Eliminating Root Causes:

Systematic problem solving is a foundational skill for everyone, addressing performance and behavioural problems to boost safety, quality, reliability, and customer satisfaction. Our problem solving courses build robust skills and provide ready-to-use tools and templates, so that you can quickly learn the principles and start solving problems in a structured and effective way.

Problem Solving Courses for Beginners to Experts

➤ Systematically solve safety, quality, realiability problems

➤ Define problem statements based on data, observations

➤ Learn proven tools and techniques to tackle problems

➤ se basic PDCA and 5-Why analysis for simple problems

➤ Use Causal Factor Analysis (CFA) for disasters, accidents

➤ Use Fault Tree Analysis (FTA) for rule-based problems

➤ Identify cause-effect relationships between factors

➤ Provide evidence to confirm or reject assumptions

➤ Drill down causes at the physical, human, latent root

➤ Develop actions to remove, reduce, control causes

Problem Solving Course for Advanced Beginners

The Beginner Course helps anyone to get started with systematic problem solving. Within a few days, students learn the basic methods and tools, and apply them to solve an actual problem. Doing so, they are building practical problem-solving skills in five steps: (1) Describe Problem, (2) Analyze Problem, (3) Identify Causes, (4) Solve Problem, (5) Evaluate Results. Quizzes and self-evaluation forms help learners to test their skills and evaluate solution effectiveness.

The Advanced Course is for managers, supervisors, and functional specialists to strengthen their problem-solving skills. The course focuses on systematic root-cause analysis and developing countermeasures to effectively contain, correct, and prevent problems from reoccurring. The advanced course is closely supported by a problem-solving expert, helping students through the process, while providing coaching feedback to get the analysis deep and right.

Problem Solving Course for Experts

The Expert Course is for engineers, managers, and quality professionals to build expert skills in systematic problem solving. The course consists of three parts: (1) Reality Tree for Causal Factor Analysis to address event-based problems, such as a major accident or a disaster; (2) Failure Tree Analysis to address rule-based problems at the physical, human, and latent root; and (3) Human Failure Analysis to understand the reasons for action errors, thinking errors, and also violations. The expert toolkit allows champions to tackle problems at the system level by eliminating, reducing, and controlling the entire set (tree) of causes.

When Using Formal Problem Solving – The 13 Reasons

- Undesirable condition

- Deviation, defect, failure

- Safety accident, incident, major risk

- Product failure due to strength, performance, reliability

- Line stopsevent

- Regulatory non-compliance

- Customer dissatisfaction or request

- Cost overrun.

- Equipment breakdown

- Process failure

- Behavioral issue, noncompliant, disengaged.

- Repetitive or transferable problem

- Detection failure

The 10 Signs of Ineffective Problem Solving

➤ Quick fix

➤ Fire fighting

➤ Going from crisis to crisis

➤ Stagnant or declining performance

➤ No time for deeper analysis

➤ Look for the guilty party: ”Who did that?”

➤ Jumping from problem into actions

➤ Generate laundry list of actions to firefight symptoms

➤ Sub-optimizing one area, spot scope

➤ Focus on lagging metrics (yield, sales, profits) and hope processes will improve as a result

The 10 Signs of Effective Problem Solving

➤ Systems thinking

➤ Continuous improvement

➤ Systematic root cause elimination

➤ Better performance after each problem

➤ Allocate time to analyze, dialogue, conclude

➤ Seek deep understanding: “How did that happen?”

➤ Acting after understanding cause-effect relationships

➤ Addressing all factors of the failure tree

➤ Optimizing the value stream, enterprise scope

➤ Focus on improving processes (capability) that effect actual performance metrics

Which Problem-Solving Method is Best?

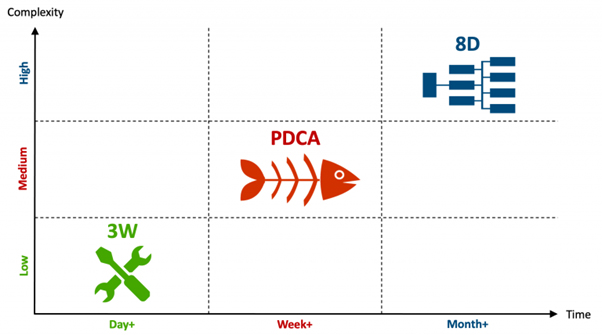

When embarking on systematic problem solving, it’s important to chose the right approach. Applying a comprehensive method to a small problem wastes time, while addressing a complex problem with a simple tool will likely not uncover the hidden causes. The optimal choice depends on the type of problem to be solved. Here an overview of the top problem solving processes by complexity-level and time-to-solve. Answer the following four questions to select the most-suitable problem-solving method:

➤ Is the problem small, medium, or large?

➤ Is the solution obvious or unknown?

➤ Is the problem reoccurring or a single incident?

➤ Single cause or multiple causes to address?

➤ Does the problem require statistical analysis?

➤ Use 3W (What-Who-When) for informal problem-solving, assigning a quick action to fix a small issue within a day.

➤ Use PDCA (Plan-Do-Check-Act) to address simple, medium-size, and reoccurring problems within a week.

➤ Use 8D (Eight Disciplines) to systematically address multiple root-causes of complex problems within a month.

Comparing Problem-Solving Methods: 3W, PDCA, 8D, A3, DMAIC, 7STEP

At their core, all scientific problem-solving methods follow a similar logic: define the problem, analyze the problem, identify causes, take action, and evaluate impact. For example, the PDCA planning phase covers the first three steps of DMAIC and the first five steps of A3 and 8D.

➤ 3W: When the problem is small and the solution is obvious, a formal analysis is not required. The 3W-method defines What to do, Who to do it, by When. This “quick-fix” is commonly applied at daily team meetings to contain and correct minor delays, defects, deviations.

—

➤ PDCA: The Deming or Shewhart cycle “Plan-Do-Check-Act” is the classic method, used by over 80% of companies that practice systematic problem solving. PDCA is most effective for medium-size problems that require a systematic analysis to uncover the root causes.

—

➤ 8D: The eight disciplines (8D) are commonly used in automotive, and the problem-solving process (PSP) is applied in avionics. Both methods are very similar, using 8 steps to address complex problems with focus on a fast reaction to deviations, completing the first three steps in three days.

—

➤ A3: The A3-report, developed by Toyota, is an 8-step improvement and problem-solving process that fits on one sheet of paper. The A3-report is most effective to address medium-size problems and to structure improvement projects.

—

➤ DMAIC: The 5-step Six Sigma process “Define-Measure-Analyze-Improve-Control” is for data-centric problem solving. DMAIC is used to structure larger projects and solve complex problems that require statistical analysis to develop the solution (e.g. process parameter settings to reduce yield loss).

—

➤ 7STEP: This seven-step (7S) problem-solving process shares elements with A3 and 8D, but does not include a formal step for containment. Because of this weakness, the 7STEP process is rarely used today, replaced by 8D to address complex problems and by PDCA for medium-size problems

How to Solve Simple Problems with PDCA

➤ Plan-1 Record Problem: Describe what happened, where and when, and who is involved solving it.

➤ Plan-2 Analyze Problem:Assign potential causes to categories: Man, Method, Machine, Material, Management, Milieu (Environment).

➤ Plan-3 Identify Causes:Ask “why” to drill down to root causes; for complex problems, use several forms, one per branch or issue.

➤ Do Implement Actions: Create and implement an action plan to contain, correct, and prevent the problem from reoccurring.

➤ Check Results and Act:Review impact, standardize solution; close the case or initiate further actions by starting a new PDCA cycle.

How to Solve Complex Problems with 8D

➤ D0 Plan: Register problem and define emergency response.

➤ D1 Team: Identify team members to address the problem.

➤ D2 Problem: Grasp the situation and describe the problem.

➤ D3 Containment: Prevent the problem from spreading.

➤ D4 Diagnostics: Identify direct causes and root causes.

➤ D5 Correction: Define and prioritize corrective actions.

➤ D6 Validation: Implement actions and evaluate effectiveness.

➤ D7 Prevention: Systemize solutions to prevent reoccurrence.

➤ D8 Completion: Transfer knowledge and recognize contributors.

Ready to Become a Certified Problem Solver? Take the Course and Build Your Problem-Solving Skills

Problems occur every day, and failure to properly understand and address them often leads to permanent damage to health, environment, customer relationships, and business results. Our courses help you build problem-solving skills to become more effective at your daily work; achieving better results by systematically eliminating, reducing, or controlling identified causes at the physical, human, and latent root. Being a professional problem solver will not only increase teamwork and customer satisfaction, but also provide opportunities to advance your career. Build your skills now!

➤ Build basic skills in systematic problem solving

➤ Ideal for beginners from any function, any level

➤ Formally analyze and solve a basic problem

➤ Takes 2-5 days effort during a 1-month period

➤ Get access to basic videos, templates, toolkit

➤ Apply multi-5-why to identify root causes

➤ Formally implement a solution using PDCA

➤ Generate real benefits; typically $2,000+

➤ Get your certificate “Problem Solver”

➤ Build advanced skills in problem-solving

➤ Ideal for managers, supervisors, specialists

➤ Solve an advanced problem and get feedback

➤ Takes 5-10 days effort during a 2-month period

➤ Get access to advanced videos, templates, tools

➤ Perform root cause analysis and test robustness

➤ Formally implement solutions, test effectiveness

➤ Generate real benefits; typically $5,000+

➤ Get your certificate “Advanced Problem Solver”

➤ Build expert skills in systematic problem solving

➤ For engineers. managers, quality professionals

➤ Solve a major problem, supported by a coach

➤ Takes 10-20 days effort during a 3-month period

➤ Get access to expert videos, templates, toolkit

➤ Identify physical, human, and latent causes

➤ Formally eliminate, reduce, control causes

➤ Generate real benefits; typically $10,000+

➤ Get your certificate “Expert Problem Solver”