Maximizing Value Creation:

The Lean Transformation Program (LTP) helps companies to get significantly better performance results, while building a continuous improvement culture to sustain success. The program delivers significant gains in quality, delivery, efficiency by simultaneously addressing structure, skills, processes, and operating system. Such Lean transformation is therefore not a ‘quick fix’ intervention; it requires time to redesign processes bottom-up and to build the skills to operate in the new way. The following video explains how to launch such a program.

Lean Corporation 4.0 – Lean Application in 2021

Do Businesses Really Need Lean?

Waste is everywhere, sometimes hidden but most of the time, right in front of us. Think of your past workday. Did you get exactly what you expected? Was every single minute of your time well spent? Was everything right first time? If you answered “no” to any of these questions, you have experienced waste. That’s why Lean is relevant and will always be.

How Does Lean Improve Competitiveness?

Competition is global, where only the fittest survive and thrive. In sports, weak contenders don’t win championships. In

the corporate world, companies are required to permanently innovate and disrupt not only their competition, but also themselves. The bar continues to be raised. Operational fitness is no longer optional, but essential, and Lean is the fitness program to build the strength, flexibility, endurance, and speed to not only stay in the game, but to win championships.

How Does Lean Create Value? For Whom?

Lean principles are both timeless and universal. Through the systematic reduction of waste by applying flow, takt, pull, and levelling principles, Lean helps companies bring innovations faster to market, improve labor productivity, eliminate unplanned downtimes, reduce non-performance costs, and ensure customers are getting exactly what they have paid for, while building a continuous improvement culture to sustain and build on those gains.

What Is a Lean Transformation Program?

A Lean Transformation is a structured improvement program on the strategic, tactical, and operational level to create more value for all stakeholders in the value chain: better products and services for customers, better working conditions for employees, and higher returns for investors. The program delivers measurable impact by redesigning the way of working, building required skills and capabilities, and implementing systems and standards to sustain them long term.

Top-Down or Buttom-Up – Which Approach is Best?

There are two basic approaches to implement change: : BOTTOM-UP, starting from the frontline, led by a departmental manager or dedicated change agent, and then expanding upstream until the entire value stream is covered. The bottom-up approach creates quick wins through early engagement and quick buy-in of frontline people, but is challenging to scale-up when led by people with limited authority. (2) TOP-DOWN, led by the executive team in a coordinated effort to get the entire organization involved. The top-down approach is ideal to address organizational barriers, ineffective structures, and undesired behaviors. But when a transformation is purely driven top-down, it often creates a disconnect between people doing the work and managers making the decisions. The optimal approach is a combination of both, developing the Lean transformation framework with the executive team, while identifying quick-win opportunities with frontline people, and then linking both work streams into one coherent program.

How to Launch a Lean Transformation Program?

As Lean Experts, we help you design and implement a Lean program that fits your needs, that truly transforms the value-chain by engaging people, leading them through the design and deployment process, creating new ways of working, and setting up systems to meet customer needs more efficiently – so you can leave the competition behind and focus your efforts on a bright and profitable future.

How to Control the Implementation?

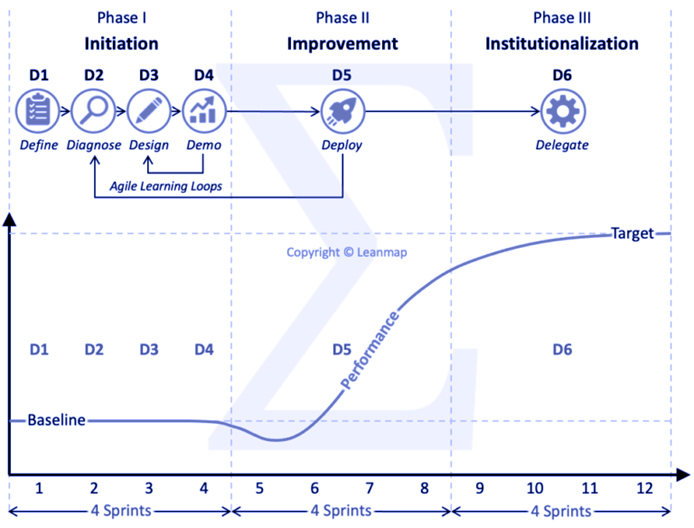

To create real change and measurable impact, the transformation must be well defined and tightly controlled. Our proprietary 6D-Method helps Lean champions to guide people systematically through the process, ensuring that improvements are properly planned and implemented. Active change management drives staff involvement and embedment of new processes. A quality gate at the end of each process ensures success criteria being met before moving to the next step.

How Long Does a Transformation Take?

Dependent on program scope, baseline capability, and resource allocation, a Lean Transformation cycle typically takes one year to design and implement major improvements across the entire value stream, while building the skills and capabilities to sustain them. As a rule of thumb, the program is launched over a 4-month initiation period to design and test improvements in a pilot area, followed by a 4-month scale-up period to get the entire organization involved, and a final 4-month institutionalization period to stabilize processes and train people, so gains will be sustained long-term. A Lean Transformation requires a long-term perspective, discipline and stamina to drive change across the entire organization and achieve breakthrough objectives.

Who Is Involved? Who Is Leading?

There are five key roles for a Lean Transformation: sponsor, champion, controller, coach, and team member. The sponsor allocates resources and provides context, such as low productivity or excessive lead times, and steers the program overall. The program champion heads the project management office (PMO), is responsible for planning, design, and implementation. The controller validates projects and tracks cost, benefits, and overall impact. Team members are responsible for specific tasks and deliverables on the functional or process level. The Leanmap consultant acts as program architect, coach, or leader (Engagement Model) to fill knowledge and resource gaps, ensuring the program delivers the expected impact.

What Are the Results?

Ultimate outcome is an agile and efficient operation with steadily-improving performance levels, while creating a competitive advantage from higher speed and flexibility. Narrowing the gap between the current and ideal state by 30% to 50% is a common breakthrough objective, reducing defect levels, productivity gaps, lead-times, and working capital by double-digit percentages each year, until the plateau is reached. To break through the plateau, we will apply Kaikaku principles, following Hiroyuki Hirano’s Ten Commanments of Kaikaku: Throw out traditional methods; (2) Think of how the new method will work; not how it won’t work; (3) Don’t accept excuses; (4) Totally deny the status quo, be ready to start new; (5) Don’t seek perfection but rather strive for a 50% improvement on the spot; (6) Correct mistakes the moment they are found; (7) Don’t spend money on Kaikaku; (8) Problems give you a chance to use your brains to ask “why” five times; (9) Ideas from ten people are better than one person’s knowledge; and (10) Kaikaku knows no limits.

How Much Does the Program Cost?

Obviously, there is an investment required to realize any improvement. Here a common example: an operation with 100 employees, $50M addressable cost base and $5M operating margin, requires at least 1 dedicated expert resource – either freed-up internally, sourced externally, or a mix of both – to identify and implement $1M improvements per year, which represents a 20% bottom-line improvement. Leverage increases with company size and program scope Contact Us for an initial scoping call ‘Quick Scan’.

Which Processes Are Targeted?

A Lean Transformation utilizes a broad range of methods and tools, such as the lean factory layout and ergonomic workstation design for maximum safety and labor productivity; mixed-model manufacturing (MMM) lines and cells; process standardization using standard operating procedures (SOP), one-point lessons (OPL) and service level agreements (SLA); capacity resource planning (CRP) process and system; sales & operations planning (S&OP); supply chain rationalization (SCR); make-buy optimization (MBO); supplier audits and supplier qualification processes; cost optimization using zero-based budgeting (ZBB), activity-based costing (ABC), total cost of ownership (TCO) principles; quality improvement with focus on first-pass yield (FPY) and rolled throughput yield (RTY); overall equipment efficiency (OEE) and overall process efficiency (OPE) of manual steps; testing robustness and gauge repeatability and reproducibility (GR&R); equipment reliability, total productive maintenance (TPM) to reduce the mean time between failures (MTBF) and mean time to repair (MTTR).

Lean Transformation Case Study

Lean-transforming an electronic assembly plant in Mexico: the maquiladora with 2,000 employees achieved within a 12-month transformation cycle 44% higher labor productivity, +66% yield improvement in first-pass quality, +25% profitability (EBITDA), at 94% less process inventory. The Lean transformation was well supported by employees and executives, resulting in a staggering 1100% (11-fold) productivity gain and 90% defect reduction over a 7-year transformation period. The two Lean transformation cycles matured the operation from Iron to Bronze to Silver level (Lean certification).

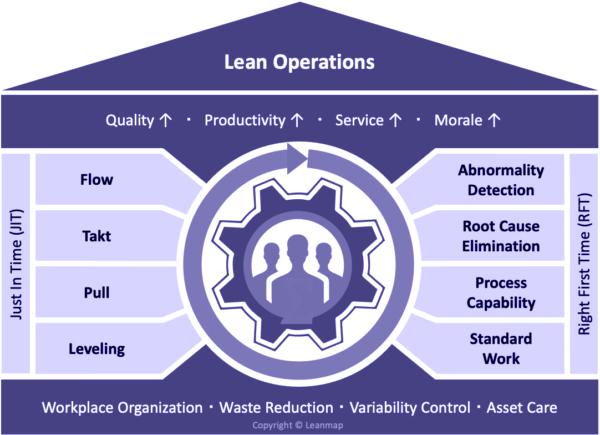

Lean Transformation Model – How It Works

Even though every organization approaches a Lean program from a different angle, there are ten steps that characterize a successful transformation: define what customers value, map the value stream to identify wastes and problems, remove barriers to make materials and information flow, adjust the pace of work to customer demand, establish pull to prevent overproduction and excess inventory, level the workload to prevent overload and underutilization, detect abnormalities to trigger the help-chain, eliminate root causes to prevent repeat problems, establish process capability to meet customer requirements, and standardize processes so that work is done the same way, every time. Doing so allows making things and providing services just-in-time (JIT) and right-first-time, the two pillars of the Lean Transformation Model.

The 10 Lean Principles to Transform Manufacturing and Service Operations

➤ Define Value

The definition of value is straightforward; it represents a product, feature, or even emotion that triggers a customer buy-decision. Producing value also refers to those activities and outputs that enable the next process. To understand value, we need to consider the expressed and latent needs, as customers may not be aware of new technologies or offerings, or they are unable or unwilling to articulate their needs. Using qualitative and quantitative techniques, such as structured surveys, focus interviews, and web research helps discovering what customers truly value, how they want products or services to be delivered, and the price they willing to pay for.

➤ Map Value Stream

Once the value has been clearly defined, we can now map the value stream, the chain of processes that coverts raw materials into finished goods and provides services to customers. Value-stream mapping (VSM) is an effective technique to identify required steps from customer need to its fulfillment. This mapping process typically covers Commercial (sales, marketing, order processing, after-sales service), Creation (R&D, engineering, product development), Supply Chain (sourcing, warehouse, logistics, distribution), Manufacturing (planning, production, quality control, maintenance), and also Administration (budgeting, resourcing, controlling). Goal is mapping material and information flows on a single page to identify wastes, opportunities for improvement. The eight deadly wastes (8W) can be easily remembered as “DOWNTIME”, which includes Defects (rework, scrap, breakdown, backflow), Overproduction (making too many or too early), Waiting (delays, downtime, idling), Non-utilized talent (wasted skills, non-compliance, behavioral issues), Transportation (internally moving materials and information around), Inventory (excessive amounts between stations and stored in warehouse, anything beyond the amount required for load-leveling), Motion (physical movements forced by the process due to an ineffective layout), and Extras (unnecessary features and activities that customers have not asked for). The VSM exercise results in a better understanding of the entire business; it allows identifying wastes and developing a leaner future state by applying just-in-time (JIT) and right-first-time (RFT) principles, the two pillars of the Lean Transformation Model.

➤ Create Flow

After wastes have been reduced or entirely removed from the value stream, the next step is organizing the remaining processes in close sequence (physically and in timing) so that material and information flows smoothly toward the customer without interruption and inventory build-up between stations. Creating flow requires breaking down processes into activities, reconfiguring those activities to maximize speed, leveling out the workload, breaking down departmental silos, creating cross-functional teams to optimally serve the value stream, and training people to be multi-skilled and adaptive. Creating flow represents a major challenge for most Lean transformations, but also delivers substantial benefits, e.g. 80% higher speed (cycle-time reduction) and 50% efficiency gains (resource minutes per unit of output) are not uncommon.

➤ Sync with Takt

Takt time is the rate at which a product needs to be completed or a service to be delivered to meet customer demand. For example, producing 30 pizzas per hour equals a takt time of 2 minutes per pizza produced. The term originates from the German word “takt”, which means a beat or a pulse. Takt time is considered the sell rate or heart beat of the operation. It applies not only to repetitive manufacturing but also to project work, delivering incremental work elements at predefined sprints, such as in Agile development. The application of takt allows right-sizing capacity and adjusting the rhythm of work to be in sync with demand, the rate of customer orders (for products) and actual consumption (for services). Doing so prevents overproduction, excess inventory, and stock-outs. To define takt time, divide the available work time (excluding time for breaks, meetings, maintenance) by the actual customer demand. As demand fluctuates, it is advisable to produce to a takt image, allowing small buffers to level the load. Some confusion exists between takt time (TT), cycle time (CT), process time (PT), and lead time (LT). Takt time is always the rate of customer DEMAND, regardless of production capacity, equipment capability, loading or manning. Cycle time is the time required to complete a process step under real conditions, including setup, reporting, and inefficiencies. Process time is the time for one resource (person or machine) to complete the process (unit or batch) in an uninterrupted way. Lead time is the time to move through the process or value chain, the actual time for process plus waiting. A capable Lean manager considers all four timing metrics (TT, CT, PT, LT) to design an effective workflow.

➤ Establish Pull

Overproduction is considered the worst waste by making too many or too early, causing additional defects, transportation, inventory, and bureaucracy. The goal of a pull system is to allocate resources strictly based on consumption, so that nothing gets made, touched, or moved before the downstream process actually signals a requirement. Doing so lowers working capital by limiting work in process (WIP) and finished-goods inventory, while ensuring that required materials and information are available as needed. A pull activity is triggered by an actual need, which means that the internal or external customer can pull the product or service as needed, so that products do not need to be built in advance, preventing expensive inventory and complex flows to be managed, saving money for both the provider and the customer.

➤ Level Load

We will now balance the work to prevent overload and underutilization, periods of stress and boredom. Reducing unevenness through Heijunka (Japanese term for load levelling) results in a smoothened schedule where capacity is aligned with demand, avoiding resources shortages and idle times. Because maximizing operating efficiency requires a balanced workload, it made Heijunka a key strategy of Lean Manufacturing and integral part of the Toyota Production System. Understanding the pattern of customer demand and its drivers is the first step. Unevenness can be caused by external factors, such as more ice cream is consumed during the summer season, but also internally through sales promotions that cause peak loads for manufacturing and logistics. For economic load-leveling, consider the cost of excessive resourcing to meet peak demand or the premium to be paid for flexibilized resources, versus the cost of lost business from non-delivery. In some cases, the incremental margin from a sales promotion might not cover for the extra cost of producing to an unbalanced schedule. Calculate carefully!

➤ Detect Abnormalities

To improve performance we need to detect abnormalities before they grow into major defects. The 1-10-100 rule states that correcting a deviation early in the process is less costly than correcting a defect at the end of the value chain. As a rule of thumb, costs balloon by factor-10 each time a problem escapes detection. To detect a problem, most people think of an Andon, the Japanese word for lantern, e.g. the red alarm light at a machine or the system error message on a computer. But the concept of abnormality detection covers much more, it includes the detection device itself (sensor or visual control), the automatic stop feature to prevent more or larger problems, the response process or ‘help-chain’ to correct the abnormality and reinstate normal operating conditions. To produce just-in-time (JIT) demands zero defects, or else these defects will disrupt the process chain, prevent an orderly flow of work. Follow the Detect-Stop-Correct (DSC) principle to prevent major disruptions and drive continuous improvement.

➤ Eliminate Causes

After a problem is detected, it takes discipline to analyze the causes rather than ‘jumping’ to conclusions. Root cause analysis refers to a structured method of solving a problem at its source, rather than just treating its symptoms through quick-fix containment actions. One of simplest and broadly-used technique is the 5-why analysis: state the problem, ask yourself why the problem has occurred, list potential reasons and ask why they happened, repeat this process until the root cause is identified. For more complex problem, the simply 5-why technique is not sufficient, because the root consists of many branches, direct causes, indirect causes, and root causes. Use the Fault Tree Analysis (FTA) for rule-based problems, such as yield losses, and Causal Factor Analysis (CFA) for event-based problems, such as accidents and major breakdowns. After analyzing the problem at the physical level, covering material, machines, and information, we need to go one step deeper and identify their drivers at the human and latent root. Human failures include mistakes, errors, and violations, while the latent root exposes weaknesses in the management system. Deploying Lean means making processes and systems immune to failure through early detection, effective correction and prevention.

➤ Establish Capability

Process output must meet product specifications and service levels to satisfy stakeholders’ needs per voice of the customer (VOC), voice of the business (VOB), and voice of the employee (VOE). Process capability refers to the repeatability and reproducibility of a manufacturing or service process to create a consistent output. Capability indices help to determine whether a process, given its natural variation, is capable of meeting performance levels within specification limits. Process capability also provides a measure of the manufacturability of a product with given processes. If a process is in statistical control, the output follows a normal distribution, and the process mean is centered on the target, then the process capability index Cp can be calculated by dividing the tolerance range between upper and lower specification limits by 6 standard deviations: Cp = (USL – LSL) / 6 sigma. Cp<1 indicates that process variation exceeds specification limits, causing defects. Cp=1 means that the process is just meeting specifications with a defect rate 0.3%. Cp>1 means that the process variation is within tolerance limits. For processes that are not centered, we calculate Cpk based on the shortest distance between the mean and the closest specification limit, divided by 3 standard deviations: Cpk = min (USL-u, u-LSL) / 3 sigma. To calculate the capability of the entire value chain, we need to consider all processes in scope. For a value chain that consists of 100 processes, each operating at 3-sigma capability (Cpk=1, yield=99.7%), the rolled throughput yield (RTY) is 0.997 EXP 100 = 74%. After increasing process capability to six sigma at each process, the overall quality level of the value chain is 99.97%. Establishing process capability is critical to achieve a consistent output quality.

➤ Standardize Work

Standard work refers to the detailed definition of the current best practices for performing a process. The term ‘current’ means that the standard is never fixed, subject to continuous improvement, to continuously evolve by incorporating latest insights. Standards define the most efficient and effective way to deliver value to the customer, while providing the baseline for quality, speed, efficiency to measure improvements against. Repetitive and potentially-dangerous activities benefit most from standardization, such as assembling a product, hot-swapping an electrical device, or performing a complex surgery. But even creative processes, such as discovery and development improve through standardization, e.g. by defining the effective way to research, structure results, and narrow them down to a final design. Without standards, results are unpredictable, performance erodes, and costs increases. Without a reference point, continuous improvement is impossible, while standardizing the way of working (WOW) makes wastes visible, allows effective training of employees, and reduces process variability, defect rates, inventory levels, operating costs, and overall lead times.

Applying the Principles

The 10 Lean principles provide a framework for creating efficient processes and effectively leading an improvement team. Lean allows managers to discover and systematically eliminate inefficiencies in their organization, to deliver more value to stakeholders, decrease the cost of doing business, increase profitability, and create a competitive advantage from a Lean operating system.

Checking Your Process

For any process to be called ‘Lean’, it must meet the following five checkpoints:

➤ Valuable: customer is willing to pay for and would object if not delivered.

➤ Capable: producing a good outcome (product or service) every time.

➤ Available: being able to operate whenever required by the customer.

➤ Adequate: having the capacity to keep working in continuous flow.

➤ Flexible: changing from one work to another without batching and delays

Lean Transformation Phases: Initiation, Improvement, Institutionalization

Our 6D-method keeps people focused and the Lean transformation program on track, ensuring that productivity improvements are not only discussed but also delivered. Review gates at the end of each phase ensure deliverables per Lean transformation roadmap are being met Improvement Process.

- Definethe problem, align on goals and scope, create the project charter, ensure commitment and communicate the program to stakeholders.

- Diagnosethe current state, identify value leaks, causes and allocations, confirm the baseline and quantify the improvement opportunity.

- Designthe future state, applying flow, takt, pull, levelling, abnormality detection, root cause elimination, process capability, work standards.

- Demonstrateeffectiveness in a pilot area; testing the design (pilot) under real conditions in a selected area to evaluate assumptions.

- Deliverimprovements during the rollout period; reconfiguring processes, systems, jobs, structures, spans, controls to meet new requirements.

- Delegateownership and validate impact, while implementing standards and training people to sustain the new way of working.