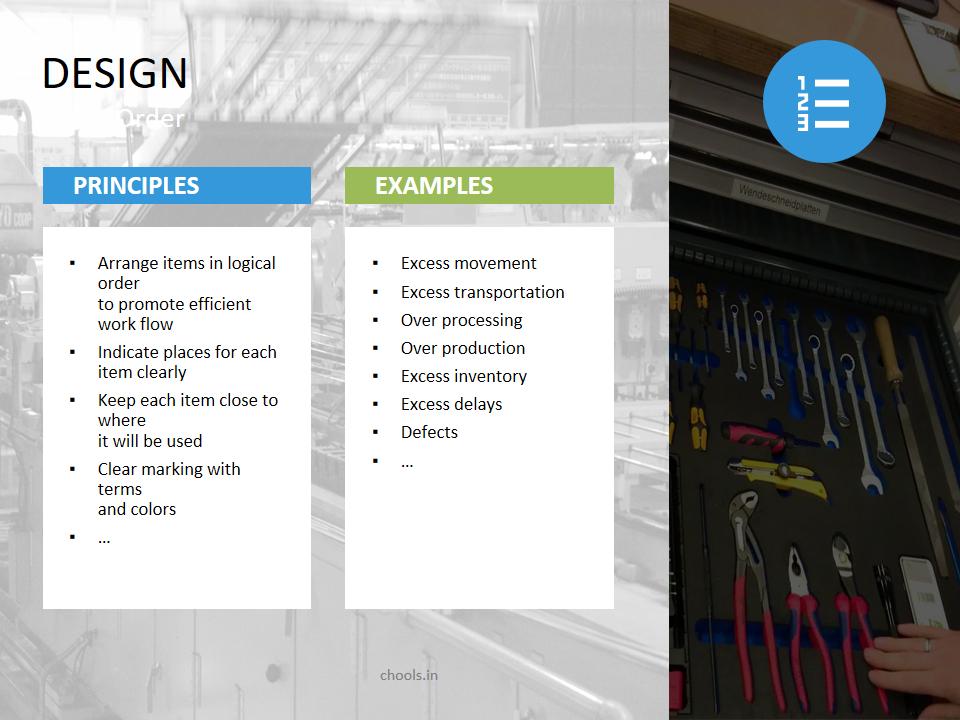

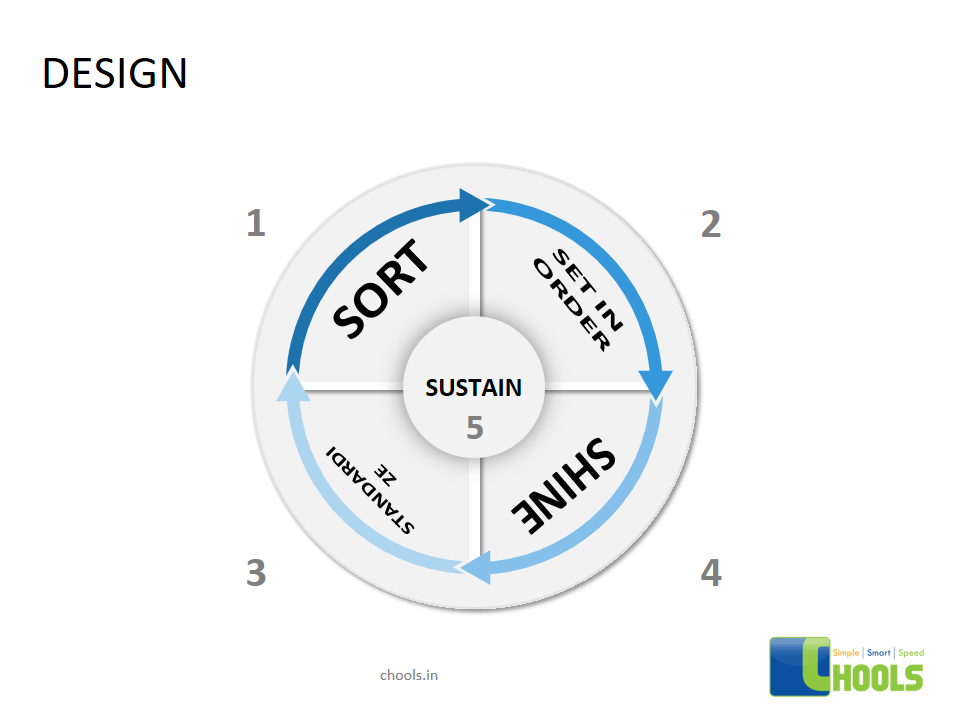

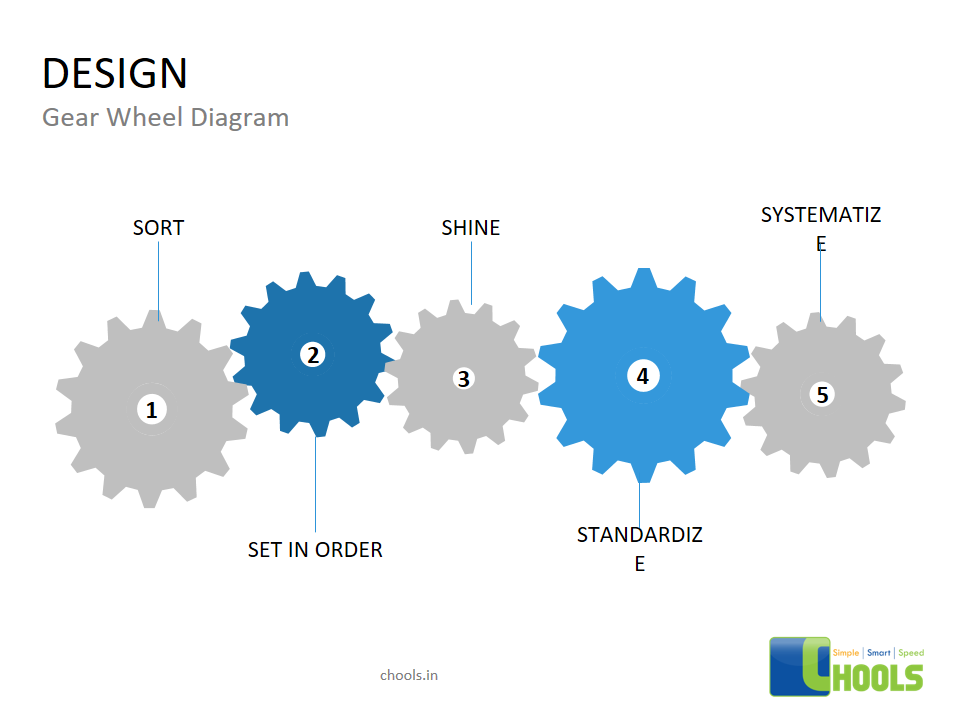

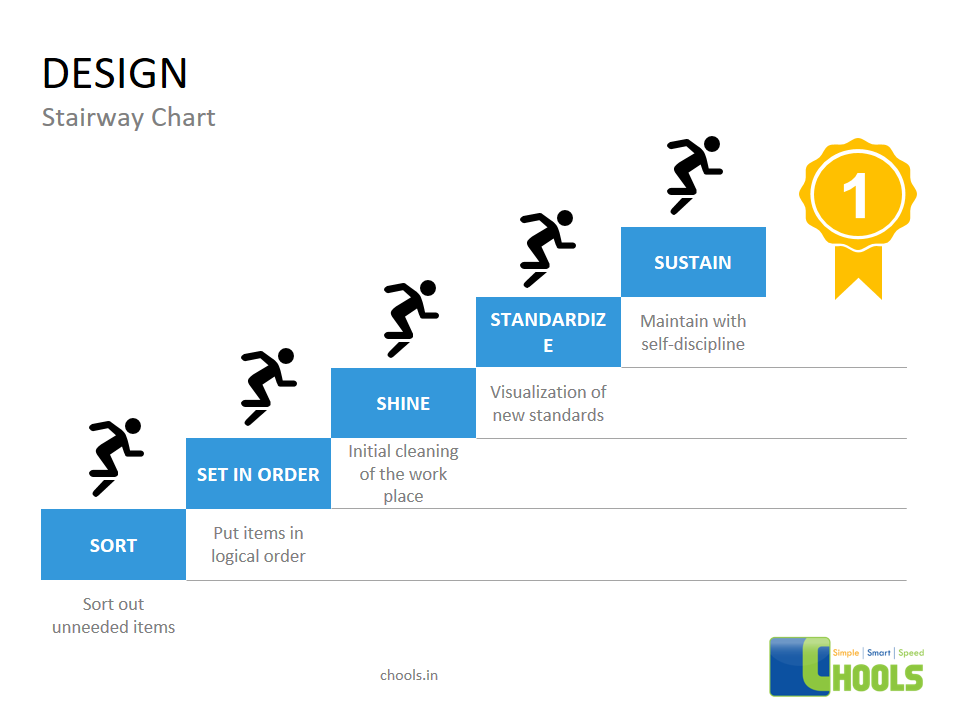

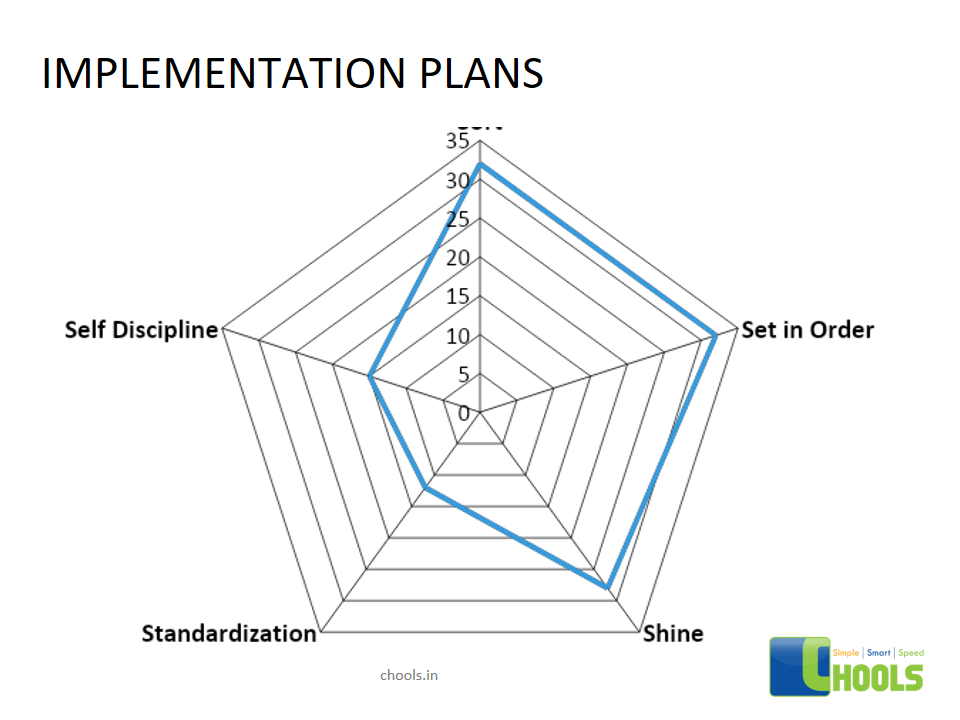

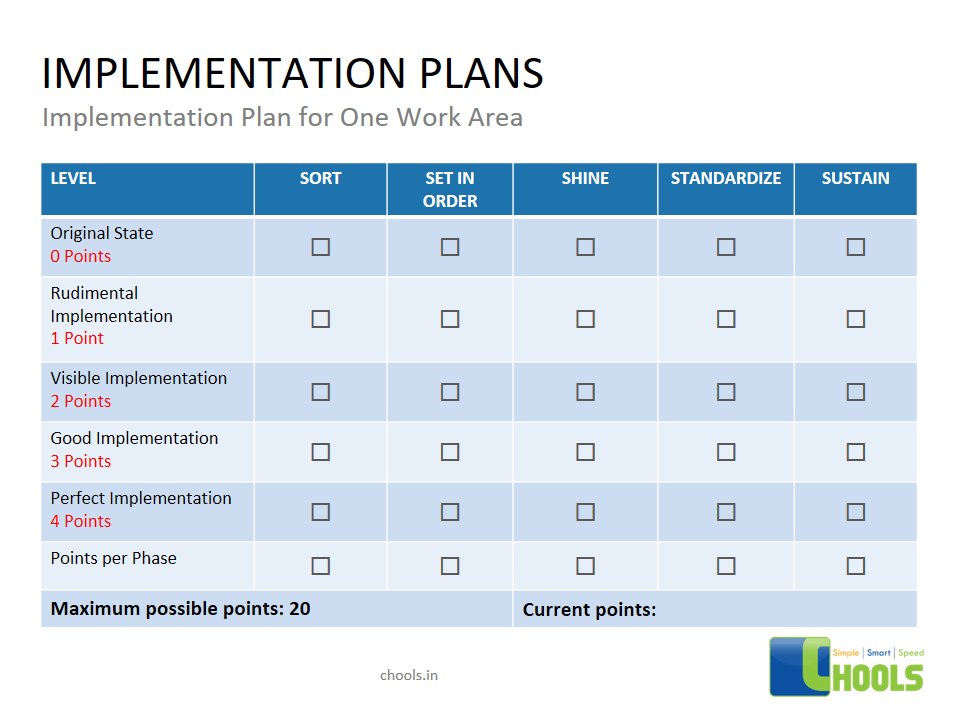

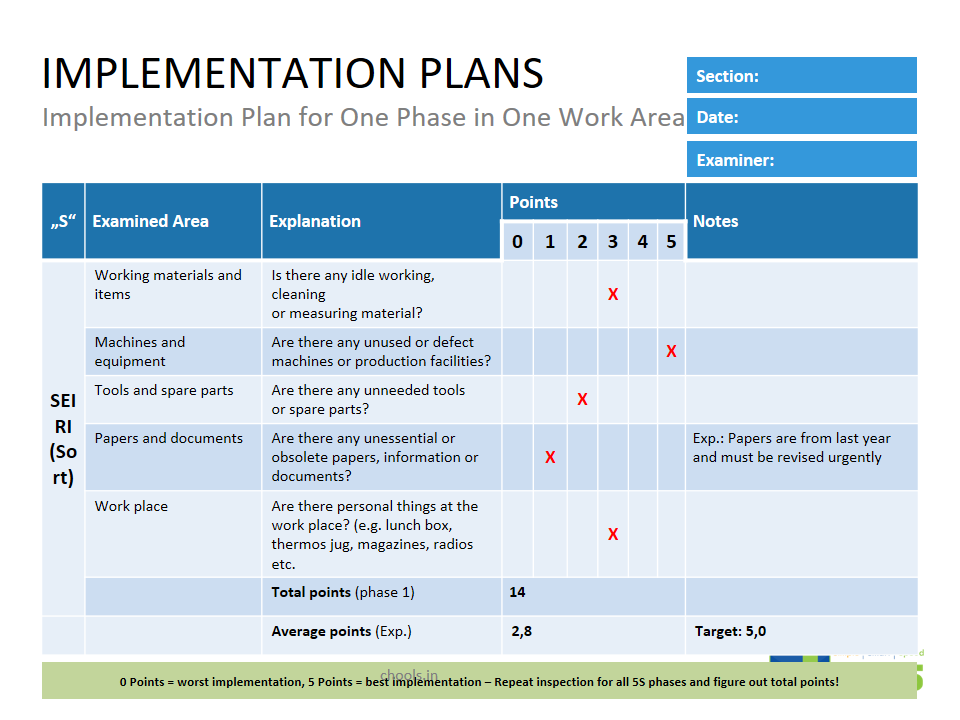

6. THE 5S CONCEPT

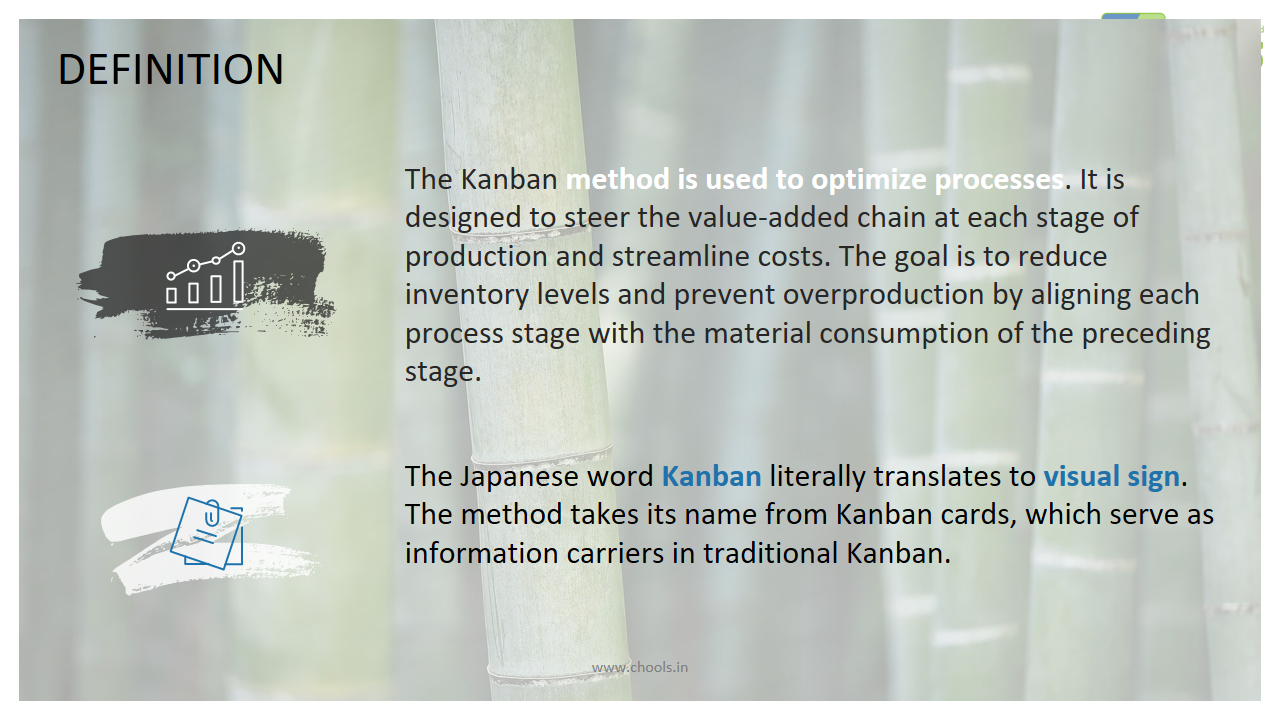

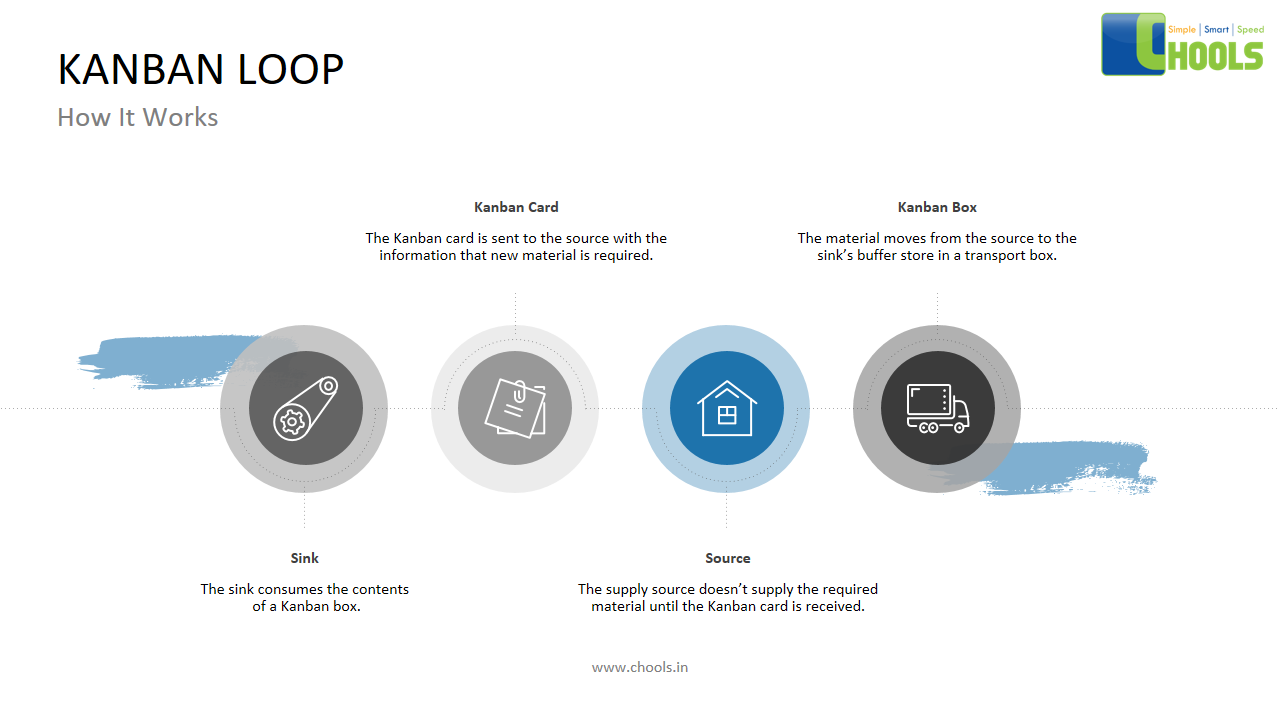

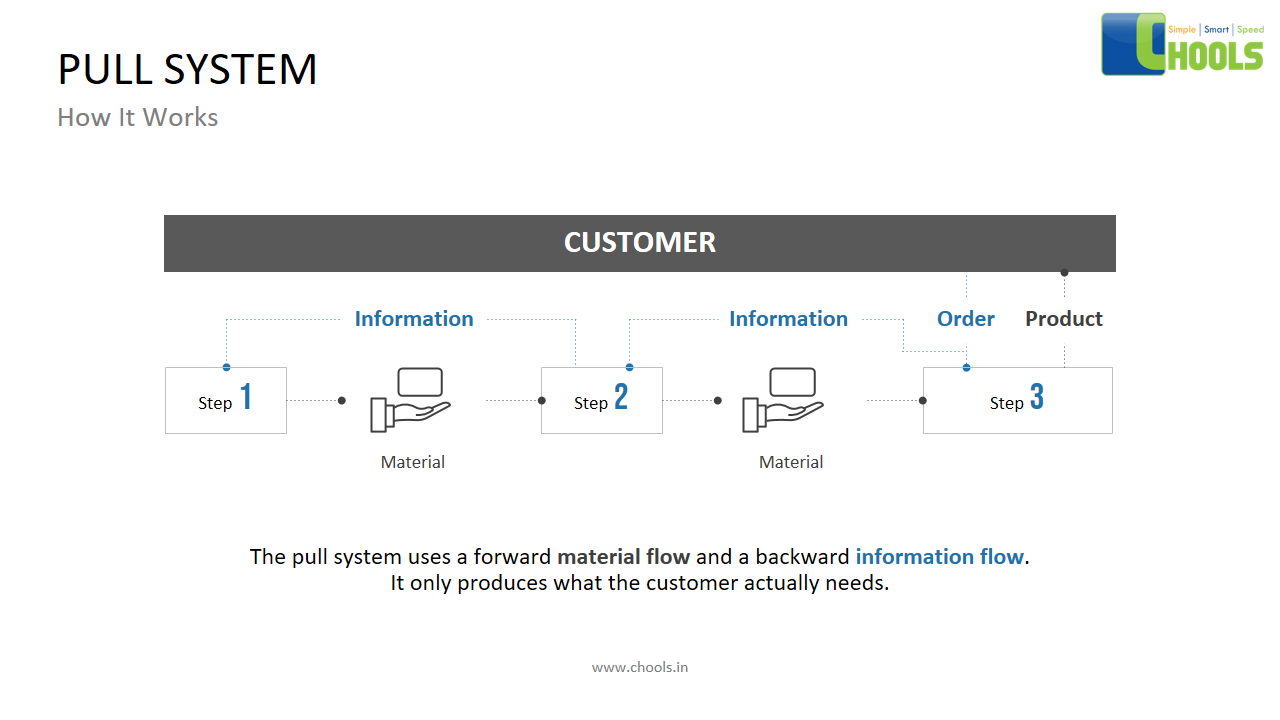

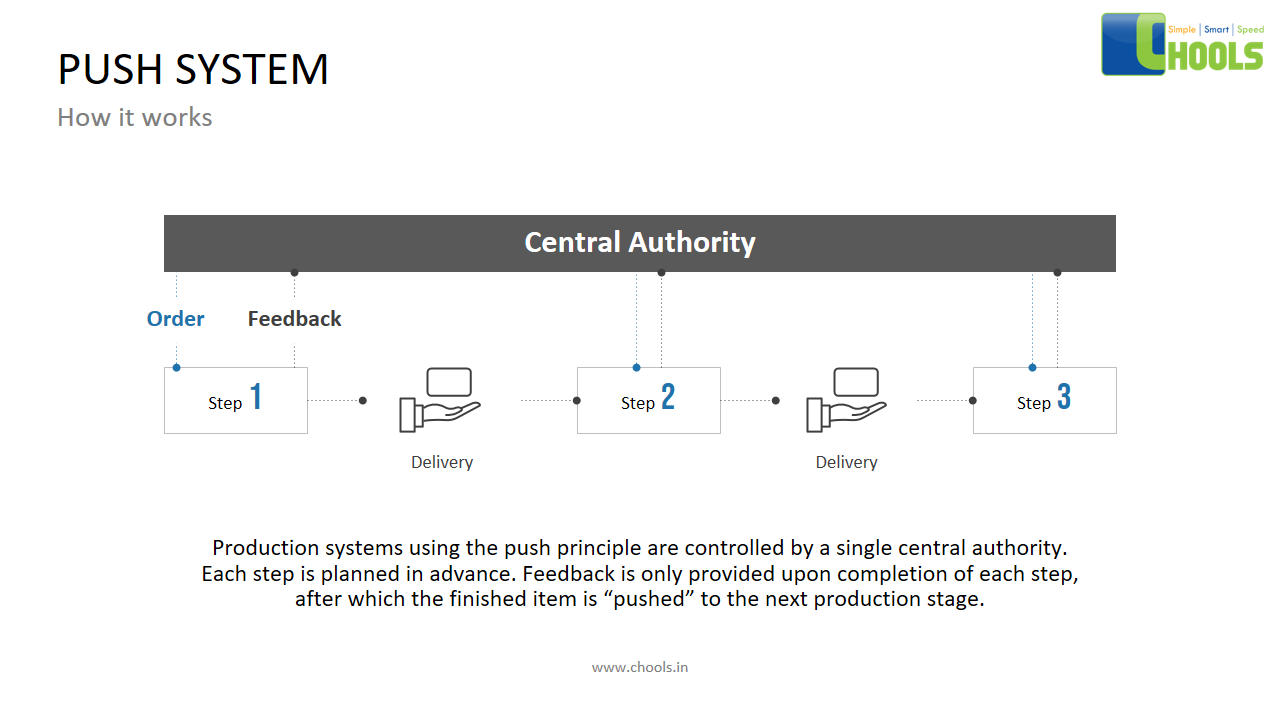

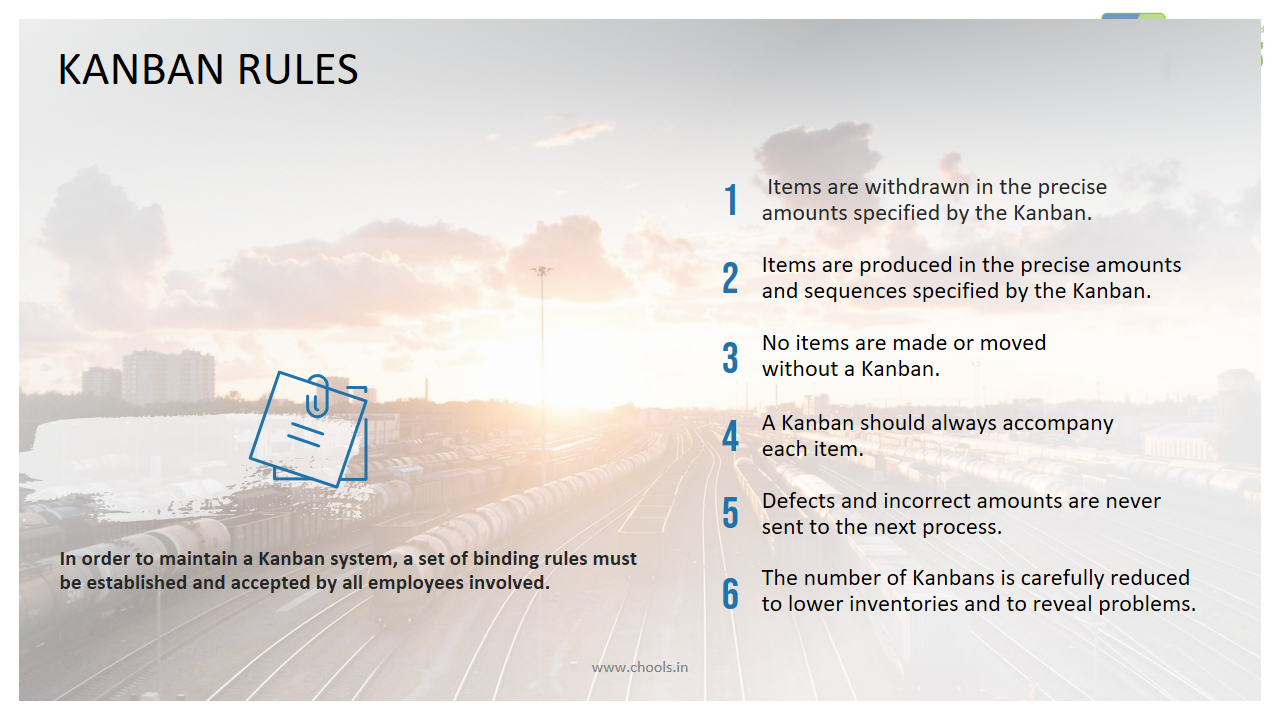

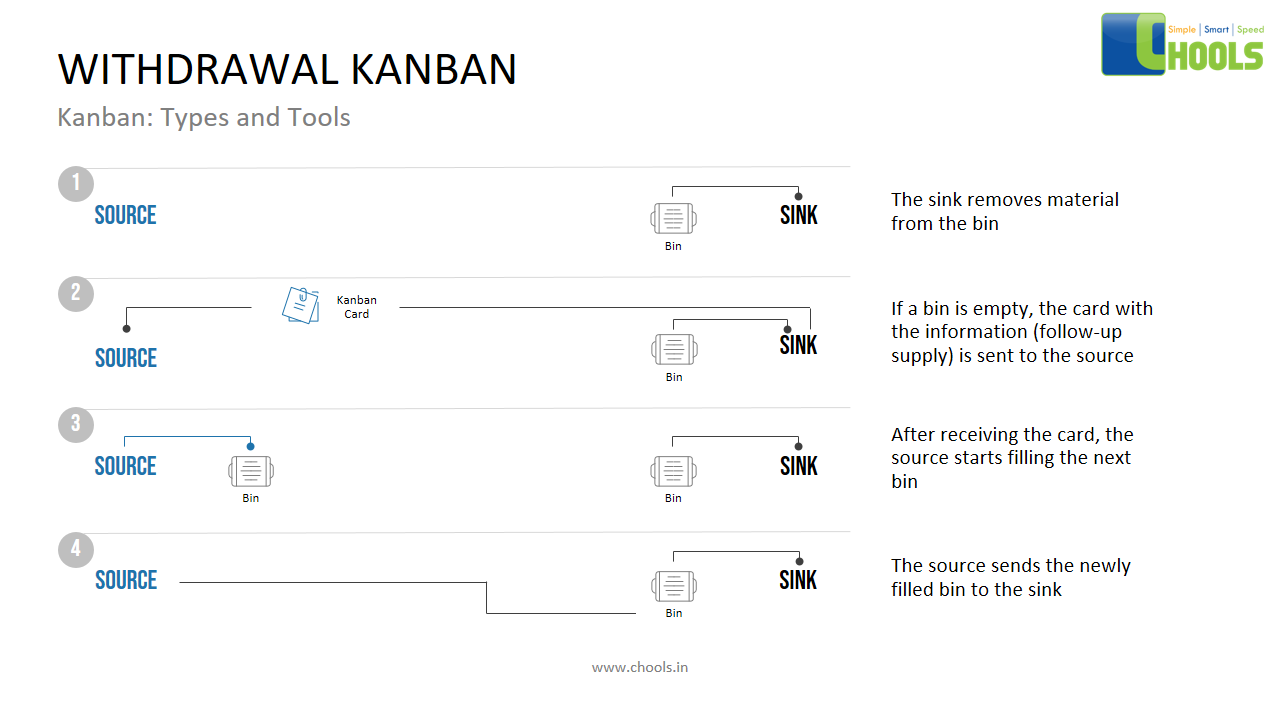

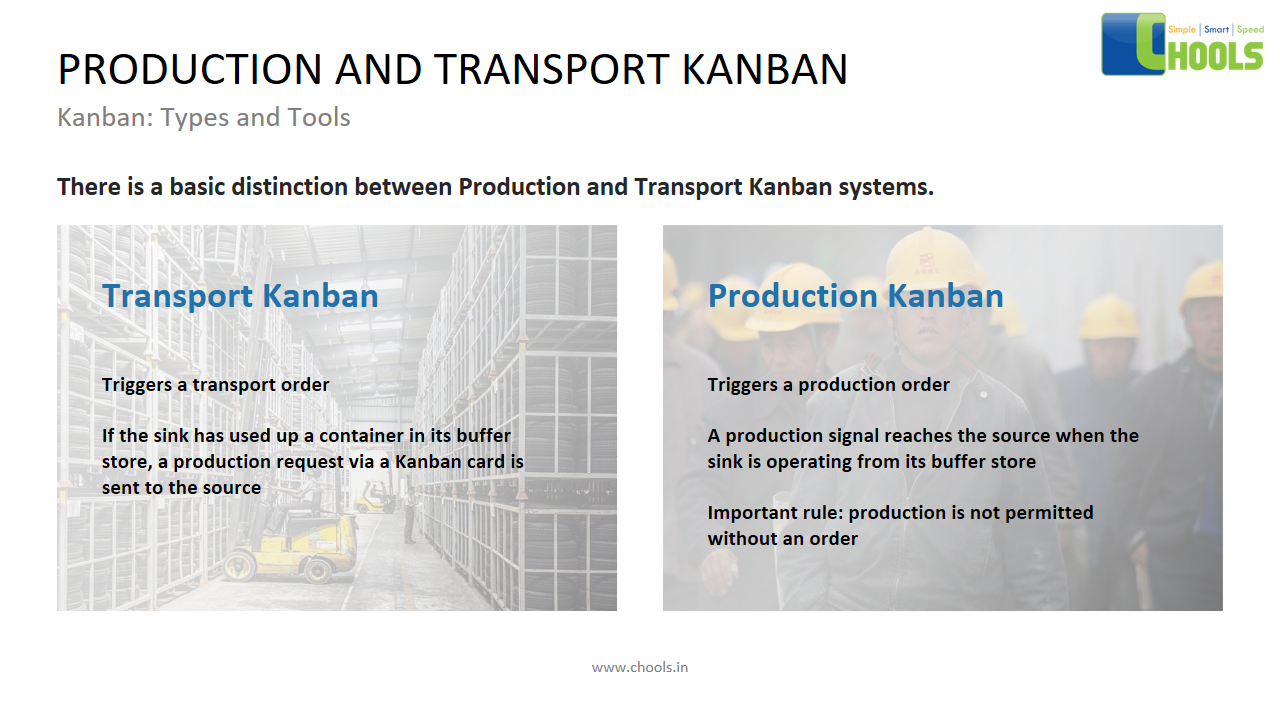

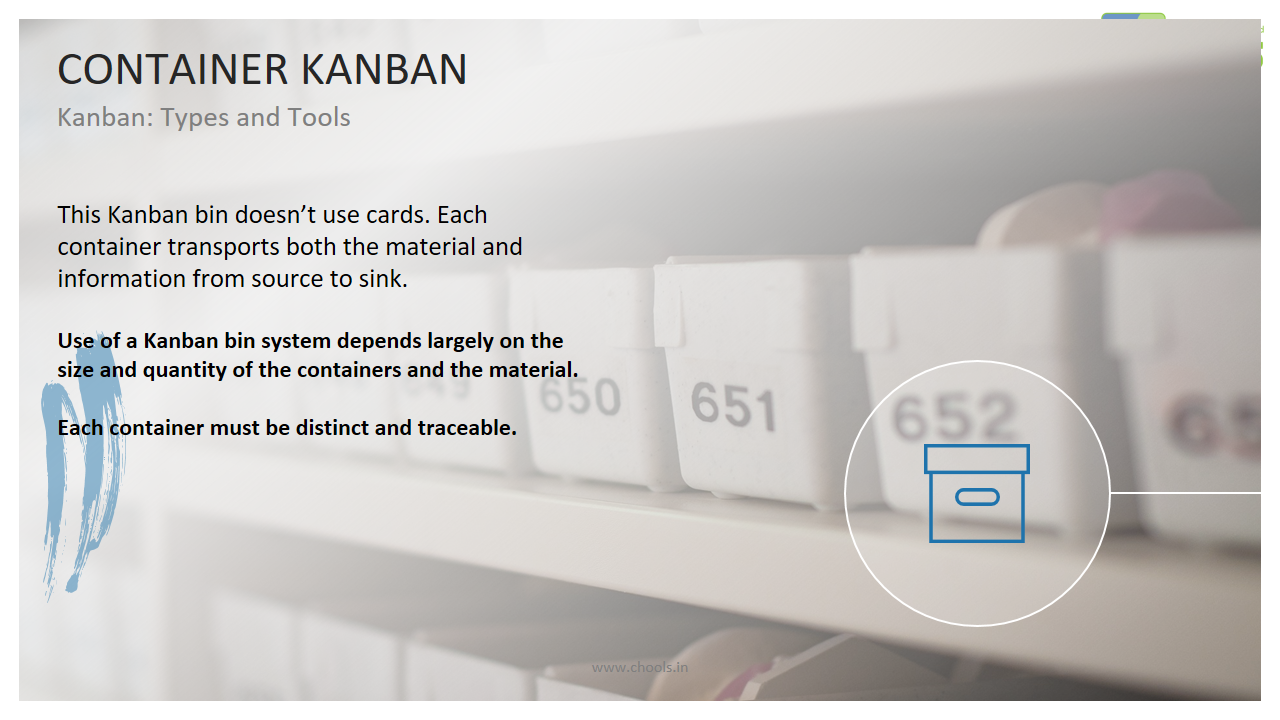

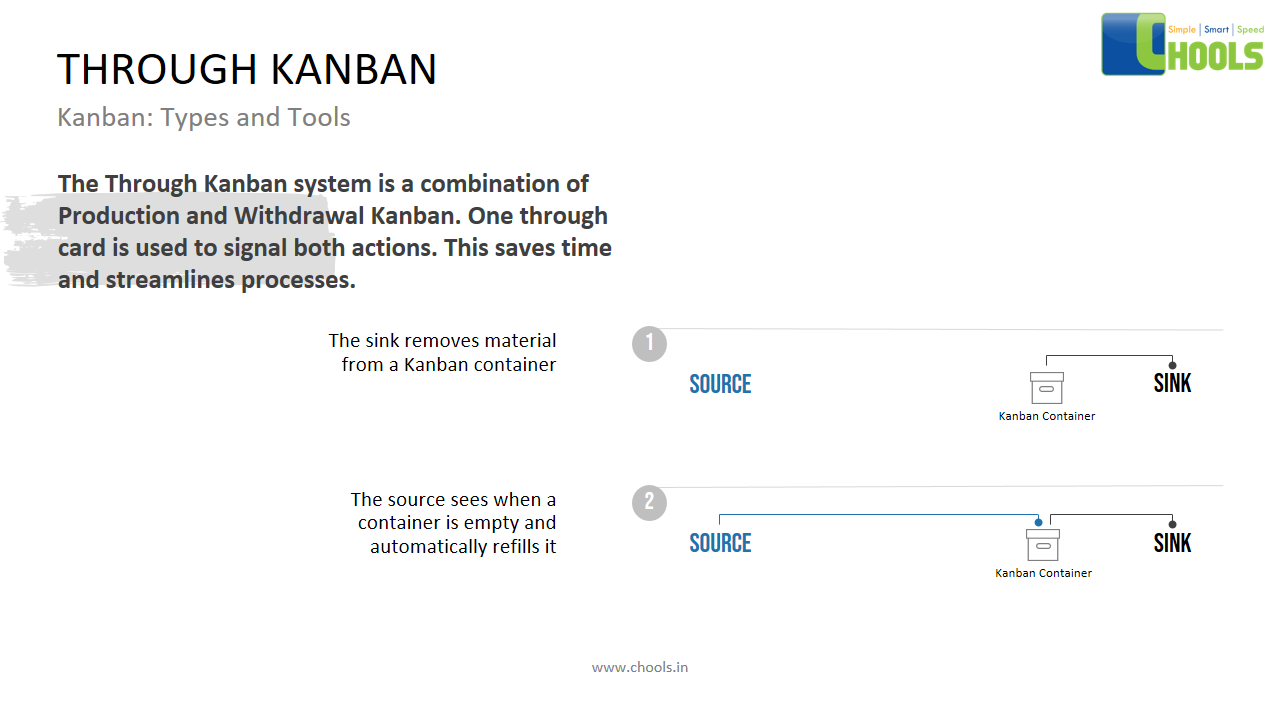

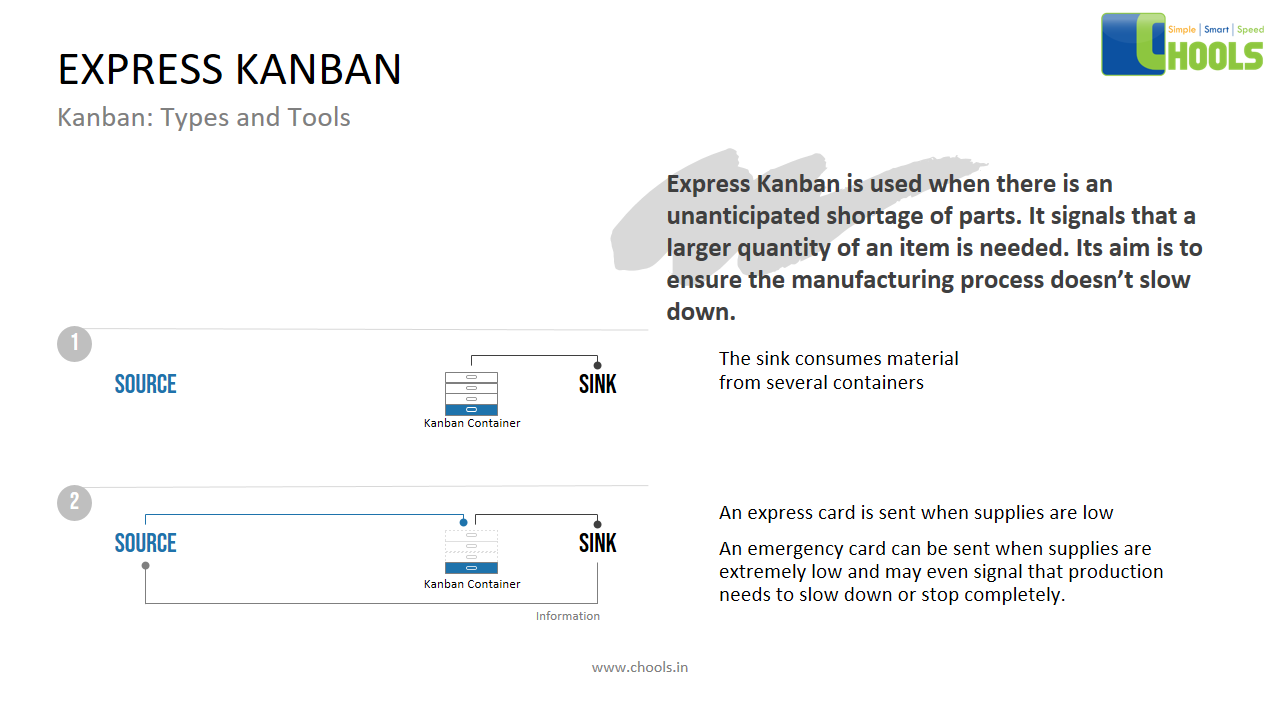

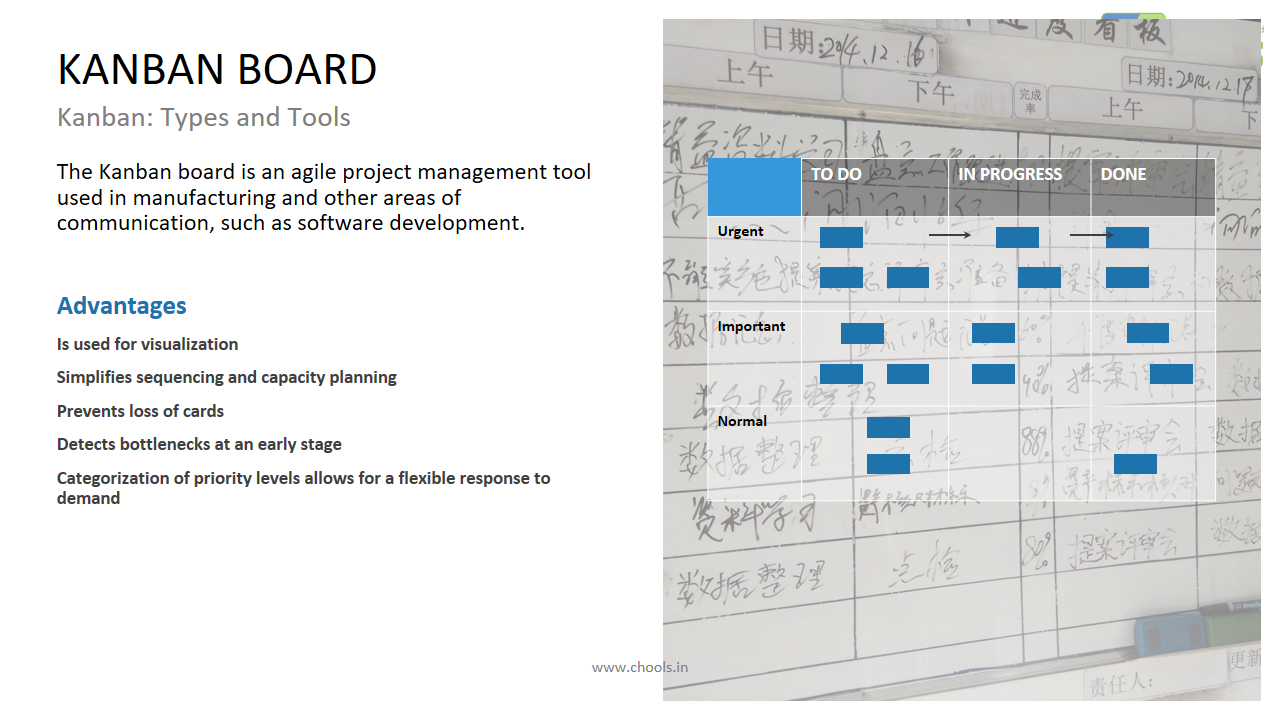

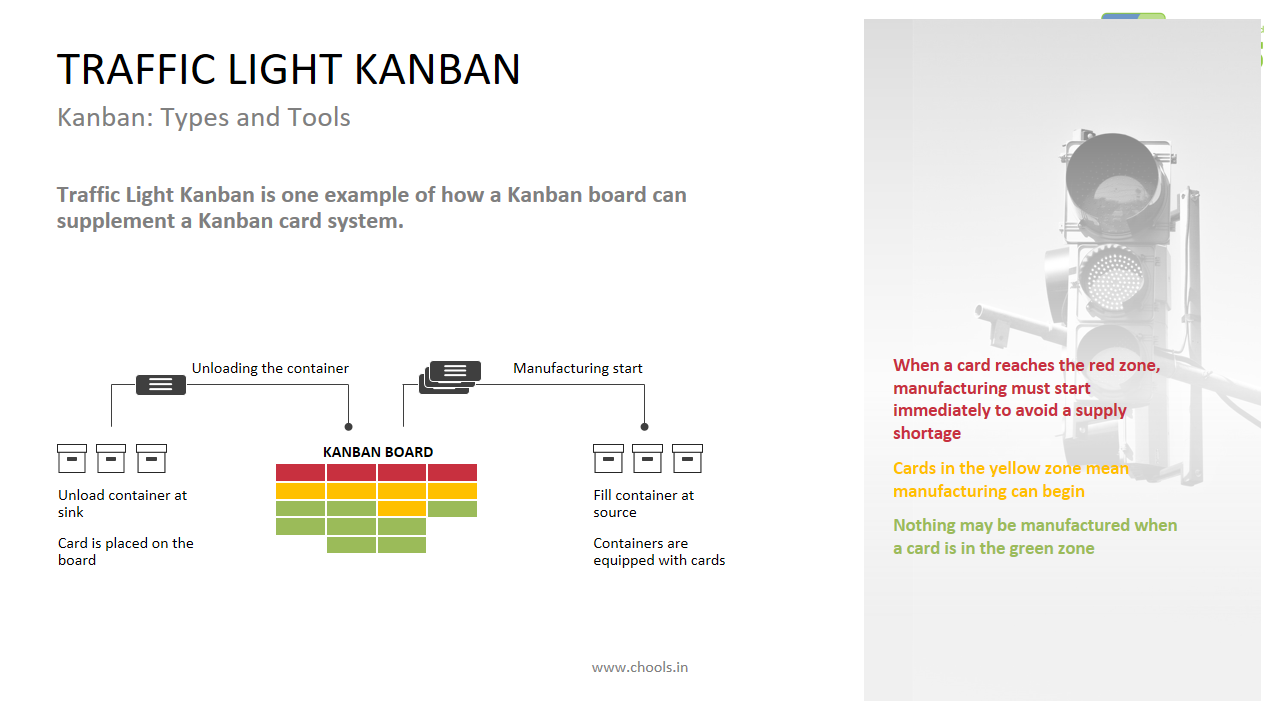

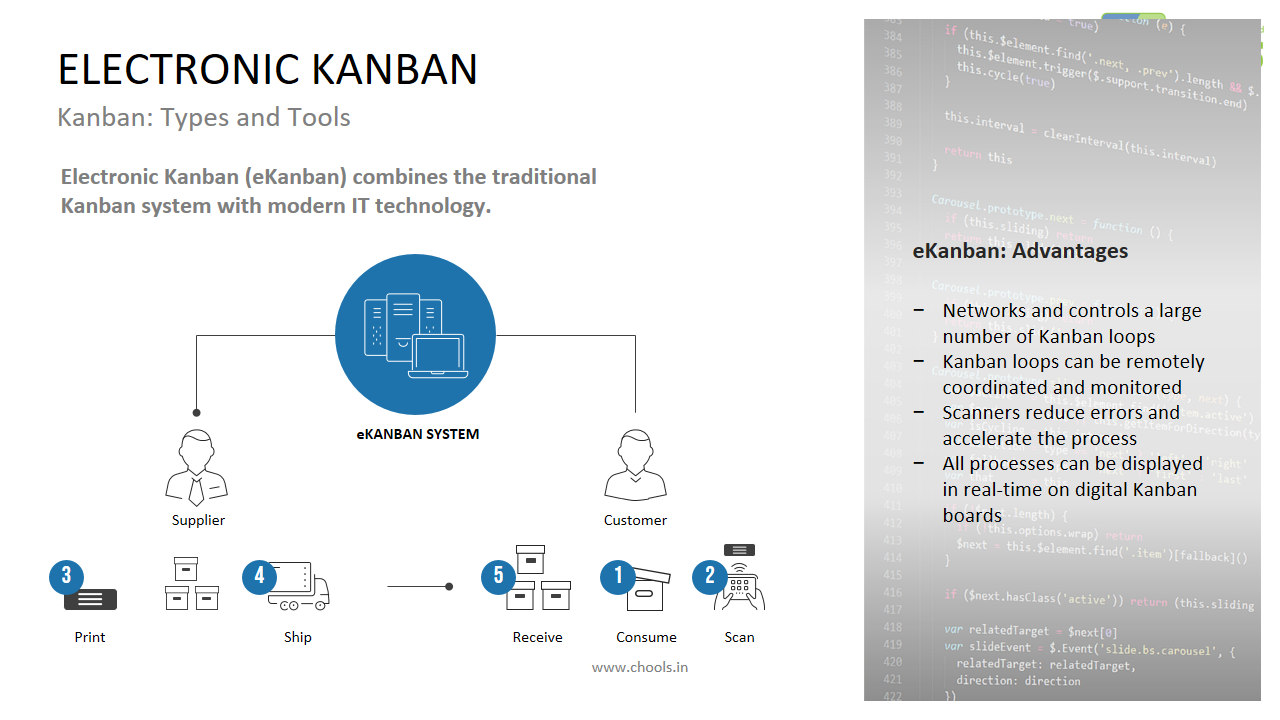

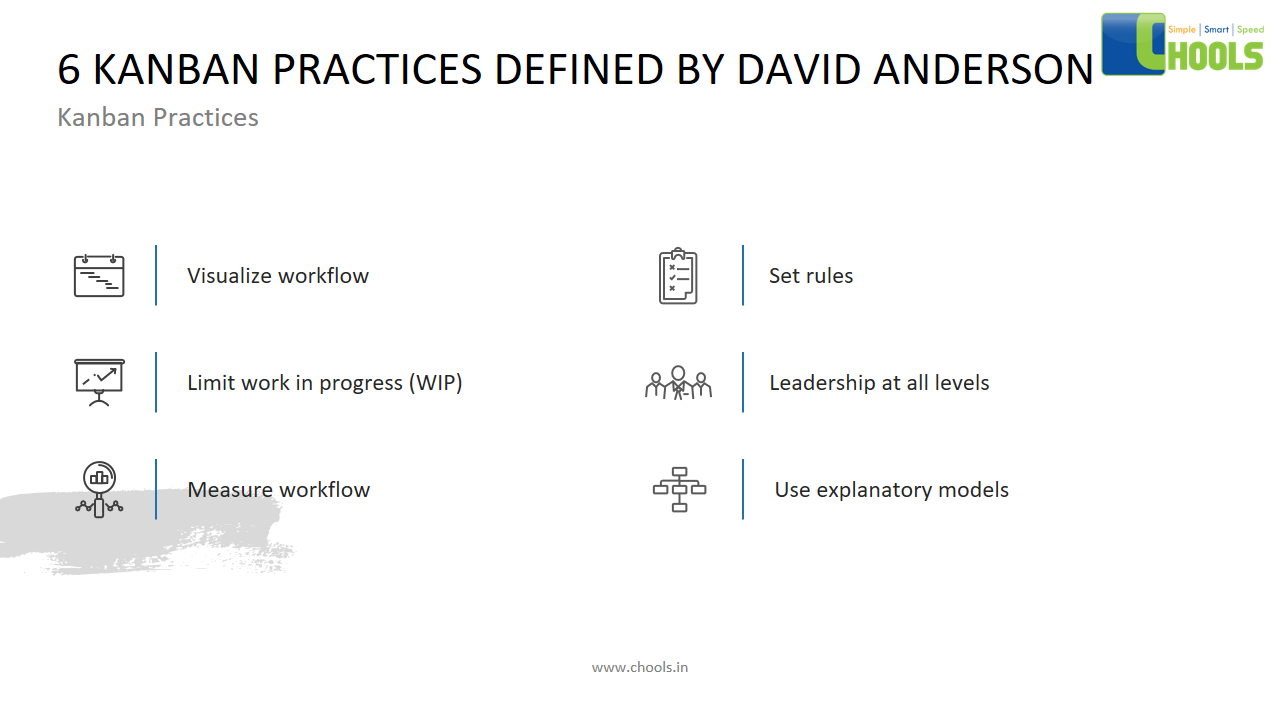

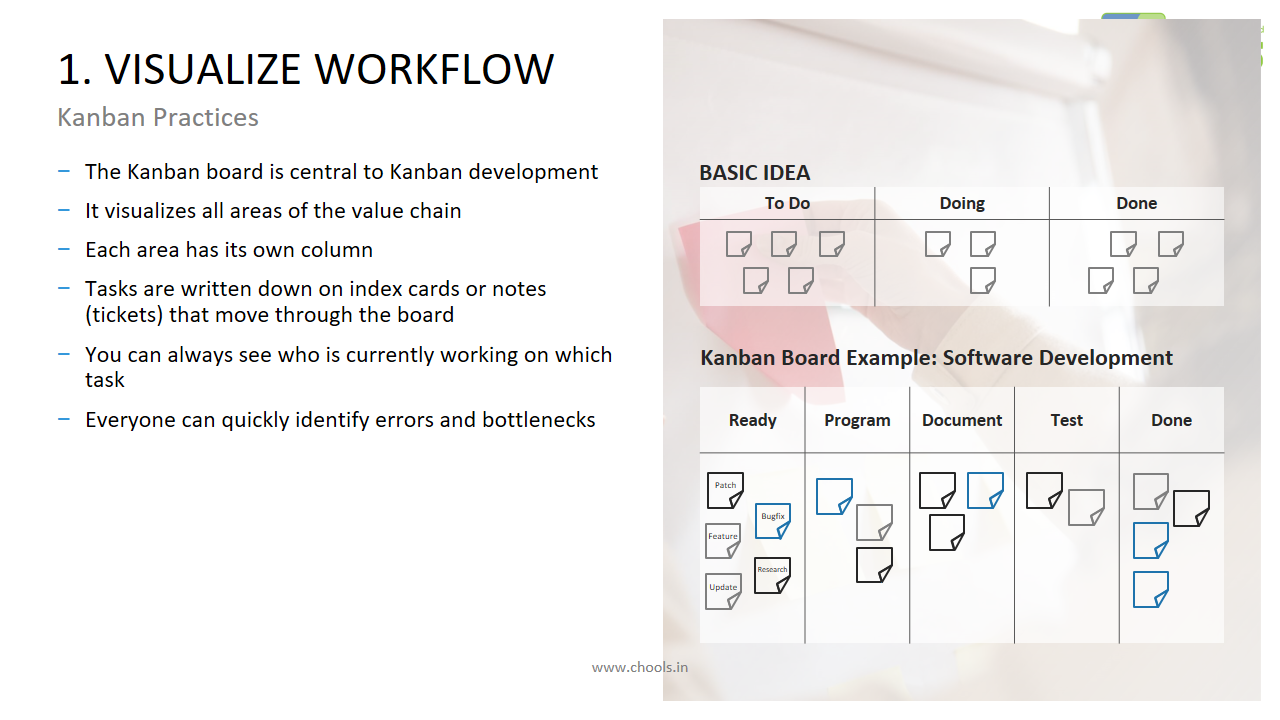

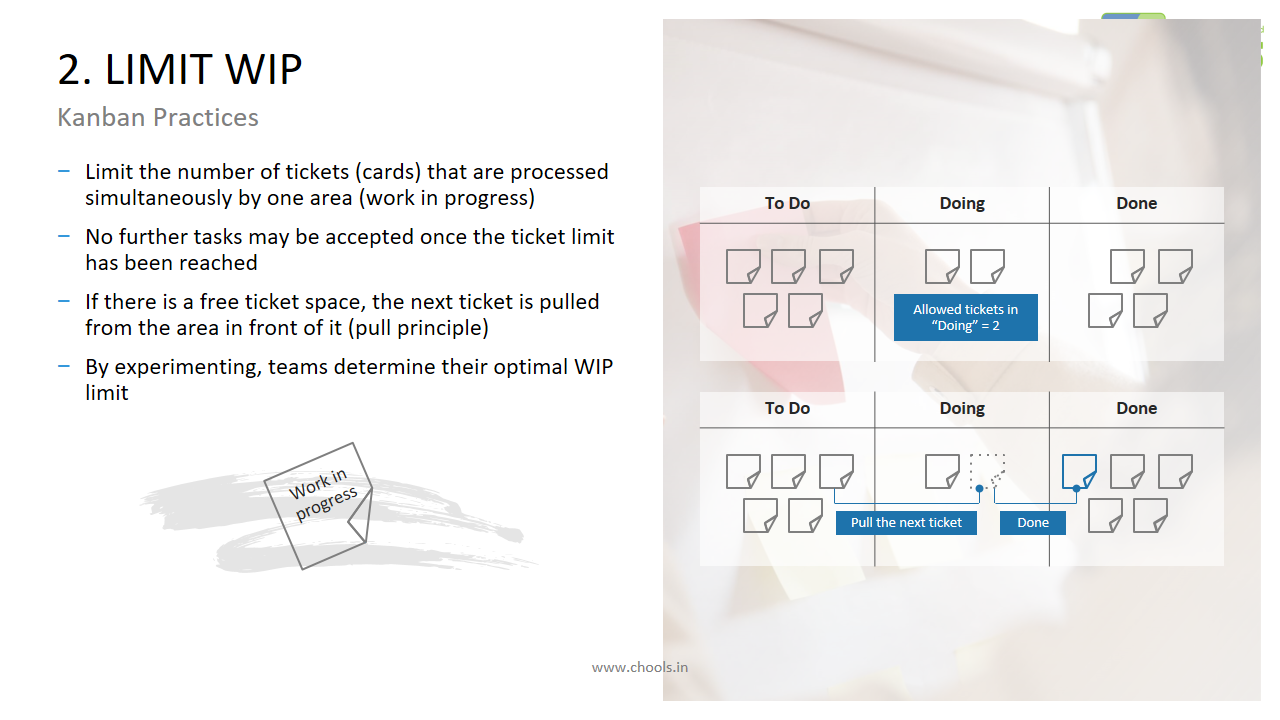

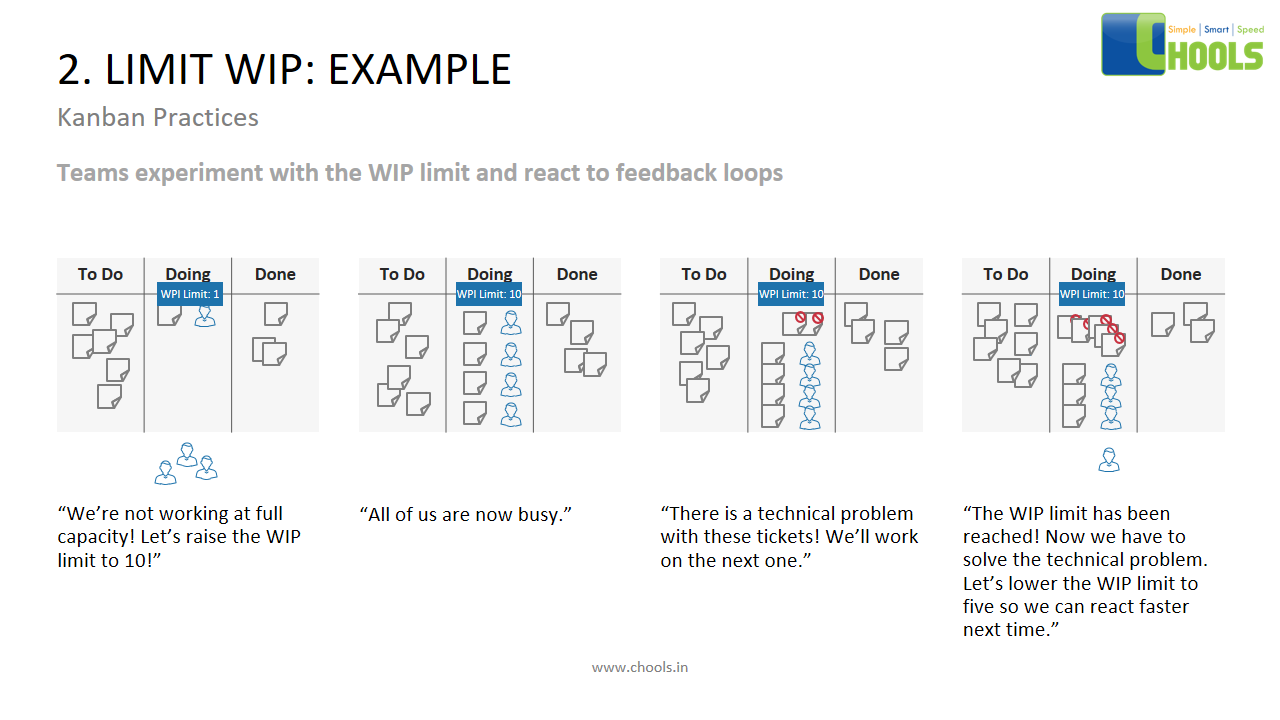

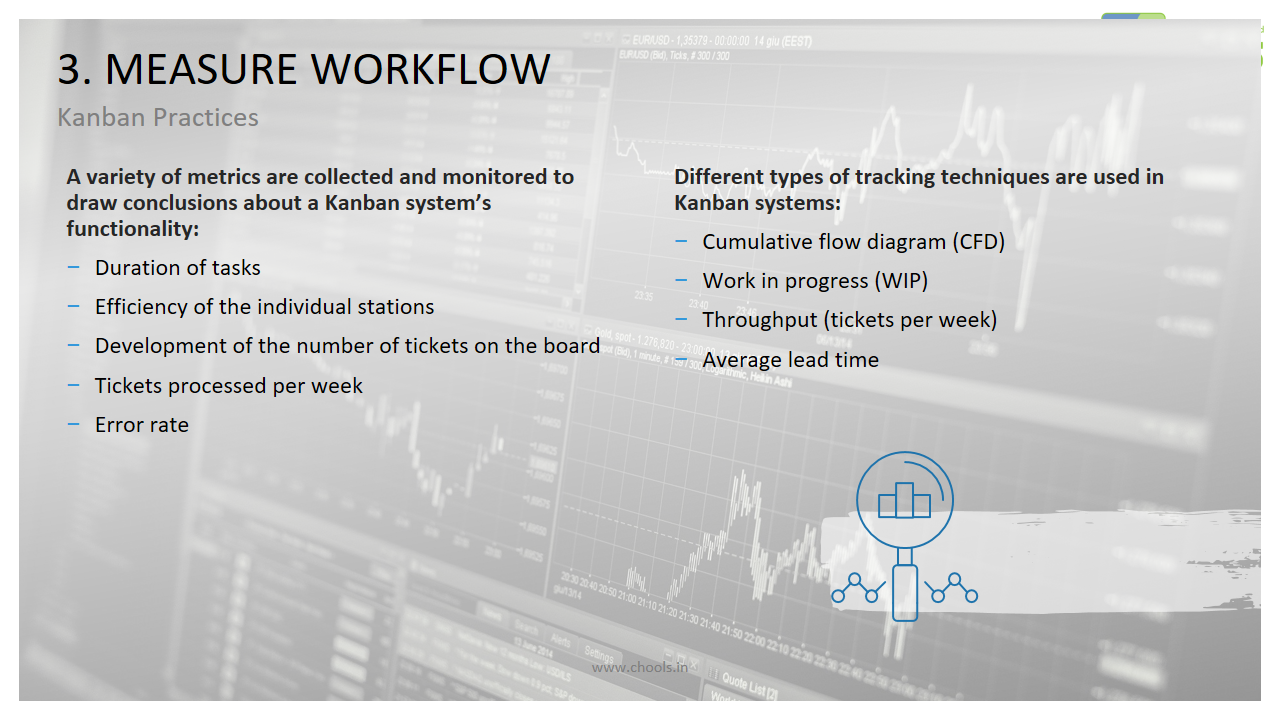

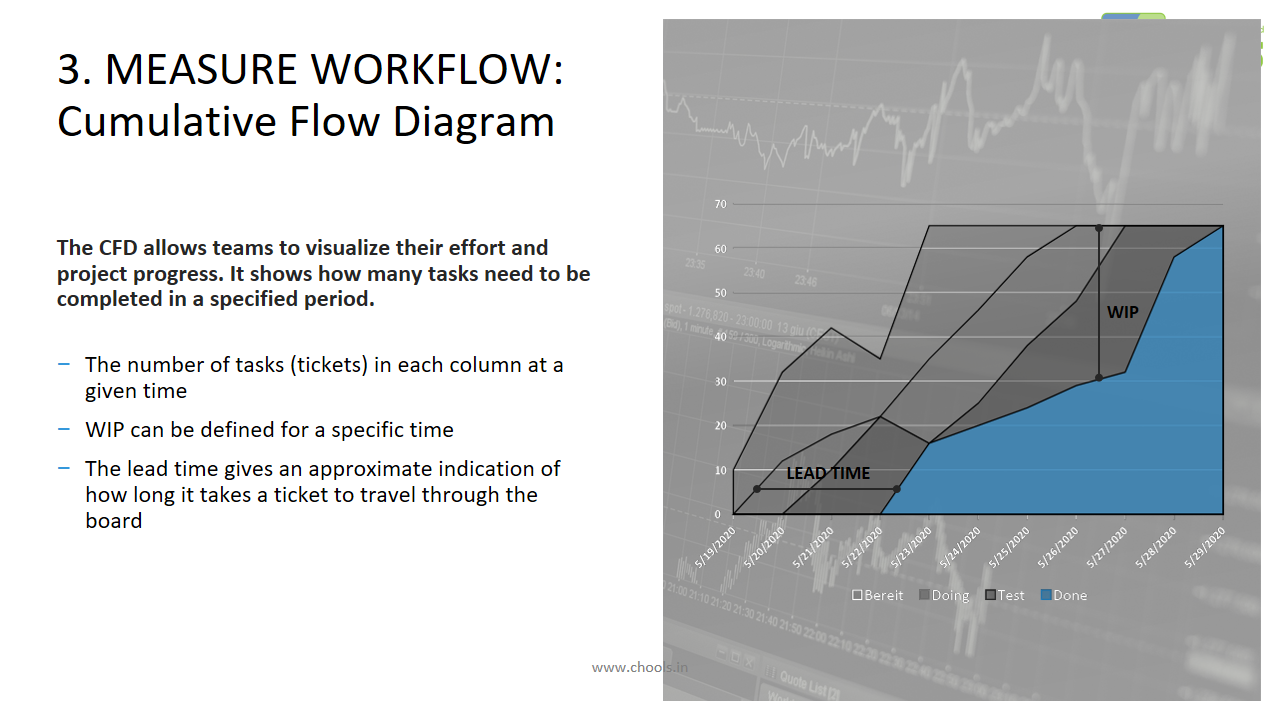

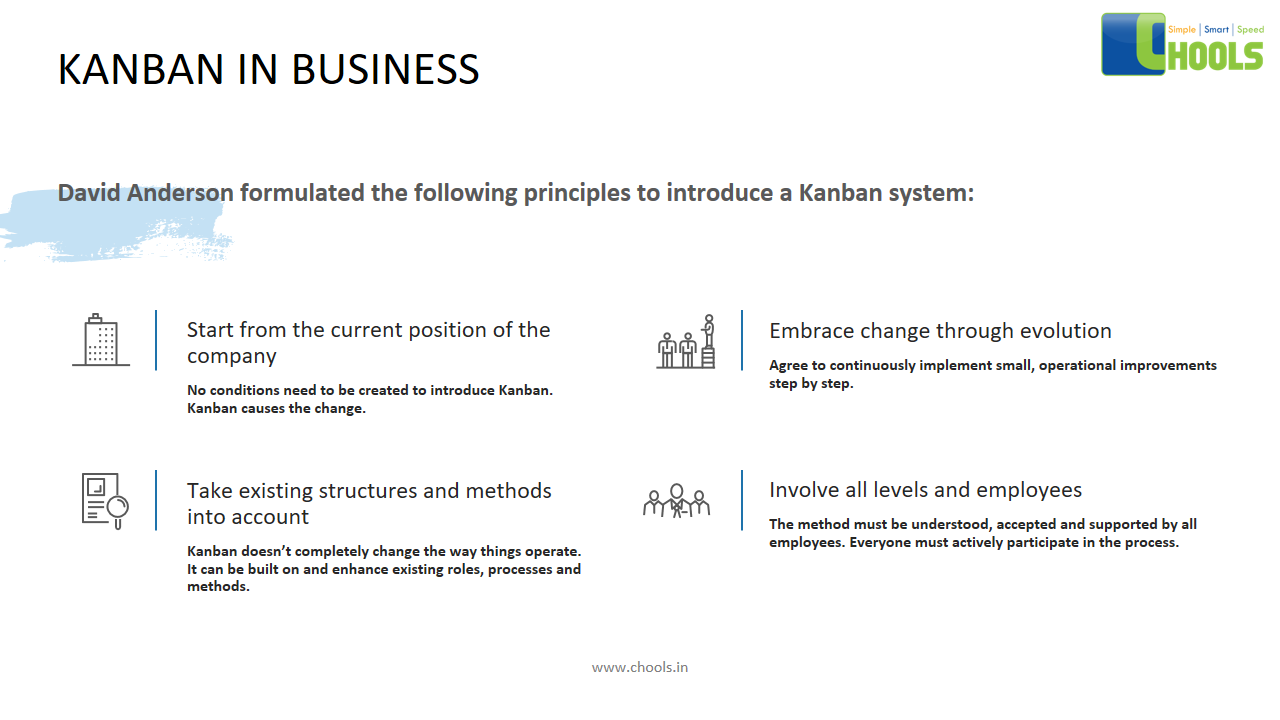

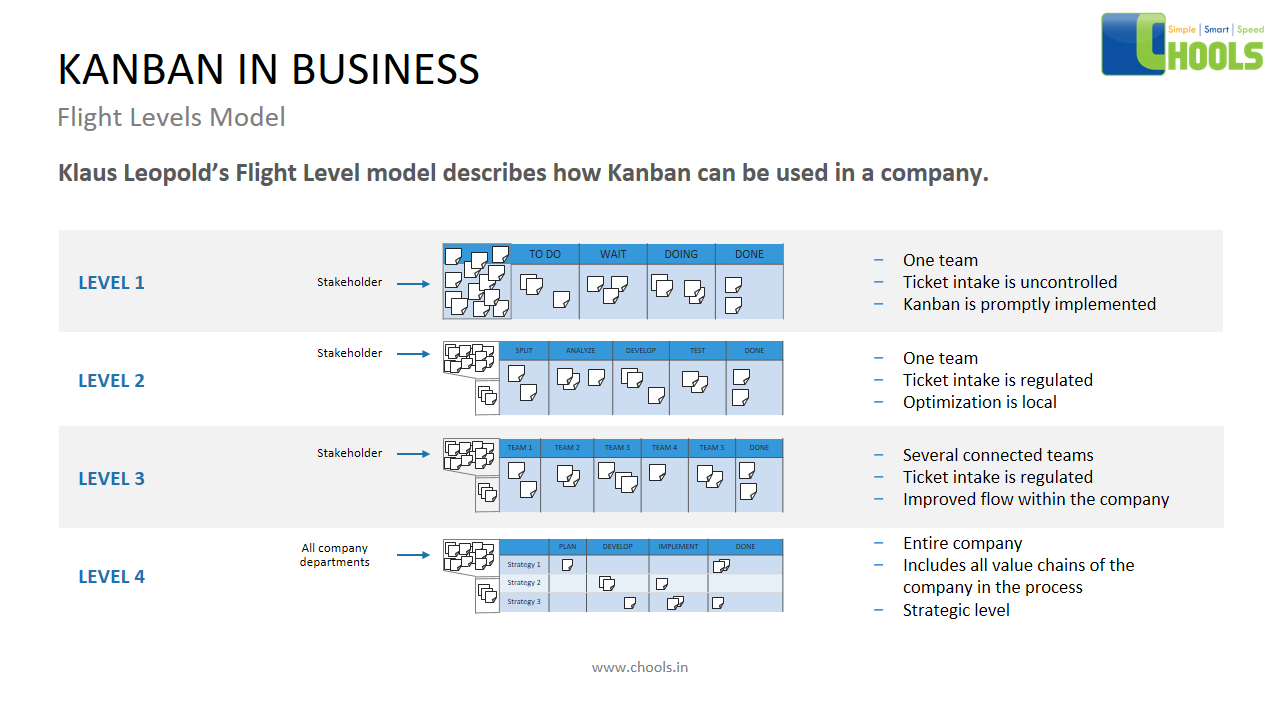

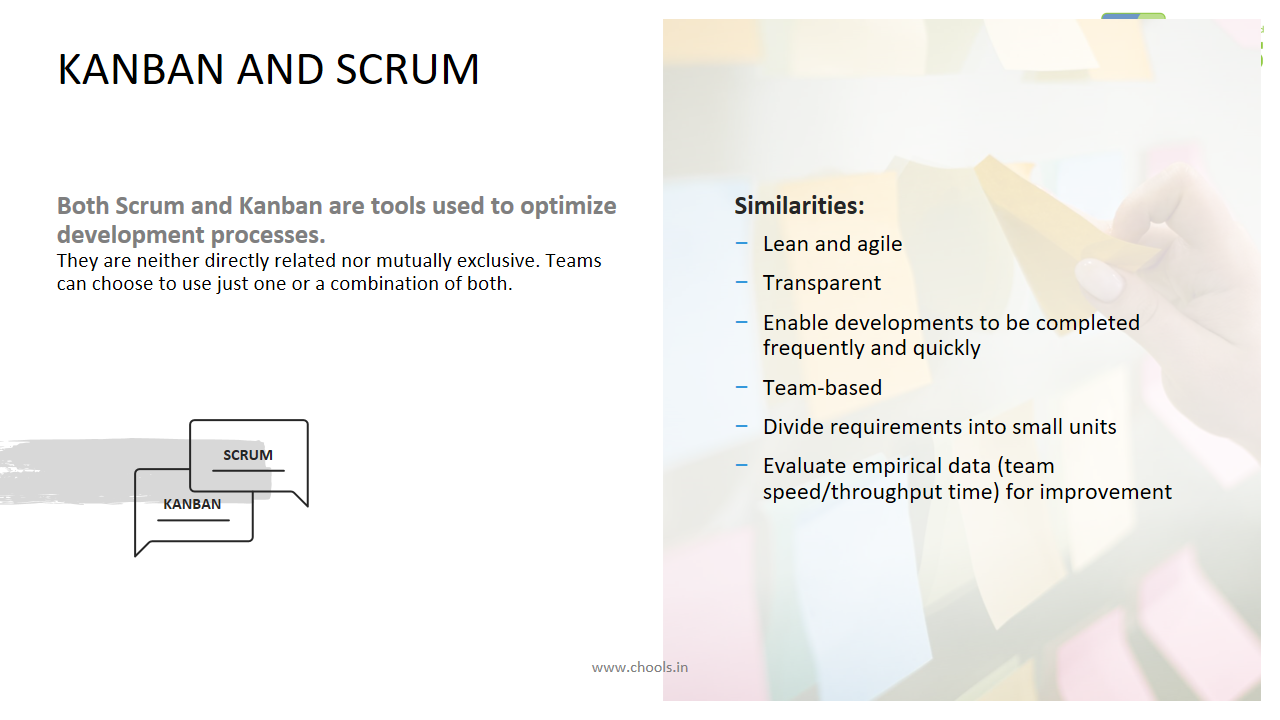

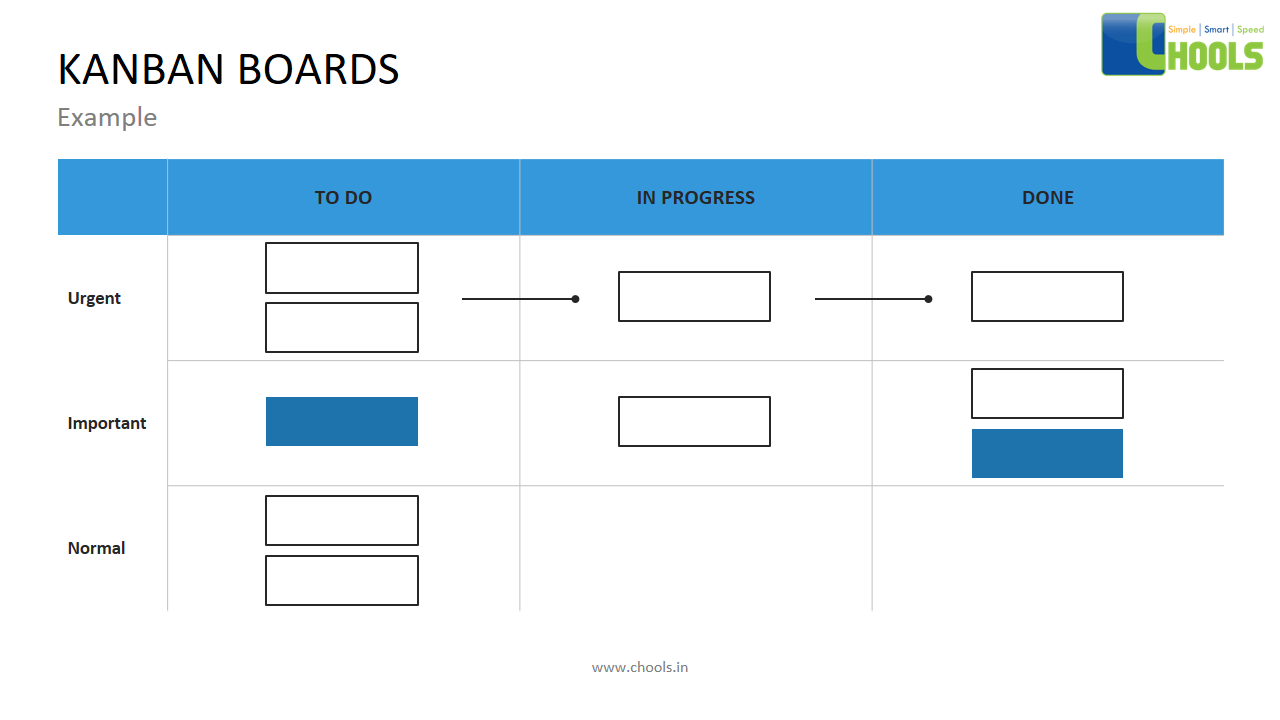

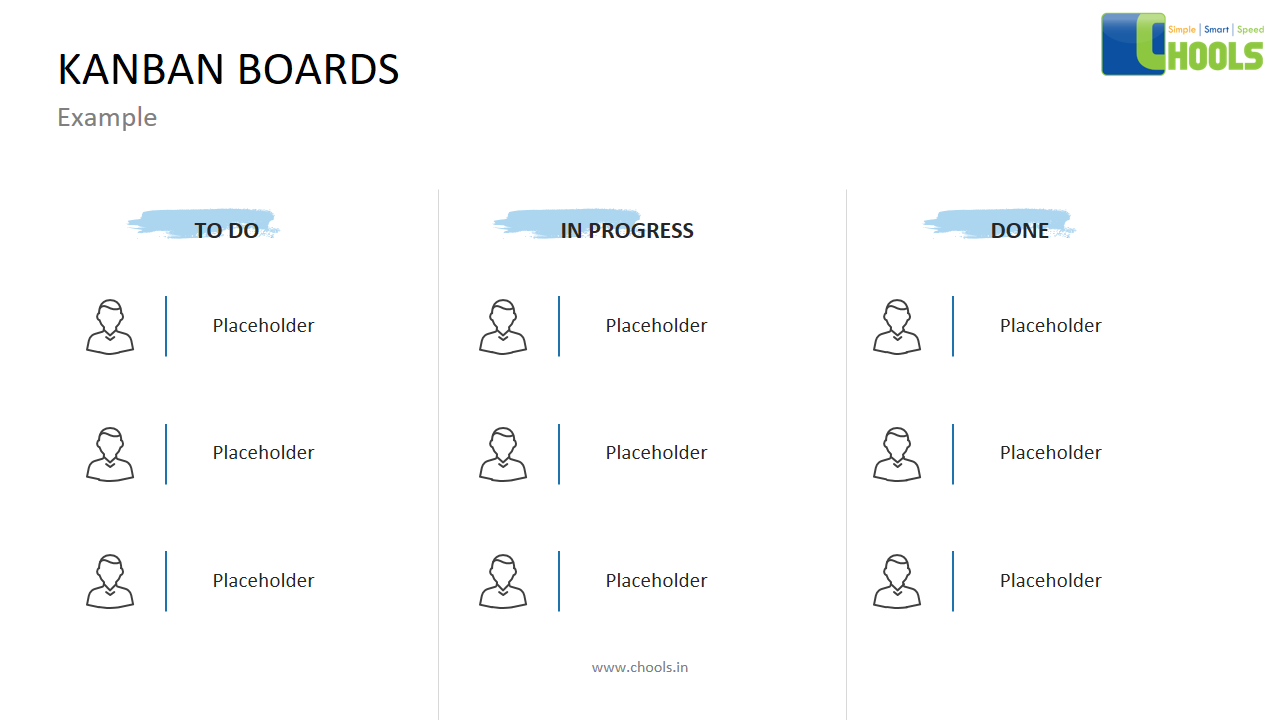

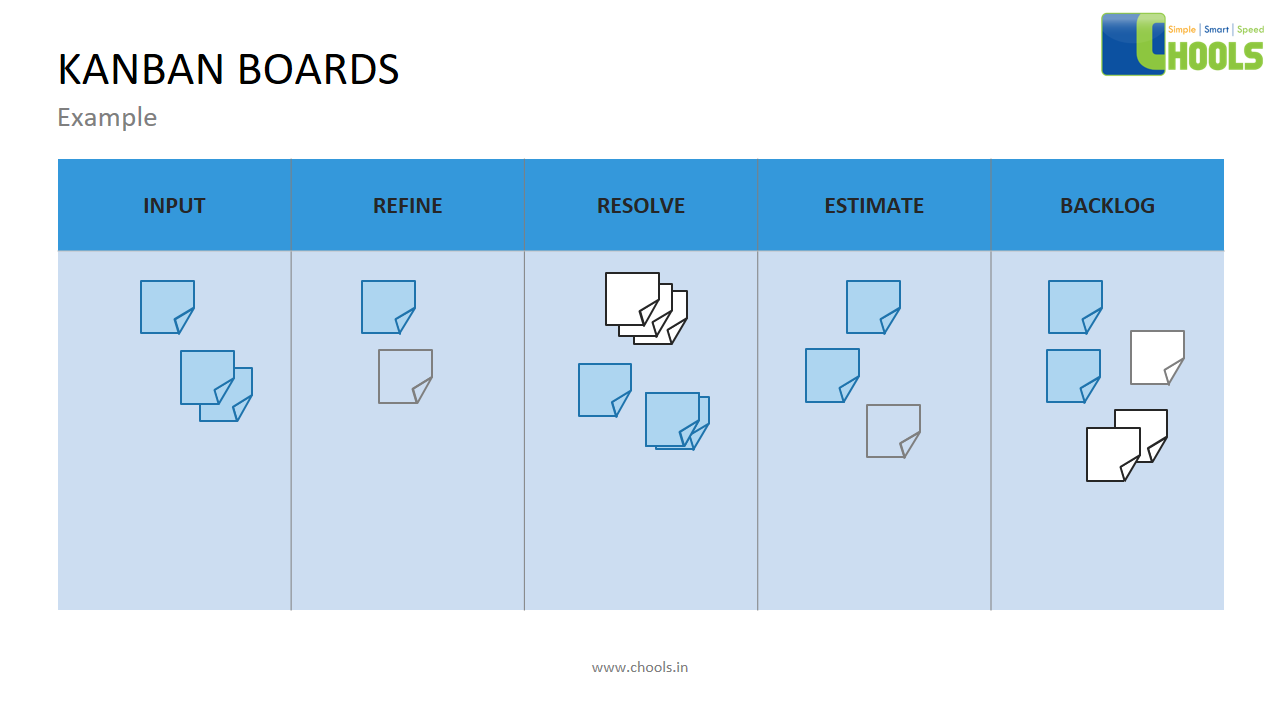

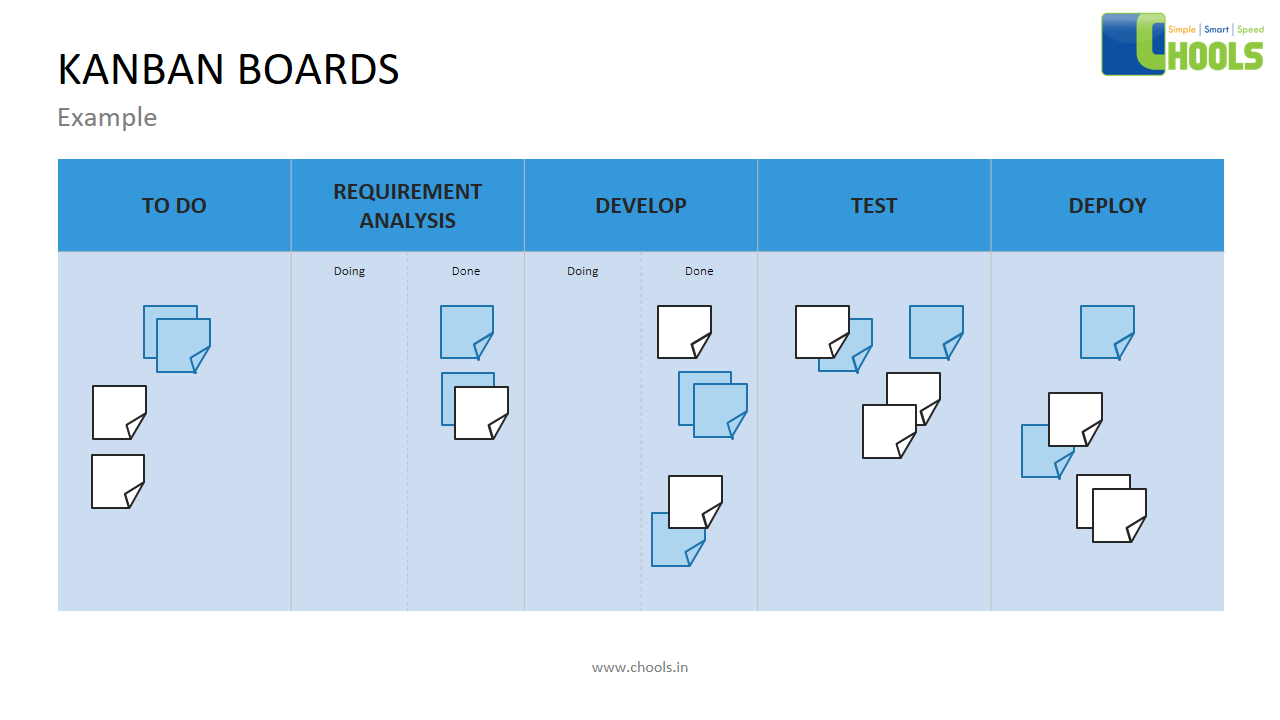

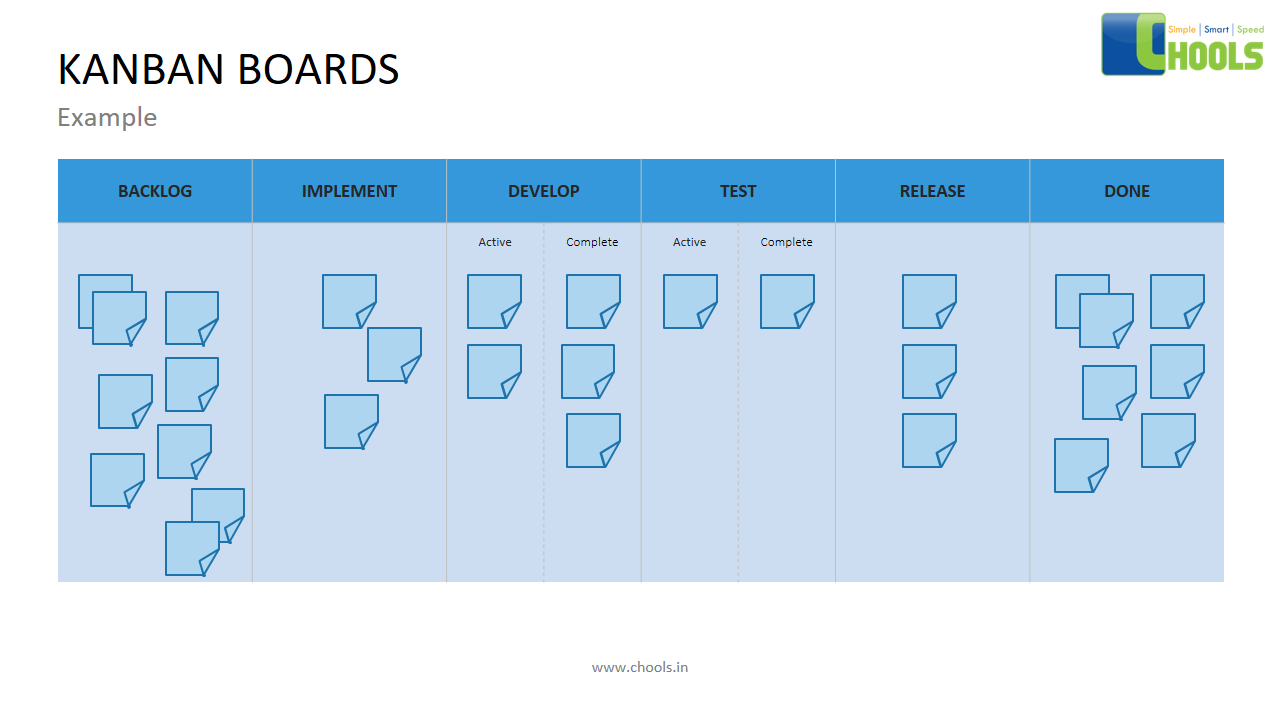

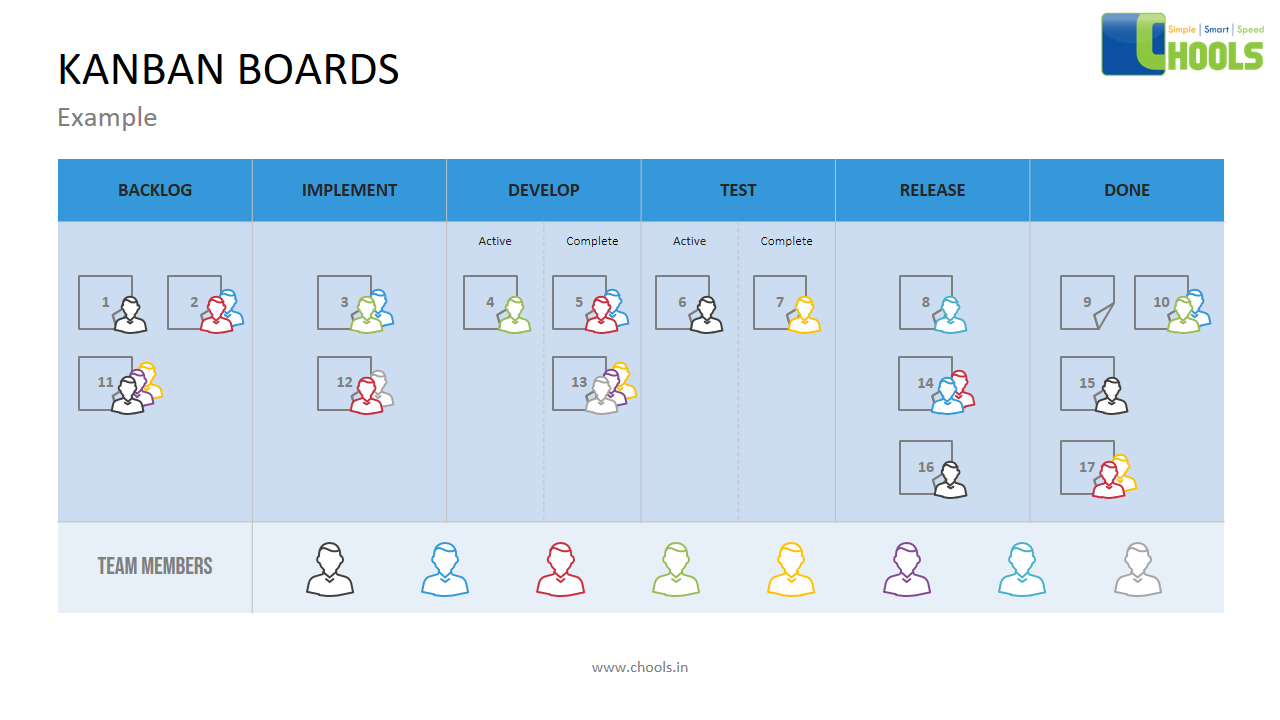

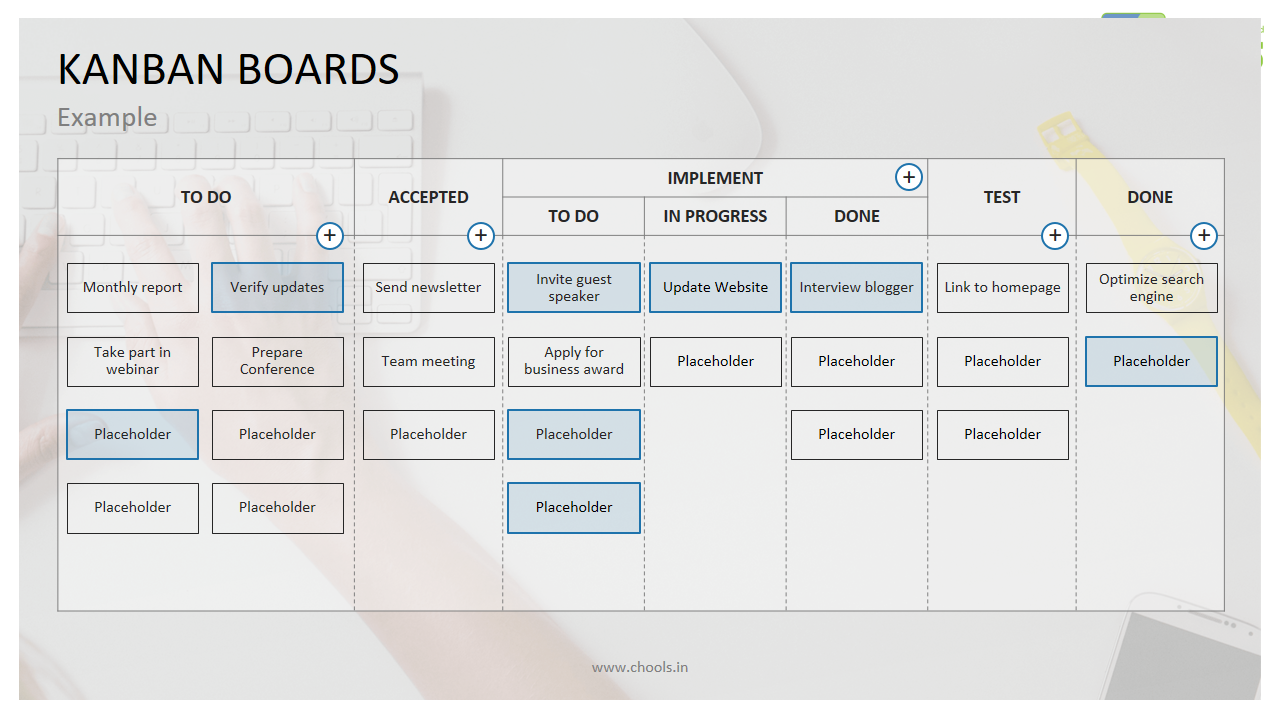

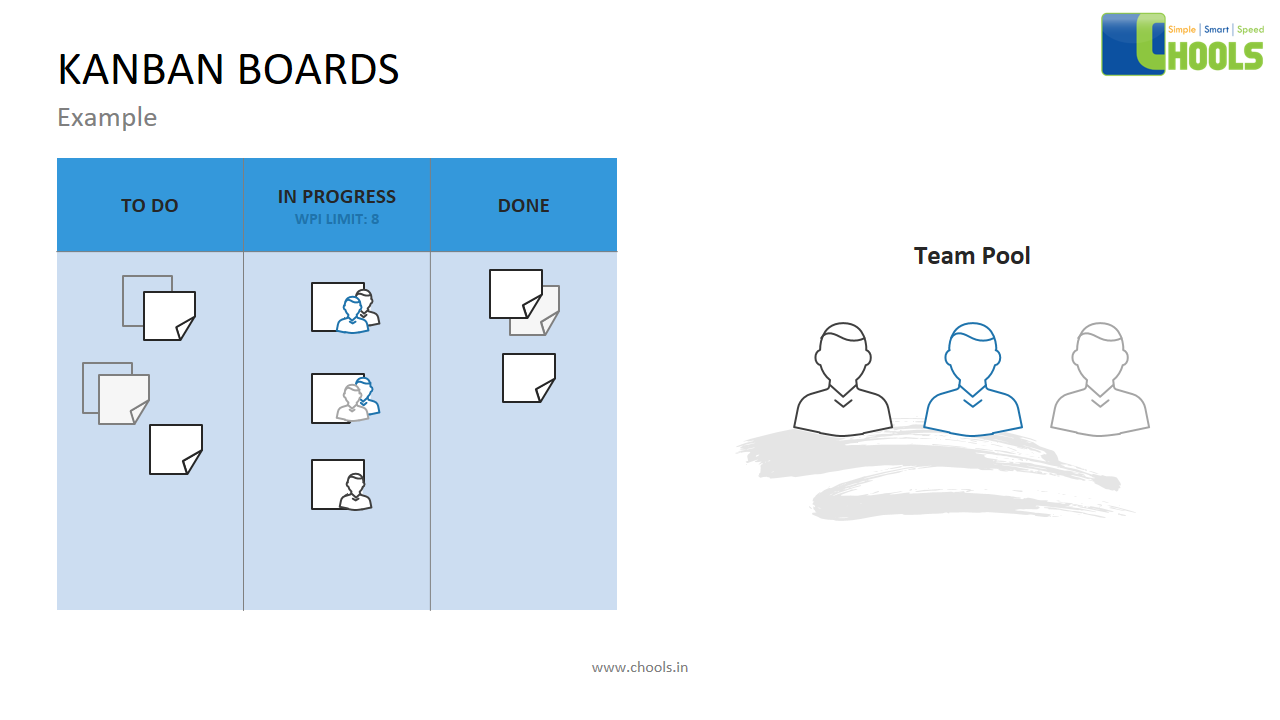

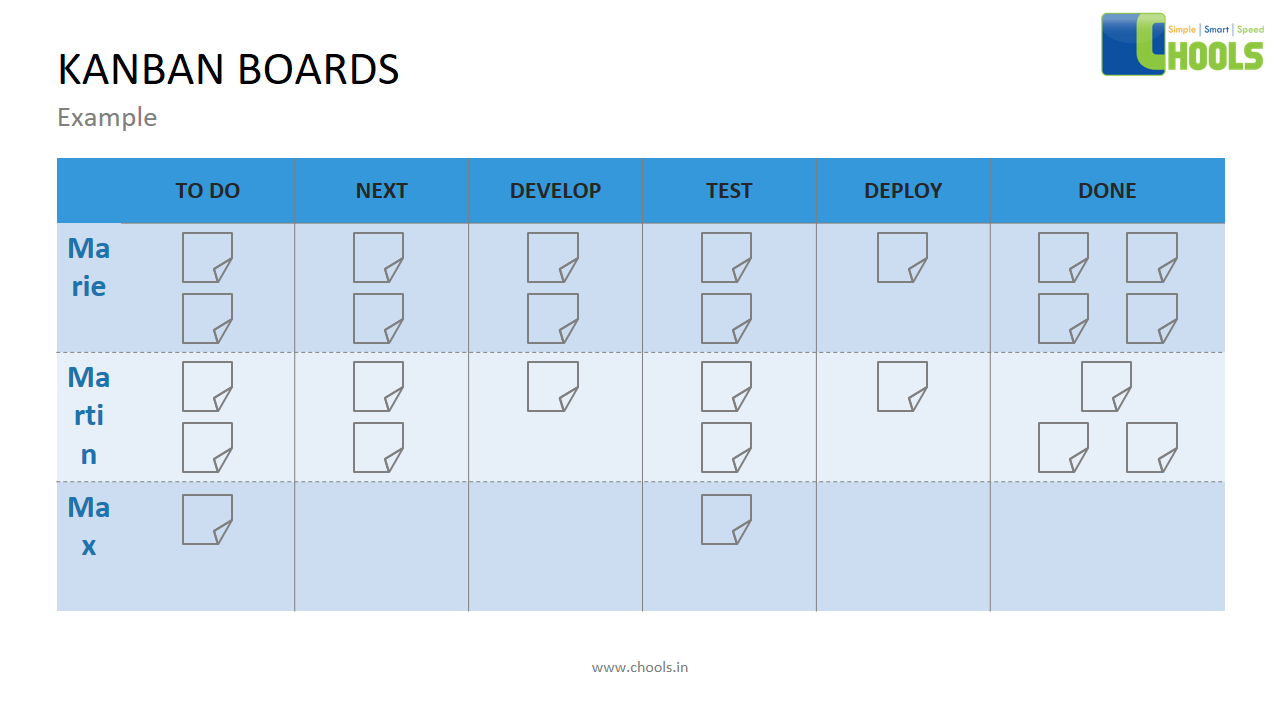

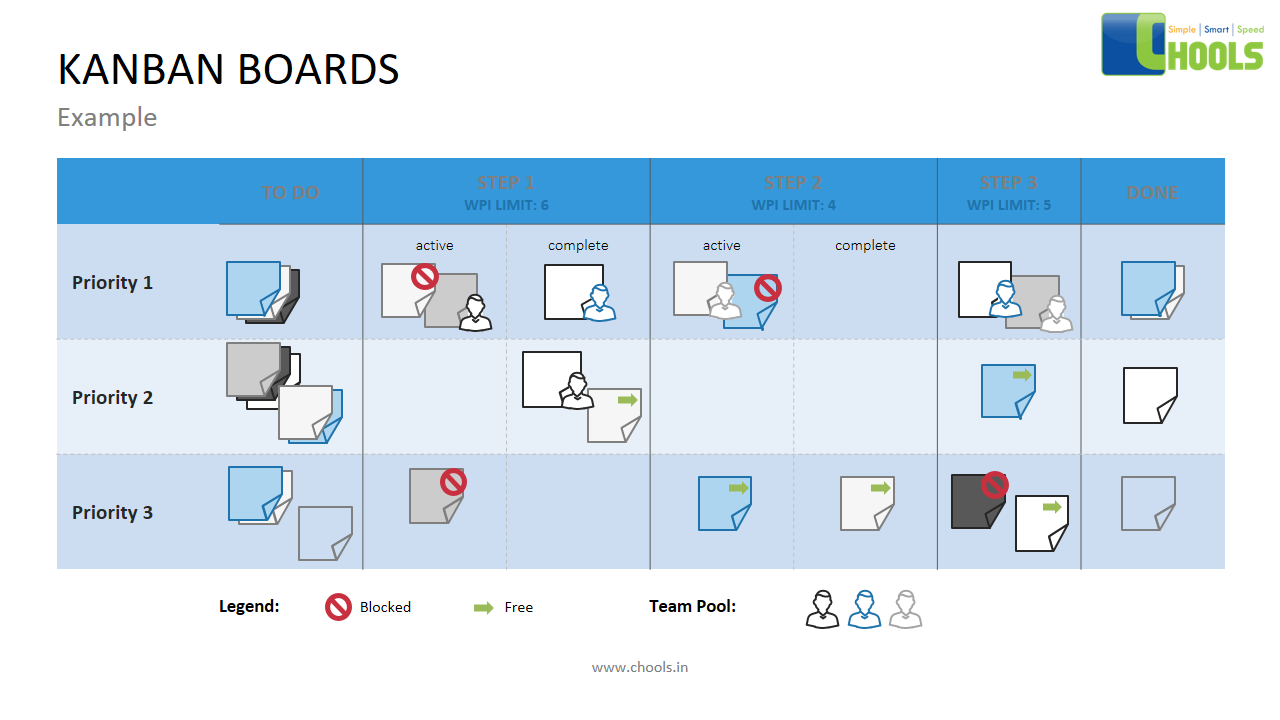

7. KANBAN

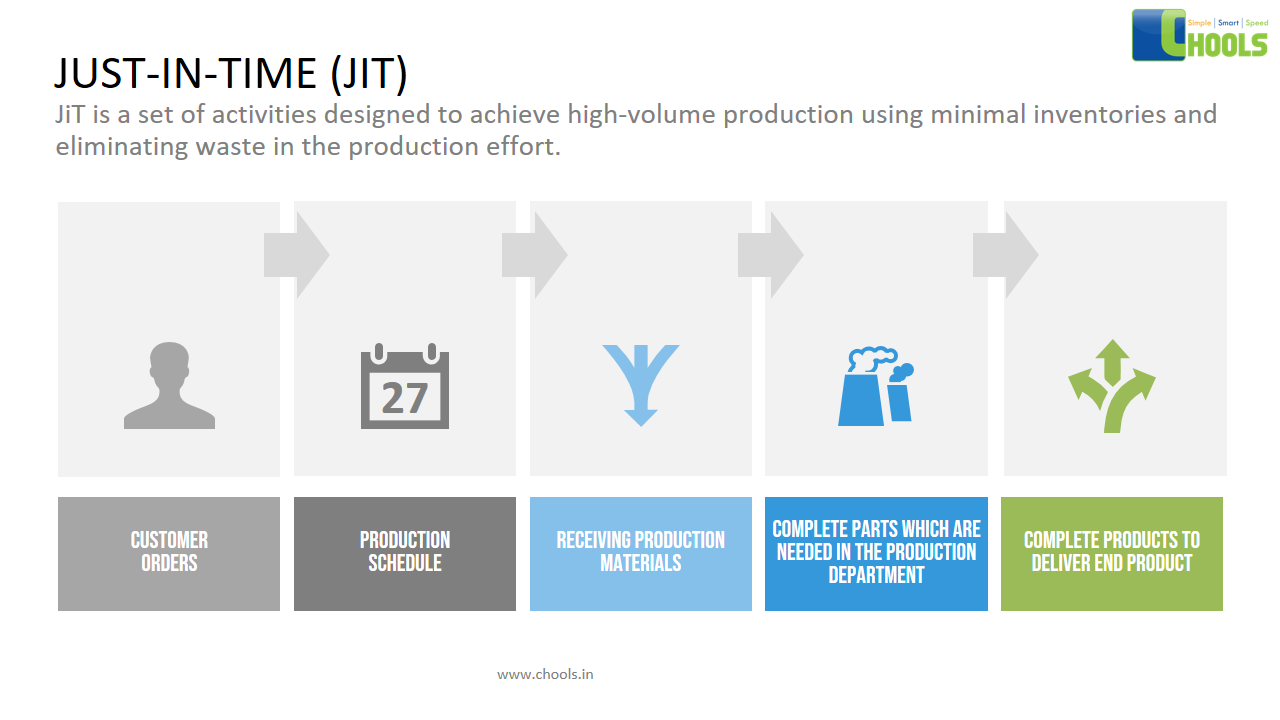

8. MANUFACTURING OPERATIONS

9. TOTAL QUALITY MANAGEMENT TOOLBOX

10. MANUFACTURING OPERATIONS

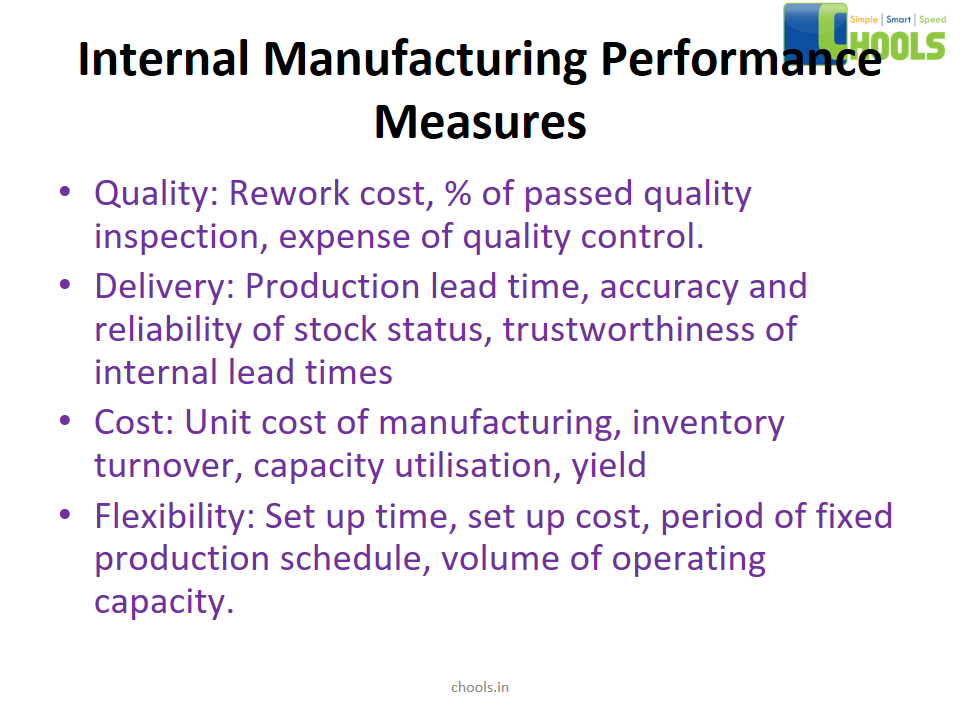

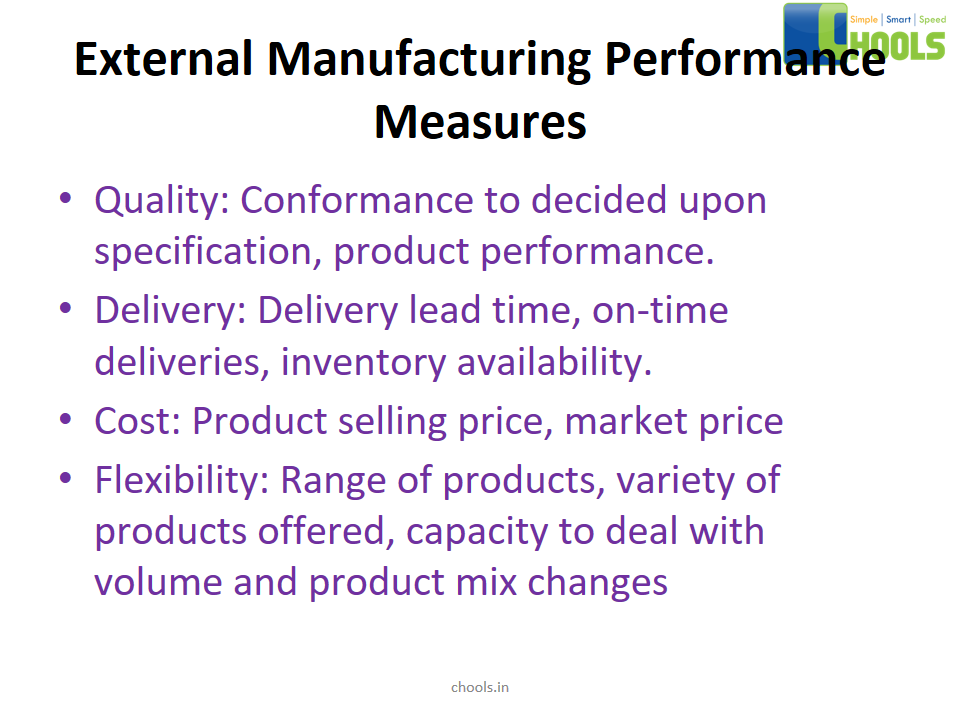

11. MANUFACTURING PERFORMANCE MEASURES

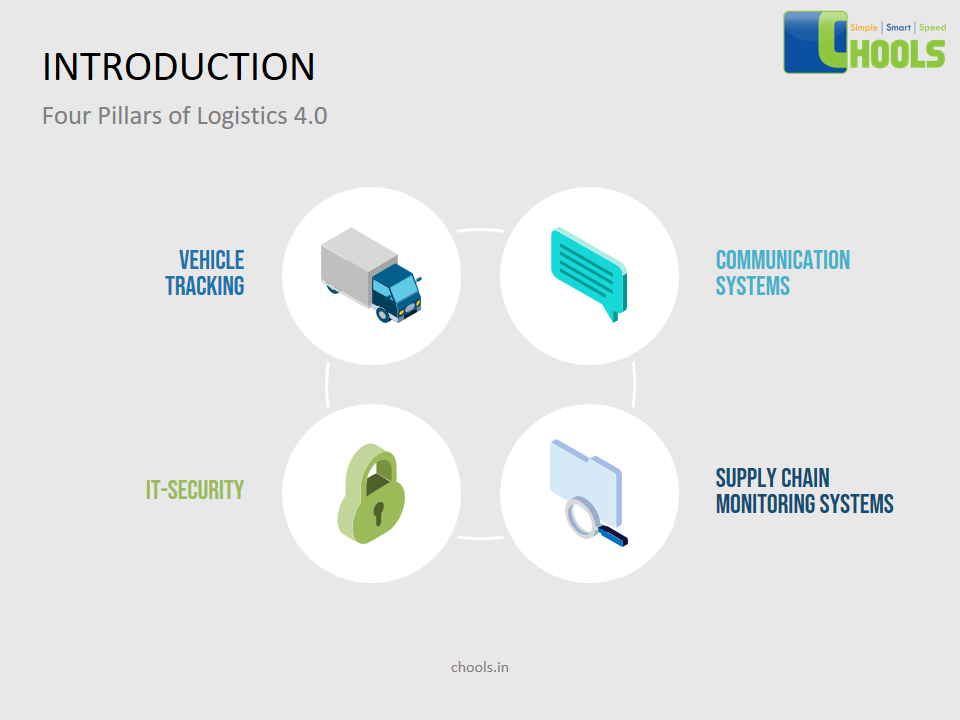

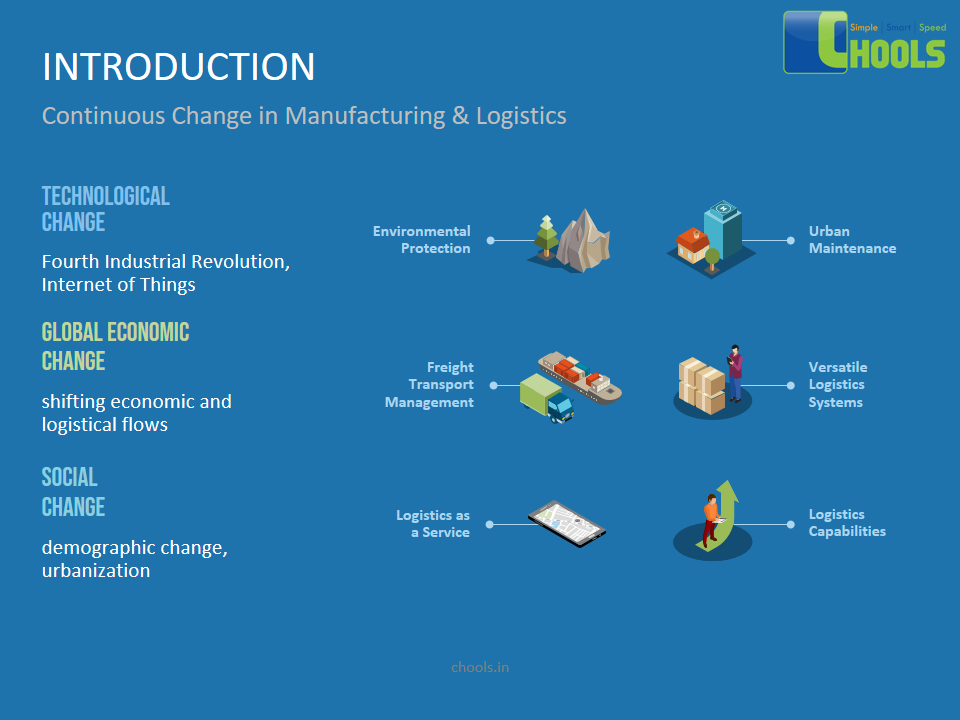

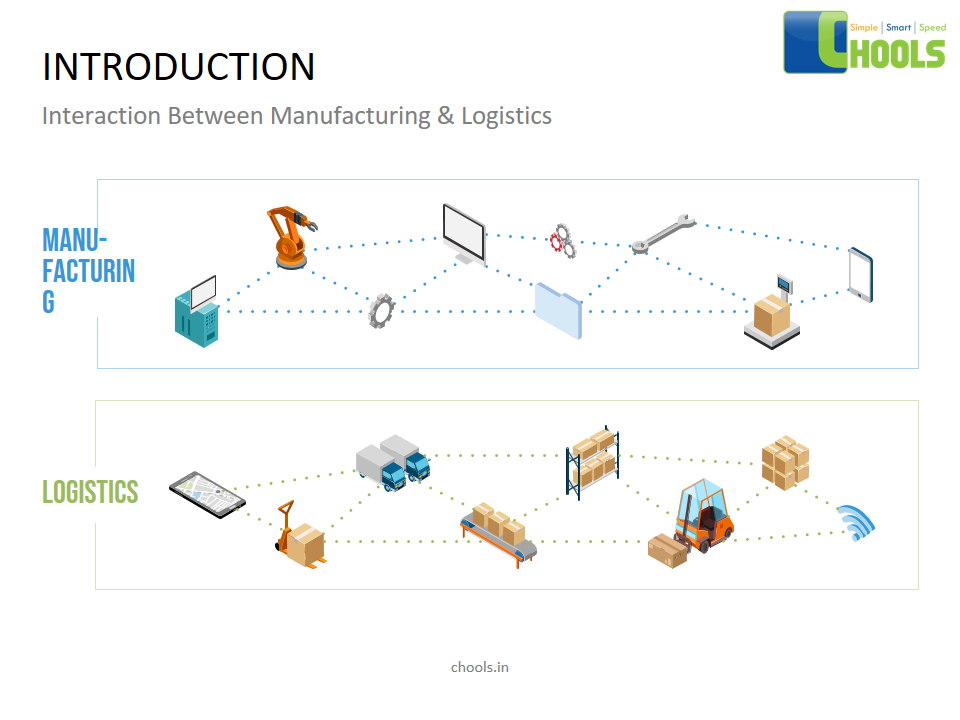

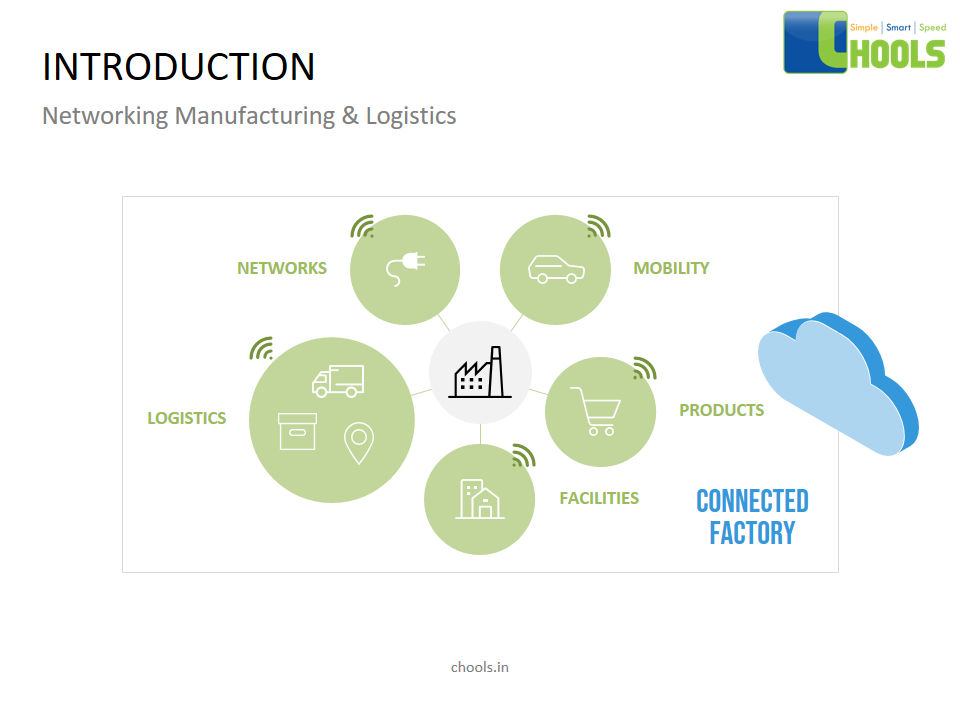

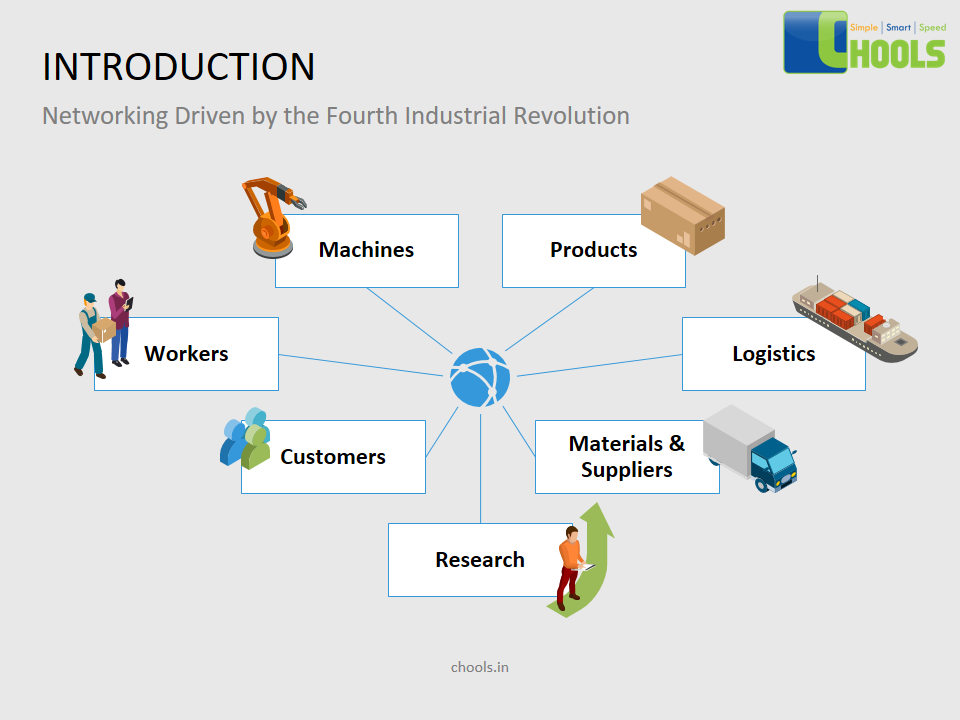

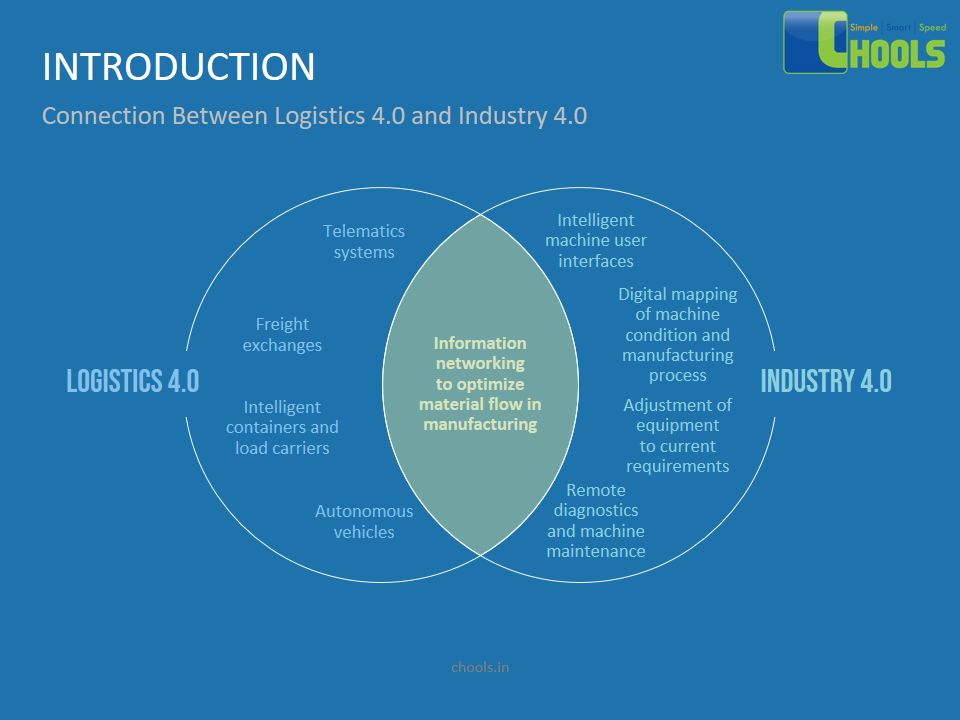

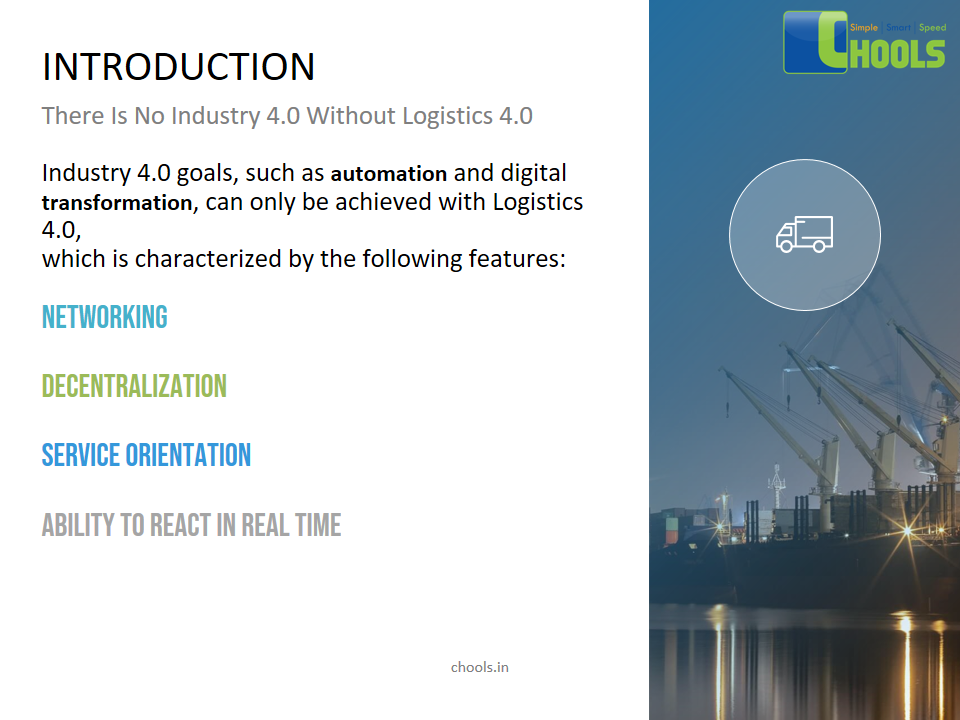

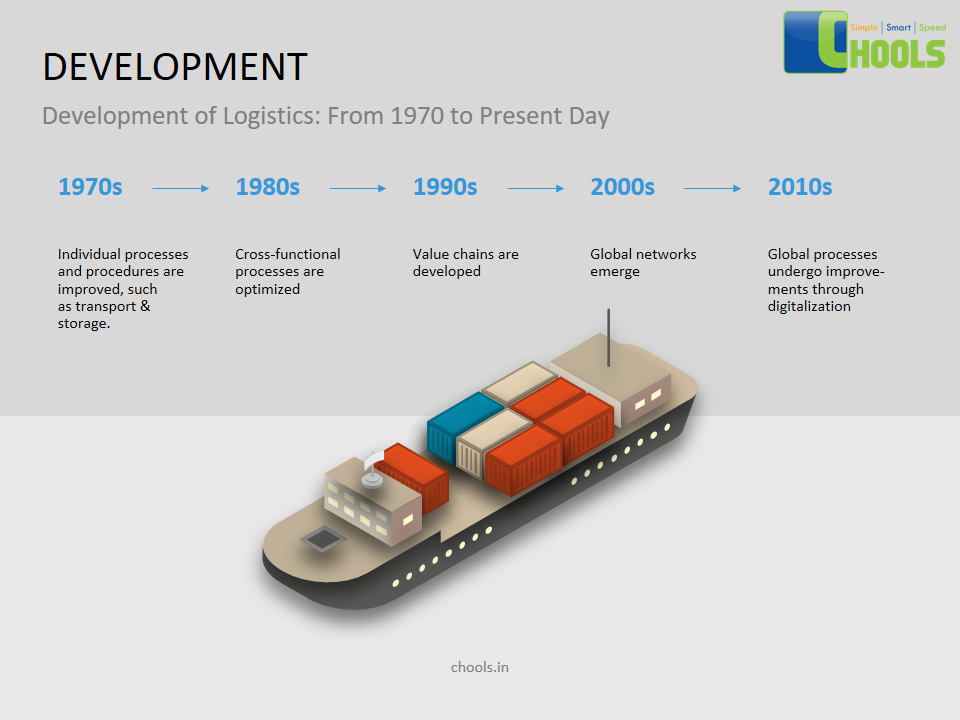

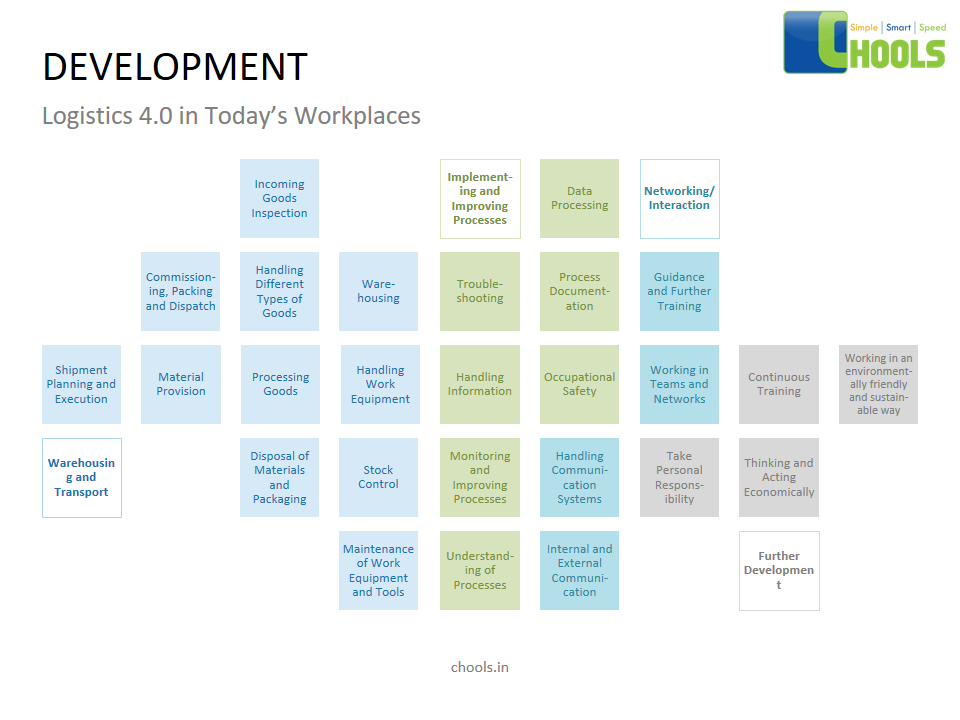

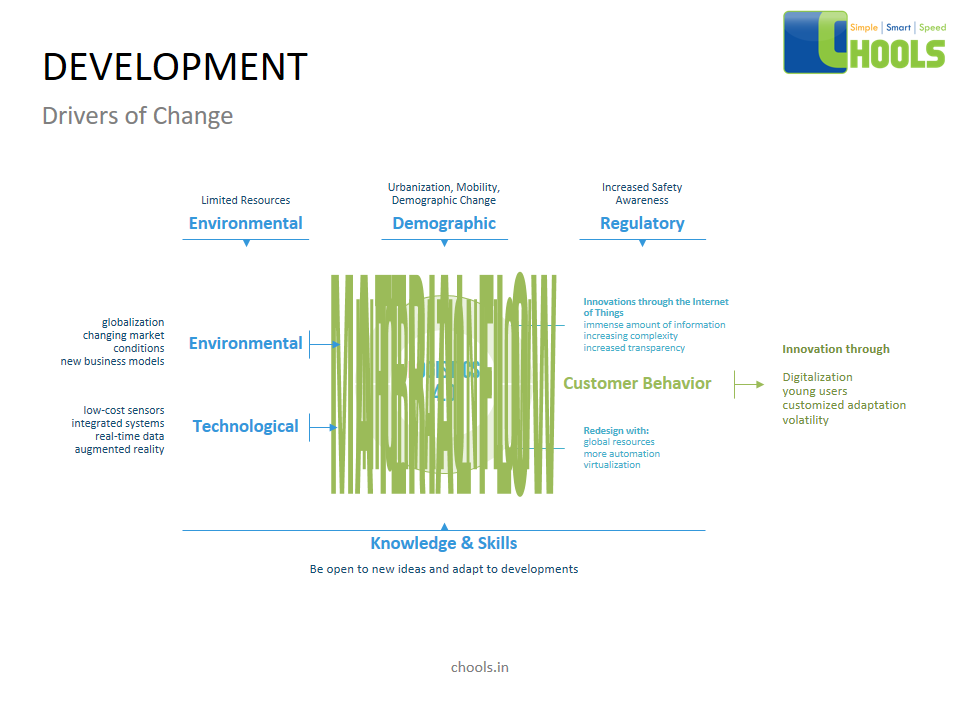

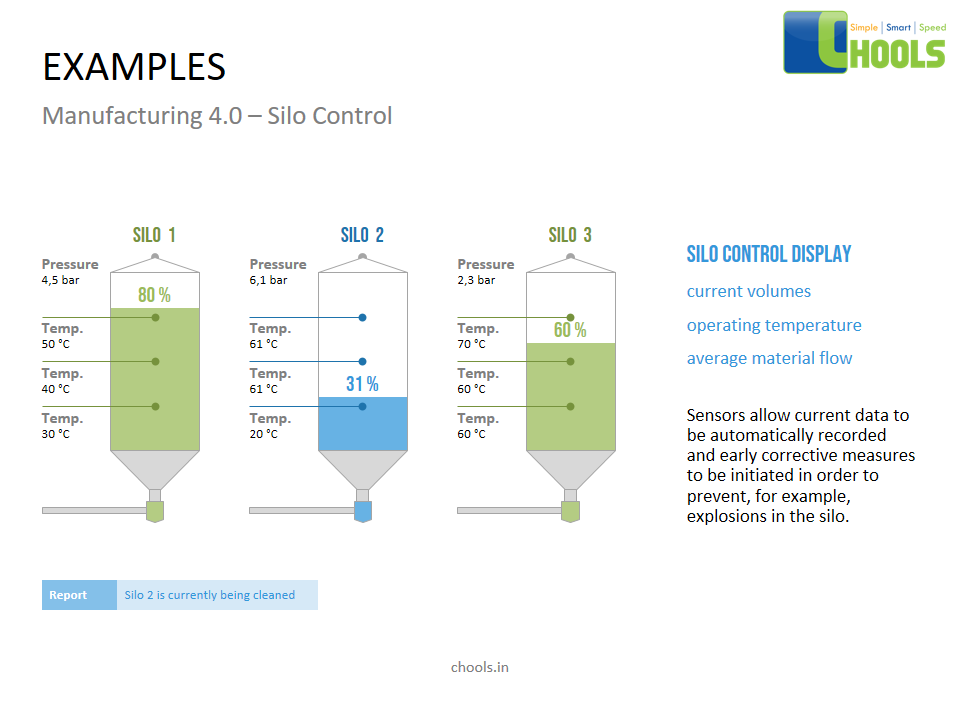

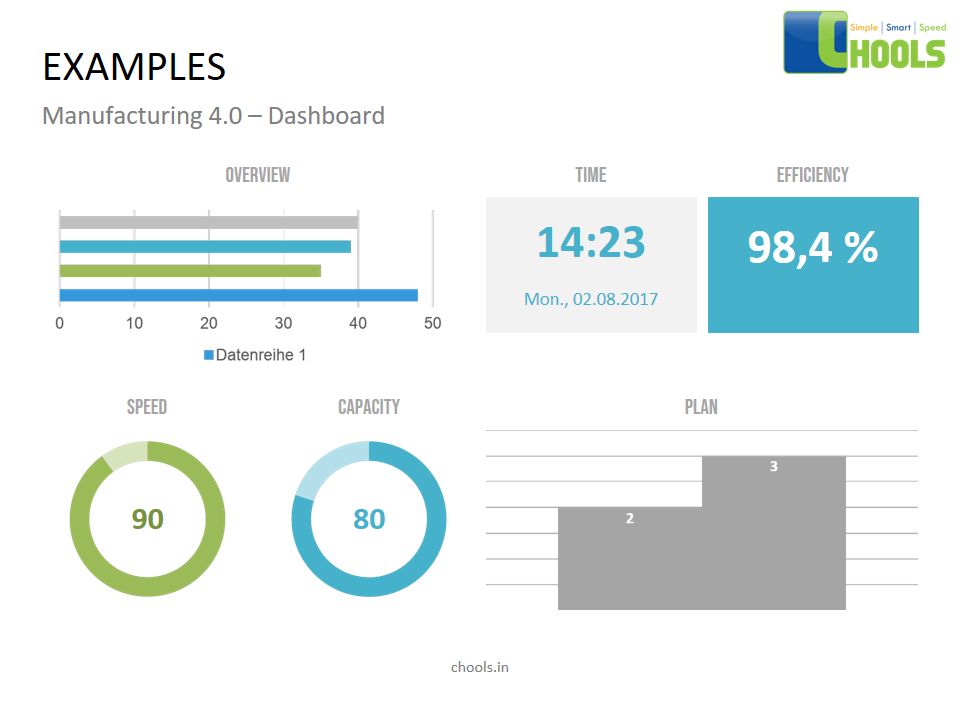

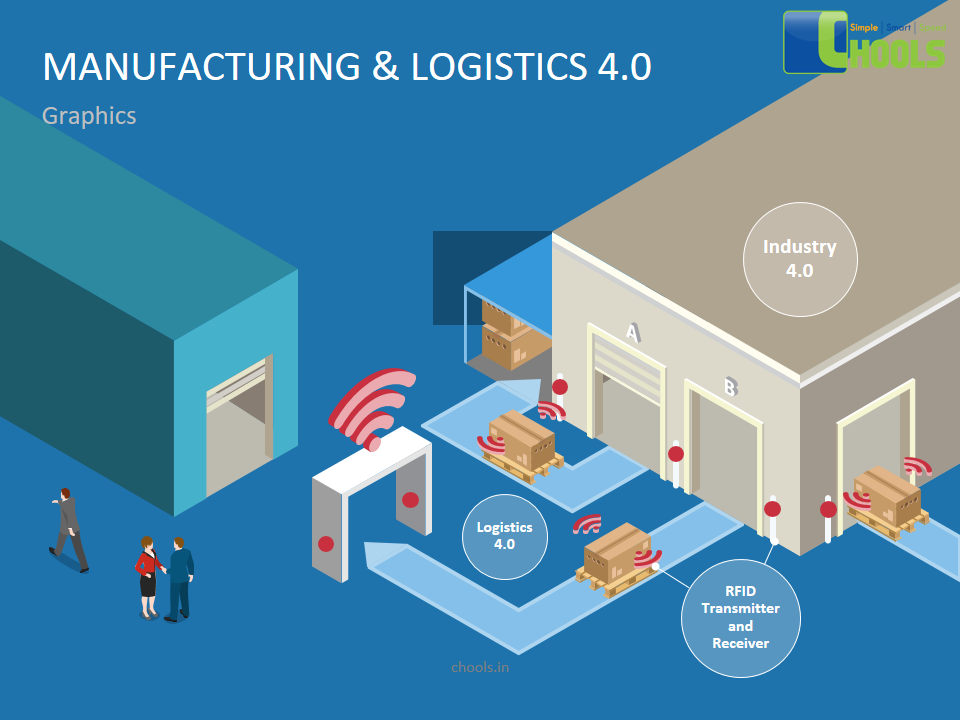

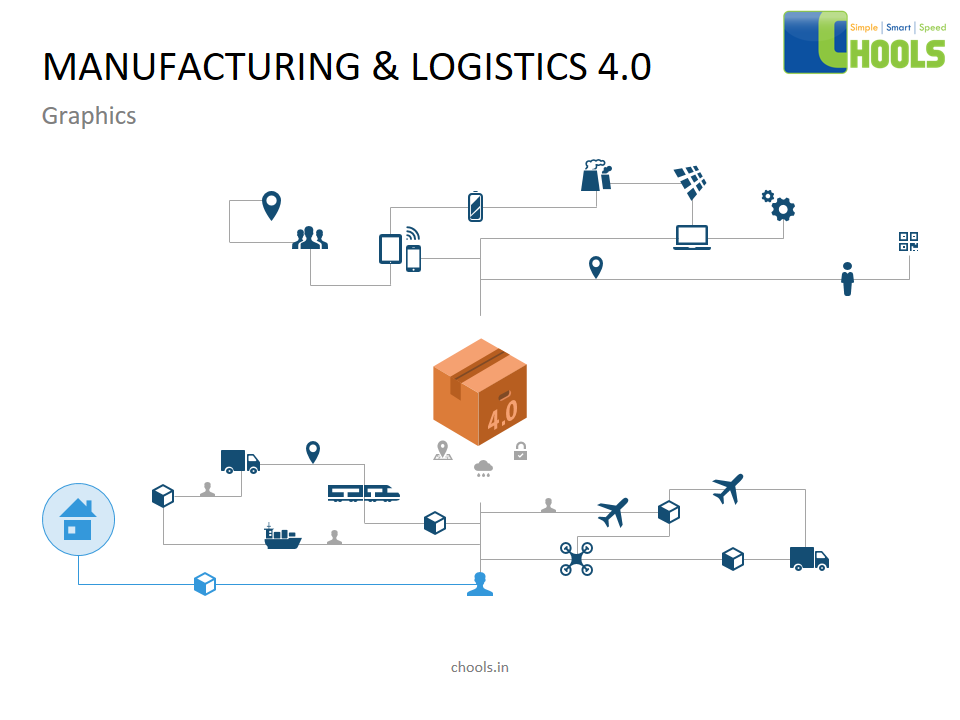

12. MANUFACTURING AND LOGISTICS

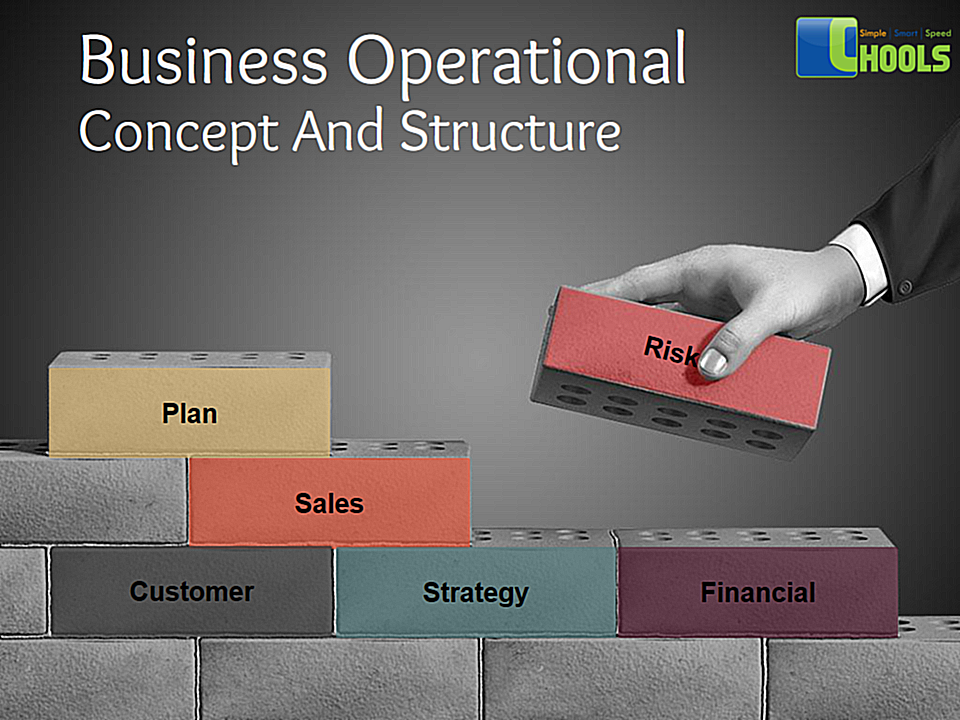

13. BUSINESS OPERATIONAL CONCEPT AND STRUCTURE

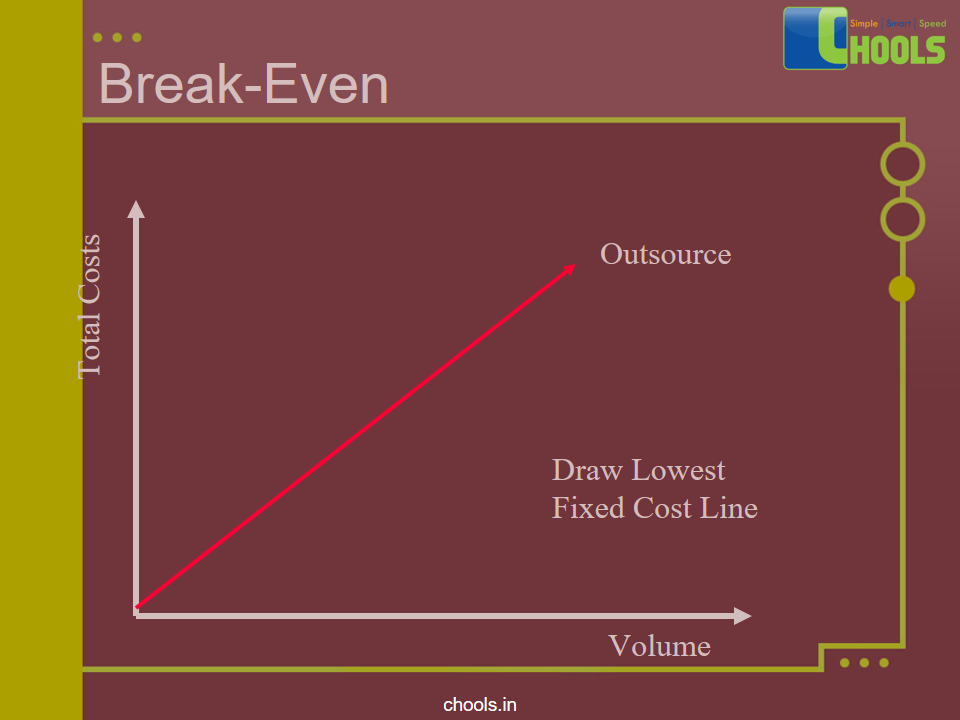

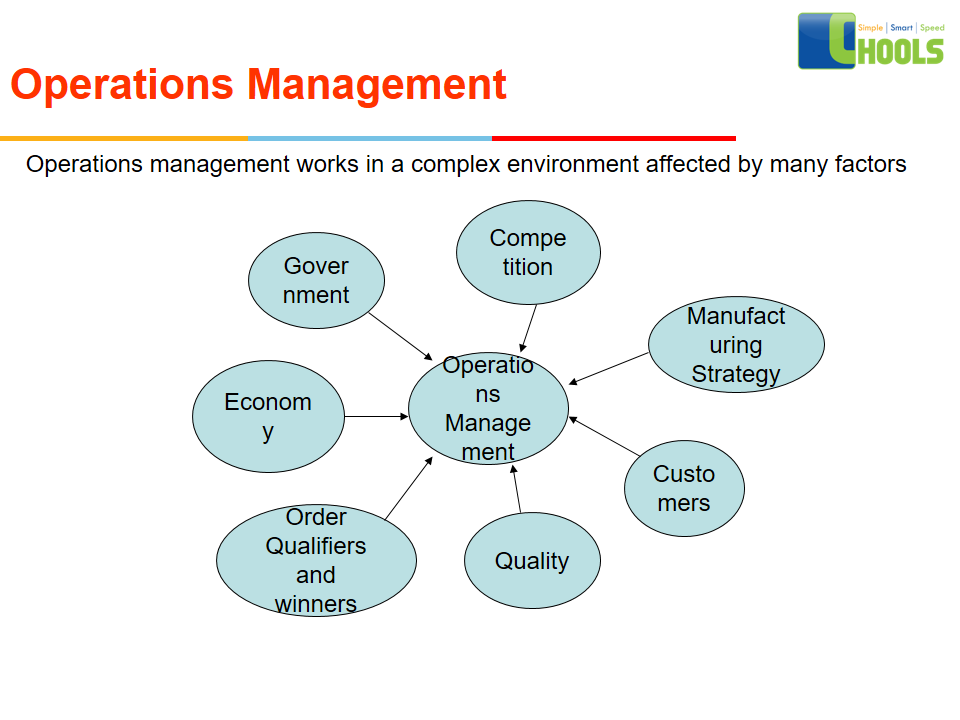

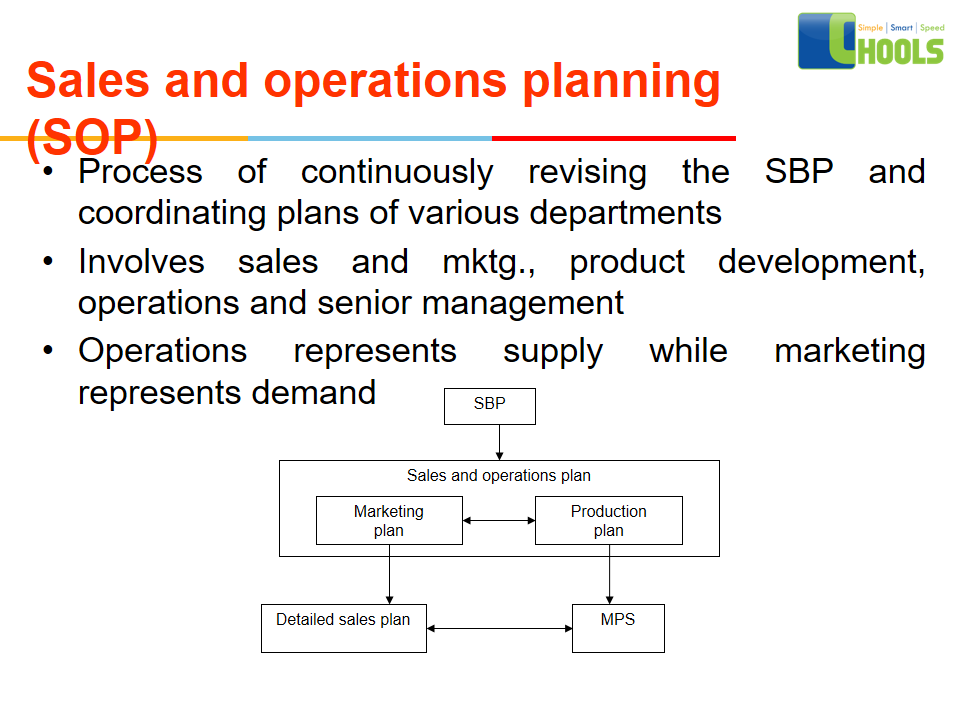

14. OPERATIONS MANAGEMENT

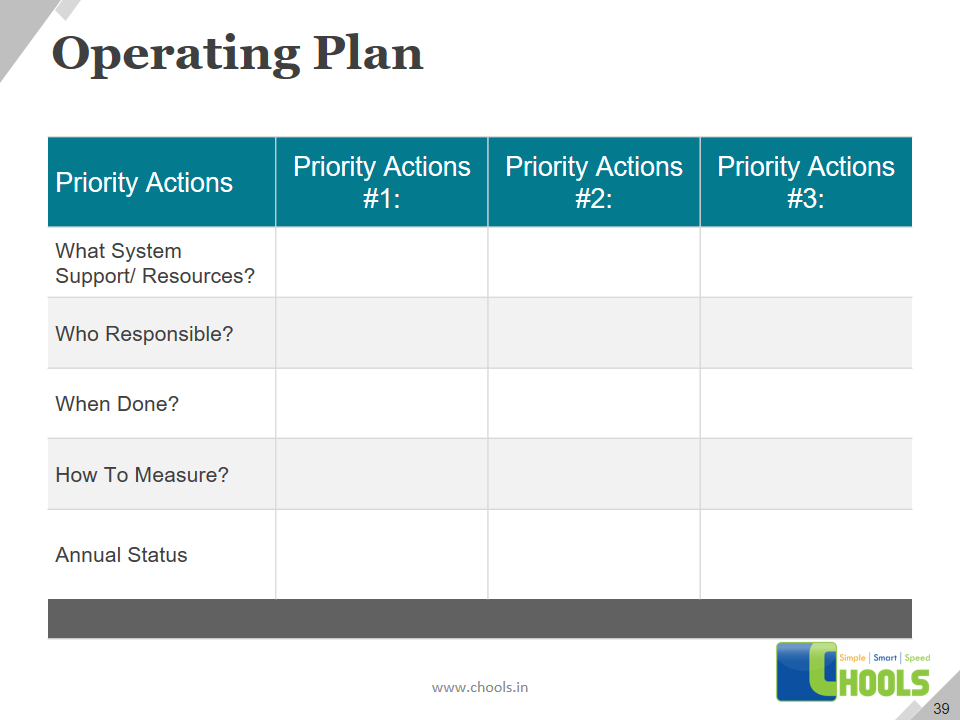

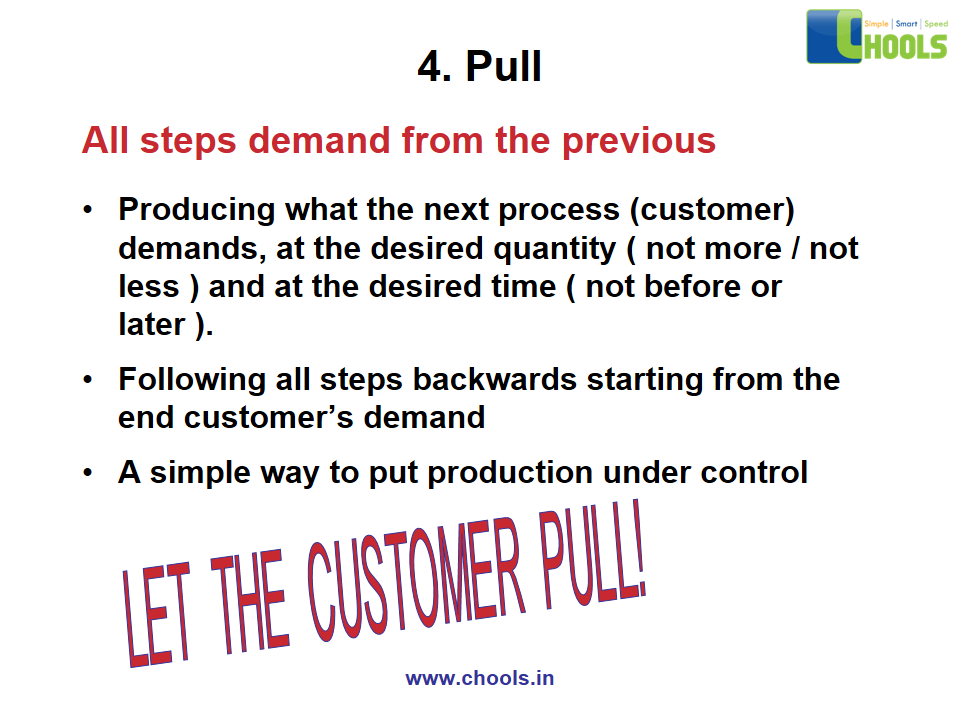

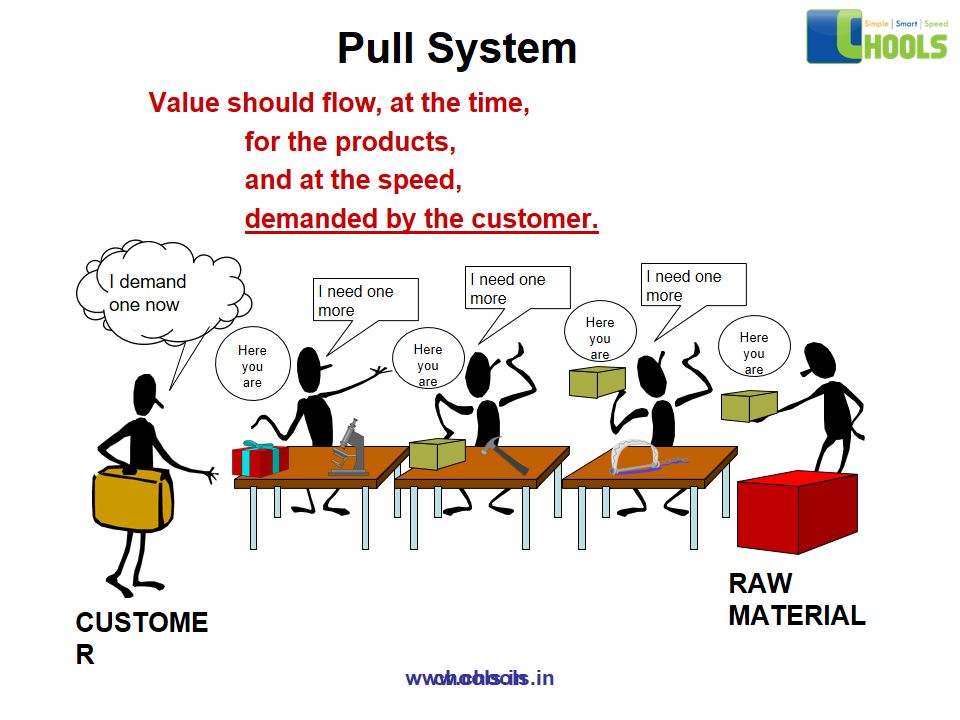

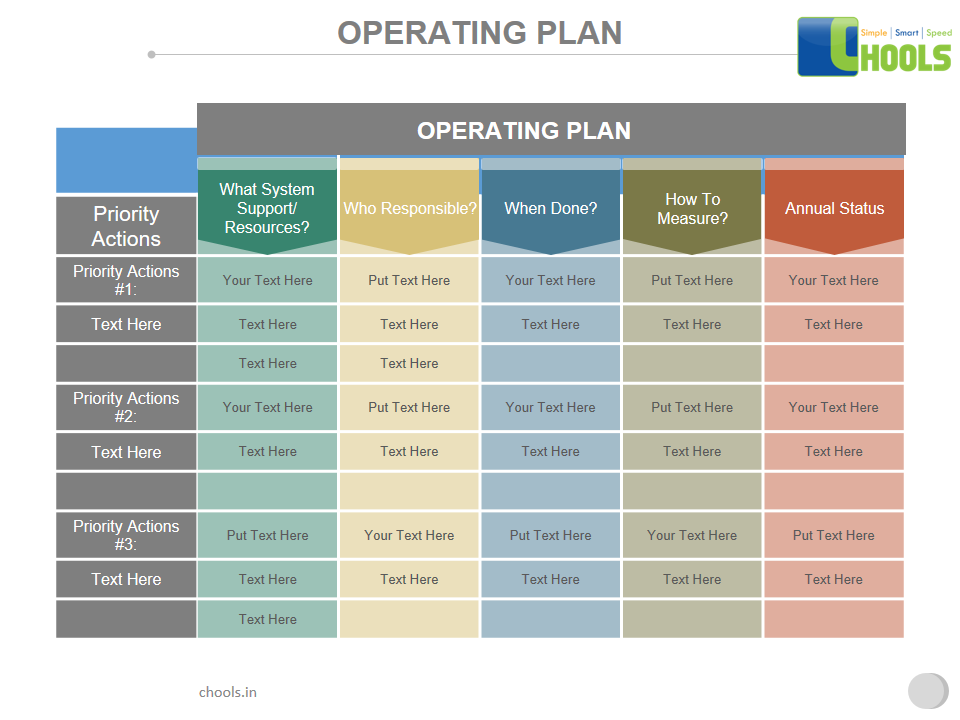

15. BUSINESS OPERATIONAL PLAN

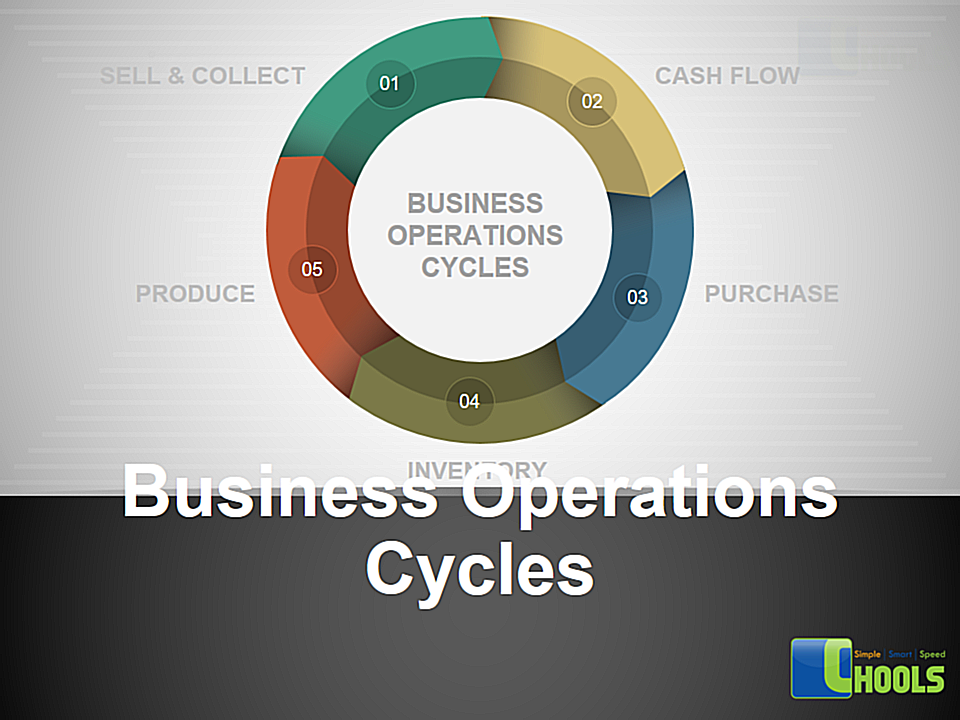

16. BUSINESS OPERATIONS CYCLES

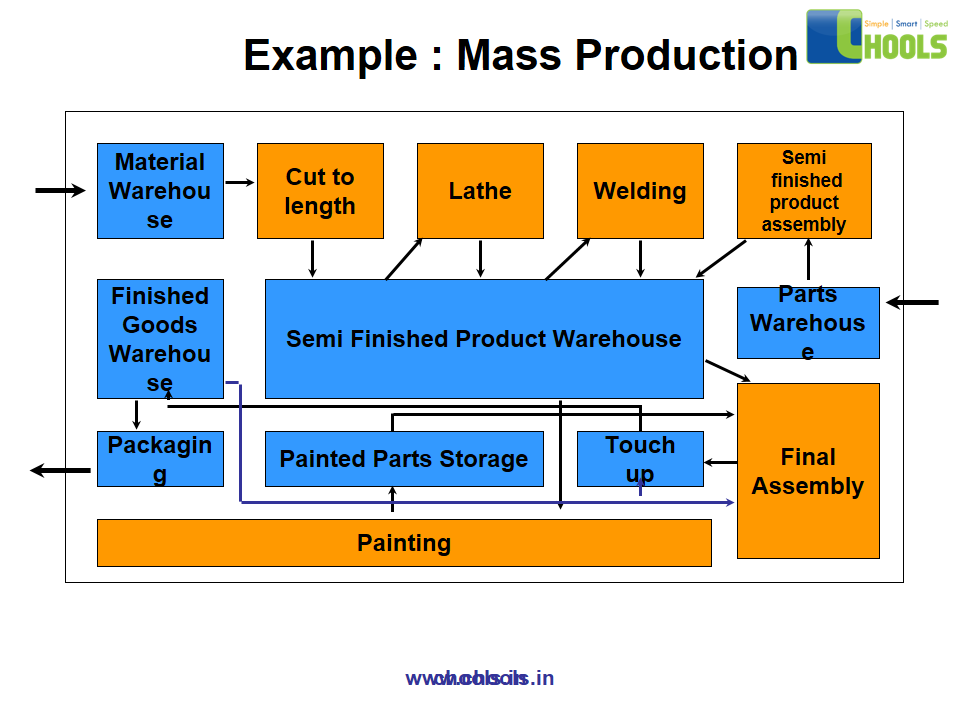

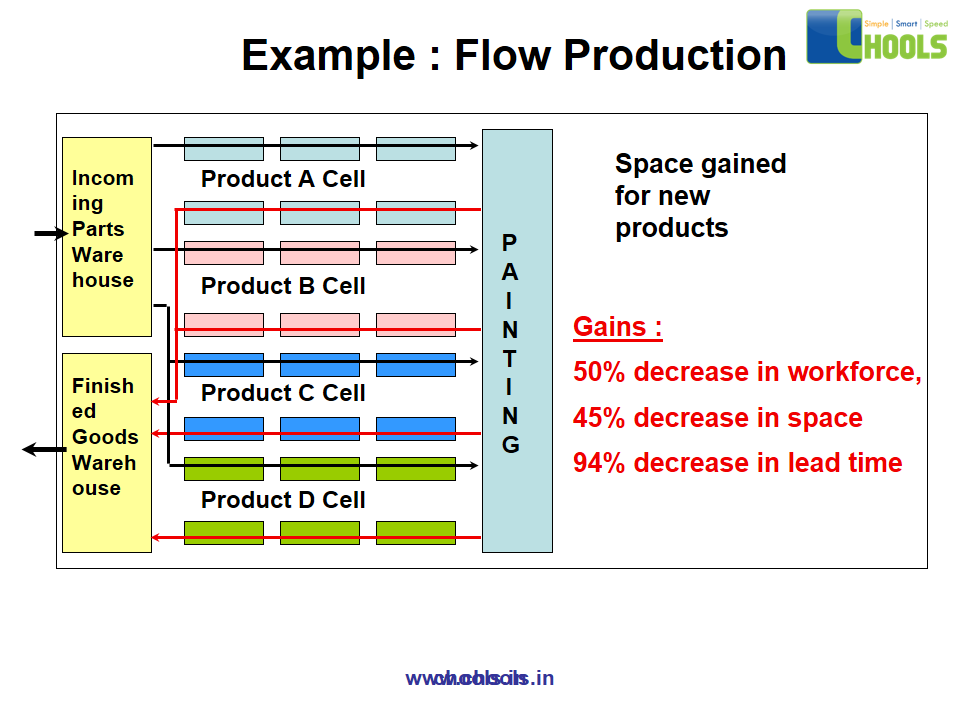

17. MANUFACTURING OPERATIONS PROCESS

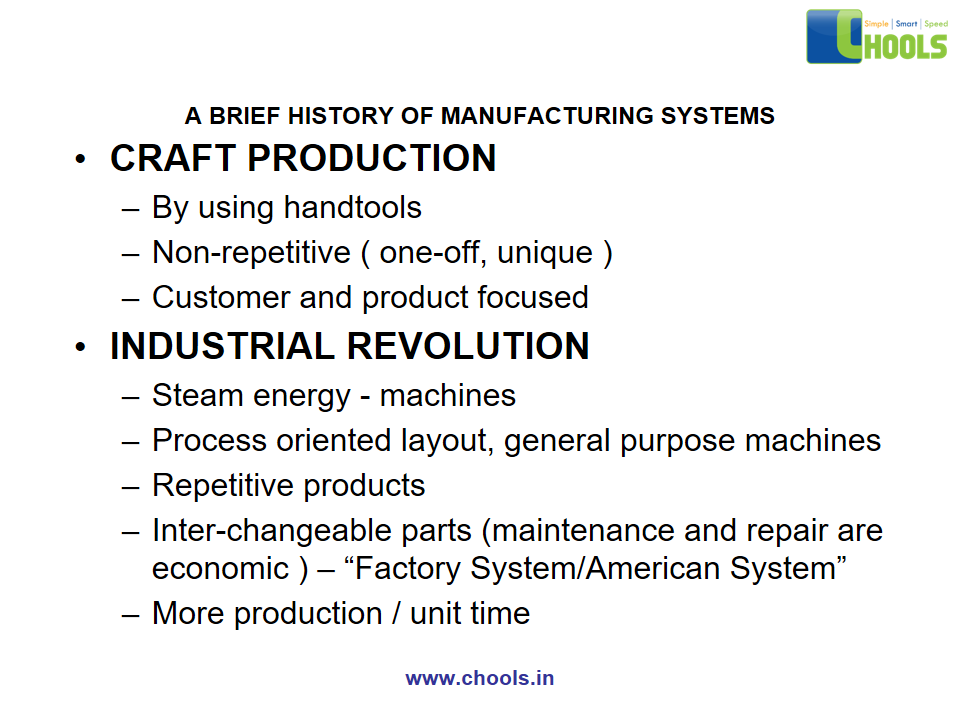

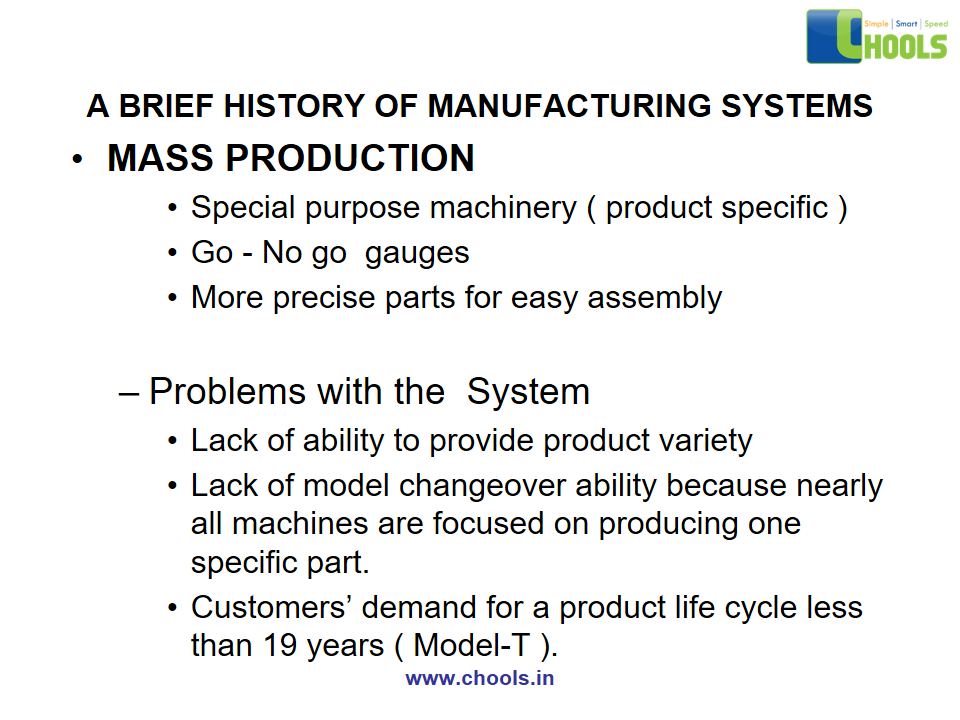

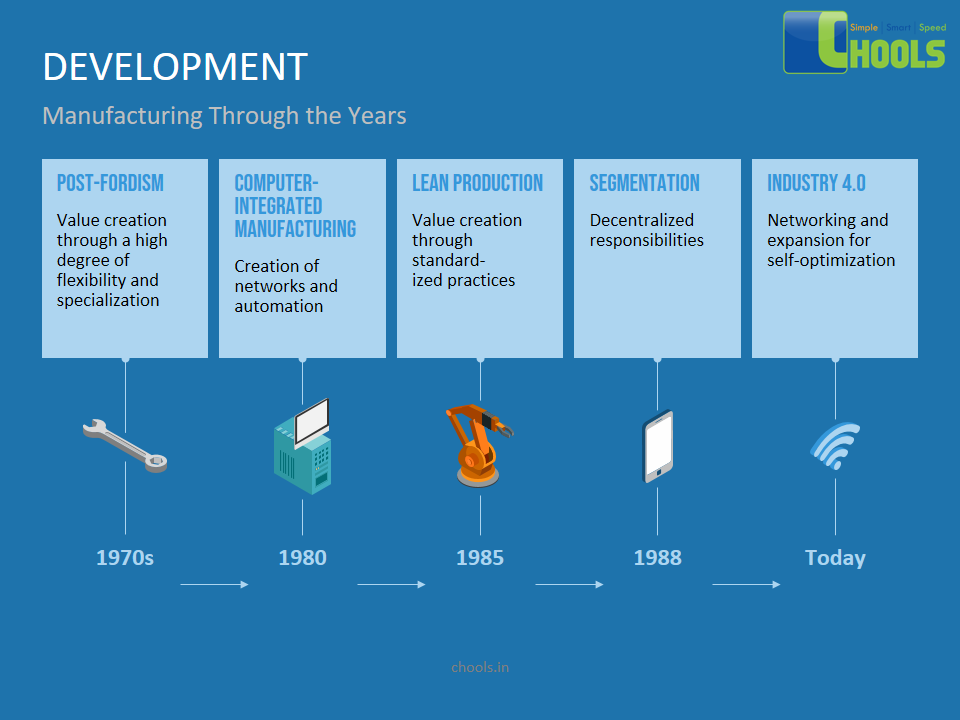

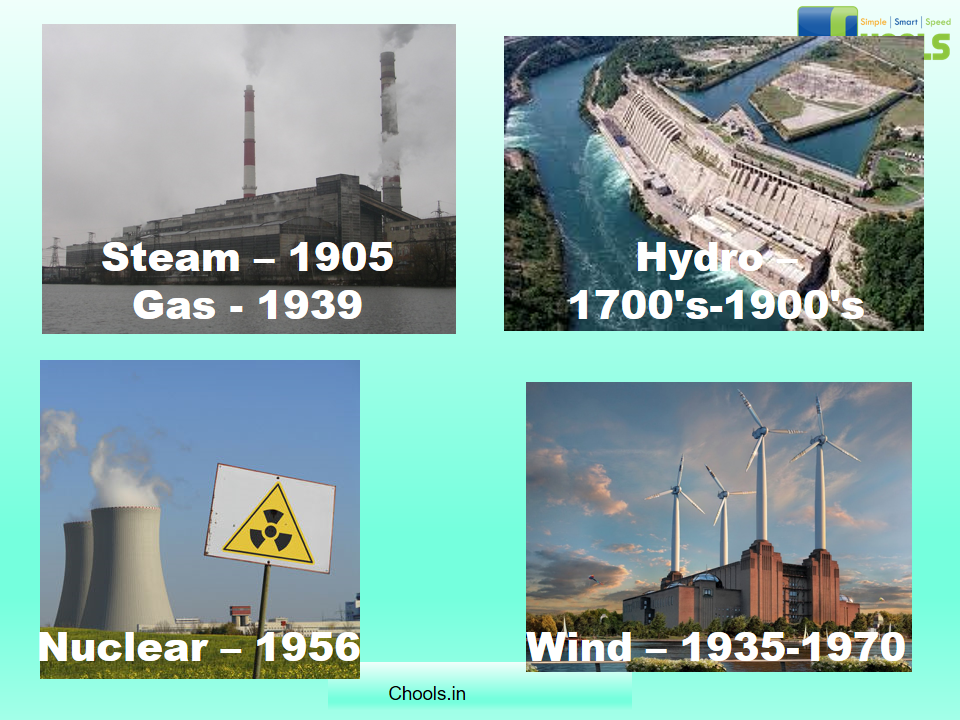

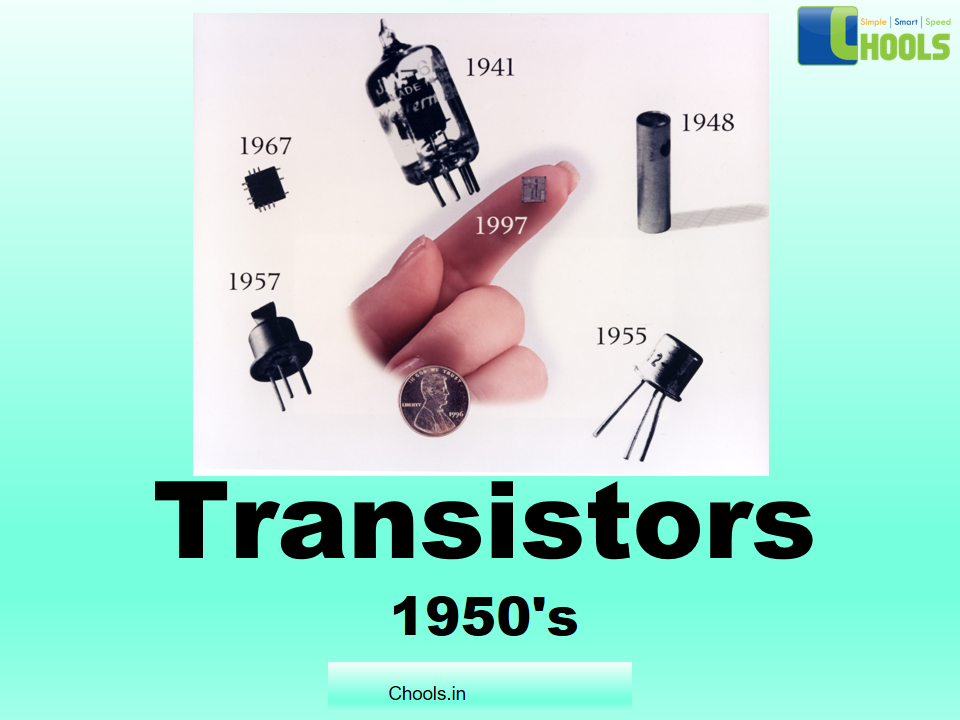

18. MANUFACTURING OPERATIONS TECHNOLOGICAL CHANGE

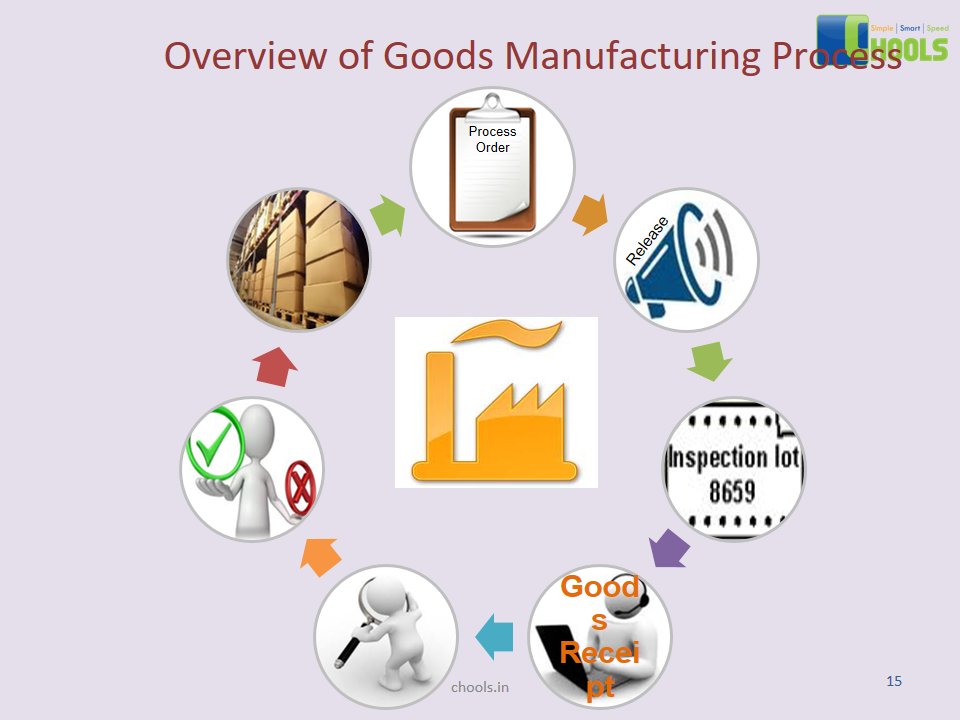

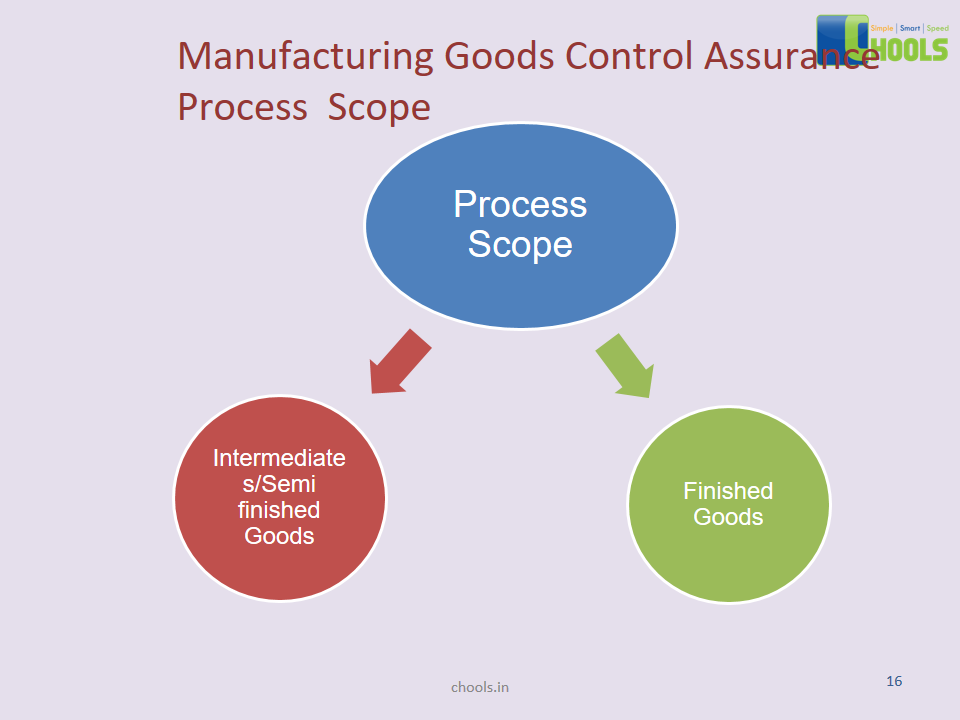

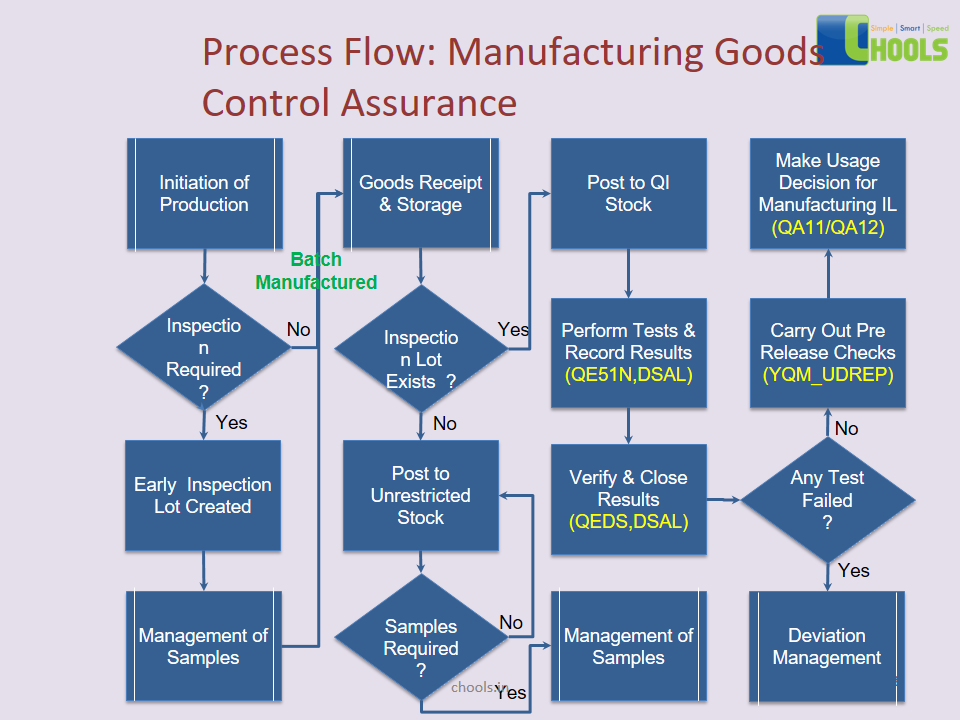

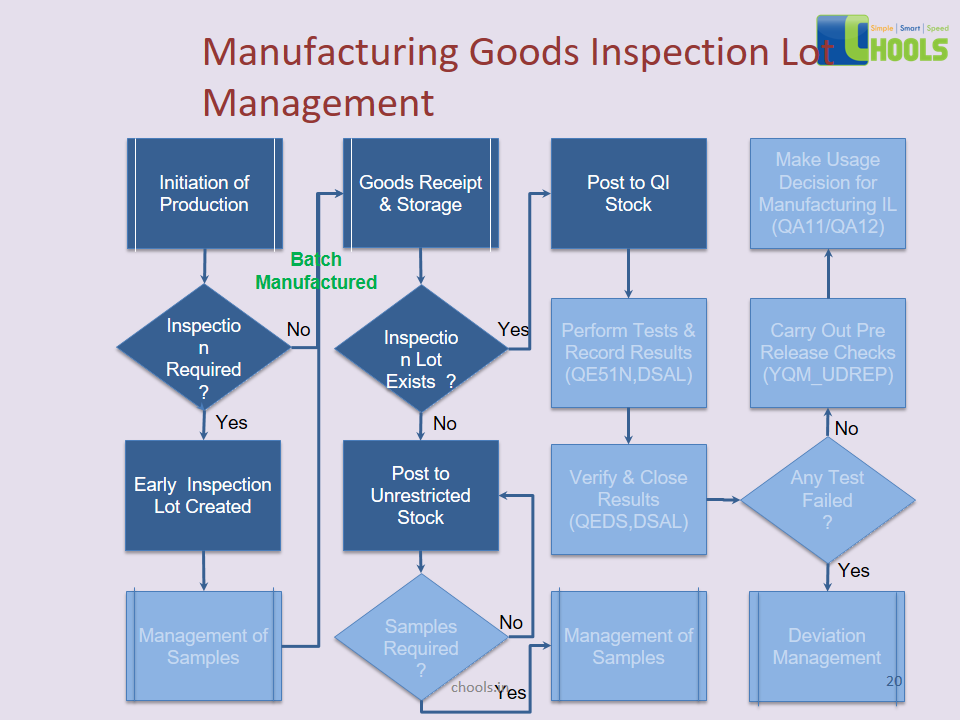

19. MANUFACTURING OPERATIONS GOODS CONTROL

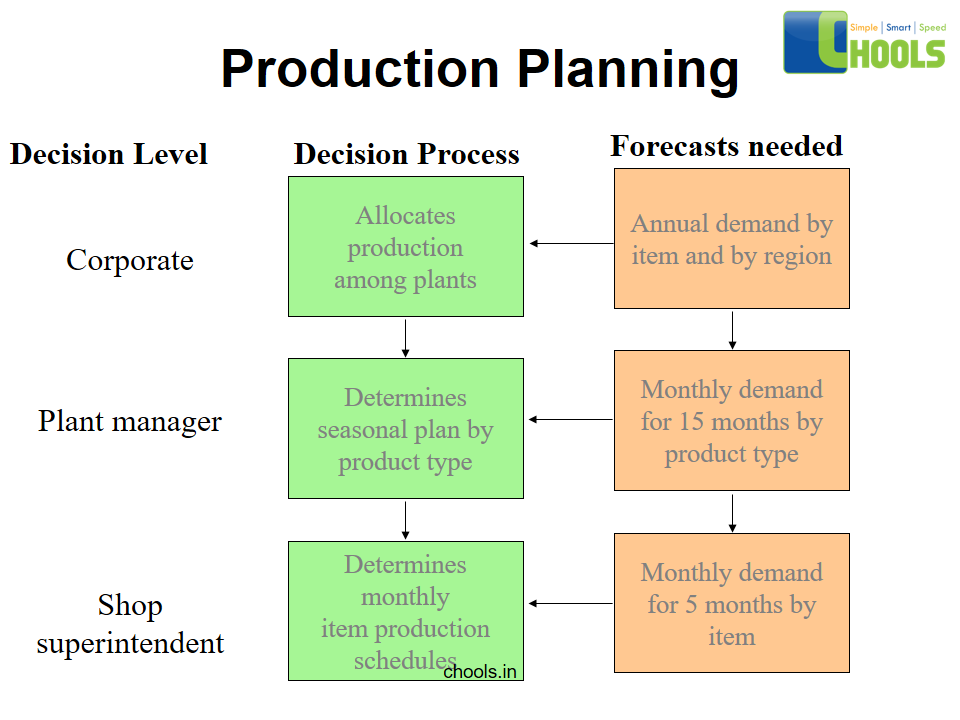

20. PRODUCTION STRATEGY

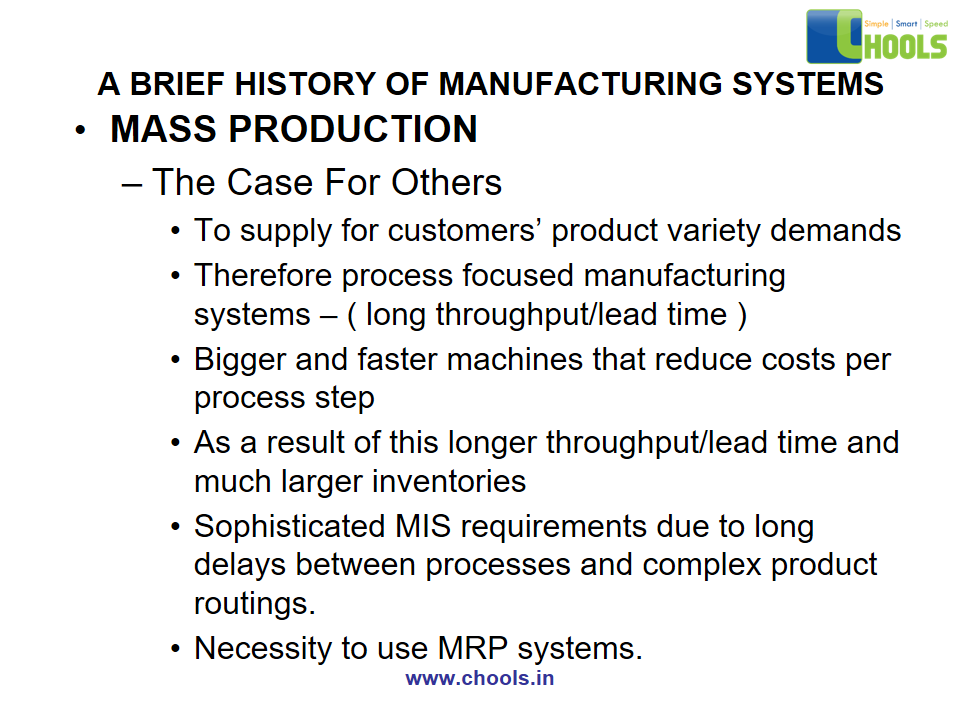

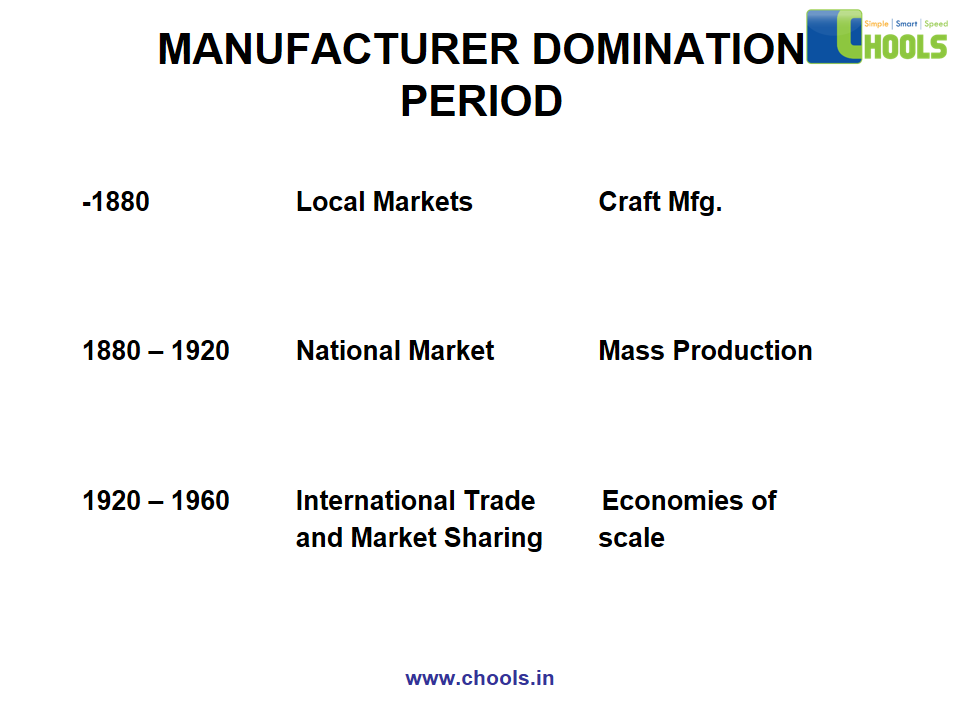

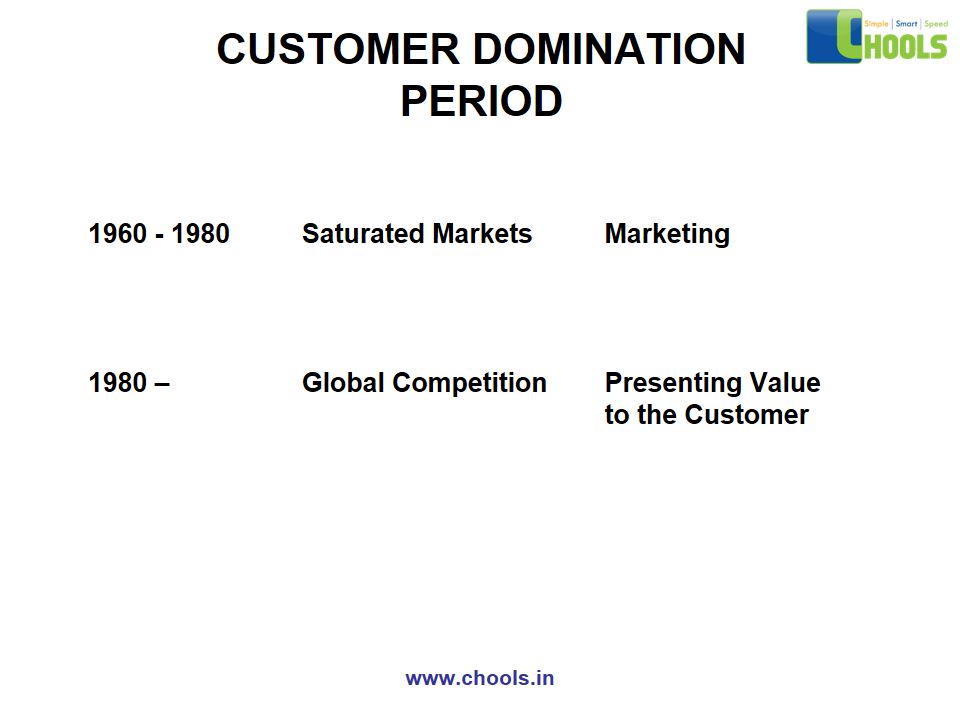

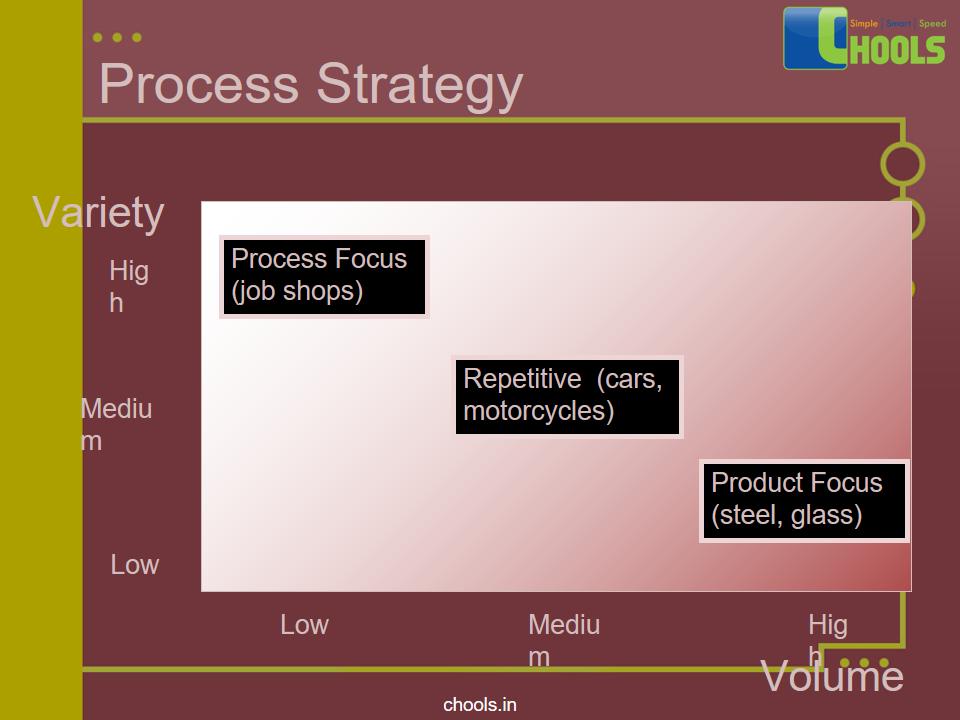

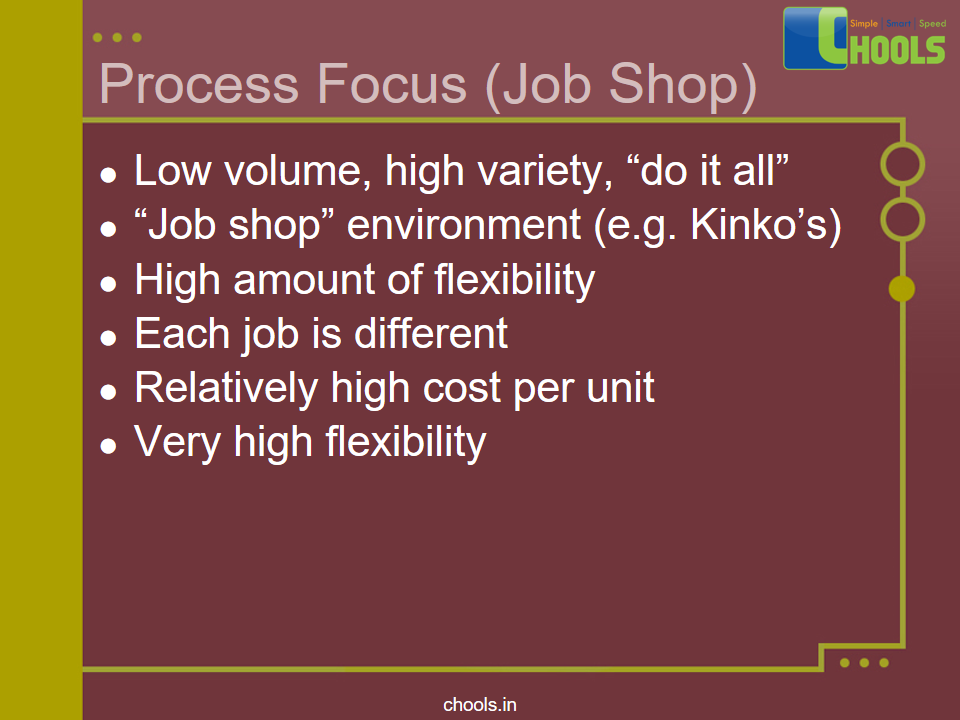

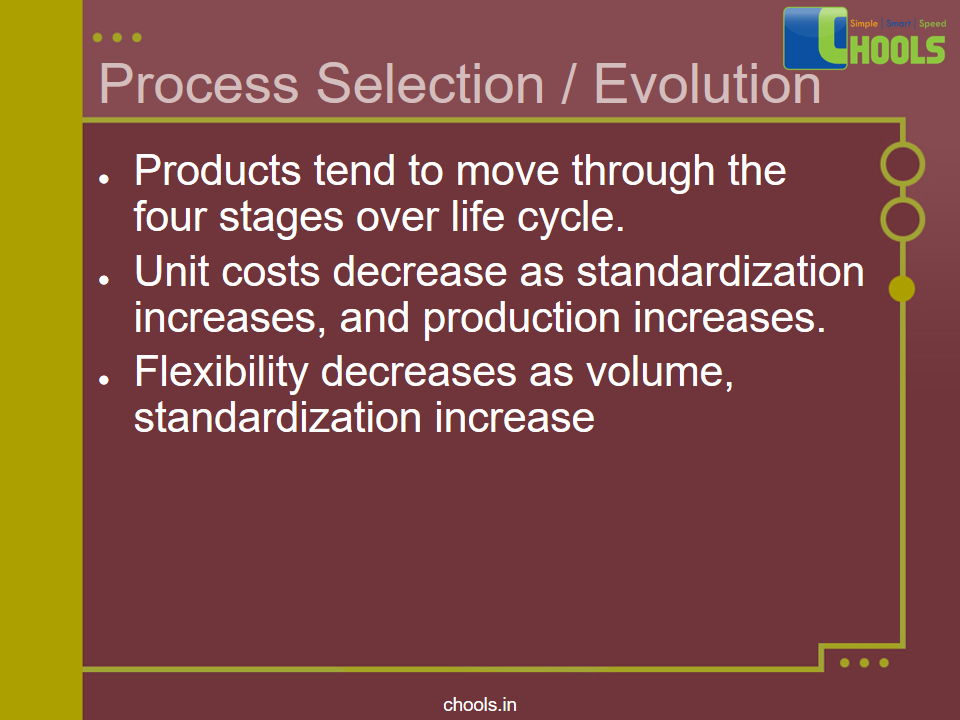

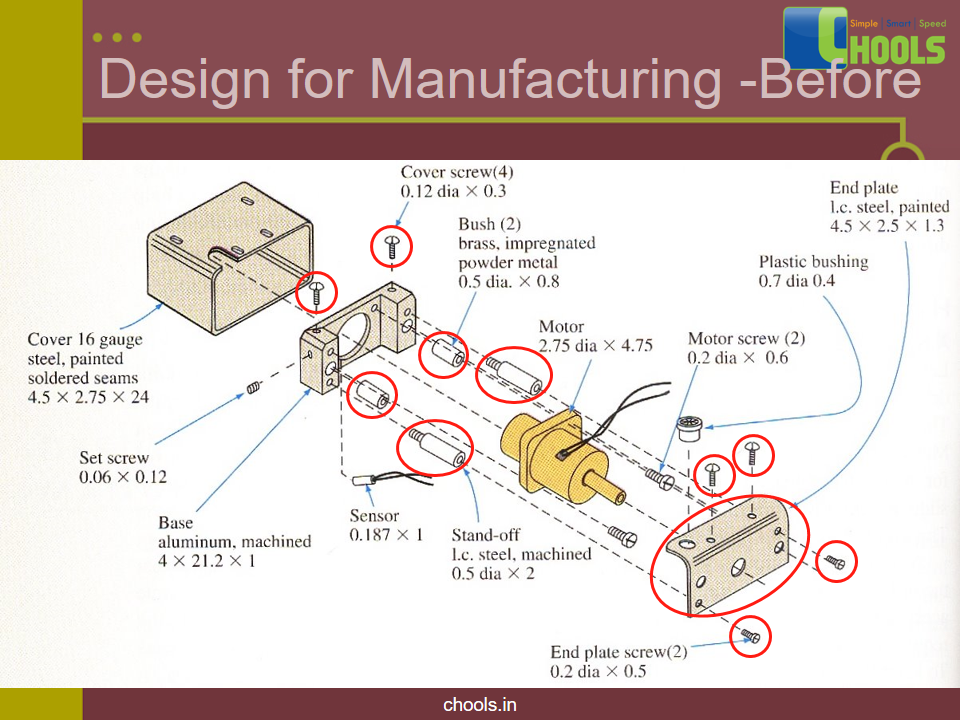

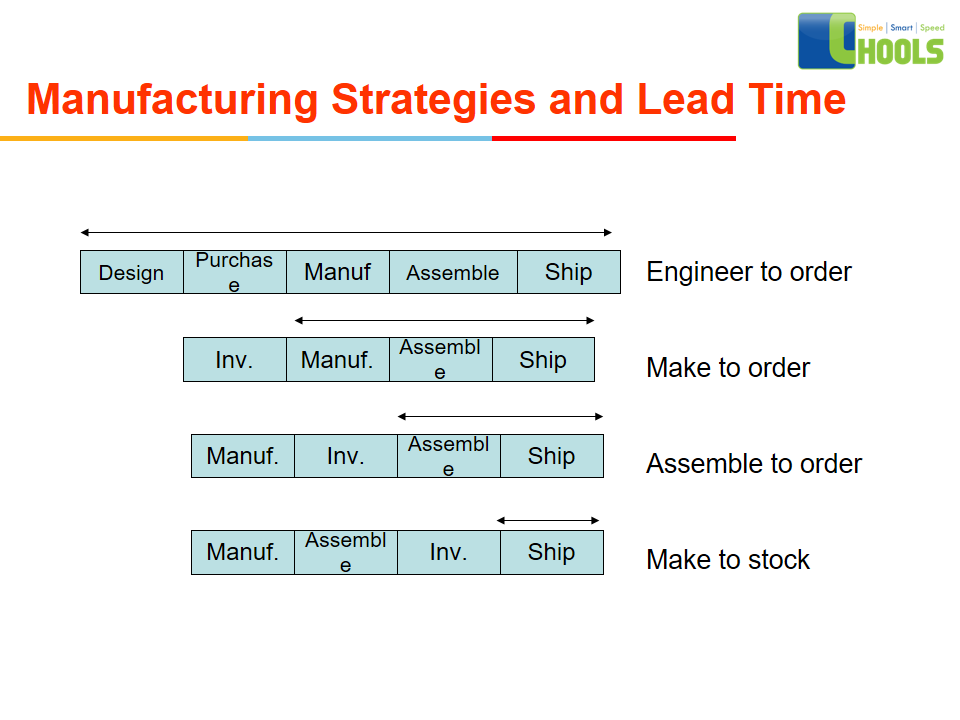

21. STRATEGIES AND DESIGN OF MANUFACTURING SYSTEM

22. MANUFACTURING OPERATIONS

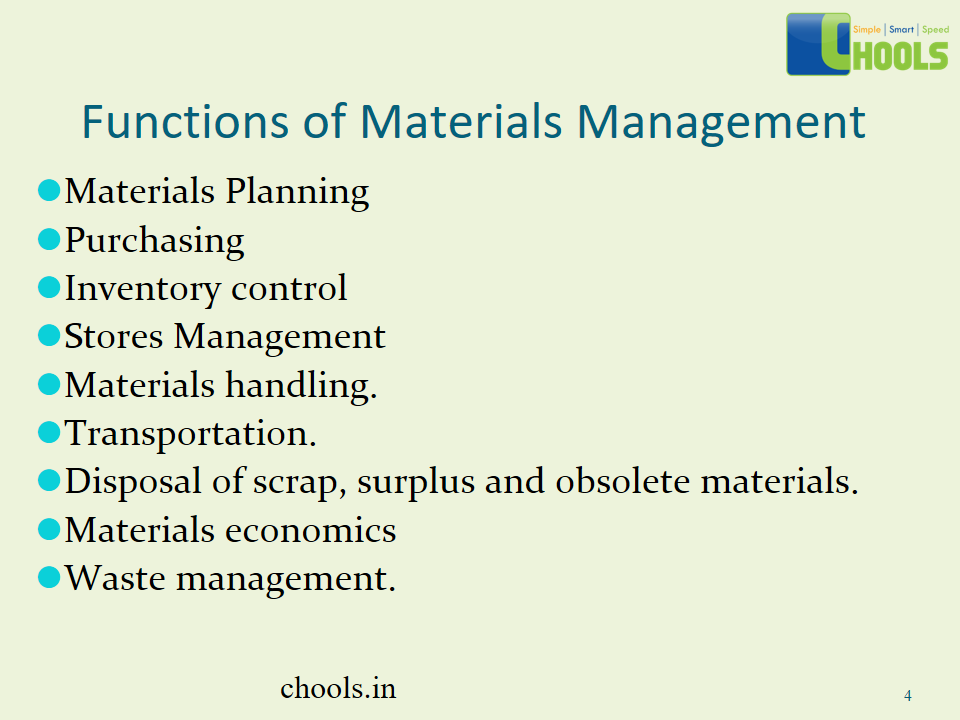

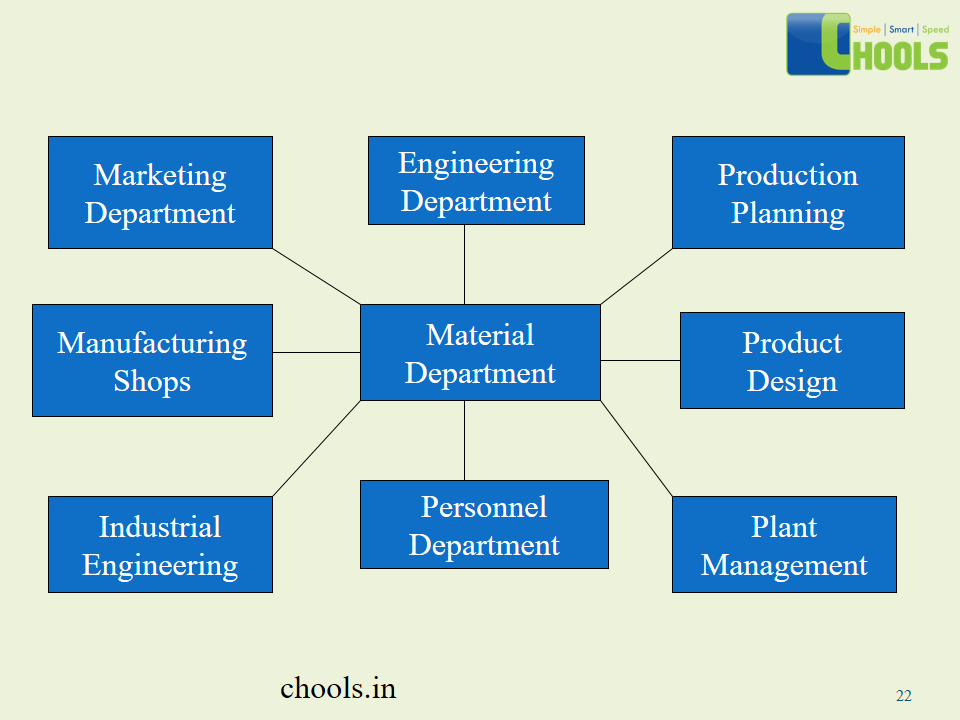

23. MATERIAL MANAGEMENT

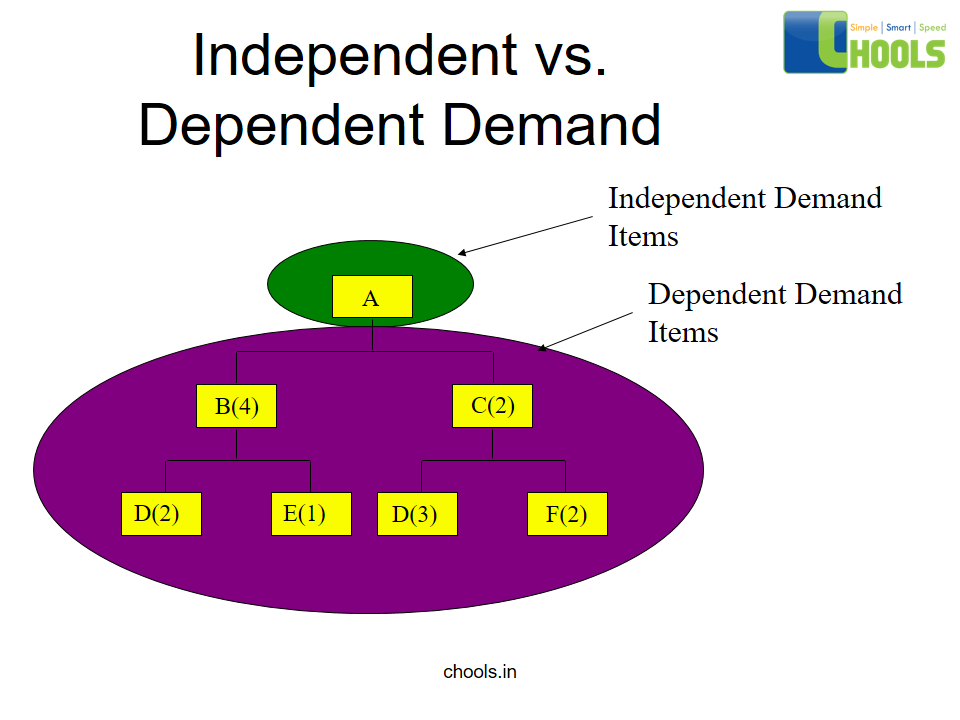

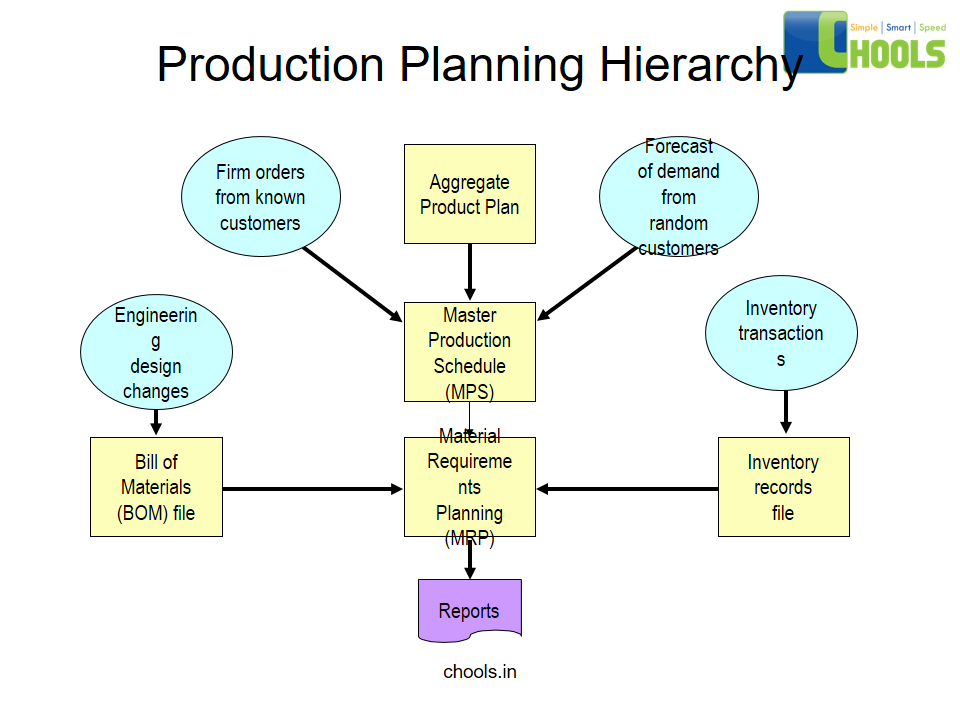

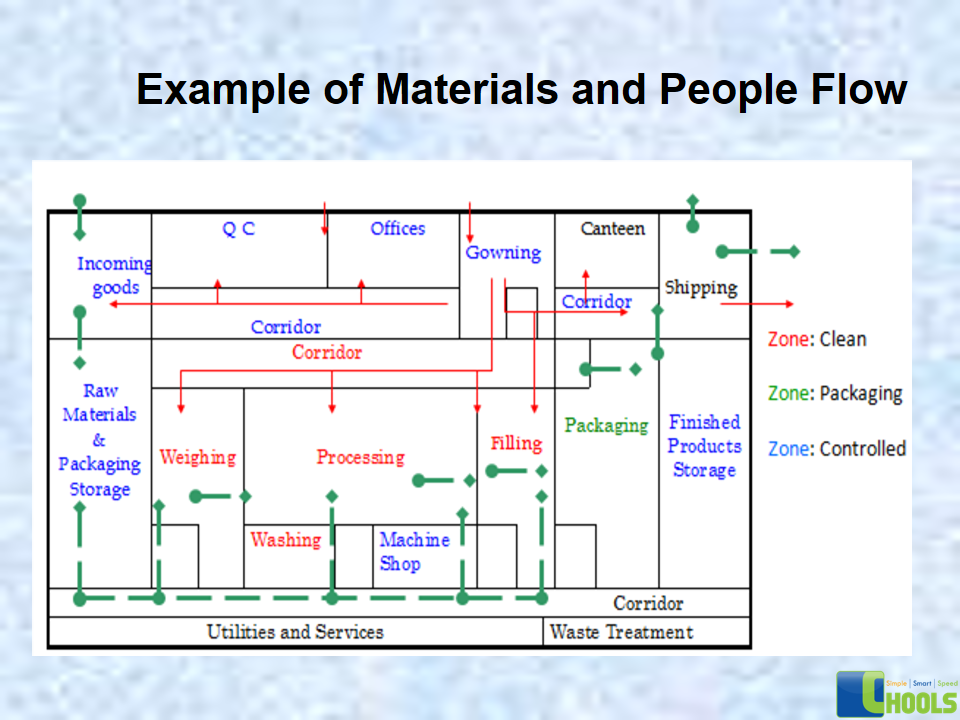

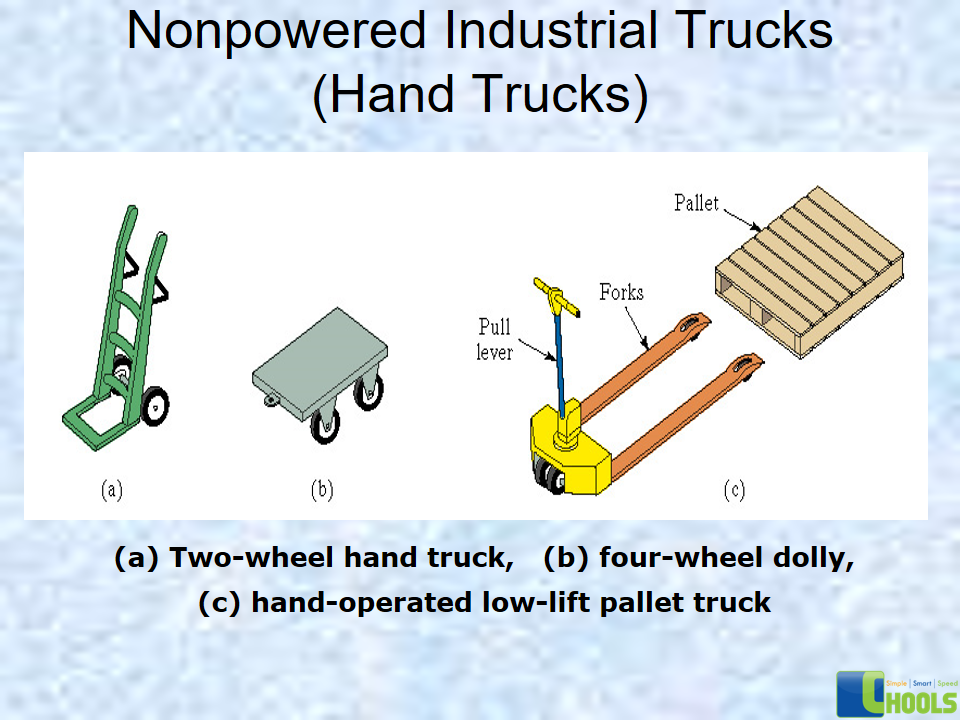

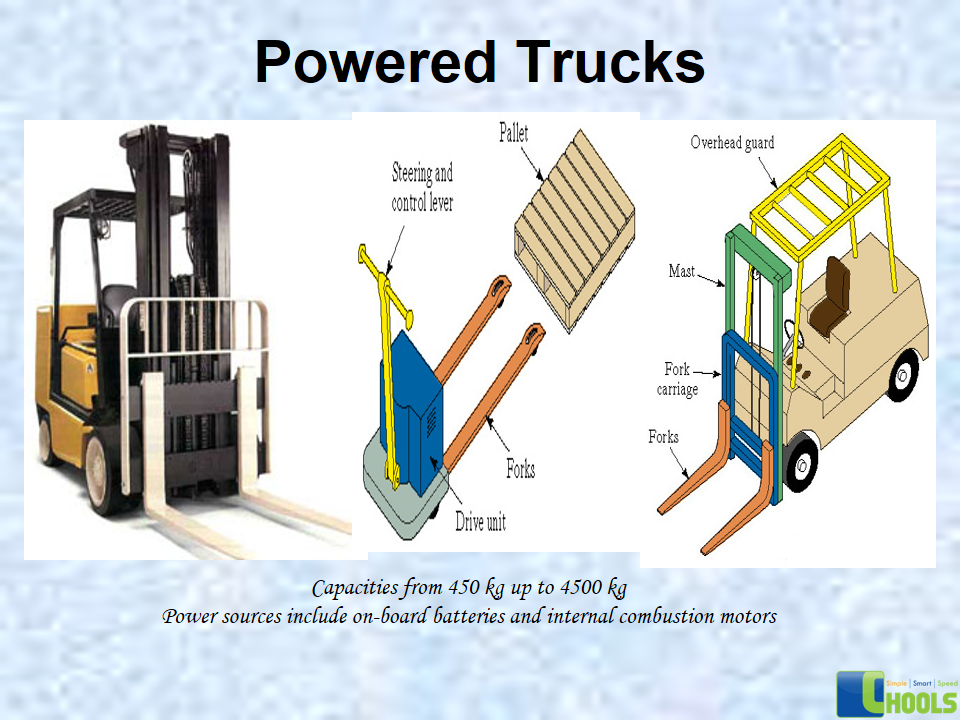

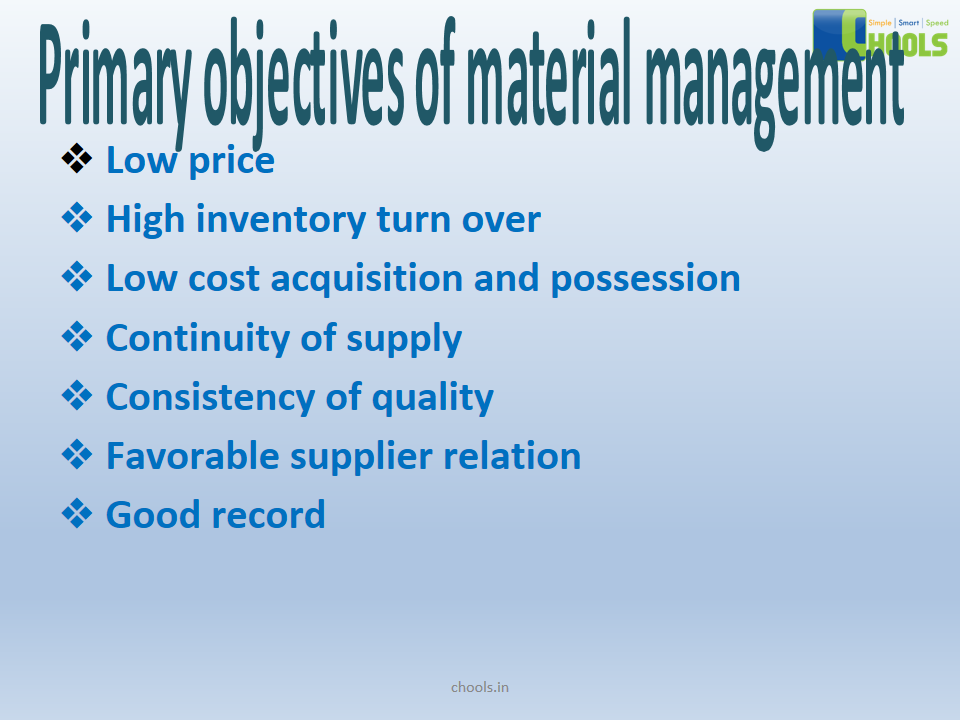

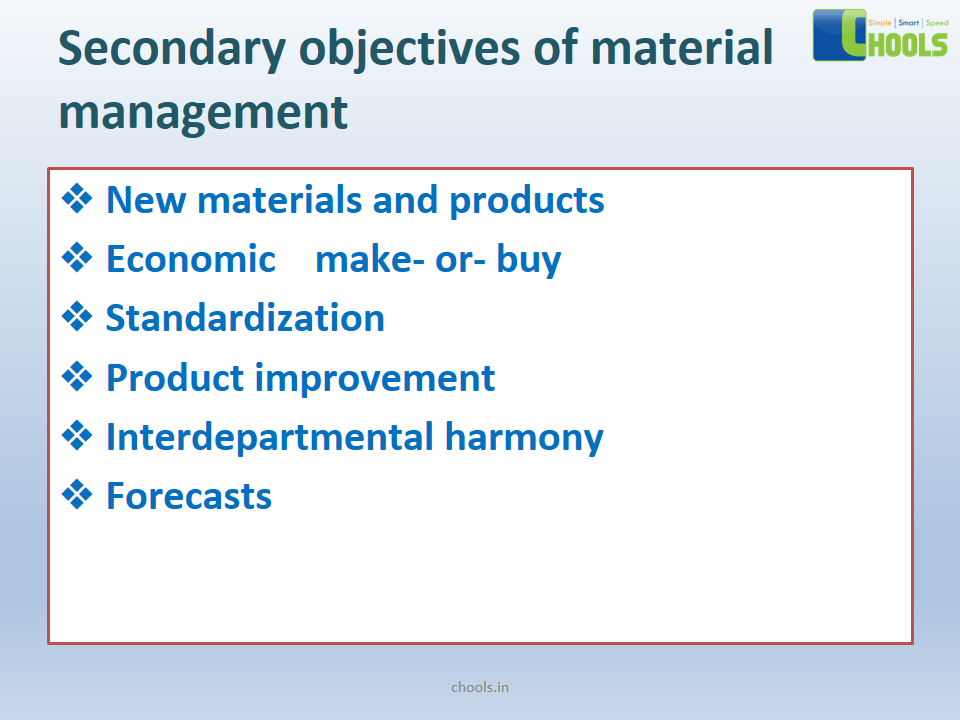

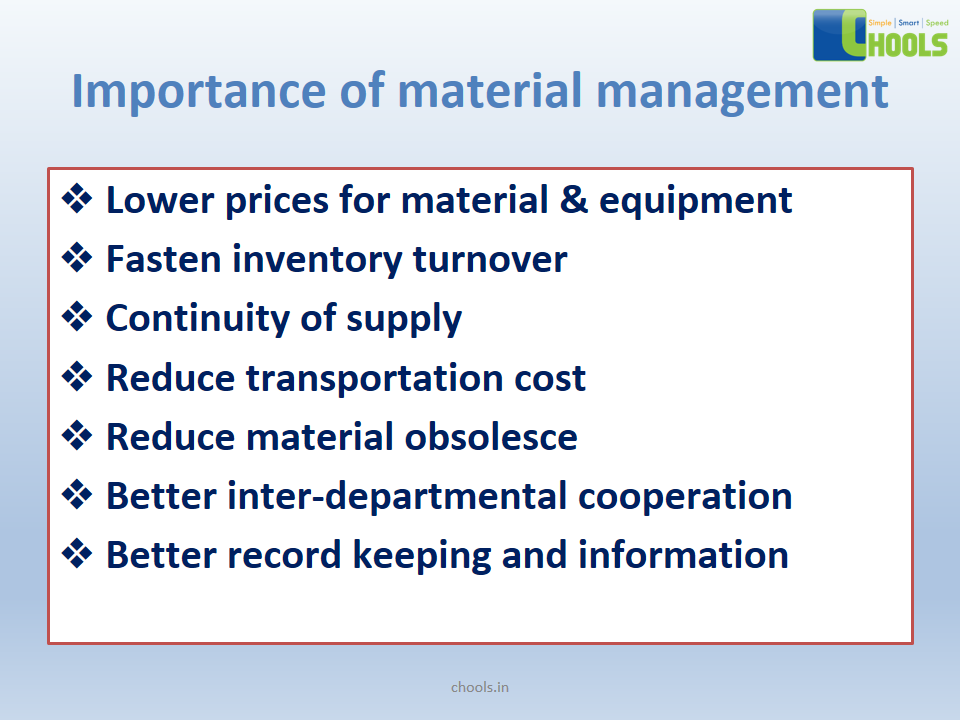

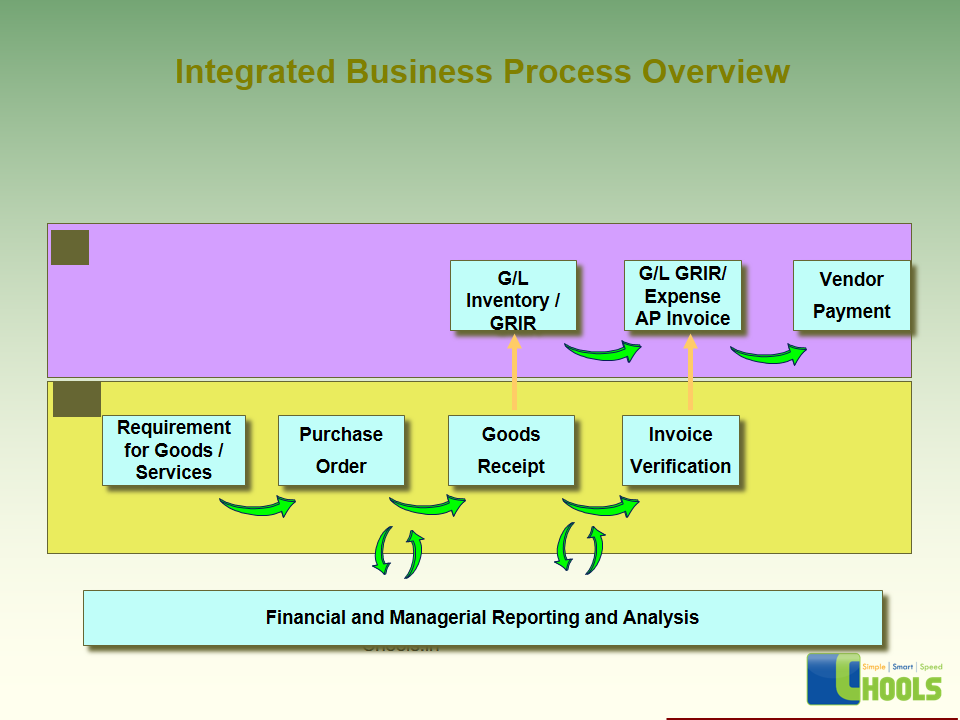

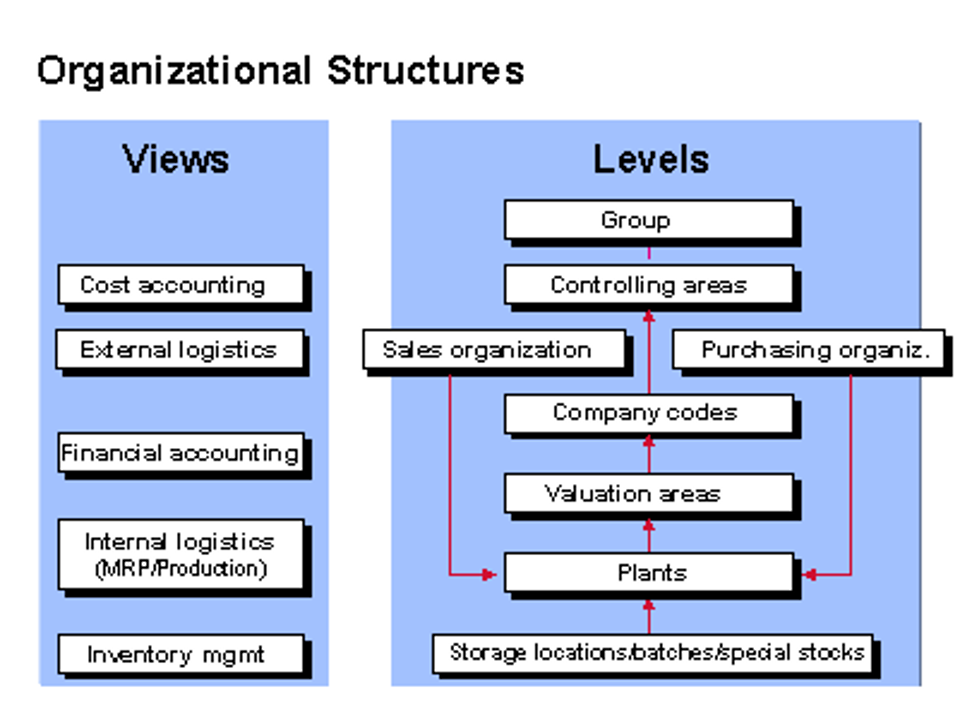

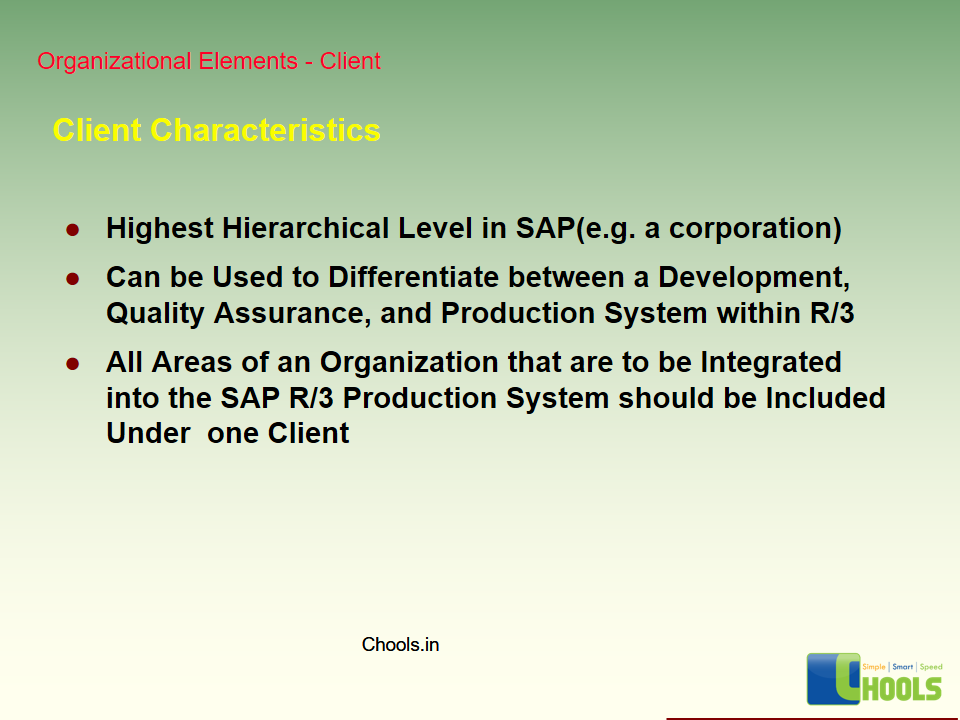

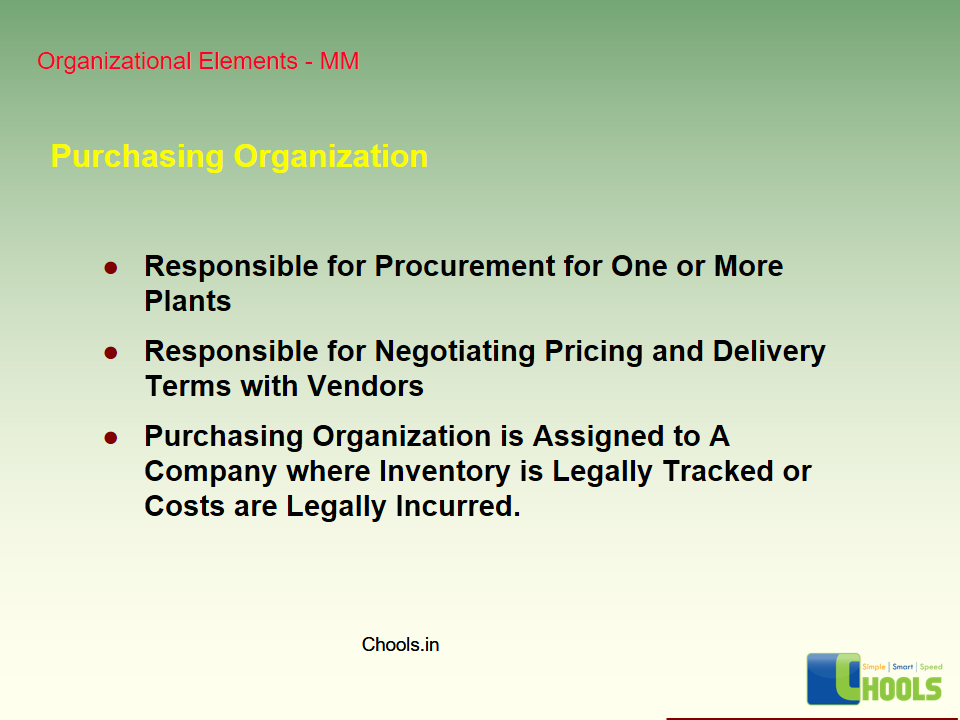

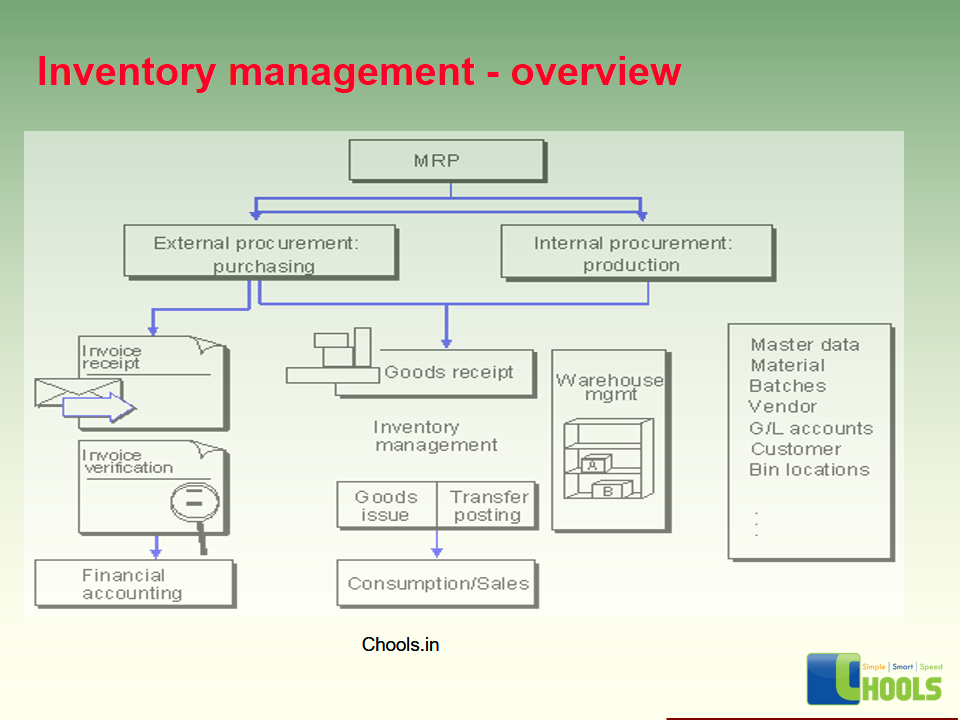

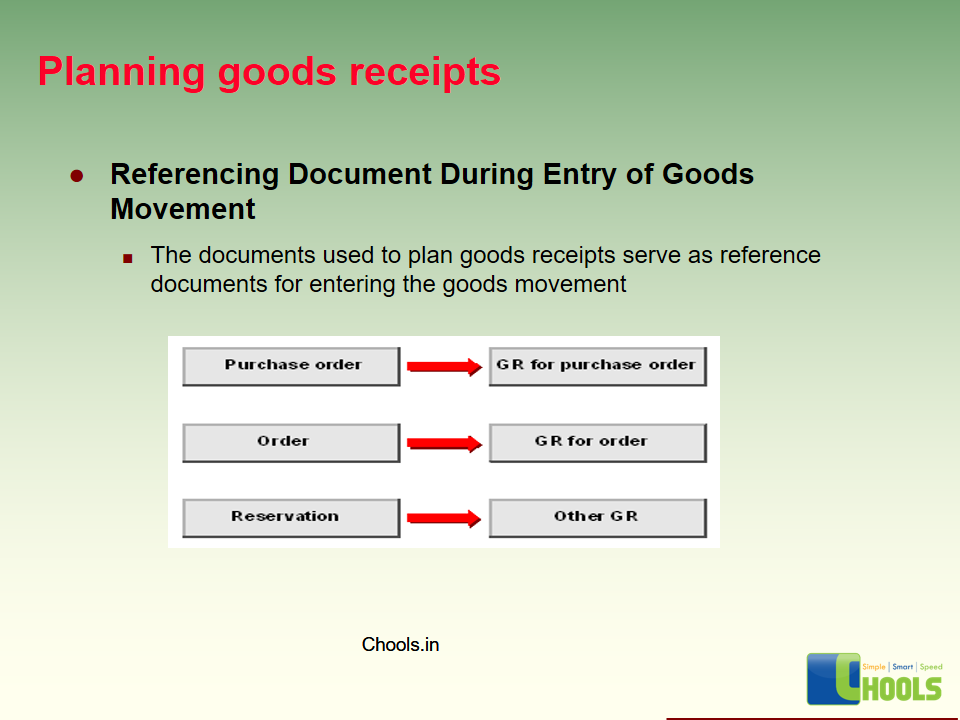

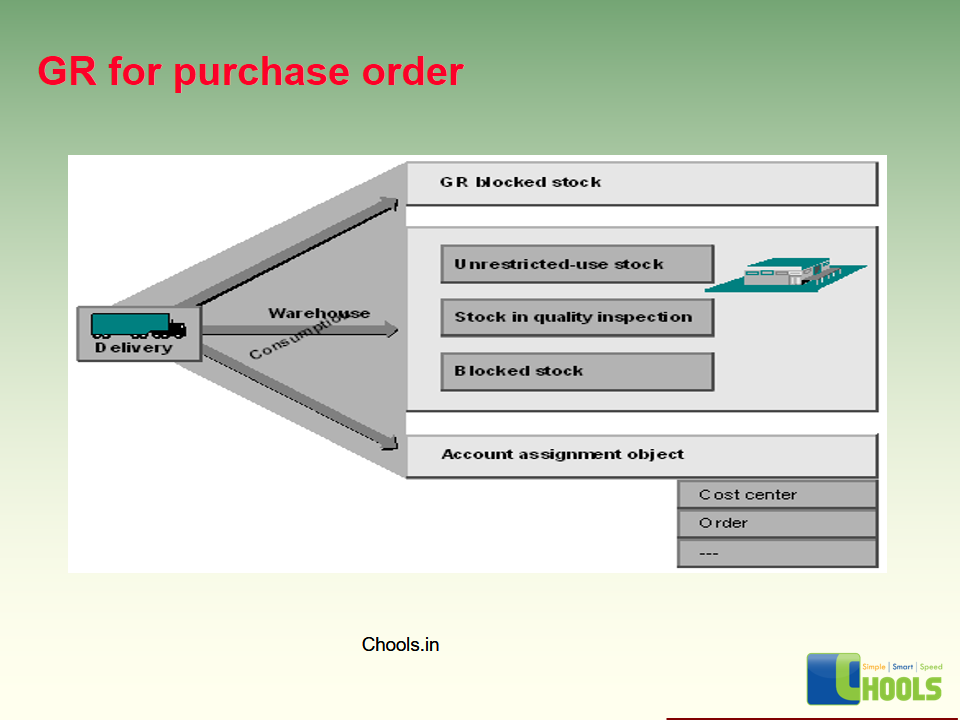

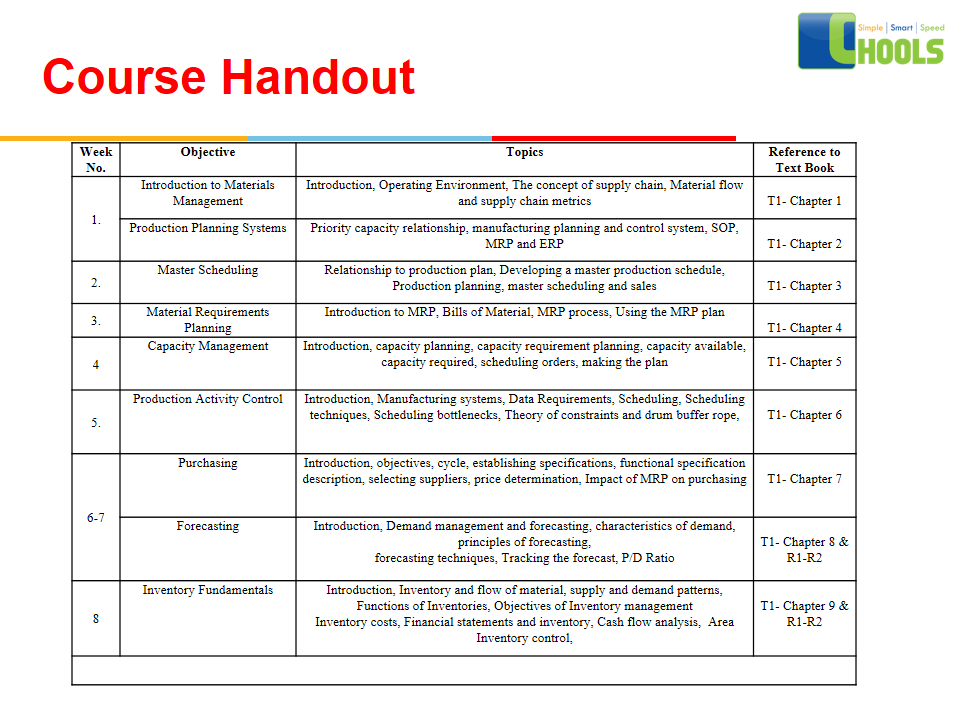

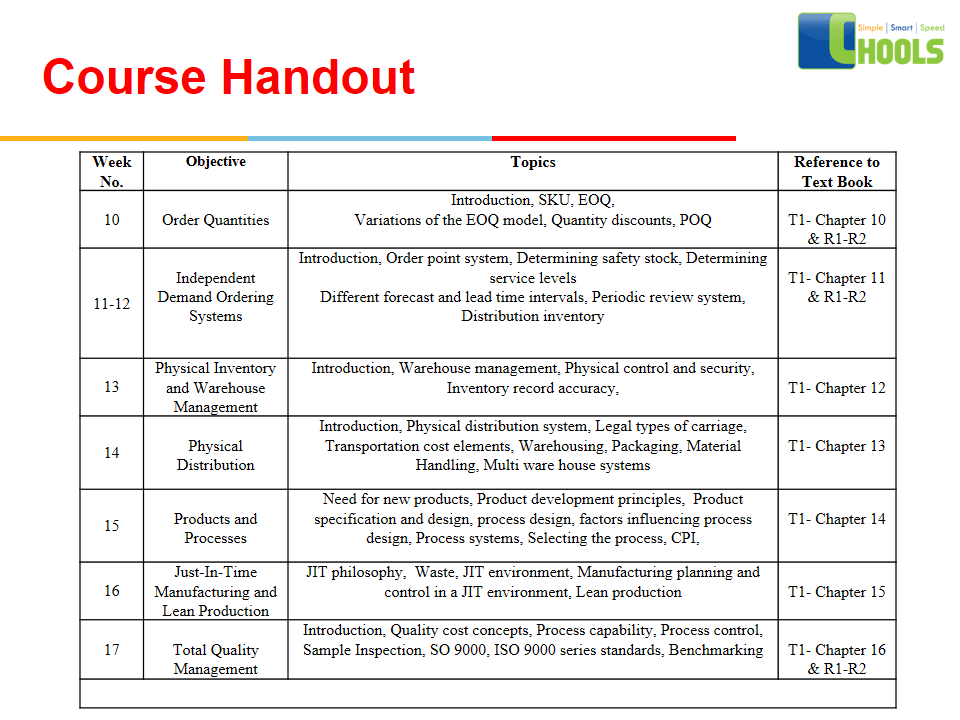

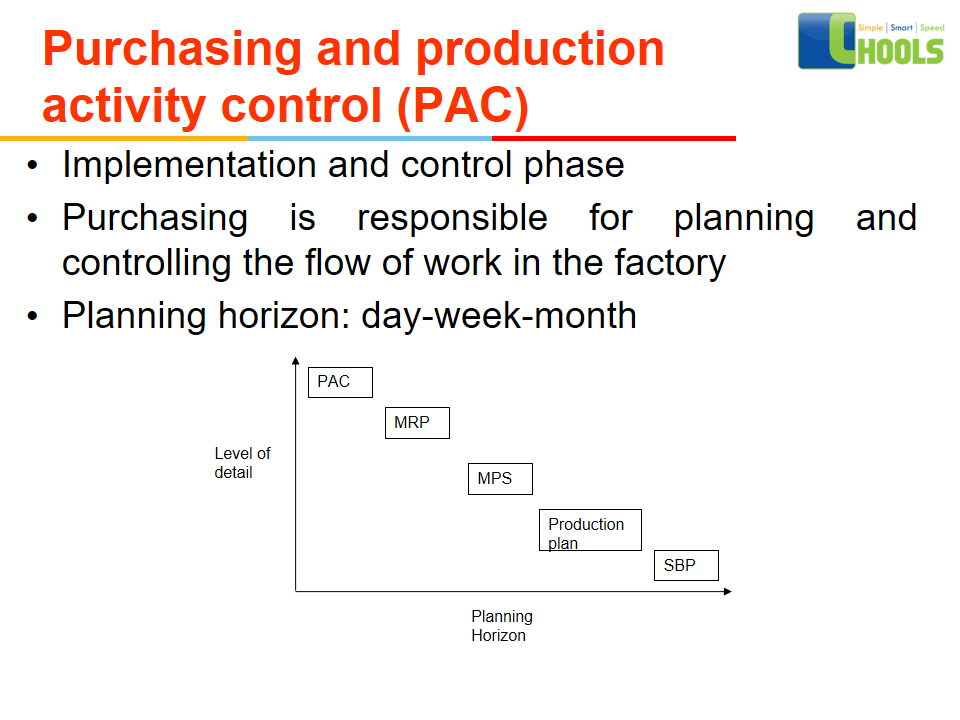

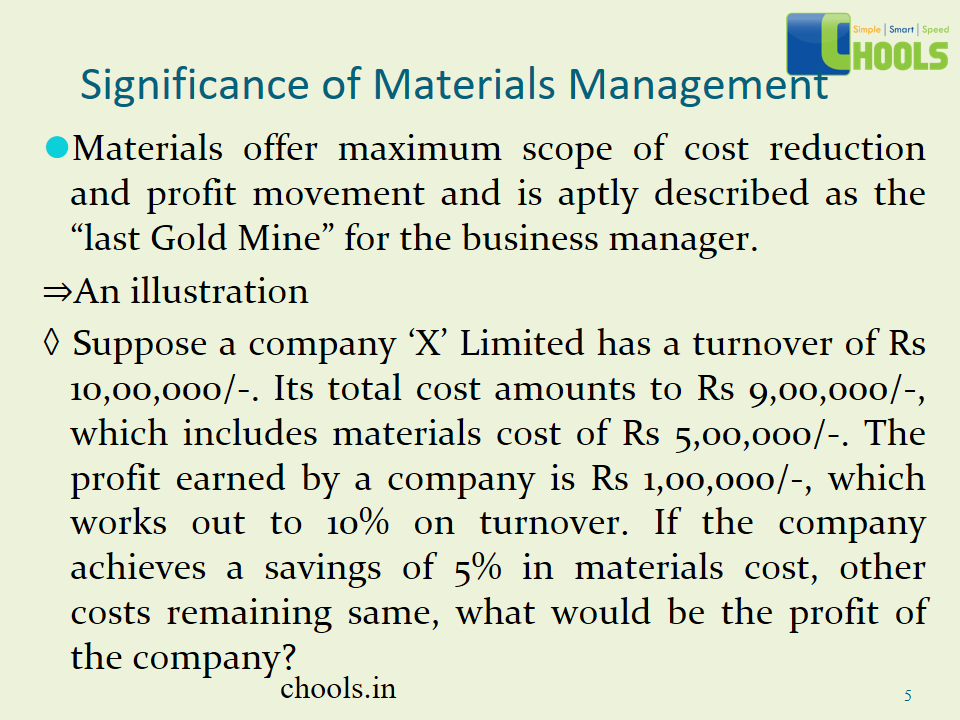

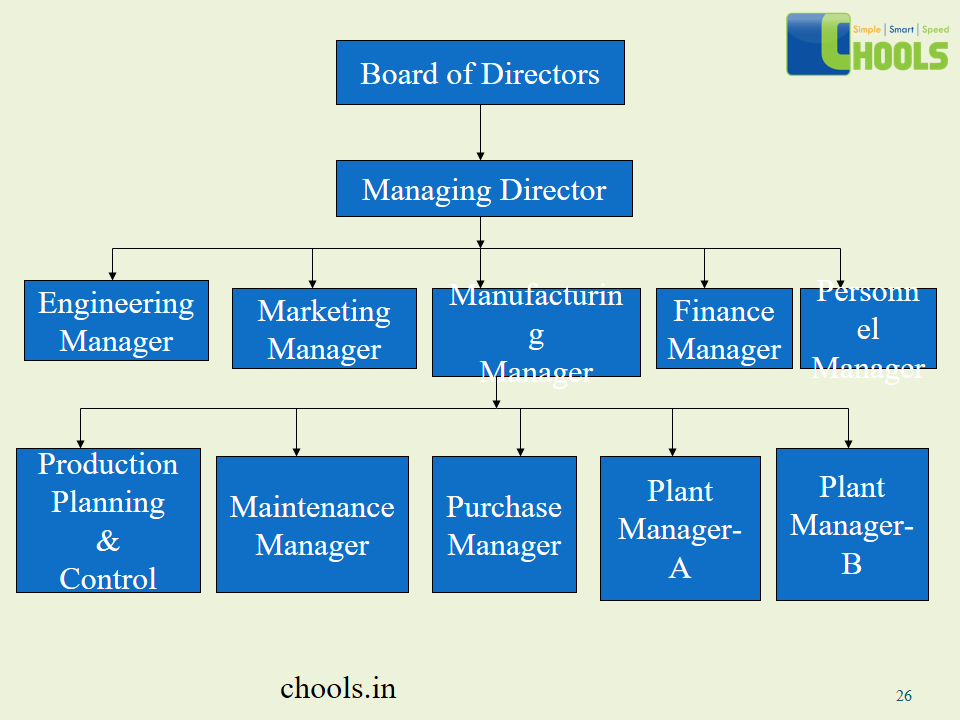

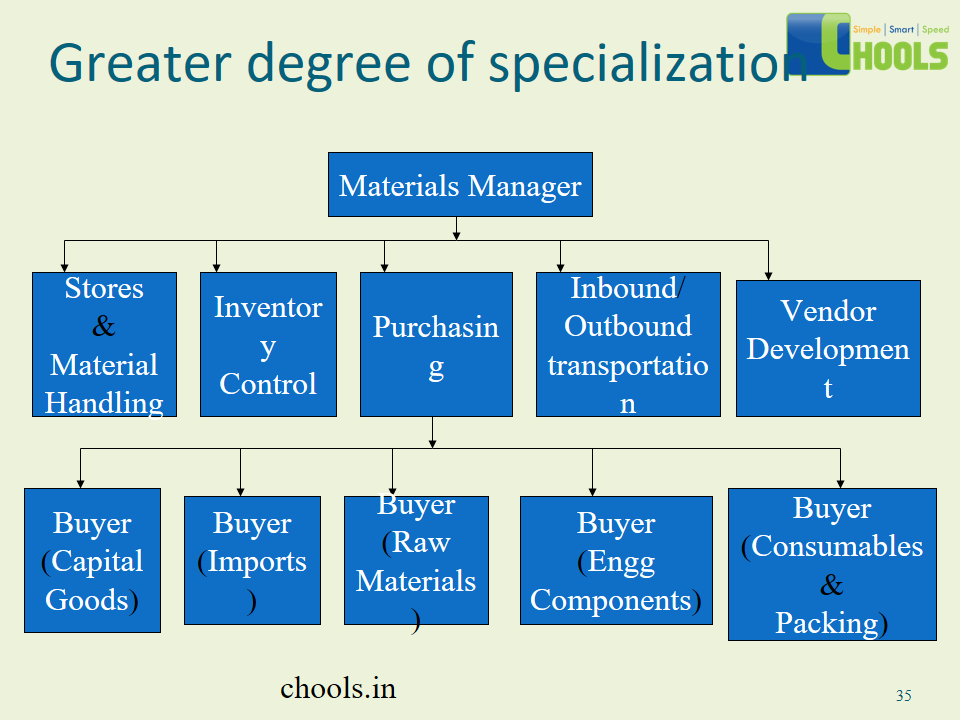

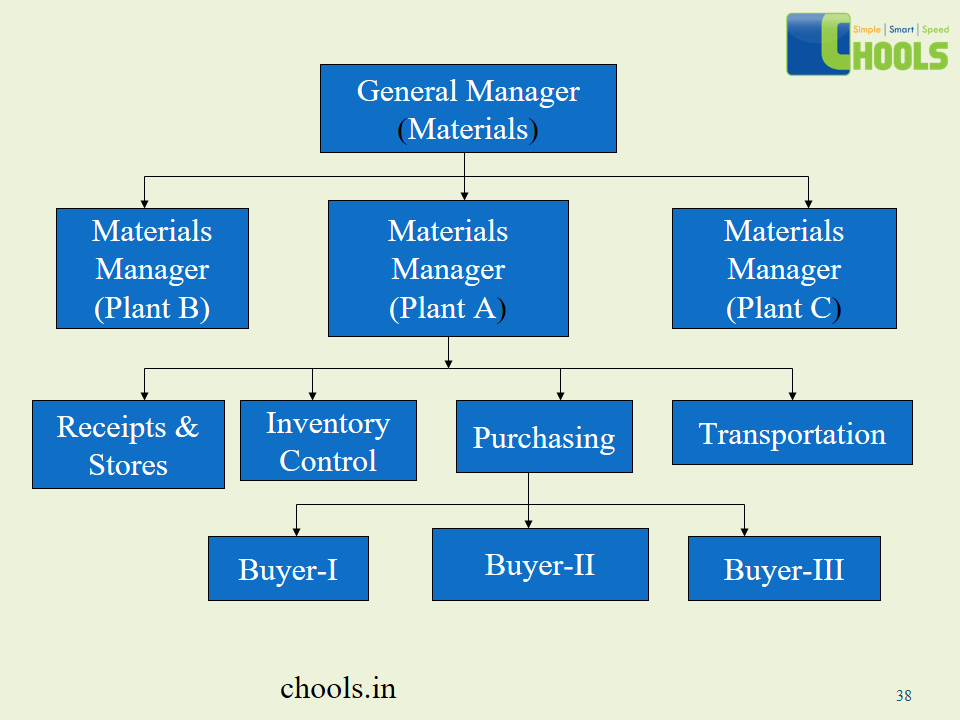

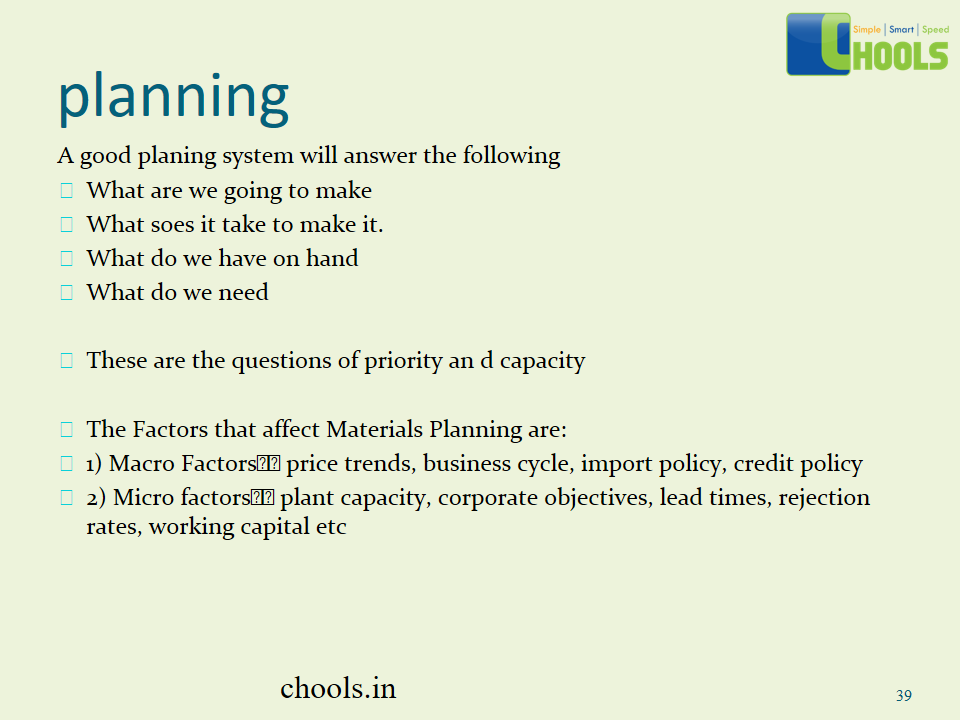

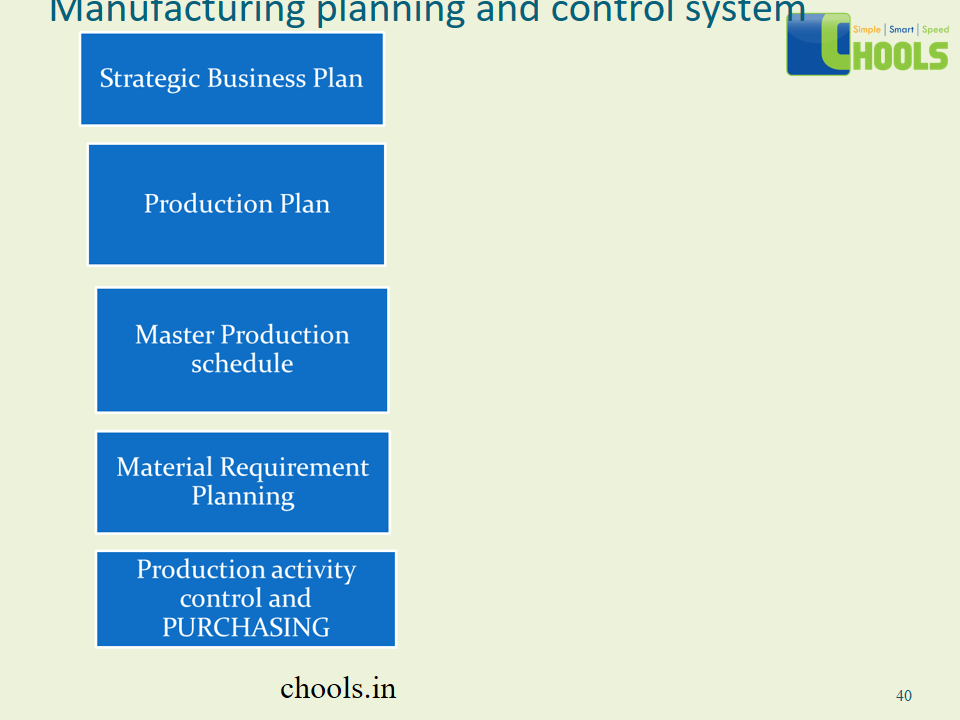

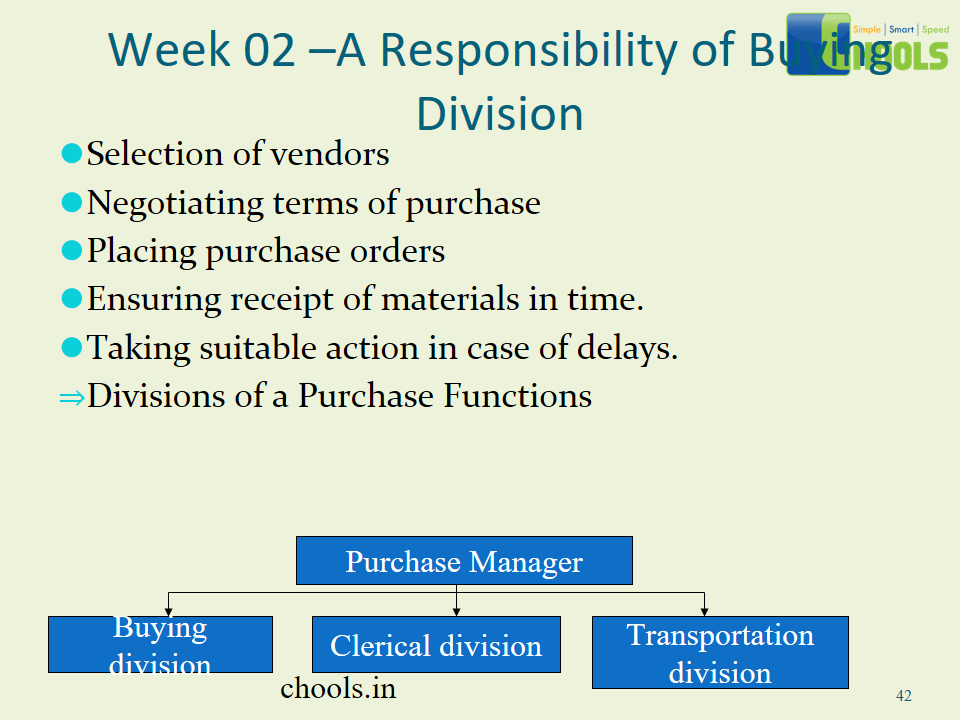

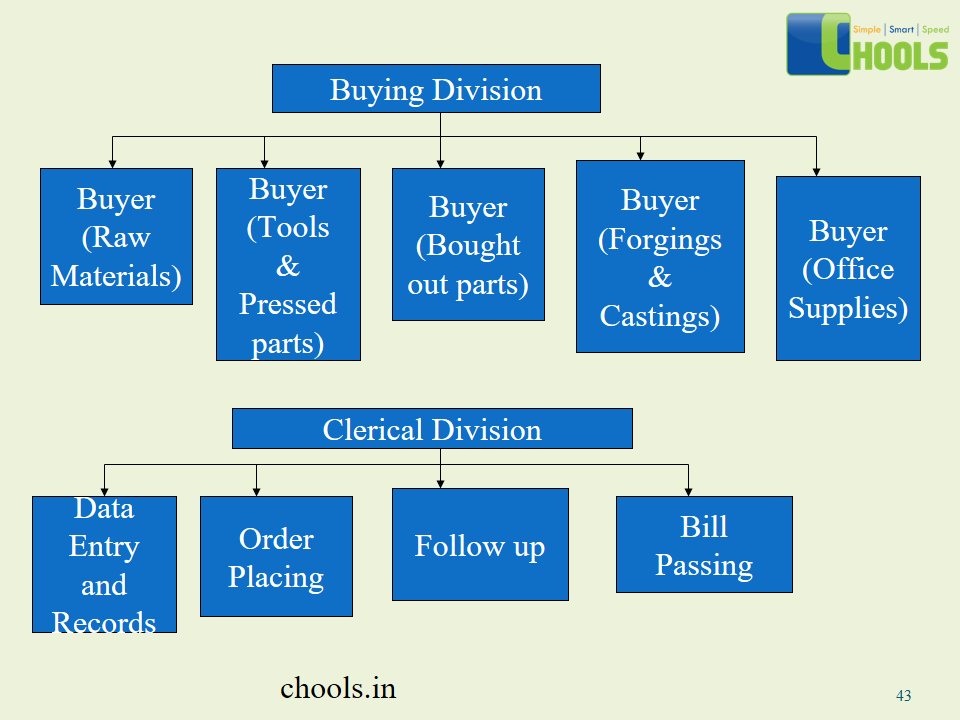

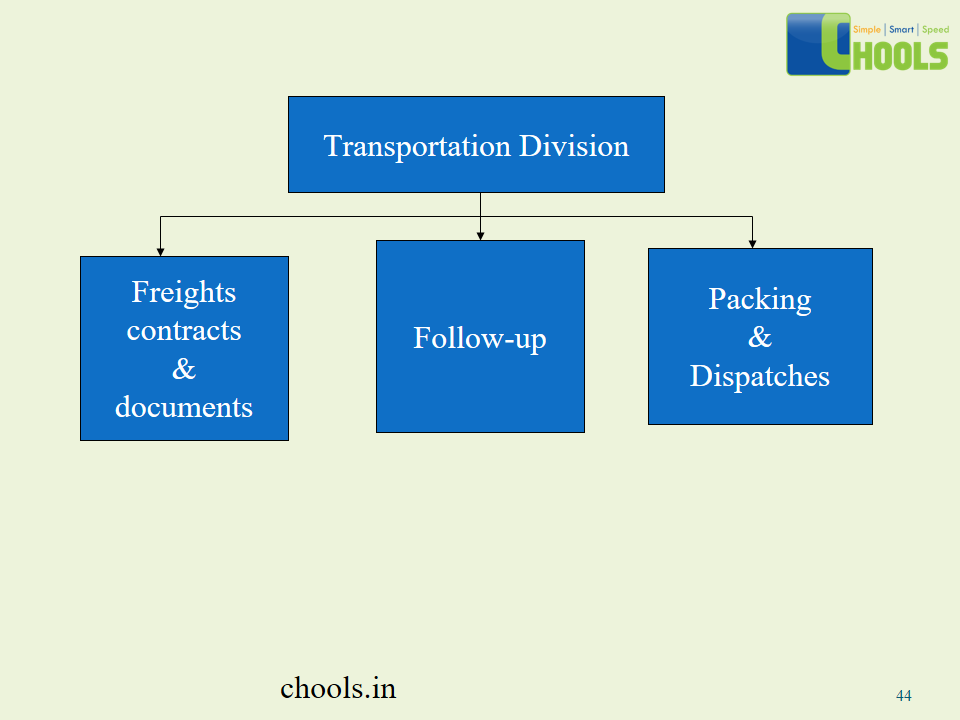

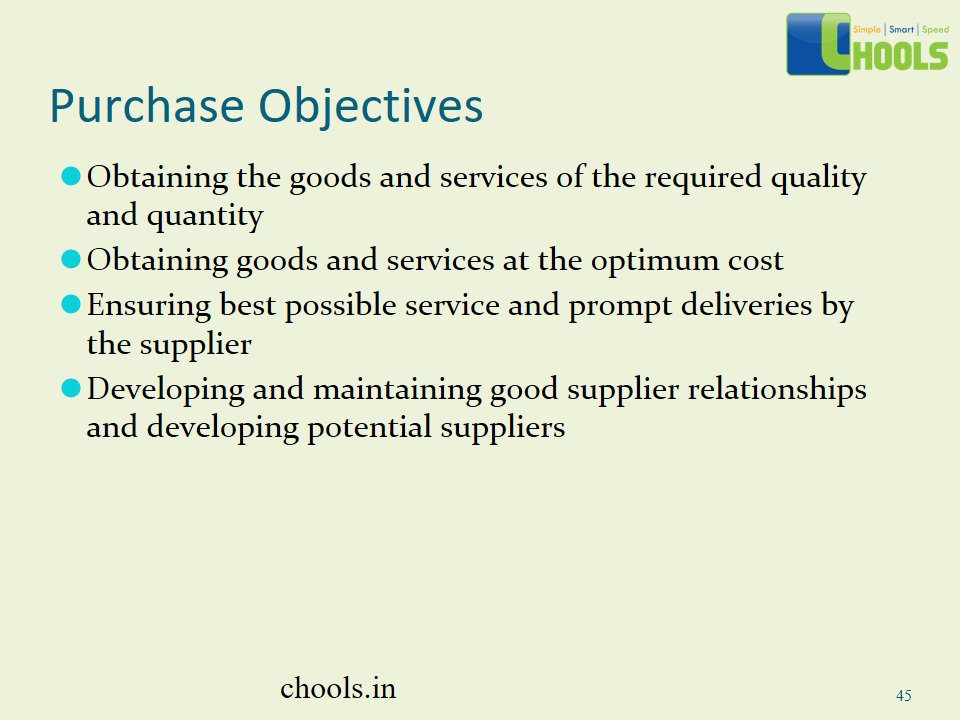

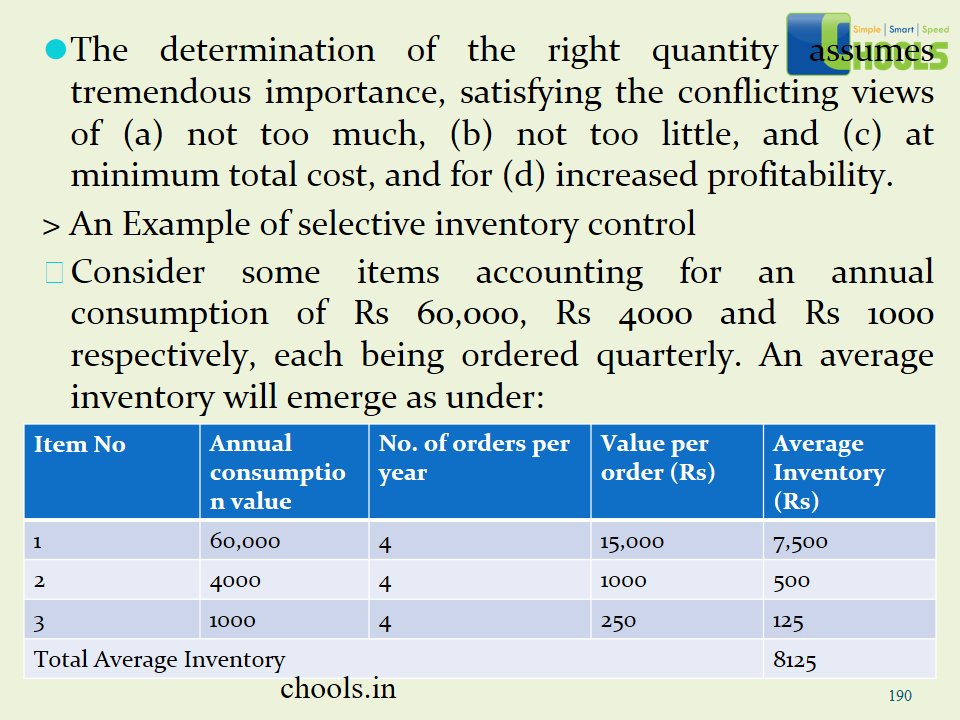

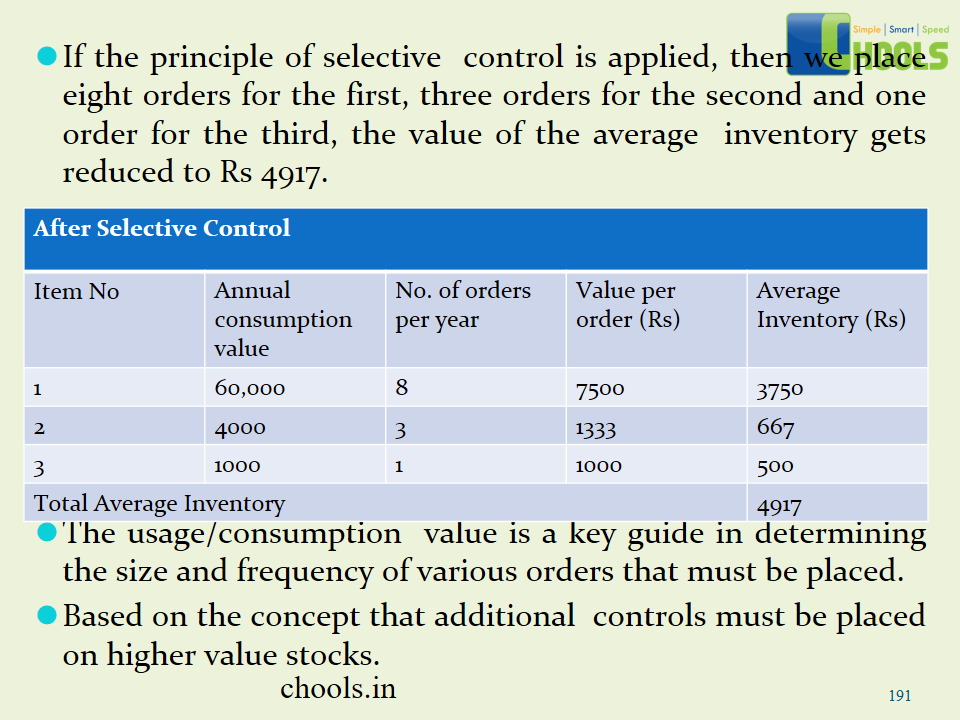

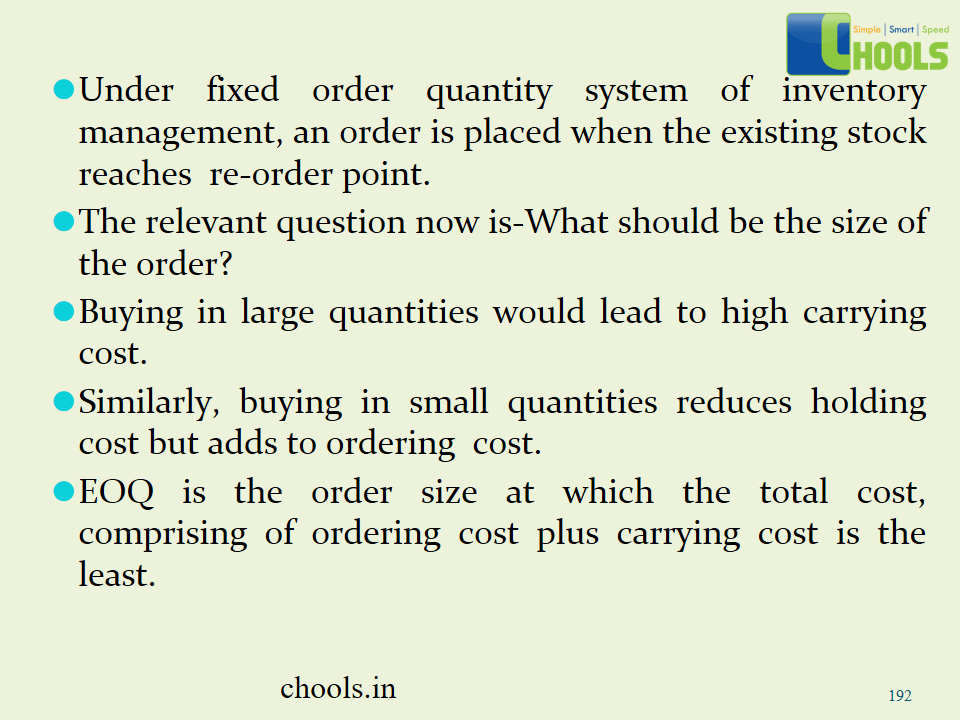

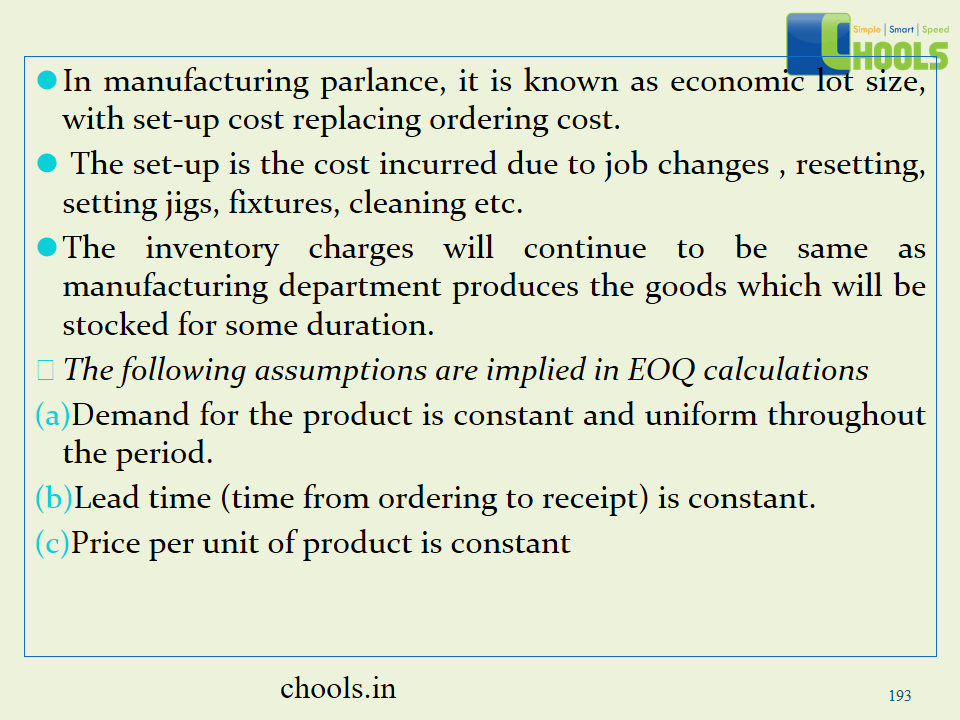

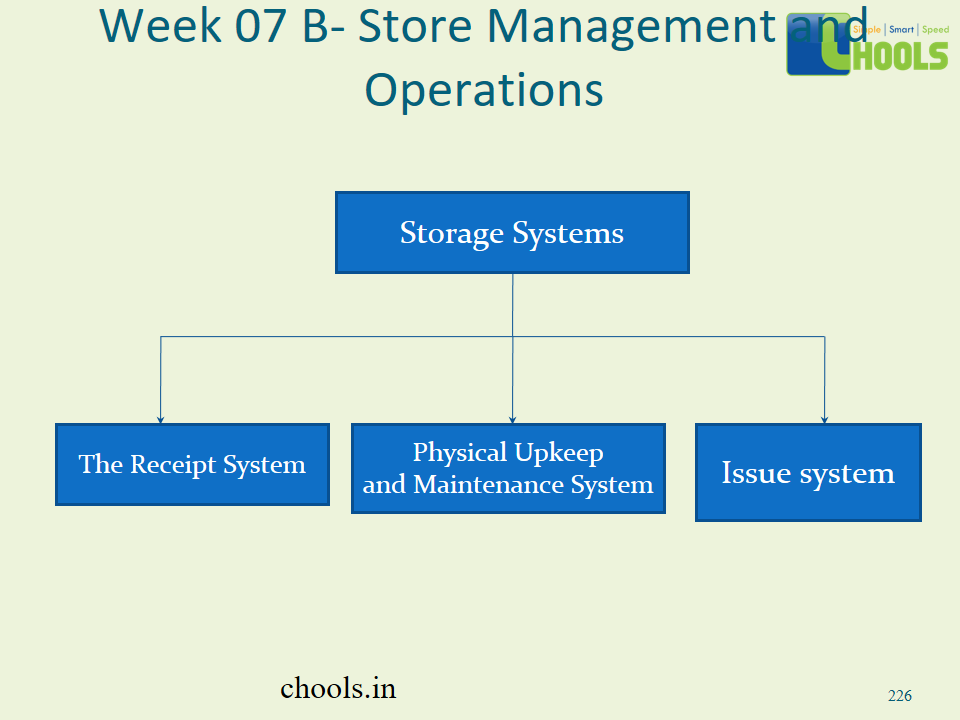

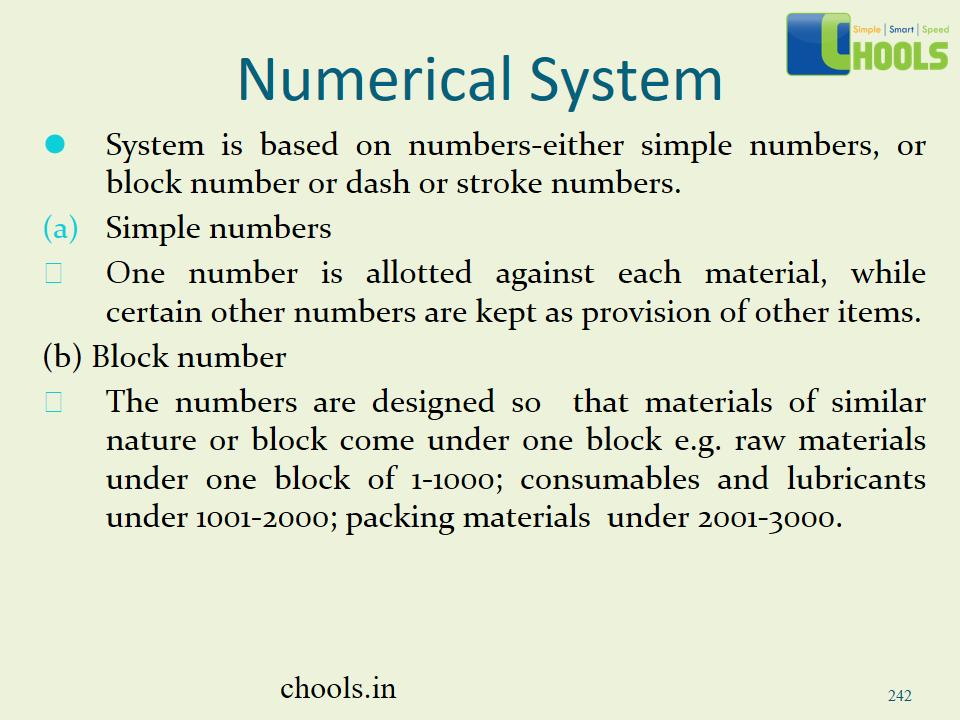

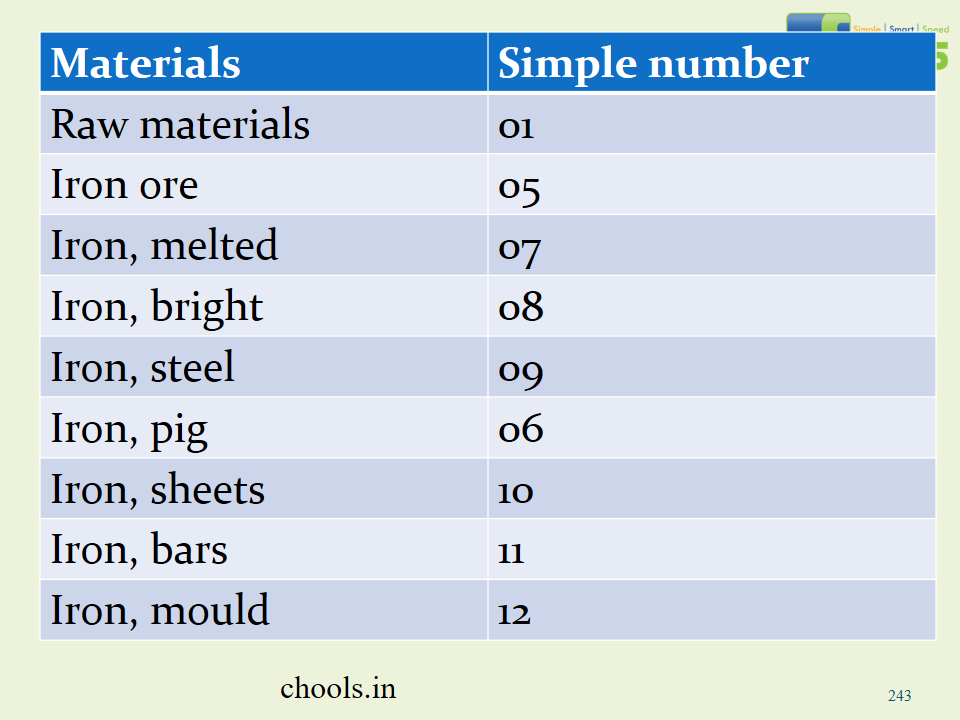

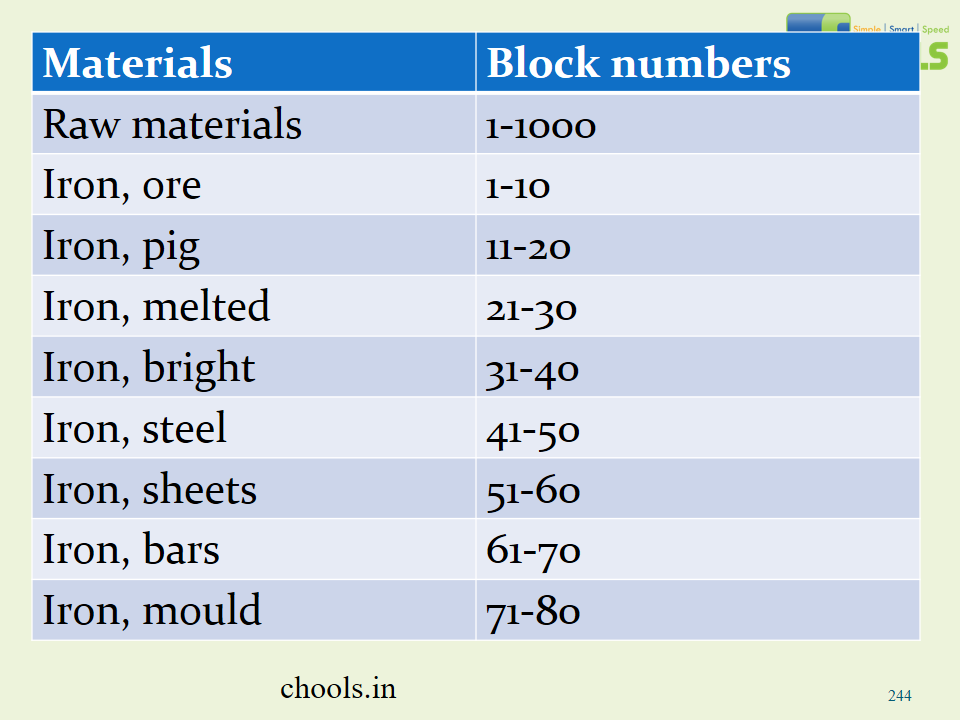

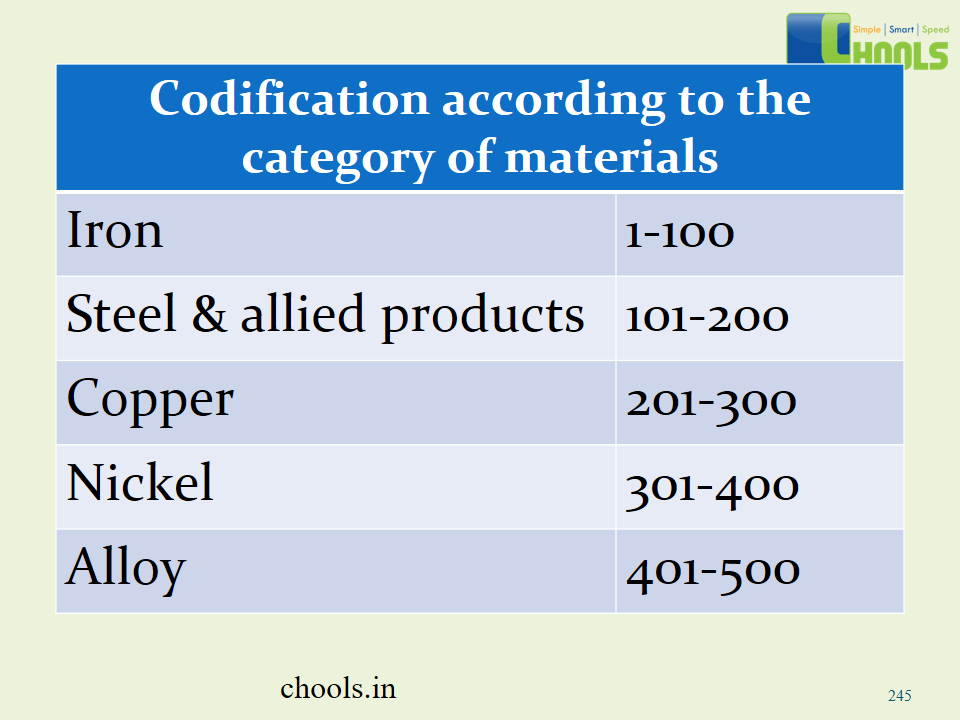

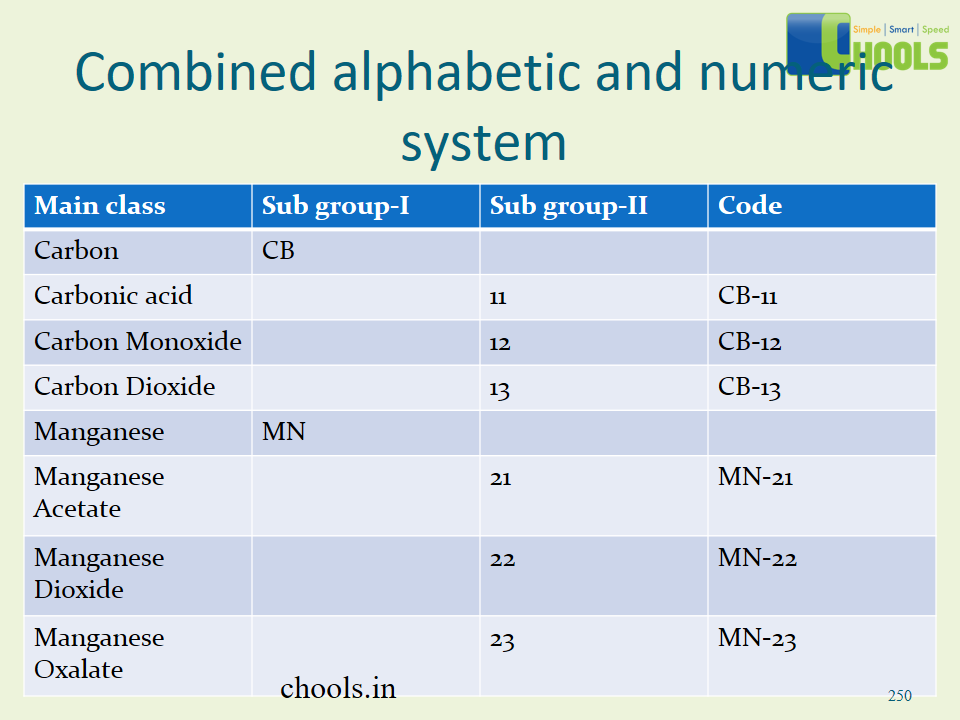

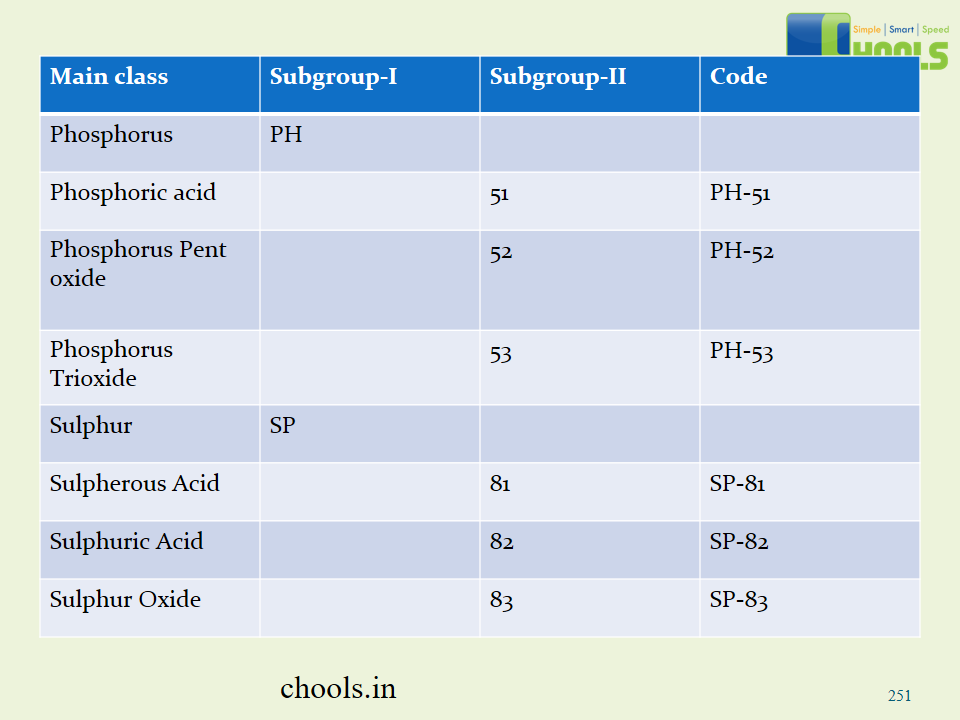

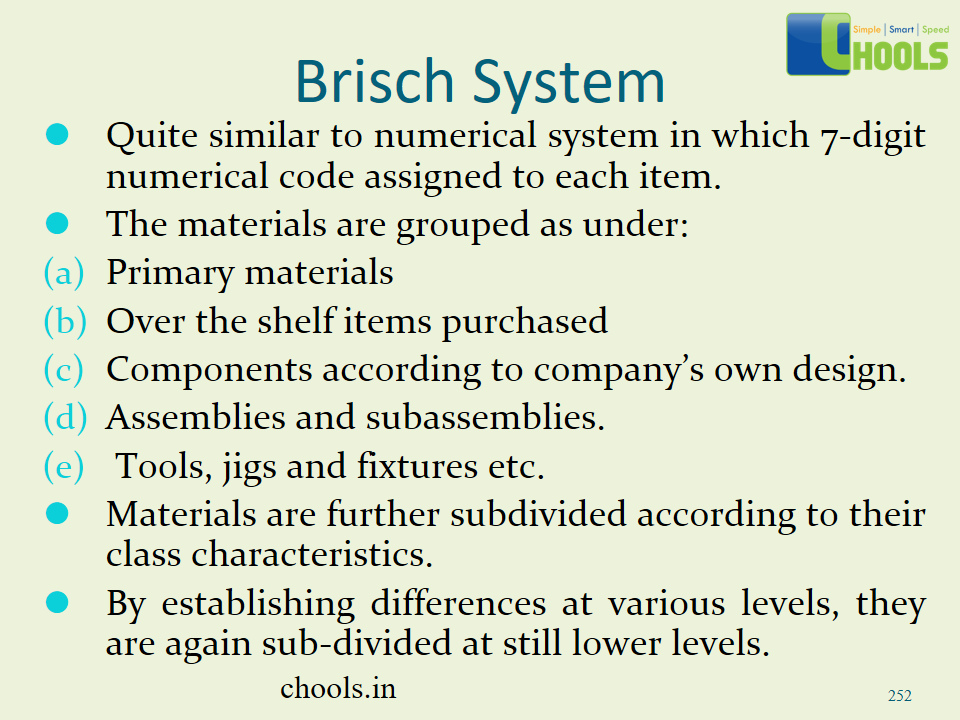

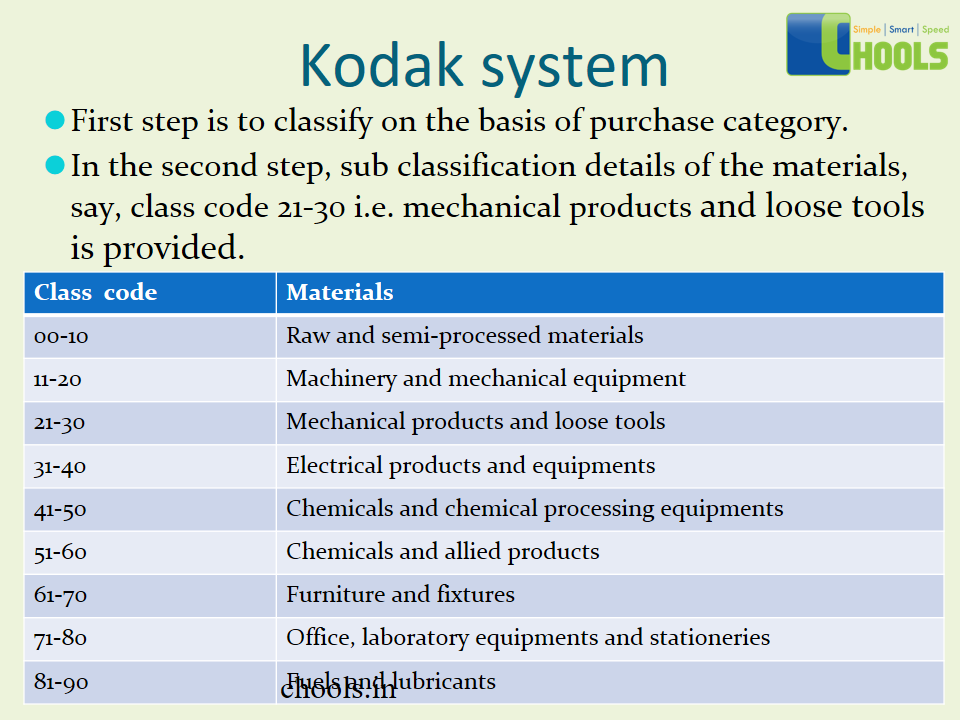

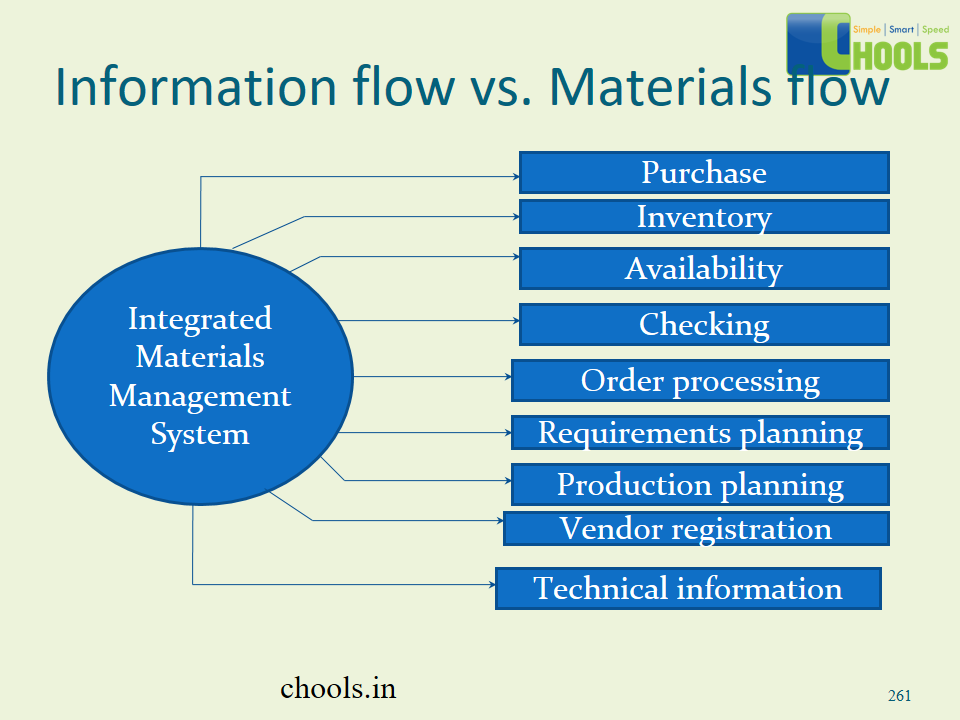

24. OVERVIEW OF MATERIALS MANAGEMENTS

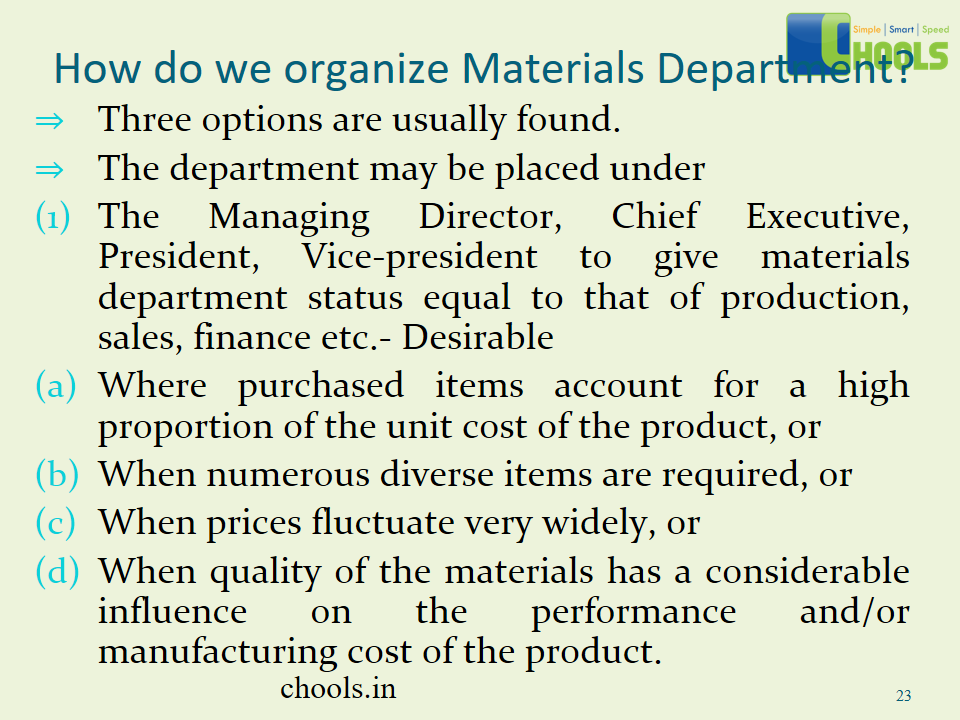

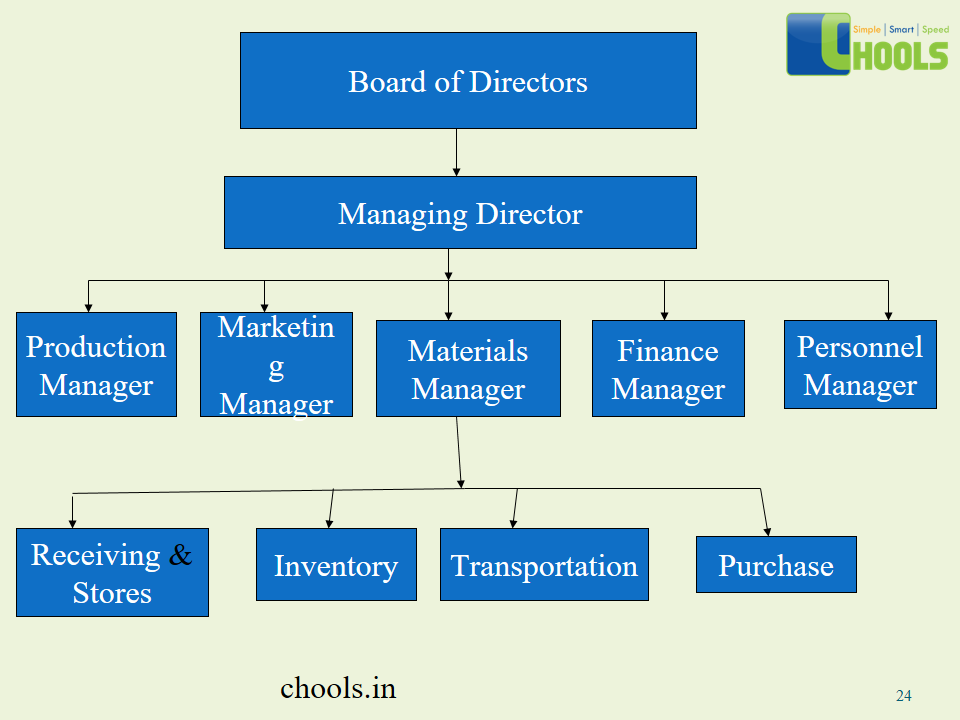

25. MATERIALS MANAGEMENTS

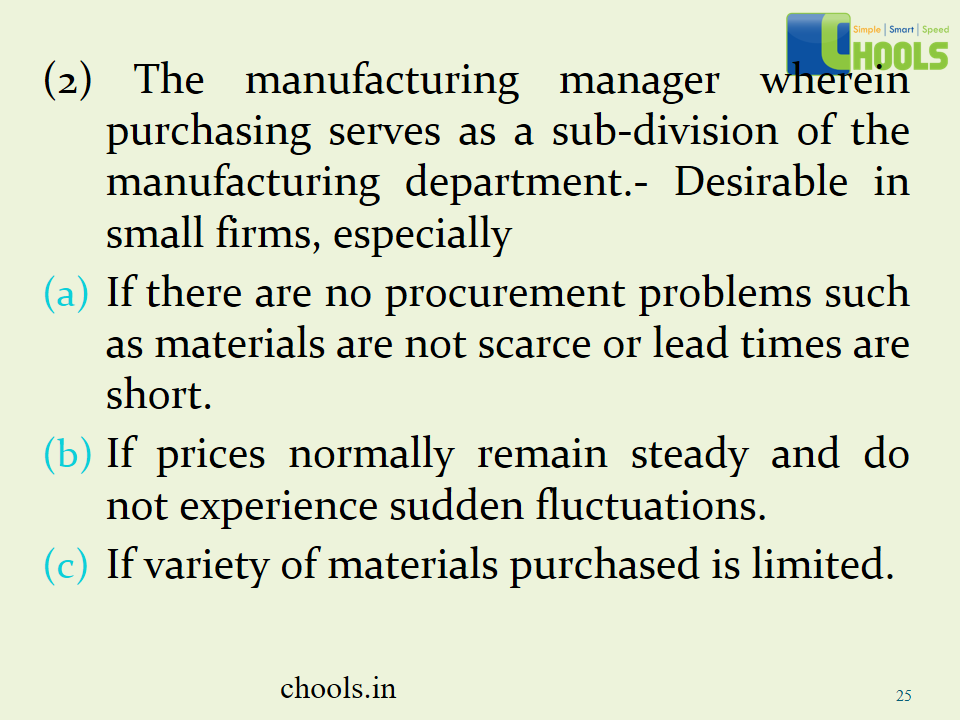

26. MANUFACTURING OPERATIONS MATERIALS MANAGEMENTS